Galvanic Compatibility Chart

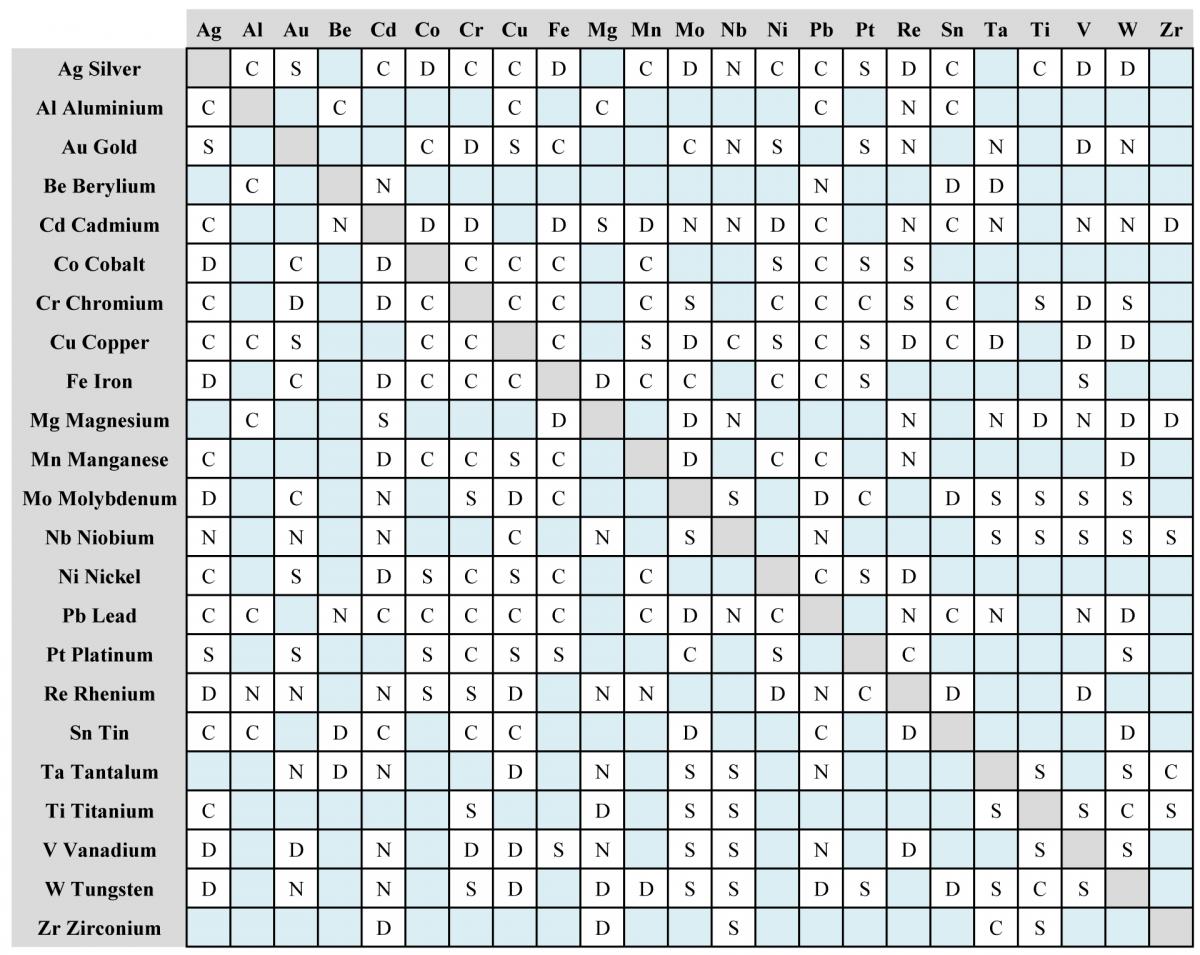

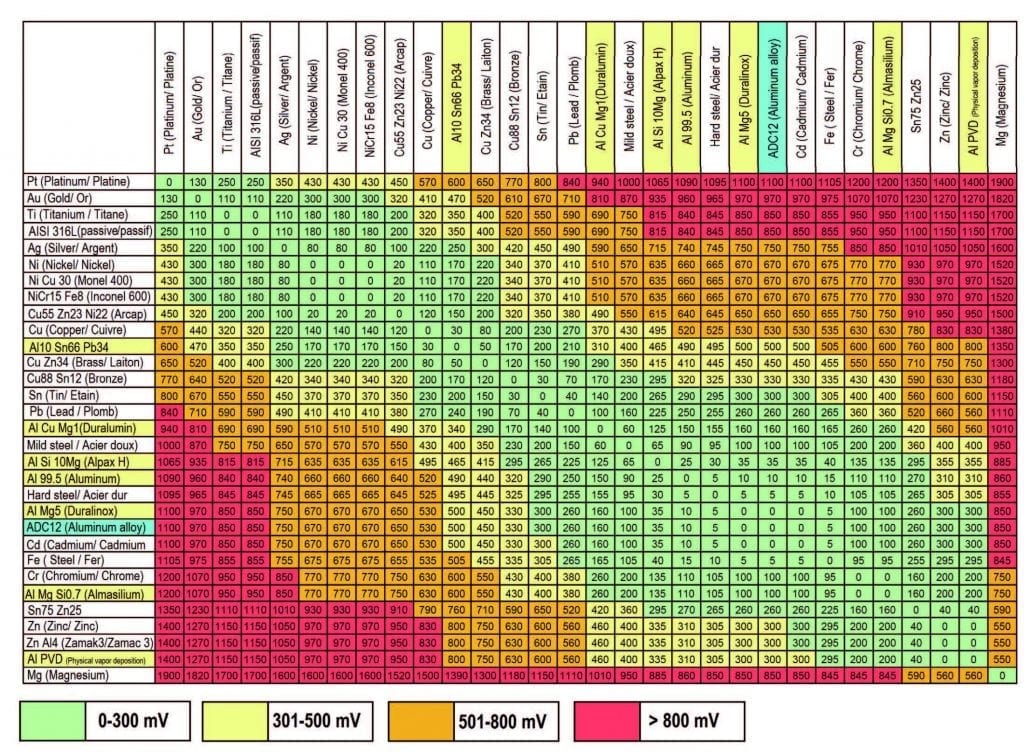

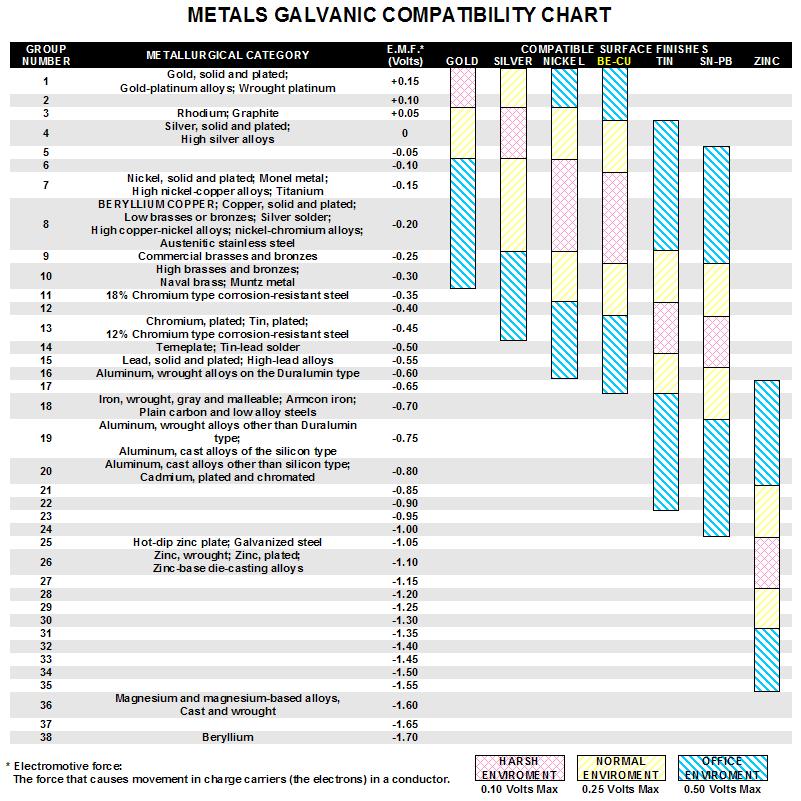

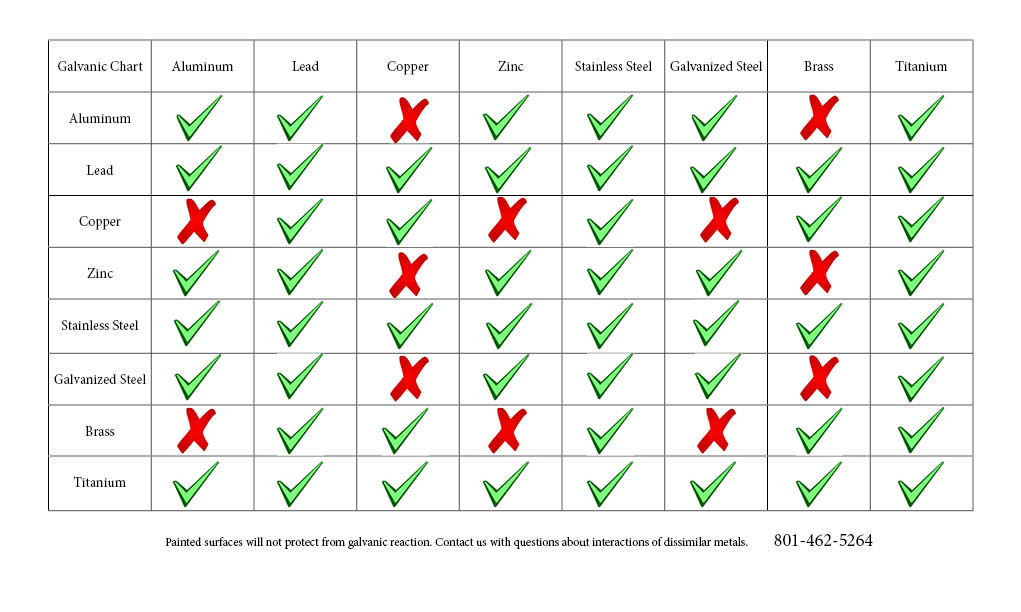

Galvanic Compatibility Chart - The closer together the material are on the chart to the right, the less galvanic action will occur. By using the chart, contractors and homeowners can determine metal compatibility and predict galvanic corrosion likelihood and severity. It includes a chart that shows how different plating materials react to one another with regard to their galvanic potential. Web the galvanic corrosion chart, also referred to as the galvanic series or compatibility chart, is a valuable tool used to assess the compatibility of different metal combinations and predict their susceptibility to galvanic corrosion. Galvanic series / galvanic table. Web to minimize galvanic corrosion, select fasteners based on their material compatibility with the substrates. Web below is a galvanic reaction chart for dissimilar metals. This chart is designed to assist in broadly assessing the risk of galvanic corrosion associated with a given metal coming into contact with another metal. So, for example, choosing zinc on zinc would have the lowest risk for corrosion. Web read on to find out about what it is and how to use it to analyse the compatibility of joining metals. First there must be two electrochemically dissimilar metals present. Galvanic series / galvanic table. The following are to links of corrosion and galvanic capatibility resources, tools, articles and other useful data. Web the metal with the higher potential forms the anode and is corroded. Web fastener material galvanic compatibility table chart. It provides a galvanic series chart that lists metals from most anodic (likely to corrode) to most cathodic (unlikely to corrode). By using the chart, contractors and homeowners can determine metal compatibility and predict galvanic corrosion likelihood and severity. Web below is a galvanic reaction chart for dissimilar metals. Use this chart below to better understand what metals will work. Web view our galvanic series chart, pictures, definitions, and even a mnemonic device! So, for example, choosing zinc on zinc would have the lowest risk for corrosion. Web view this chart of galvanic compatibility. Web engineering application & design. The first card recreates the information shown in table i for the chosen material pair. Most architects know enough about it to be dangerous, but what exactly causes this breakdown? There are three conditions that must exist for galvanic corrosion to occur. This chart is designed to assist in broadly assessing the risk of galvanic corrosion associated with a given metal coming into contact with another metal. The following are to links of corrosion and. So, for example, choosing zinc on zinc would have the lowest risk for corrosion. For any combination of dissimilar metals, the metal with the lower number will act as an anode and will corrode preferentially. Web below, we give a brief overview of galvanic corrosion and provide a galvanic corrosion chart to help fabricators and machinists avoid using the wrong. Web engineering application & design. Most architects know enough about it to be dangerous, but what exactly causes this breakdown? The closer together the material are on the chart to the right, the less galvanic action will occur. Often when design requires that dissimilar metals come in contact, the galvanic compatibility is managed by finishes and plating. Web the galvanic. Web view this chart of galvanic compatibility. Web view our galvanic series chart, pictures, definitions, and even a mnemonic device! Web by knowing the relationships of the metals in the series, galvanic compatibility can be determined, preventing the possible harmful effects of galvanic corrosion. So, for example, choosing zinc on zinc would have the lowest risk for corrosion. Web the. If you're a designer working with exterior metals, you've probably heard of galvanic corrosion. The following galvanic table lists metals in the order of their relative activity in seawater environment. Web galvanic corrosion (also called bimetallic corrosion or dissimilar metal corrosion) is an electrochemical process in which one metal corrodes preferentially when it is in electrical contact with another, in. Often when design requires that dissimilar metals come in contact, the galvanic compatibility is managed by finishes and plating. Web galvanic corrosion (also called bimetallic corrosion or dissimilar metal corrosion) is an electrochemical process in which one metal corrodes preferentially when it is in electrical contact with another, in the presence of an electrolyte. Web below, we give a brief. Web galvanic corrosion (some times called dissimilar metal corrosion) is the process by which the materials in contact with each other oxidizes or corrodes. Web view our galvanic series chart, pictures, definitions, and even a mnemonic device! So, for example, choosing zinc on zinc would have the lowest risk for corrosion. Web to minimize galvanic corrosion, select fasteners based on. Web galvanic corrosion (also called bimetallic corrosion or dissimilar metal corrosion) is an electrochemical process in which one metal corrodes preferentially when it is in electrical contact with another, in the presence of an electrolyte. Web the document discusses galvanic corrosion that can occur when dissimilar metals are in contact. Web galvanic corrosion (some times called dissimilar metal corrosion) is the process by which the materials in contact with each other oxidizes or corrodes. Use this chart below to better understand what metals will work best together without potential for galvanic corrosion: The closer together the material are on the chart to the right, the less galvanic action will occur. The larger the separation distance in the electromotive chart between the two metals in contact, the higher the contact potential and chances for corrosion. Web however, you can completely avoid galvanic corrosion by choosing matching metal anchors. For any combination of dissimilar metals, the metal with the lower number will act as an anode and will corrode preferentially. Often when design requires that dissimilar metals come in contact, the galvanic compatibility is managed by finishes and plating. The following galvanic table lists metals in the order of their relative activity in seawater environment. So, for example, choosing zinc on zinc would have the lowest risk for corrosion. Web below is a galvanic reaction chart for dissimilar metals. Most architects know enough about it to be dangerous, but what exactly causes this breakdown? The first card recreates the information shown in table i for the chosen material pair. Web view this chart of galvanic compatibility. The following are to links of corrosion and galvanic capatibility resources, tools, articles and other useful data.

Galvanic Corrosion Compatibility Chart

Galvanic Corrosion Chart Metals

Galvanic Action Corrosion Prevention Architect's Blog

Galvanic Action Corrosion Prevention Architect's Blog

Galvanic Corrosion Compatibility Chart

Galvanic Corrosion Compatibility Chart

Omega Shielding Products Metals Galvanic Compatibility Chart

Galvanic Corrosion Compatibility Chart

Galvanic Chart For Metals

Galvanic Series, or Nobility Chart for Dissimilar Metals Fair Wind

The Corrosion Of The Base Metal Is Not Increased By The Fastener.

Web The Galvanic Corrosion Chart, Also Referred To As The Galvanic Series Or Compatibility Chart, Is A Valuable Tool Used To Assess The Compatibility Of Different Metal Combinations And Predict Their Susceptibility To Galvanic Corrosion.

First There Must Be Two Electrochemically Dissimilar Metals Present.

You Can Also Learn More About Overcoming Potentially Compatibility Issues Between Metals.

Related Post: