Hdpe Pipe Fusion Time Chart

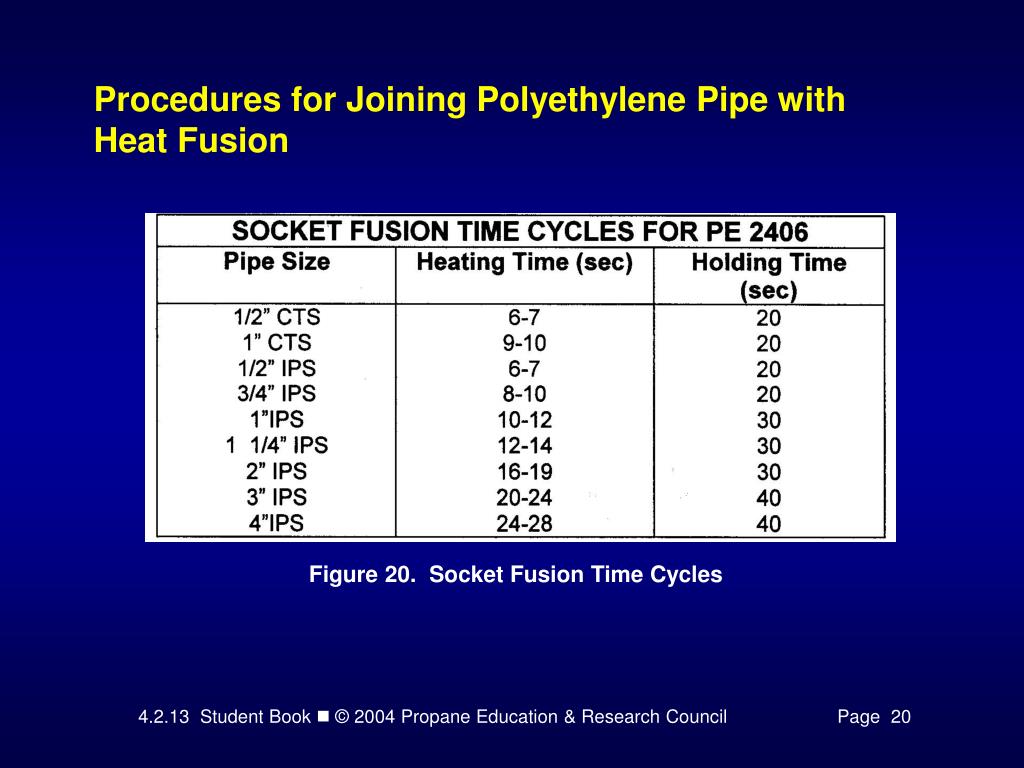

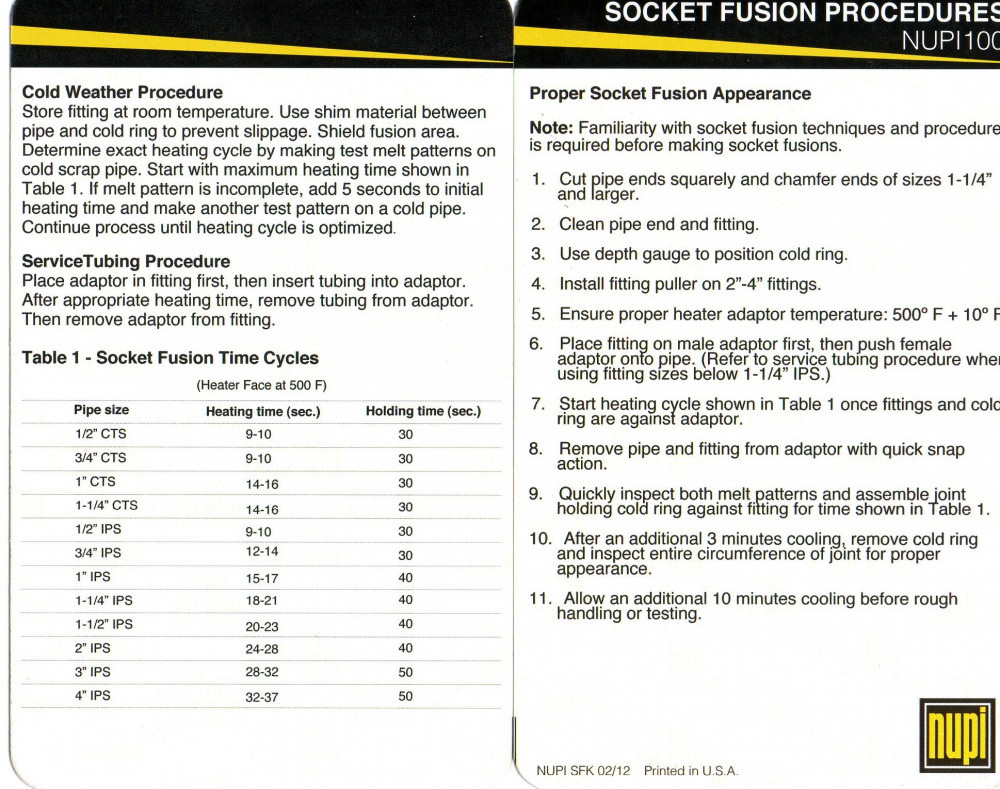

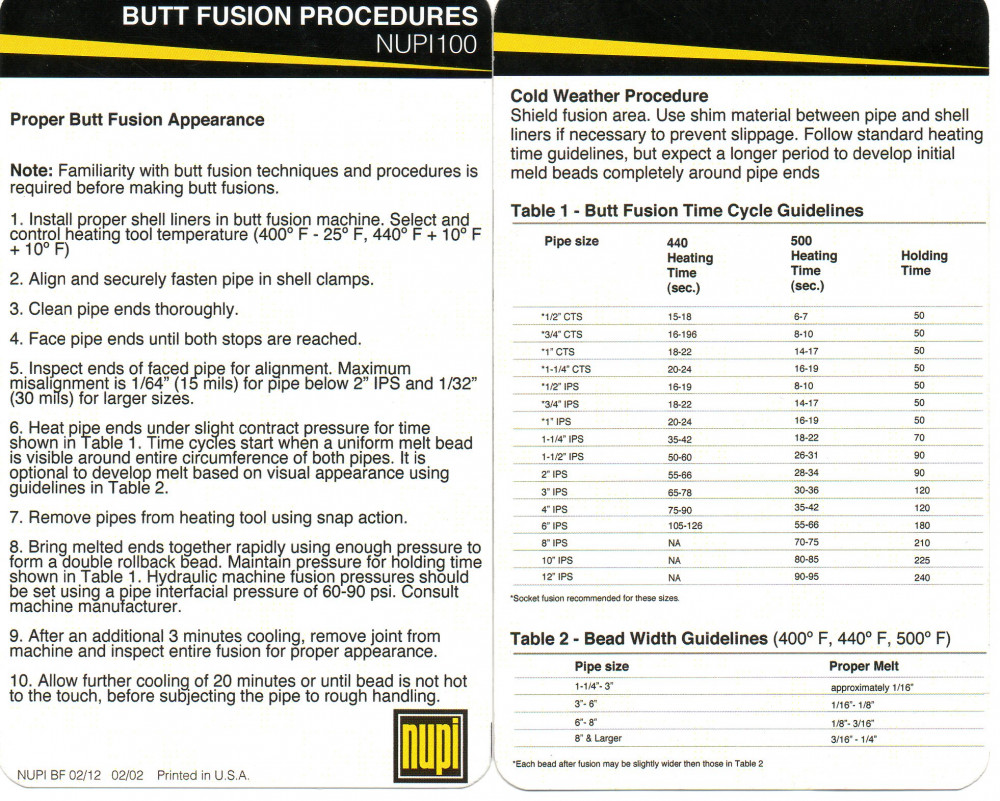

Hdpe Pipe Fusion Time Chart - Place the heater adapter between the pipe and the fitting. Hdpe pipe and fittings manufacturers have approved ppi’s generic joining procedures in an attempt to standardize the joining procedures of hdpe. Web use mcelroy's fusion pressure calculator to quickly find the right fusion pressure for your job. For socket fusion, astm standard f1056 is referenced. Get expert training and guidance, and discover the ultimate guide to successful hdpe pipe joining. This includes any and all points that will come in contact with the pipe. There are three types of heat fusion joints currently used in the industry: Heating tool surfaces must be clean to allow proper fusion. Please reference the pipe manufacture for specific heating time and insertion depths. Web this is a general guide to socket fusion. Please reference the pipe manufacture for specific heating time and insertion depths. Place the heater adapter between the pipe and the fitting. For socket fusion, astm standard f1056 is referenced. Get expert training and guidance, and discover the ultimate guide to successful hdpe pipe joining. This guide will explain how to most efficiently weld hdpe pipe and get the most. Web because of its value, it is very important to weld pipe together properly to get the most value out of a length of pipe. For socket fusion, astm standard f1056 is referenced. Web this is a general guide to socket fusion. To properly fuse pipe the fusion pressure must be adjusted so the pipe manufacturers recommended interfacial pressure is. Web this is a general guide to socket fusion. Web use mcelroy's fusion pressure calculator to quickly find the right fusion pressure for your job. Apply heat for the amount of time shown on the table and. This includes any and all points that will come in contact with the pipe. Please reference the pipe manufacture for specific heating time. Please reference the pipe manufacture for specific heating time and insertion depths. To properly fuse pipe the fusion pressure must be adjusted so the pipe manufacturers recommended interfacial pressure is achieved. For socket fusion, astm standard f1056 is referenced. There are three types of heat fusion joints currently used in the industry: Web because of its value, it is very. Get expert training and guidance, and discover the ultimate guide to successful hdpe pipe joining. For socket fusion, astm standard f1056 is referenced. Butt, saddle and socket fusion. To properly fuse pipe the fusion pressure must be adjusted so the pipe manufacturers recommended interfacial pressure is achieved. There are three types of heat fusion joints currently used in the industry: Natural color polyethylene pipe being fused, 1959, in caney, kansas. Butt, saddle and socket fusion. Get expert training and guidance, and discover the ultimate guide to successful hdpe pipe joining. Apply heat for the amount of time shown on the table and. Web because of its value, it is very important to weld pipe together properly to get the most. Web this is a general guide to socket fusion. Web connect the fusion unit to the pipe. Hdpe pipe and fittings manufacturers have approved ppi’s generic joining procedures in an attempt to standardize the joining procedures of hdpe. Web because of its value, it is very important to weld pipe together properly to get the most value out of a. Please reference the pipe manufacture for specific heating time and insertion depths. Hdpe pipe and fittings manufacturers have approved ppi’s generic joining procedures in an attempt to standardize the joining procedures of hdpe. Butt, saddle and socket fusion. Web this is a general guide to socket fusion. To properly fuse pipe the fusion pressure must be adjusted so the pipe. Web connect the fusion unit to the pipe. Apply heat for the amount of time shown on the table and. For socket fusion, astm standard f1056 is referenced. There are three types of heat fusion joints currently used in the industry: Cut squarely and remove burrs or chips inside pipe ends. Web connect the fusion unit to the pipe. Web the integrity and versatility of the joining techniques used for polyethylene (pe) pipe allow the designer to take advantage of the performance benefits of pe in a wide variety of applications. Web this is a general guide to socket fusion. Hdpe pipe and fittings manufacturers have approved ppi’s generic joining procedures. Butt, saddle and socket fusion. Place the heater adapter between the pipe and the fitting. This includes any and all points that will come in contact with the pipe. Heating tool surfaces must be clean to allow proper fusion. For socket fusion, astm standard f1056 is referenced. Apply heat for the amount of time shown on the table and. Web connect the fusion unit to the pipe. This guide will explain how to most efficiently weld hdpe pipe and get the most out of an investment and to have sturdy, solid fuses in the field. Get expert training and guidance, and discover the ultimate guide to successful hdpe pipe joining. Web use mcelroy's fusion pressure calculator to quickly find the right fusion pressure for your job. Natural color polyethylene pipe being fused, 1959, in caney, kansas. Hdpe pipe and fittings manufacturers have approved ppi’s generic joining procedures in an attempt to standardize the joining procedures of hdpe. Web this is a general guide to socket fusion. To properly fuse pipe the fusion pressure must be adjusted so the pipe manufacturers recommended interfacial pressure is achieved. Web the integrity and versatility of the joining techniques used for polyethylene (pe) pipe allow the designer to take advantage of the performance benefits of pe in a wide variety of applications.

Hdpe Fusion Time Chart

![How to fuse polyethylene butt joints together? [with graphics]](https://www.finishing.com/61/6107.png)

How to fuse polyethylene butt joints together? [with graphics]

High Country Fusion HDPE Pipe DIPS Chart by FRED Issuu

Schematic showing butt fusion welding method of HDPE pipes in different

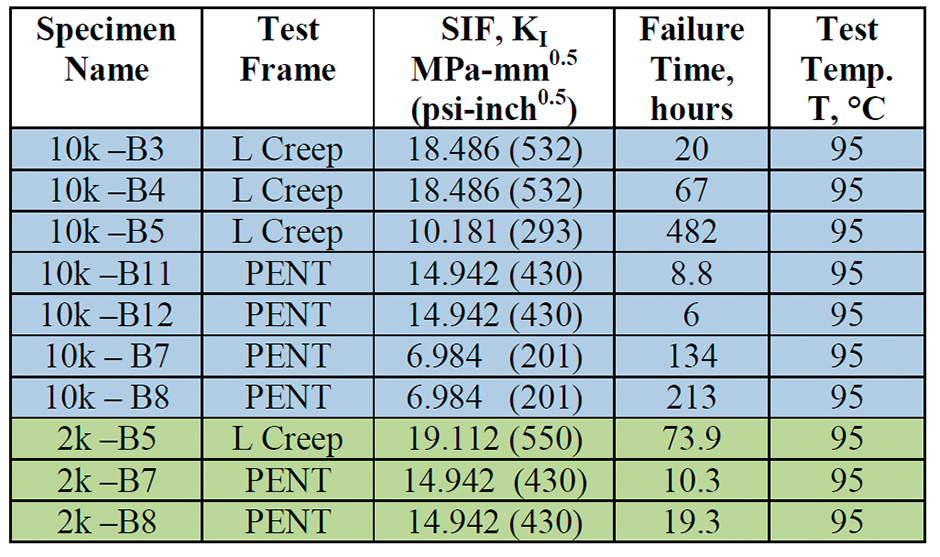

A Fracture Mechanics Approach to Service Life Prediction of HDPE Fusion

PPT 4.2.13 PowerPoint Presentation, free download ID479602

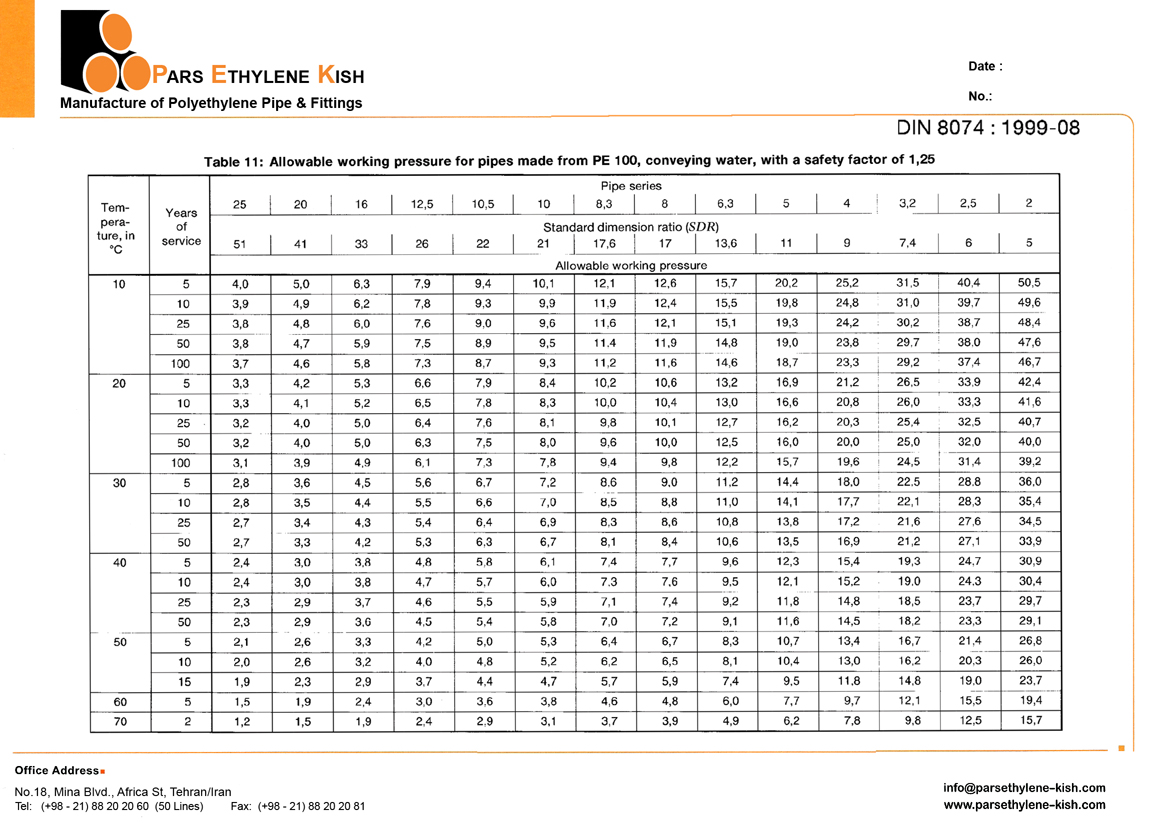

Catalog andTechnical Data od HDPE Pipe

Product Information B & D Mfg., Inc.

Hdpe Fusion Time Chart

Product Information B & D Mfg., Inc.

There Are Three Types Of Heat Fusion Joints Currently Used In The Industry:

Cut Squarely And Remove Burrs Or Chips Inside Pipe Ends.

Web Because Of Its Value, It Is Very Important To Weld Pipe Together Properly To Get The Most Value Out Of A Length Of Pipe.

Please Reference The Pipe Manufacture For Specific Heating Time And Insertion Depths.

Related Post: