Injection Molding Design Guide

Injection Molding Design Guide - Avoid thin protruding sections and long flow lengths as these can lead to issues with fill and packout. This injection molding resin is fc eu, fda food contact compliant and has nsf/ansi 61, acs, wras, and. Web unlock the power of injection molding and unleash your design potential with our exclusive ebook. The injection molding design guidelines provided in this glossary can provide you with general rules for proper design. Gain valuable insights and expert tips that will empower designers and engineers to create optimized parts, ultimately reducing costs and enhancing quality. The two mold halves close. Importance of design for injection molding design for injection molding Following some basic rules of injection molded part design will result in parts that are easier to manufacture and assemble, and are typically much stronger in service. Design symmetrically for even cooling and shrinkage. Our basic guidelines for plastic injection molding include important design considerations to help improve part moldability, enhance cosmetic appearance, and reduce overall production time. Master the basic principles of the technology and learn quickly actionable design tips that save time & cut costs. A movable mold half meets a fixed platen to seal the mold cavity and core. The two mold halves close. This guide walks you through everything from quoting, design analysis, and shipment to best practices that ensure your model is optimized. Web unlock the power of injection molding and unleash your design potential with our exclusive ebook. Complex shapes may require complex tooling which increases costs. A movable mold half meets a fixed platen to seal the mold cavity and core. This guide walks you through everything from quoting, design analysis, and shipment to best practices that ensure your model is. Design permitting, use one degree of draft for easy part ejection. Web this article contains the ultimate injection molding design rules to help you achieve the best plastic parts. Master the basic principles of the technology and learn quickly actionable design tips that save time & cut costs. Web unlock the power of injection molding and unleash your design potential. This guide walks you through everything from quoting, design analysis, and shipment to best practices that ensure your model is optimized for molding. Design permitting, use one degree of draft for easy part ejection. Design symmetrically for even cooling and shrinkage. You will also learn the details of process control, the vital guide on designing mold, and tips on how. Web injection molding design guide. Web lsr injection molding design. Material selection and part complexity. Web a guide to polyolefin injection molding introduction polyolefins are the most widely used plastics for injection molding. Cycle time and heat transfer. Cycle time and heat transfer. Web definitive guide to cnc machining. This increases the demand for even tighter tolerances over traditional the. This injection molding resin is fc eu, fda food contact compliant and has nsf/ansi 61, acs, wras, and. Gain valuable insights and expert tips that will empower designers and engineers to create optimized parts, ultimately reducing costs and. Following some basic rules of injection molded part design will result in parts that are easier to manufacture and assemble, and are typically much stronger in service. Our basic guidelines for plastic injection molding include important design considerations to help improve part moldability, enhance cosmetic appearance, and reduce overall production time. This increases the demand for even tighter tolerances over. The basic principles of injection molding and its key benefits, limitations and applications. Master the basic principles of the technology and learn quickly actionable design tips that save time & cut costs. Web lsr injection molding design. In this journey through product development, designers collaborate closely with manufacturing experts to optimize efficiency, costs, and product quality from concept to production.. Design tips to reduce the cost of your next project. Web unlock the power of injection molding and unleash your design potential with our exclusive ebook. Gain valuable insights and expert tips that will empower designers and engineers to create optimized parts, ultimately reducing costs and enhancing quality. Cycle time and heat transfer. Web to get the most out of. Our downloadable guide offers tips on optimizing your design for machining, tolerances and threading considerations, choosing the right material for your parts, and much more. The two mold halves close. This manual, a guide to polyolefin injection molding, contains general information concerning materials, methods and equipment for producing high quality, injection molded, polyolefin products at optimum production rates. An internal. The injection molding design guidelines provided in this glossary can provide you with general rules for proper design. 30 ton, 1.5 fl oz (45 cm3) engel. The two mold halves close. Our downloadable guide offers tips on optimizing your design for machining, tolerances and threading considerations, choosing the right material for your parts, and much more. Web learn how to use injection molding to mass produce plastic parts. Following some basic rules of injection molded part design will result in parts that are easier to manufacture and assemble, and are typically much stronger in service. The most common injection molding materials & finishes and their main use. This injection molding resin is fc eu, fda food contact compliant and has nsf/ansi 61, acs, wras, and. Injection molding machine for wheel fabrication. Resin injection, primary gas penetration, and secondary gas penetration (see figure 1). Web injection molding design guide. Simple and uniform part geometries are best for injection molding. Design symmetrically for even cooling and shrinkage. Web lsr injection molding design. Design tips to reduce the cost of your next project. The basic principles of injection molding and its key benefits, limitations and applications.

Injection molding The manufacturing & design guide

![]()

LSR Mold Design Guide Liquid Silicone Rubber Injection Molding

Design Guide for Plastic Injection Molding Machine LSR Molding

![]()

LSR Mold Design Guide Liquid Silicone Rubber Injection Molding

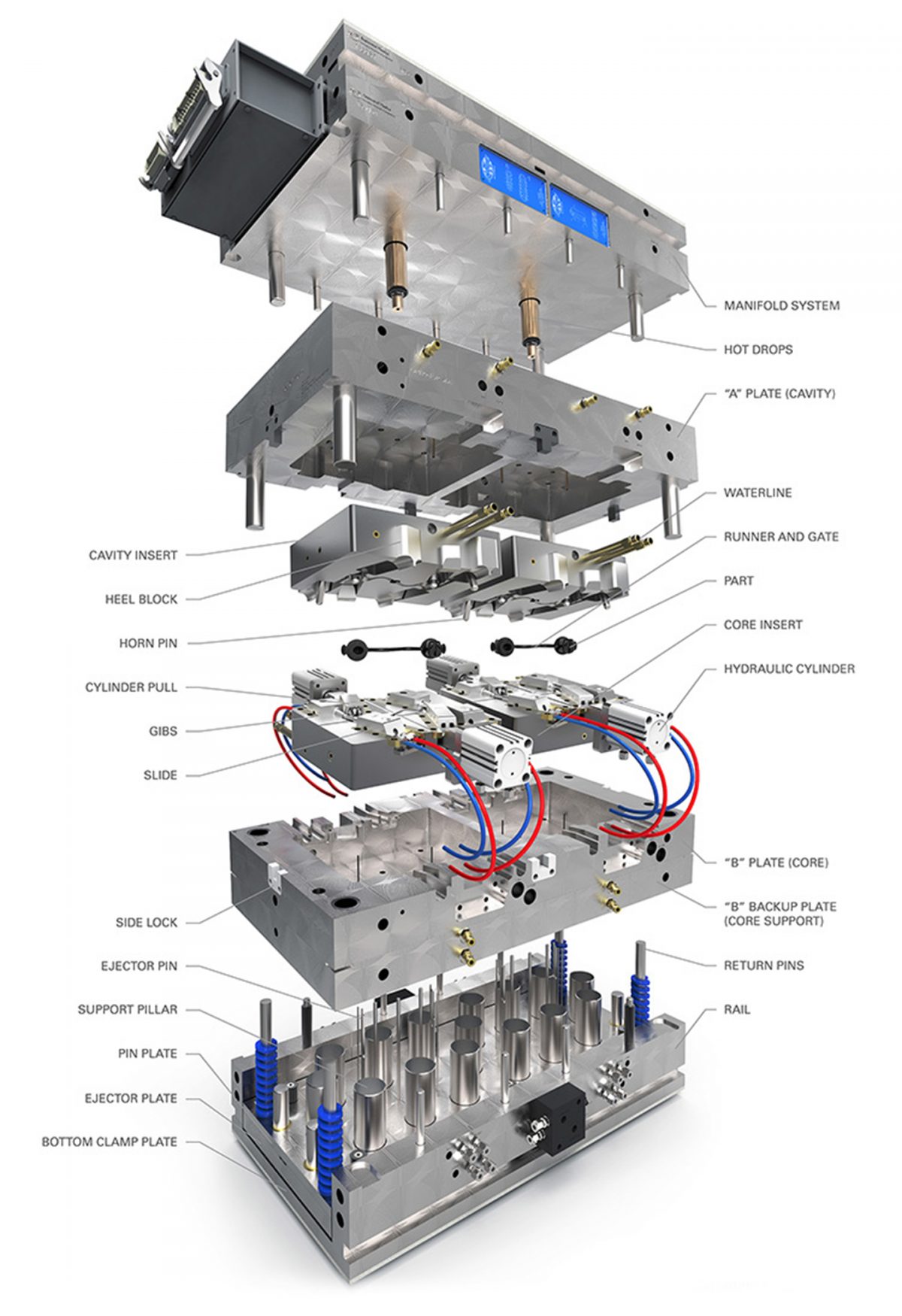

Anatomy of a Mold PTI Plastic Injection Molding

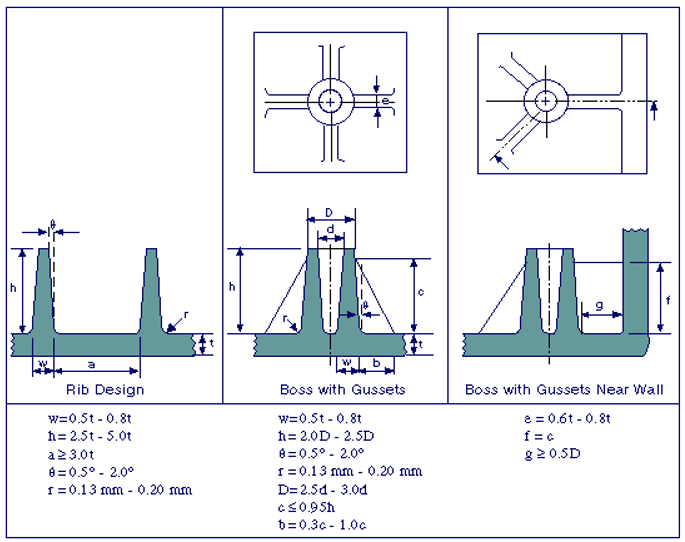

Injection Molding Design Guidelines

One Picture to Understand the Structure of an Injection Mold

How to Design for Injection Moulding MADE Products

Plastic Injection Mold Components Overview DasFormen Shop

Plastic Injection Molding Design Guide Texas Injection Molding

In This Free Guide, You'll Learn Best Practices On How To Optimize Designs For The Injection.

Injection Molding Materials Range From Commonly Used Polymers To Specialty Plastics And Polymer Blends.

Importance Of Design For Injection Molding Design For Injection Molding

This Guide Walks You Through Everything From Quoting, Design Analysis, And Shipment To Best Practices That Ensure Your Model Is Optimized For Molding.

Related Post: