Hydraulic Piston Design

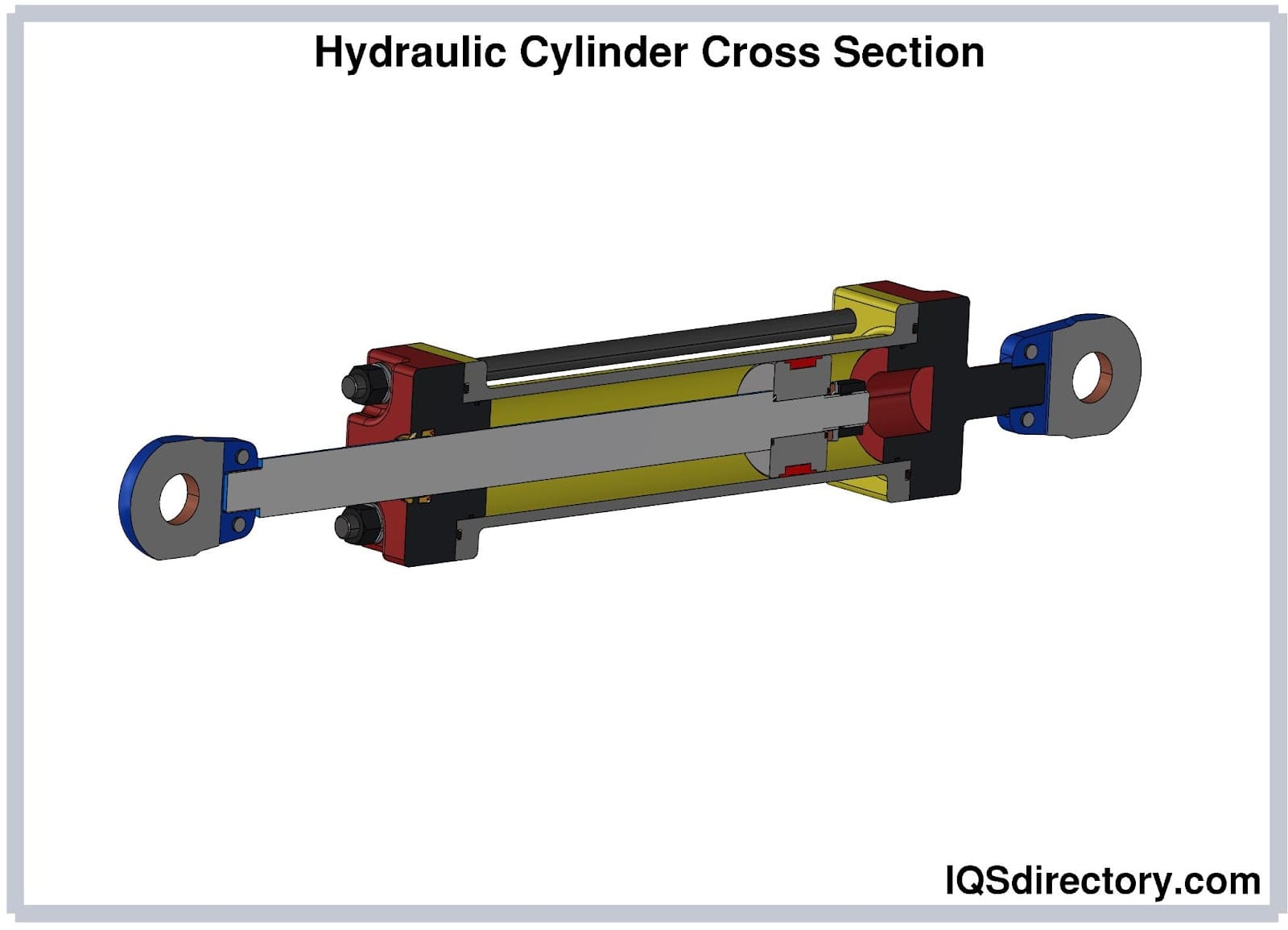

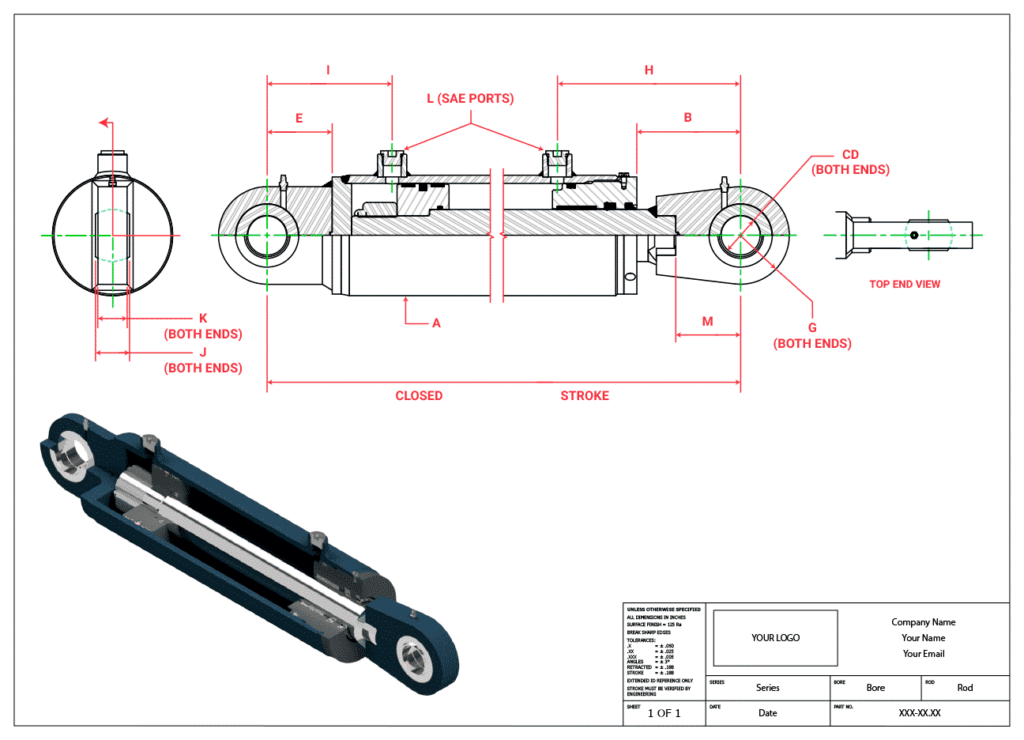

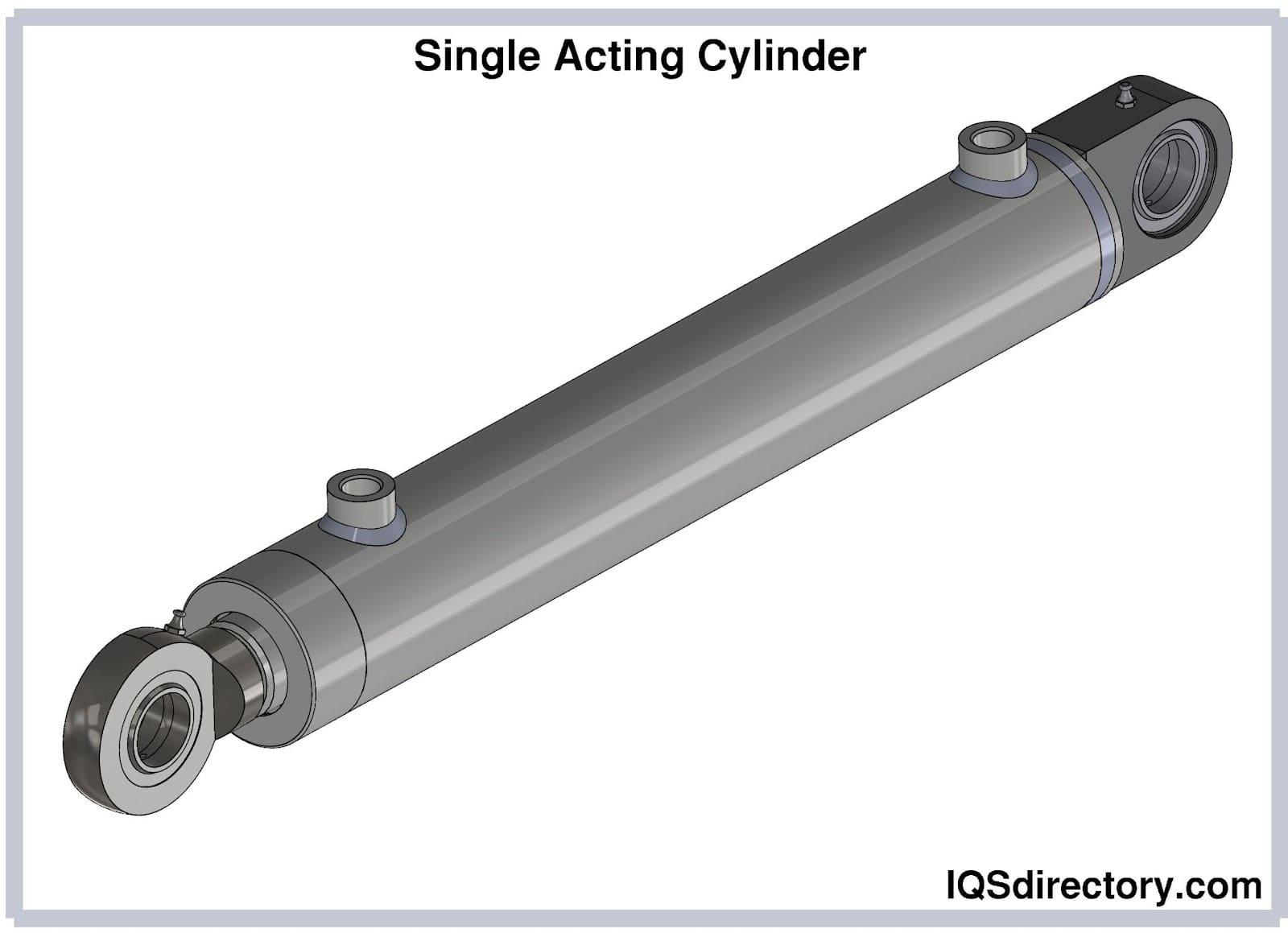

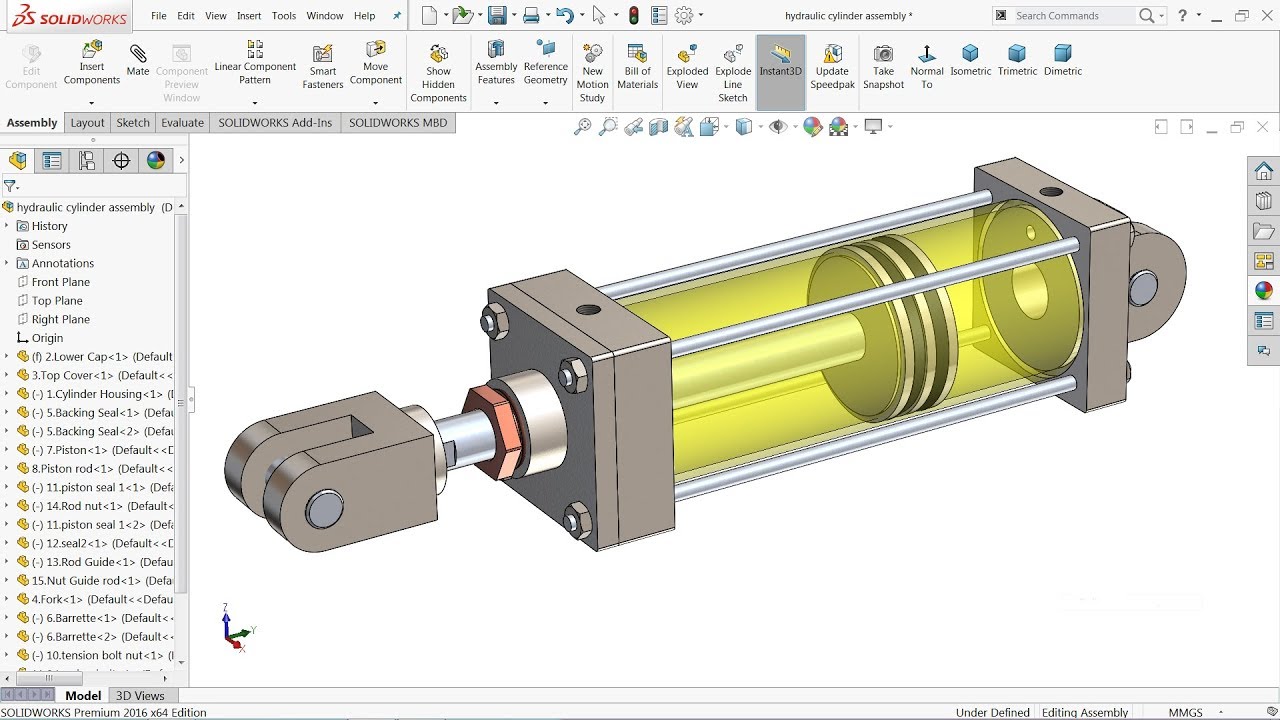

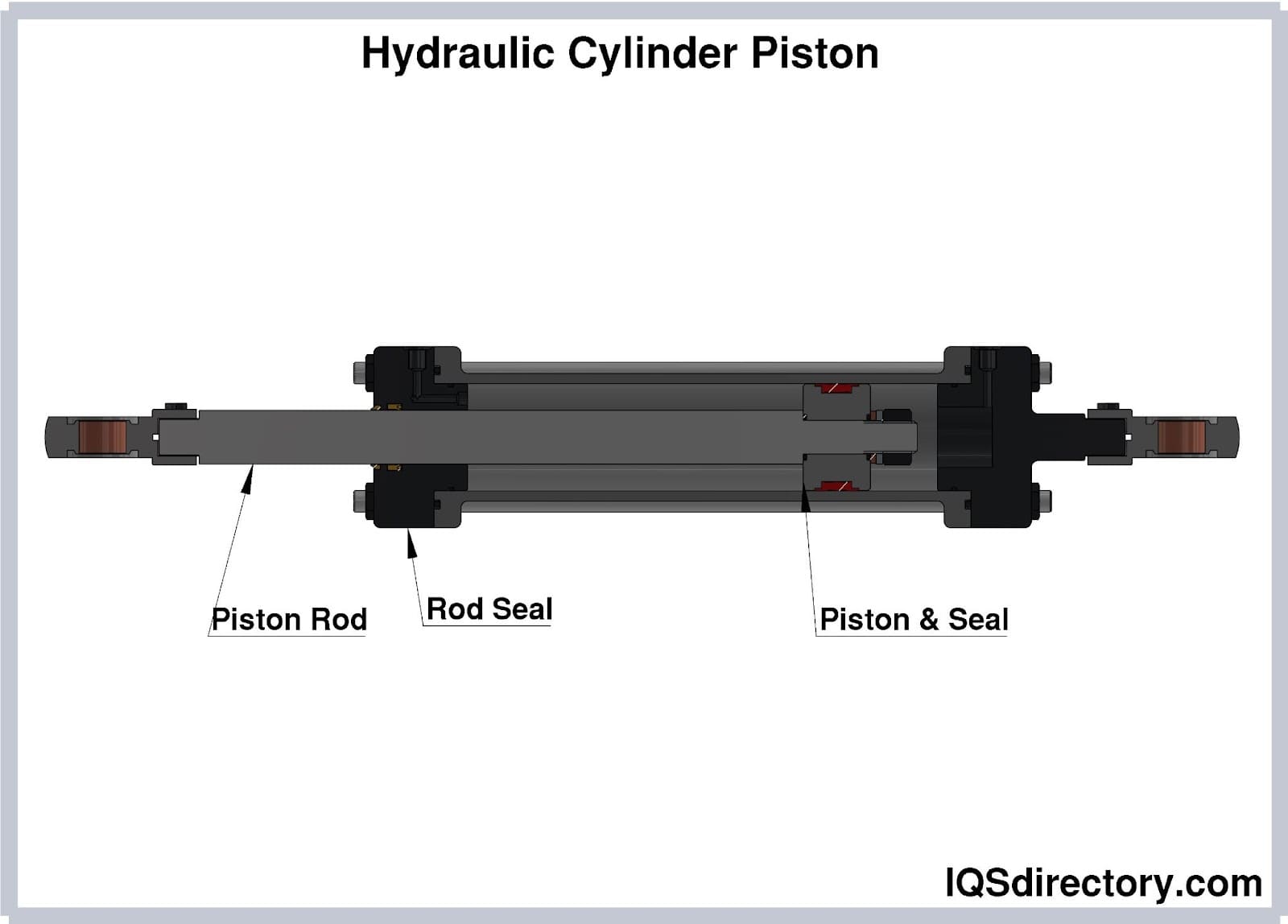

Hydraulic Piston Design - The hydraulic cylinder consists of a cylinder barrel, in which a piston connected to a piston rod moves back and forth. Web hydraulic piston configurations in cylinders. Web we have already discussed how to design hydraulic cylinder piston. Calculation of permissible oil velocities. The following principles are crucial in optimizing piston design for efficient and durable operation within hydraulic mechanisms: Web hydraulic cylinders, also known as ‘hydraulic rams’, get their power from pressurised hydraulic fluid, normally hydraulic oil. The hydraulic cylinder consists of a cylinder barrel, in which a piston connected to a piston rod moves back and forth. Web a single action hydraulic cylinder is pressurized for motion in only one direction. With its ability to generate powerful forces and movements, the hydraulic cylinder piston remains one of the most important tools in the industrial and automotive sectors. Web hydraulic cylinder pistons can be classified into two main types: Web this book deals with hydraulic cylinders of varying designs. The principles of operation, constructional details, and classification of the hydraulic cylinders are explained in detail. Calculation of the sinusoidal movement of hydraulic cylinders and oscillating cylinders. Web a hydraulic cylinder is a hydraulic actuator that provides linear motion when hydraulic energy is converted into mechanical movement. Rod, piston, pipe,. Web hydraulic cylinder design. Pistons fitted to bores in the cylinder block are connected through piston shoes and a retracting ring, so that the shoes bear against an angled swashplate. Web calculation formulas for hydraulic cylinder design. The hydraulic cylinder consists of a cylinder barrel, in which a piston connected to a piston rod moves back and forth. Web the. Criteria for comparison preferably include motion type (rotary, linear), structural design (direct drive, used in transmission), force density,. Web we have already discussed how to design hydraulic cylinder piston. It can be likened to a muscle in that, when the hydraulic system of a machine is activated, the cylinder is. The hydraulic cylinder consists of a cylinder barrel, in which. The principles of operation, constructional details, and classification of the hydraulic cylinders are explained in detail. The hydraulic cylinder or motor can be stalled under a load. Web tutorial will discuss hydraulic cylinder piston design and sizing calculation with worked out example. Calculation of permissible oil velocities. Rod, piston, pipe, caps, seals. Web 3,000 psi hydraulic pressure at 25 gpm flow is availble as input to the cylinder. Web hydraulic cylinder pistons can be classified into two main types: Web hydraulic piston pumps move fluids throughout professional equipment and industrial machinery. Web we have already discussed how to design hydraulic cylinder piston. The hydraulic cylinder consists of a cylinder barrel, in which. The cylinder is fixed mounted vertically, rod up and the piston will contact the head or cap at the stroke ends. Instead, a bolt extends from the side of the piston out through a longitudinal slot in the barrel. Web the hydraulic cylinder piston is a critical component of any machine that requires pressurised fluid to power its movements. Pistons. Components of the hydraulic cylinder: The cylinder is fixed mounted vertically, rod up and the piston will contact the head or cap at the stroke ends. Web hydraulic cylinder pistons can be classified into two main types: Construction and working principle of the hydraulic cylinder. Web 3,000 psi hydraulic pressure at 25 gpm flow is availble as input to the. Web hydraulic piston pumps move fluids throughout professional equipment and industrial machinery. The hydraulic cylinder consists of a cylinder barrel, in which a piston connected to a piston rod moves back and forth. Calculation of permissible oil velocities. Web calculation formulas for hydraulic cylinder design. Web hydraulic cylinders, also known as ‘hydraulic rams’, get their power from pressurised hydraulic fluid,. Calculation of permissible oil velocities. Pistons fitted to bores in the cylinder block are connected through piston shoes and a retracting ring, so that the shoes bear against an angled swashplate. With its ability to generate powerful forces and movements, the hydraulic cylinder piston remains one of the most important tools in the industrial and automotive sectors. Rod, piston, pipe,. Criteria for comparison preferably include motion type (rotary, linear), structural design (direct drive, used in transmission), force density,. Construction and working principle of the hydraulic cylinder. Web tutorial will discuss hydraulic cylinder piston design and sizing calculation with worked out example. Web hydraulic cylinder design. Web hydraulic piston pumps move fluids throughout professional equipment and industrial machinery. It can be likened to a muscle in that, when the hydraulic system of a machine is activated, the cylinder is. Web hydraulic piston configurations in cylinders. It develops force in both directions of piston travel. Web hydraulic piston pumps move fluids throughout professional equipment and industrial machinery. Web a hydraulic cylinder is a hydraulic actuator that provides linear motion when hydraulic energy is converted into mechanical movement. In this sizing calculation tutorial we will see how to design hydraulic cylinder. The hydraulic cylinder consists of a cylinder barrel, in which a piston connected to a piston rod moves back and forth. Web tutorial will discuss hydraulic cylinder piston design and sizing calculation with worked out example. With its ability to generate powerful forces and movements, the hydraulic cylinder piston remains one of the most important tools in the industrial and automotive sectors. Components of the hydraulic cylinder: Web the hydraulic cylinder piston is a critical component of any machine that requires pressurised fluid to power its movements. By varying the volume flowing into the actuator (cylinder or motor) the speed is changed. Web today’s hydraulic cylinders, which essentially convert fluid pressure and flow into force and linear movement, are complex devices incorporating a wide range of individual components available in a multitude of dimensions, configurations and materials. The principles of operation, constructional details, and classification of the hydraulic cylinders are explained in detail. Criteria for comparison preferably include motion type (rotary, linear), structural design (direct drive, used in transmission), force density,. The piston returns to the starting position by an external force such as gravity or a compressed spring.

Hydraulic Cylinders Types, Design, Applications and Piston Configuration

How to design a hydraulic cylinder? AiSoar Hydraulic Cylinder

PreEngineered Hydraulic Cylinder Configurator

Hyd Valves Wiring Diagram

Hydraulic cylinder, double and single acting, plunger and telescoping

Schematic of the hydraulic cylinder (a) assembly structure, (b) piston

Design of the double action hydraulic cylinder made of plastics ϕ = 50

Hydraulic Cylinders Types, Design, Applications and Piston Configuration

Solidworks tutorial Design of Hydraulic Cylinder in Solidworks YouTube

Hydraulic Cylinders Types, Design, Applications and Piston Configuration

Web Drive Technologies Differ In The Conditions Required And Options Available To Generate Motion.

Web Inline Piston Pumps — The Simplest Type Of Axial Piston Pump Is The Swashplate Design In Which A Cylinder Block Is Turned By The Drive Shaft.

The Following Principles Are Crucial In Optimizing Piston Design For Efficient And Durable Operation Within Hydraulic Mechanisms:

It Is A Simple, Inexpensive Design.

Related Post: