Flowable Fill Mix Design

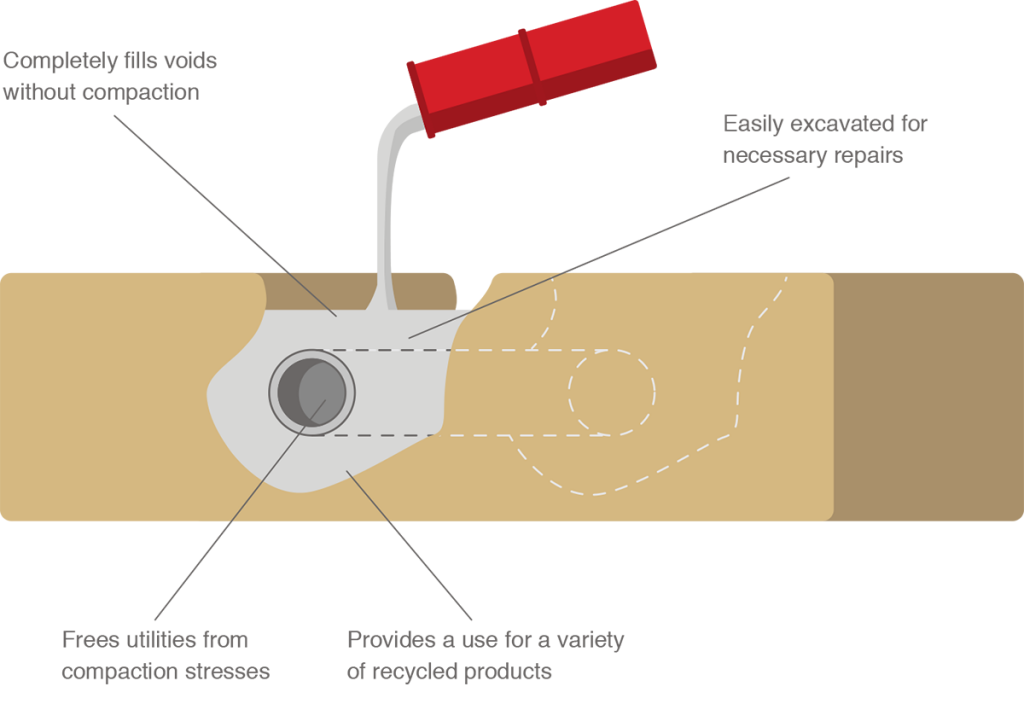

Flowable Fill Mix Design - Flowable fill is a mixture of portland cement, fly ash, fine aggregate, air entraining admixture and water. Web what is flowable fill? Web a flowable fill study batch mix design matrix.169 b lbr and compressive strength data obtained in the laboratory.185 c analysis of variance (anova), parameters, and Once the mix specifications are established, Flowable fill is not concrete, nor it is used to replace concrete. Flowable fill contains a low cementitious content for approval. Submit mix designs to the engineer for approval. Encasing tunnels, pipes or other conduits; (b) hardening for early walkability and cover; When added to the concrete mix, it generates a significant amount of entrained air to lower the overall compressive strength of the mix. Flowable fill sets in 45 minutes allowing early load application. Flowable fill is a mixture of portland cement, fly ash, fine aggregate, air entraining adm. Submit mix designs to the engineer for approval. Encasing tunnels, pipes or other conduits; The properties ordinarily desired of the mix are: This material is ideally suited to certain types of projects, primarily for use as a backfill or structural fill when native soil is not suitable, or as an alternative to compacted fill. Submit mix designs to the engineer for approval. Studies have shown that flowable fill made with foundry sands often has superior flowability to clsm made with conventional construction. Web what is flowable fill? Cellular concrete flowable fill may also contain fine aggregate, fly ash, slag and admixtures. Web flowable fill was initially developed as a solution to persistent problems stemming from poorly compacted soil or granular fill. Web design the clsm mixture using readily available materials to meet the job performance requirements. Web flowable fill mixes consists of. Most applications, however, use mixtures with strength less than 300 psi (2.1 mpa). (b) hardening for early walkability and cover; And (c) ultimate strength low enough to allow ready excavation. These mixtures comprised of large amounts of fly ash and water and experienced large volume changes due. Flowable fill contains a low cementitious content for approval. Once the mix specifications are established, Encasing tunnels, pipes or other conduits; Web flowable fill was initially developed as a solution to persistent problems stemming from poorly compacted soil or granular fill. Flowable fill is not concrete, nor it is used to replace concrete. A good flowable fill mix ratio can have more air and water in it compared to. Submit mix designs to the engineer for approval. Web design the clsm mixture using readily available materials to meet the job performance requirements. The ability to excavate flowable fill will depend on the equipment used for the strength and type of mixture placed. Web a flowable fill study batch mix design matrix.169 b lbr and compressive strength data obtained in. Web flowable fill was initially developed as a solution to persistent problems stemming from poorly compacted soil or granular fill. Flowable fill is a mixture of portland cement, fly ash, fine aggregate, air entraining admixture and water. These mixtures comprised of large amounts of fly ash and water and experienced large volume changes due. Flowable fill contains a low cementitious. The properties ordinarily desired of the mix are: Web flowable fill was initially developed as a solution to persistent problems stemming from poorly compacted soil or granular fill. Studies have shown that flowable fill made with foundry sands often has superior flowability to clsm made with conventional construction sands. The following table provides the recommended trial mixture from this specification.. A good flowable fill mix ratio can have more air and water in it compared to concrete. Flowable fill sets in 45 minutes allowing early load application. Web flowable fill mixes consists of a mixture of portland cement combined with aggregates, water, and sometimes chemical admixtures. Web since many flowable fills are designed with future excavation in mind, a lower. The specifier may cite the Web since many flowable fills are designed with future excavation in mind, a lower compressive strength is often an advantage in mix design. (b) hardening for early walkability and cover; Flowable fill contains a low cementitious content for approval. The following table provides the recommended trial mixture from this specification. Web flowable fill was initially developed as a solution to persistent problems stemming from poorly compacted soil or granular fill. Web cellular concrete flowable fill is a low density concrete made with cement, water and preformed foam to form a hardened closed cell foam material. When added to the concrete mix, it generates a significant amount of entrained air to lower the overall compressive strength of the mix. Submit mix designs to the engineer for approval. It is an excellent mix design choice for backfilling utility lines, trenches, and retaining walls; Flowable fill contains a low cementitious content for reduced strength development. Web a mix design for the use of foundry sand and coal fly ash in flowable fill was developed for ford motor company. Most applications, however, use mixtures with strength less than 300 psi (2.1 mpa). Flowable fill is a mixture of portland cement, fly ash, fine aggregate, air entraining admixture and water. Encasing tunnels, pipes or other conduits; Direction is provided on the flowable fill mix design, characterization, and usage of flowable fill. Web since many flowable fills are designed with future excavation in mind, a lower compressive strength is often an advantage in mix design. The properties ordinarily desired of the mix are: Web flowable fill mixes consists of a mixture of portland cement combined with aggregates, water, and sometimes chemical admixtures. Web what is flowable fill? Flowable fill contains a low cementitious content for approval.Illinois Ready Mixed Concrete Association Flowable Fill

1 Reviewed Mix Designs of "Sandless" Flowable Fills Download Table

Flowable Fill Admixture Fill Flow FritzPak Concrete Admixtures

Flowable Fill—Near and Dear to Our Repair Hearts

Flowable Fill Admixture Fill Flow FritzPak Concrete Admixtures

1 Reviewed Mix Designs of "Sandless" Flowable Fills Download Table

Flowable Fill and SelfConsolidating (SCC) Concrete Ozinga

Flowable Fill Concrite

Triple Crown Concrete Flowable Fill Flowable Fill Mixtures Kentucky

Flowable Fill Products in the Madison Area Advanced Concrete

And Filling Voids, Including Wells, Mines, And.

Flowable Fill Sets In 45 Minutes Allowing Early Load Application.

Web Most Flowable Fill Mix Measures A Compressive Strength Of 300 Pounds Per Square Inch Simply Because Flow Fill Concrete Does Not Bear Any Loads Or Carry Direct Vehicular Weight, Such As With A Drainage Pipe.

These Mixtures Comprised Of Large Amounts Of Fly Ash And Water And Experienced Large Volume Changes Due.

Related Post: