Injection Mold Design

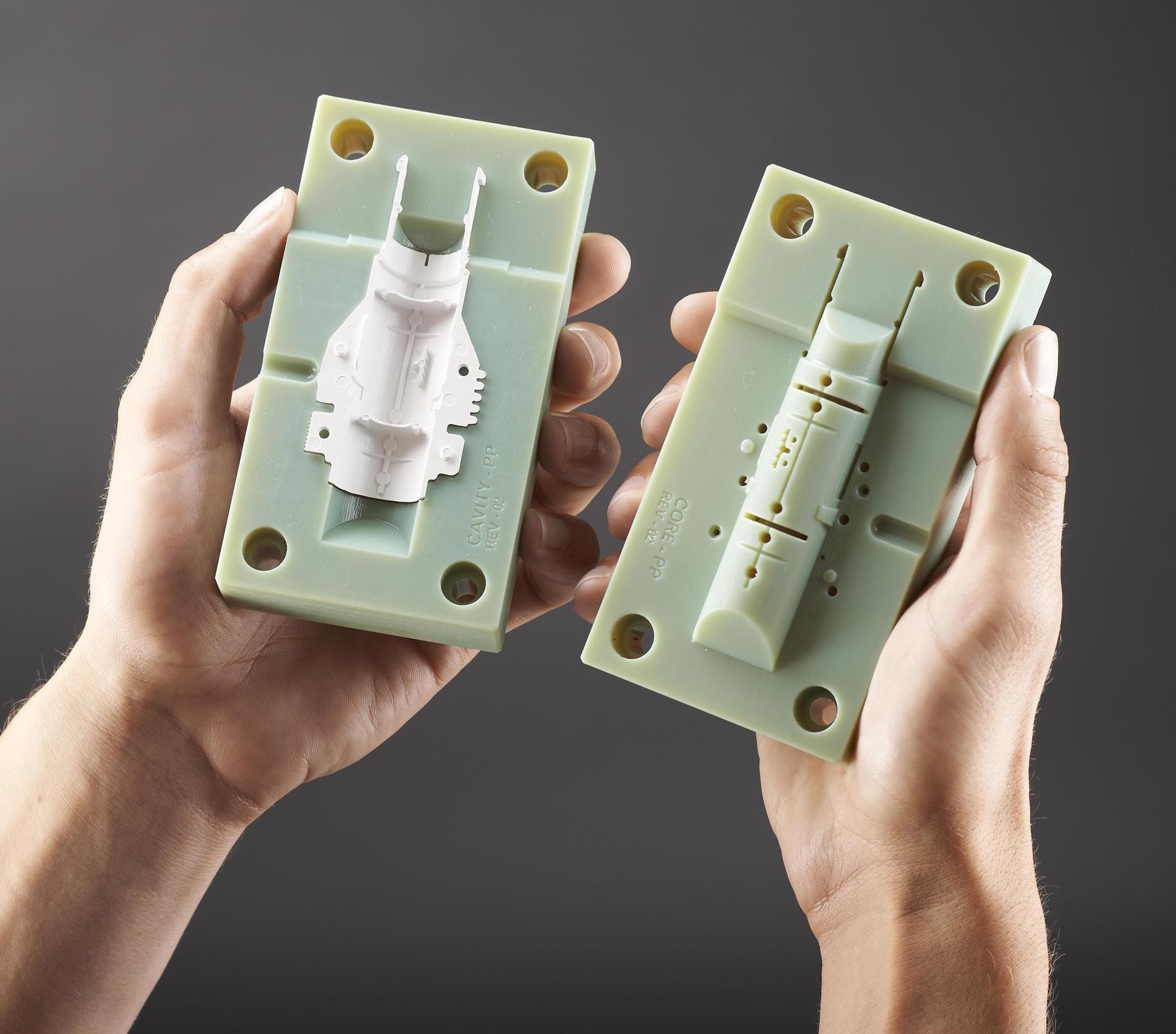

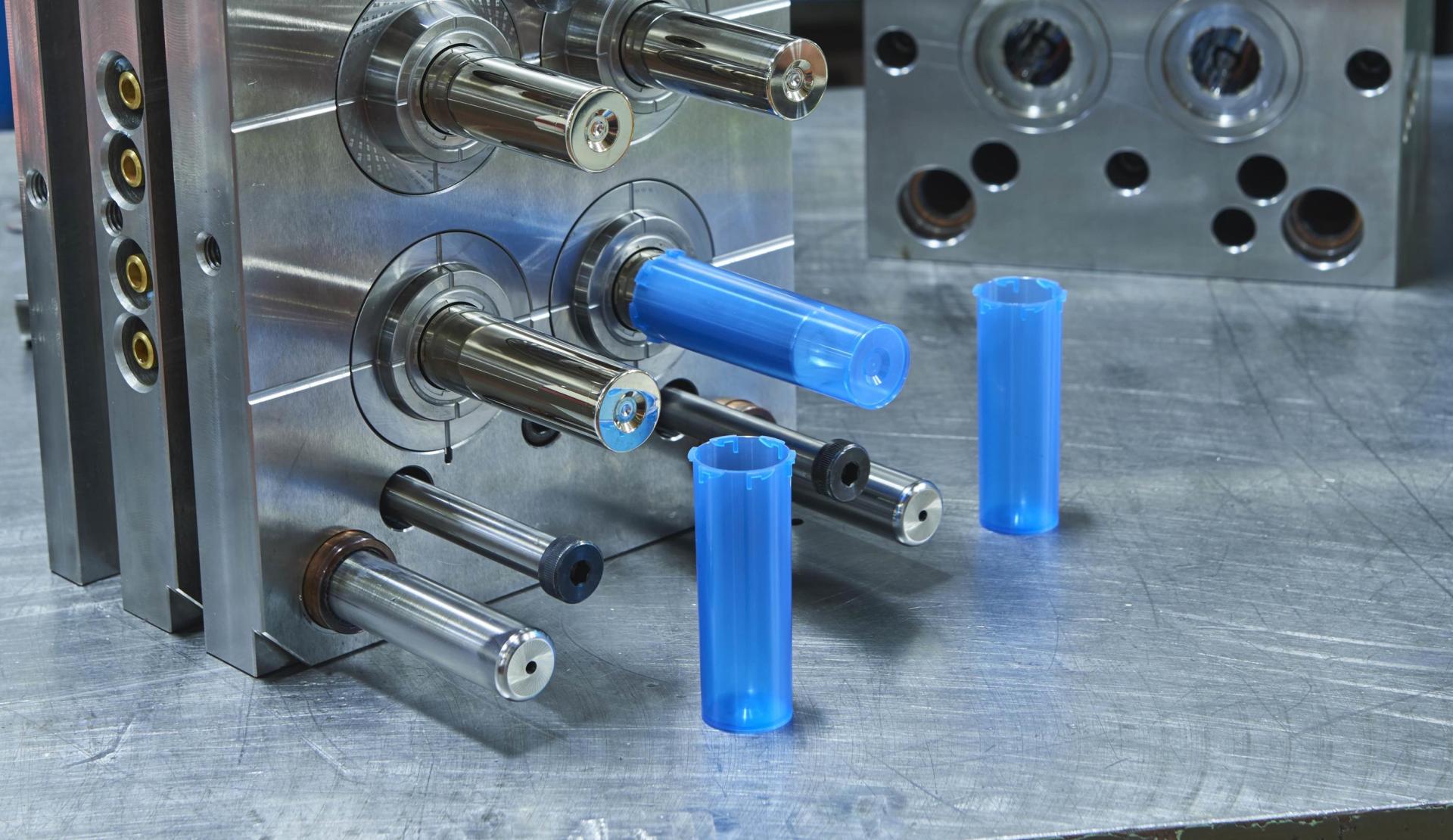

Injection Mold Design - In this video, you’ll learn the fund. Web injection molded parts design overview. The process begins with the preparation of the mold, which consists of two halves— the cavity and the core. Web injection molding design: Ferriot has created this handbook to help you understand some of the basics about injection molding so you and your injection molder can work together to. Injection molding is process tailored for producing large volumes of parts. Web before you can produce a series of plastic products with injection molding, you need to design and create a proper mold. Web injection mold design is a complex process that requires a deep understanding of the properties of different materials, the mechanics of the molding machine, and the functional requirements of the final product. Here are the steps involved in the mold design process: Common industrial applications of injection molding. In this free guide, you'll learn best practices on how to optimize designs for the injection. Web injection mold design is a complex process that requires a deep understanding of the properties of different materials, the mechanics of the molding machine, and the functional requirements of the final product. Major factors affecting the cost of injection molding. The process begins. Web the basics of plastic injection molding process includes creating the product design, making a tooling a mold to fit the product design, melting the plastic resin pellets, and using pressure to inject the melted pellets into the mold. Web what is injection molding? Ferriot has created this handbook to help you understand some of the basics about injection molding. Web injection molding is based on the principle of using a mold to shape molten material into a desired form. Understanding injection molding process basics. Web injection molding design guide. Web what is injection molding? S to achieve its full potential. This comprehensive guide covers key design considerations and best practices for optimizing injection molded parts for manufacturability. Here are the steps involved in the mold design process: S to achieve its full potential. Web learn how to design the most common features encountered in injection molded parts with these practical guidelines. Molding also has the highest variety of materials, colors,. Injection molding is used to create many things such as electronic housings, containers, bottle caps, automotive interiors, combs, and most other plastic products available today. Understanding injection molding process basics. Web learn how to design the most common features encountered in injection molded parts with these practical guidelines. Common industrial applications of injection molding. In this free guide, you'll learn. Injection molding is used to create many things such as electronic housings, containers, bottle caps, automotive interiors, combs, and most other plastic products available today. Here are the steps involved in the mold design process: Use them to improve the functionality of your designs, while still complying with the basic design rules. Web during step 1 of the injection molding. Web the basics of plastic injection molding process includes creating the product design, making a tooling a mold to fit the product design, melting the plastic resin pellets, and using pressure to inject the melted pellets into the mold. Molding also has the highest variety of materials, colors, and configurations compared to cnc machining or. Compared to other manufacturing technologies—like. Web injection molding design guide. In this video, you’ll learn the fund. Injection molding is process tailored for producing large volumes of parts. Major factors affecting the cost of injection molding. Web understanding injection molding basics such as draft, radii, and wall thickness can improve moldability. Major factors affecting the cost of injection molding. This tip offers advice for helping your design. The design process involves numerous considerations, from material selection and wall thickness to the location of gates and ejector pins. Web injection molding design guide. Here are the steps involved in the mold design process: Use them to improve the functionality of your designs, while still complying with the basic design rules. Web designing your part for injection molding is critical to realize those advantages. This comprehensive guide covers key design considerations and best practices for optimizing injection molded parts for manufacturability. Web injection molding design guide. Web injection molding is a manufacturing process that. Use them to improve the functionality of your designs, while still complying with the basic design rules. Web injection molding design: This tip offers advice for helping your design. This comprehensive guide covers key design considerations and best practices for optimizing injection molded parts for manufacturability. Major factors affecting the cost of injection molding. Here are the steps involved in the mold design process: Injection molding is used to create many things such as electronic housings, containers, bottle caps, automotive interiors, combs, and most other plastic products available today. Web injection mold design is a complex process that requires a deep understanding of the properties of different materials, the mechanics of the molding machine, and the functional requirements of the final product. Ferriot has created this handbook to help you understand some of the basics about injection molding so you and your injection molder can work together to. Web injection molding is based on the principle of using a mold to shape molten material into a desired form. Web learn how to design the most common features encountered in injection molded parts with these practical guidelines. When it comes to plastic part production, there is no manufacturing method that comes close to the popularity of. In this video, you’ll learn the fund. Compared to other manufacturing technologies—like cnc machining and 3d printing—it requires an upfront, capital investment into tooling. During step 2, fictiv reviews your design for manufacturability. Web injection molded parts design overview.![]()

LSR Mold Design Guide Liquid Silicone Rubber Injection Molding

Injection Molding Design Validation Medical Device Biopolymers

Are Injection Mold Design Jobs Still Good To Pursue

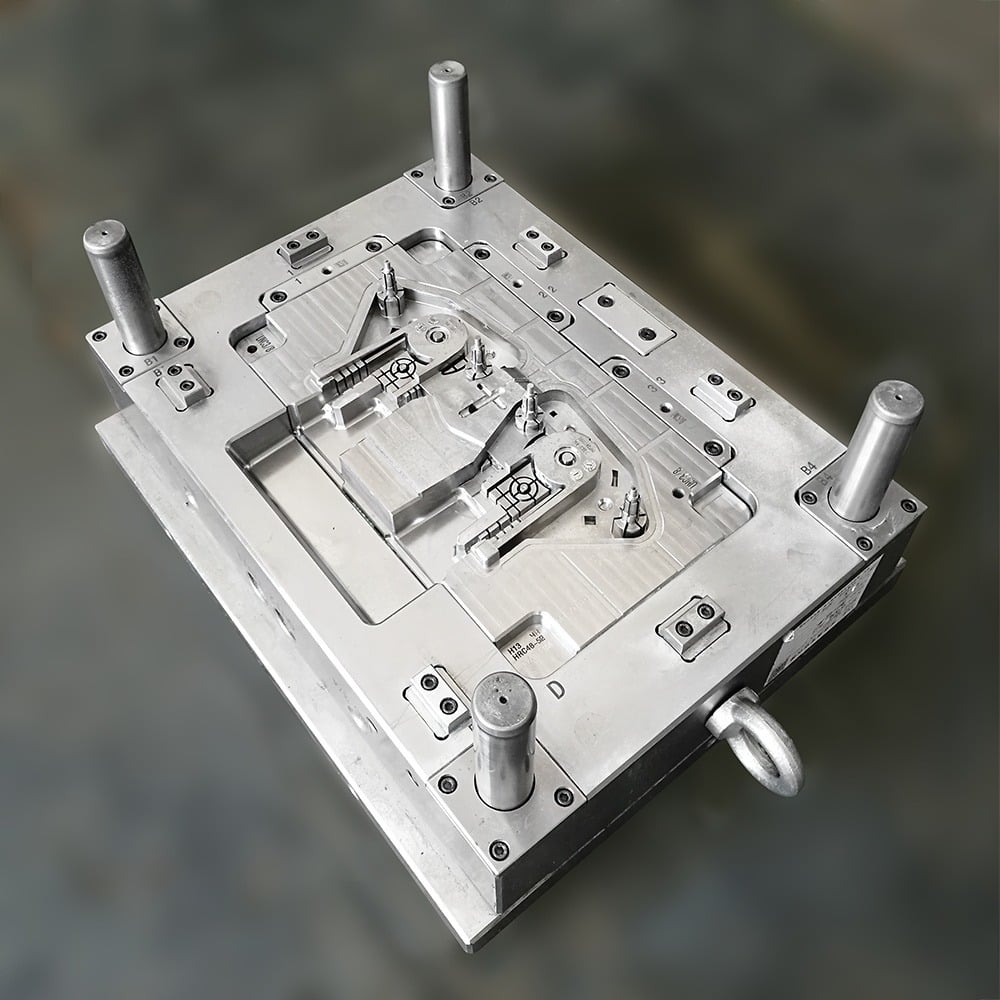

This mold was built for a large tier one automotive supplier. The part

Revolutionizing the Injection Molding Process

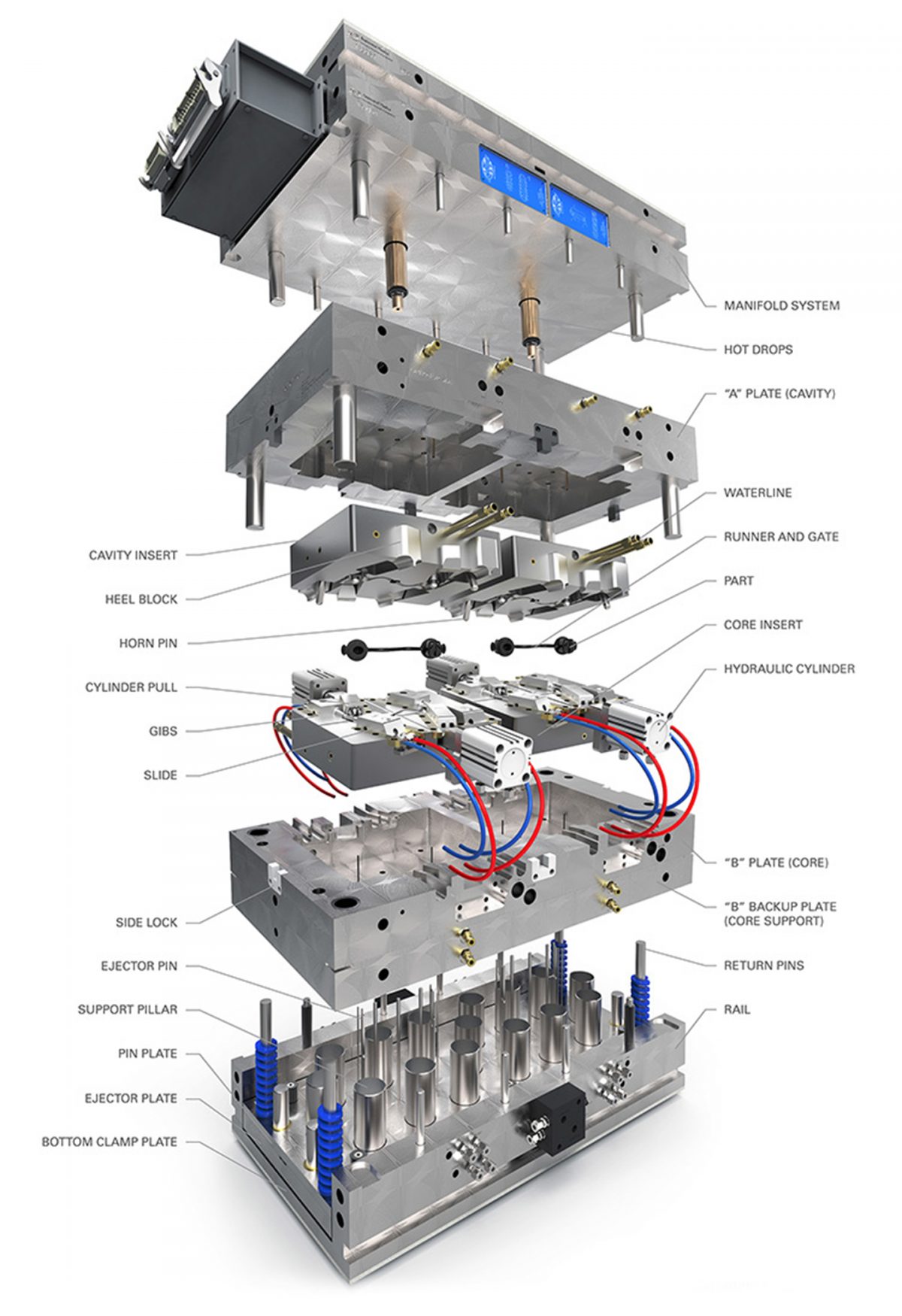

One Picture to Understand the Structure of an Injection Mold

Lifter mold design in 2021 Mould design, Plastic injection molding

Anatomy of a Mold PTI Plastic Injection Molding

The Basic Process Of Injection Molding Mold Design

Basics of Injection Molding Design 3D Systems

S To Achieve Its Full Potential.

Web Injection Molding Design Guide.

Web The Basics Of Plastic Injection Molding Process Includes Creating The Product Design, Making A Tooling A Mold To Fit The Product Design, Melting The Plastic Resin Pellets, And Using Pressure To Inject The Melted Pellets Into The Mold.

Molding Also Has The Highest Variety Of Materials, Colors, And Configurations Compared To Cnc Machining Or.

Related Post: