Flywheel Design

Flywheel Design - Explained in detail with diagrams & download pdf of this. Web the project involves the design and analysis of fly wheel to minimize the fluctuation in torque, the flywheel is subjected to a constant rpm. This design can potentially scale up for higher energy storage capacity. Six problems, including some past board exams, are explained. Web the program is intended for a design of a flywheel, its analysis, and determination of dimensions. Design of flywheel dimensions based on a required moment of inertia 3. Web a solid circular steel disk, 25 mm thick, is used as flywheel. In automobile engines, the flywheel serves to smooth out the pulses of energy provided by combustion in the cylinders and provide energy for the compression stroke of the pistons. The mass density of steel is 7800 kg/m 3 while poisson’s ratio is 0.3. Choose the shape that resembles a flywheel, such as a circle or an oval. Open powerpoint and create a new slide. The large variation that is possible between different machine designs shows that dynamic measurement or kinematic analysis is necessary to determine the torque fluctuation. A flywheel can be used to smooth energy fluctuations and make the energy flow intermittent operating machine more uniform. Web a solid circular steel disk, 25 mm thick, is. Web a flywheel system stores energy mechanically in the form of kinetic energy by spinning a mass at high speed. In this article, we will study definition, function, construction, working principle, material, advantages, application in detail. Web what's the best design for a flywheel? 0:00 introduction and formulas 6:50 problem 1 8:40. Web an engineered rotating mass designed specifically to. It follows on from these basic laws of physics that a flywheel will store more energy if it has either a higher moment of inertia (more mass or mass positioned further from its center) or if it spins at a higher speed. In automobile engines, the flywheel serves to smooth out the pulses of energy provided by combustion in the. Web after the industrial revolution, james watt was the first to design a modern flywheel with a crank mechanism for a steam engine. It also allows to solve a crank mechanism and to determine parameters of asynchronous motors. Web flywheel design and sizing calculation principles, formulae and practical example with step by step numerical solution is explained here which is. Open powerpoint and create a new slide. Web what's the best design for a flywheel? Web a solid circular steel disk, 25 mm thick, is used as flywheel. This flywheel design and sizing calculation shows how to find out mass, size, cross section, maximum internal tangential stress and factor of safety for a flywheel. The objective of present work is. In automobile engines, the flywheel serves to smooth out the pulses of energy provided by combustion in the cylinders and provide energy for the compression stroke of the pistons. Web to create a flywheel in powerpoint for your presentation design, follow these steps: The mass density of steel is 7800 kg/m 3 while poisson’s ratio is 0.3. Web this video. The flywheel operates at a nominal speed of 40,000 rpm. Web the ω yield gives the critical speed of the flywheel. The energy storage system involving a flywheel as its primary unit is called a flywheel energy storage system (fes). The mass density of steel is 7800 kg/m 3 while poisson’s ratio is 0.3. Open powerpoint and create a new. In this article, we will study definition, function, construction, working principle, material, advantages, application in detail. The mass density of steel is 7800 kg/m 3 while poisson’s ratio is 0.3. Electrical inputs spin the flywheel rotor and keep it spinning until called upon to release the stored energy. Explained in detail with diagrams & download pdf of this. Web a. The energy storage system involving a flywheel as its primary unit is called a flywheel energy storage system (fes). Open powerpoint and create a new slide. A flywheel can be used to smooth energy fluctuations and make the energy flow intermittent operating machine more uniform. Web an engineered rotating mass designed specifically to store energy as a result of it. It also allows to solve a crank mechanism and to determine parameters of asynchronous motors. Calculate the outer radius of the fl ywheel disk and the maximum stresses induced in it. Electrical inputs spin the flywheel rotor and keep it spinning until called upon to release the stored energy. Six problems, including some past board exams, are explained. Web an. Draw the shape on your slide and resize it as needed. Flywheel mass, size design calculator. Web the project involves the design and analysis of fly wheel to minimize the fluctuation in torque, the flywheel is subjected to a constant rpm. Web flywheels & turning moment diagramstimestamp:00:00 introduction & significance of flywheel01:36 analogy & functions of a flywheel03:20 where do we need flywh. Web flywheel design and sizing calculation principles, formulae and practical example with step by step numerical solution is explained here which is useful for sizing ic engine, sheet metal press, compressors and other applications. A flywheel can be used to smooth energy fluctuations and make the energy flow intermittent operating machine more uniform. Its parts, function, and types of the flywheel. In this article, we will study definition, function, construction, working principle, material, advantages, application in detail. Web silicon valley inventor bill gray has a new flywheel design that would deliver distributed and highly scalable storage for around $1,333 a kilowatt, making it price competitive with pumped hydro. Web the ω yield gives the critical speed of the flywheel. This flywheel design and sizing calculation shows how to find out mass, size, cross section, maximum internal tangential stress and factor of safety for a flywheel. Calculate the outer radius of the fl ywheel disk and the maximum stresses induced in it. 0:00 introduction and formulas 6:50 problem 1 8:40. Web in this video from the gang at centerforce, will baty with centerforce university walks you through the three main types of flywheels—cast iron, billet steel, and billet aluminum—and explains the key differences between each while explaining which type is best for a particular application. Web a flywheel is a mechanical device that uses the conservation of angular momentum to store rotational energy, a form of kinetic energy proportional to the product of its moment of inertia and the square of its rotational speed. The flywheel operates at a nominal speed of 40,000 rpm.

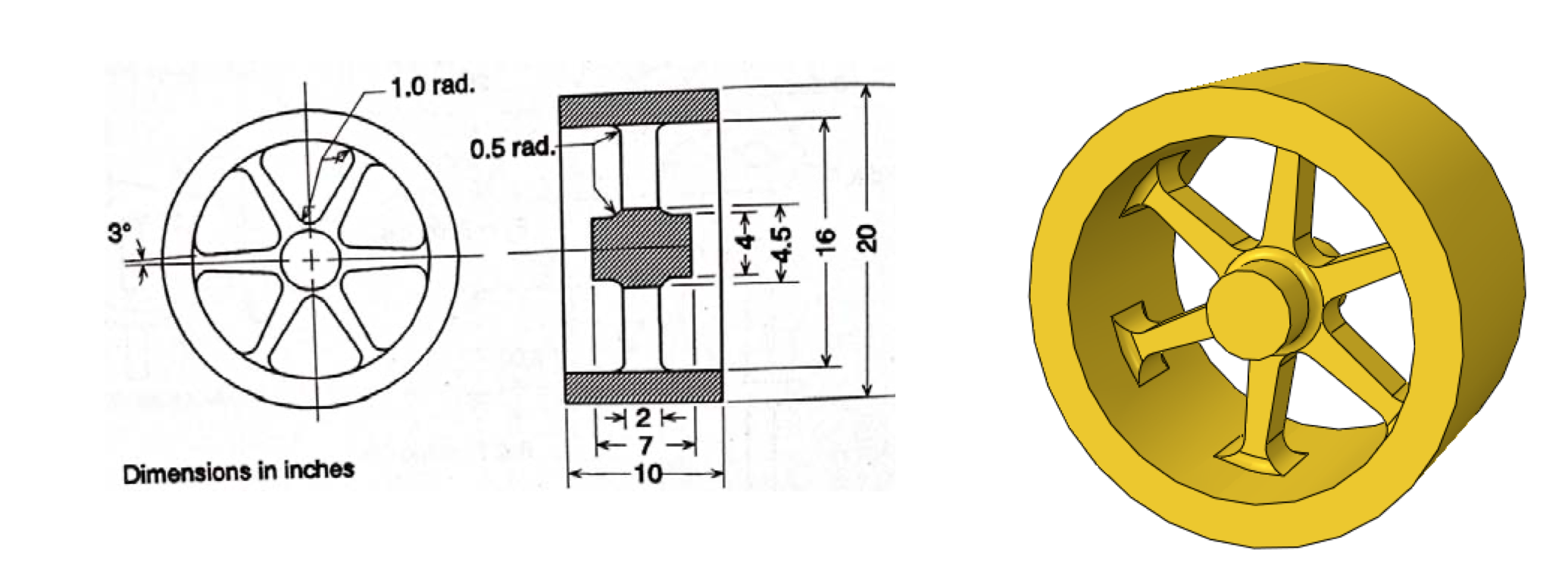

Flywheel Design Principles

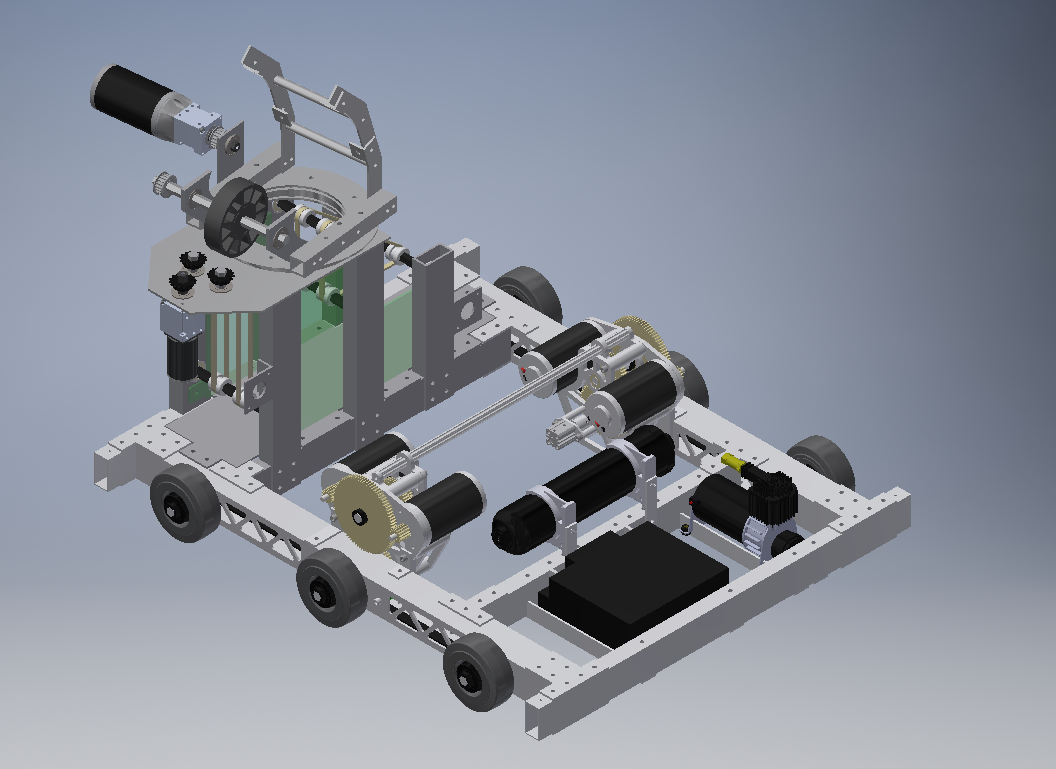

Team 41 2020 Preseason Flywheel Design Release Inventor Chief Delphi

The final design of the flywheel, shown together with its principal

Design of flywheel

Solved 2) Design of a flywheel is shown in the figure. It is

Powerpoint Flywheel Template

Engine Flywheel 3D Model AD ,EngineFlywheelModel Flyer Design

CADforYOU Design of Flywheel

Design of Flywheel and Simple Solved Problems on Flywheels YouTube

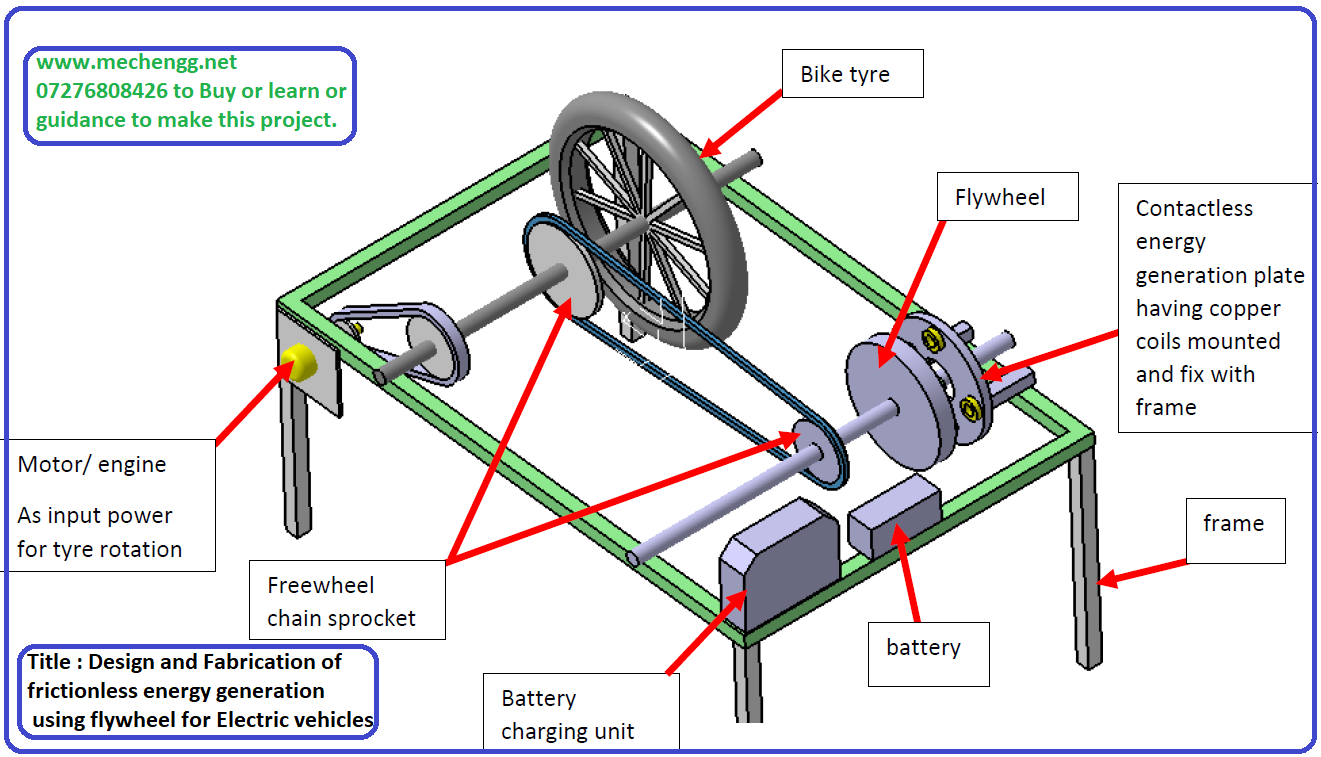

Free Energy Generator Diagram

Six Problems, Including Some Past Board Exams, Are Explained.

Web The Program Is Intended For A Design Of A Flywheel, Its Analysis, And Determination Of Dimensions.

Web If You Inspect The Clutch Assembly And Flywheel And Notice Discoloration Or Cracking, You Need To Resurface Or Replace Your Vehicle’s Flywheel.

The Energy Storage System Involving A Flywheel As Its Primary Unit Is Called A Flywheel Energy Storage System (Fes).

Related Post: