Flexure Design

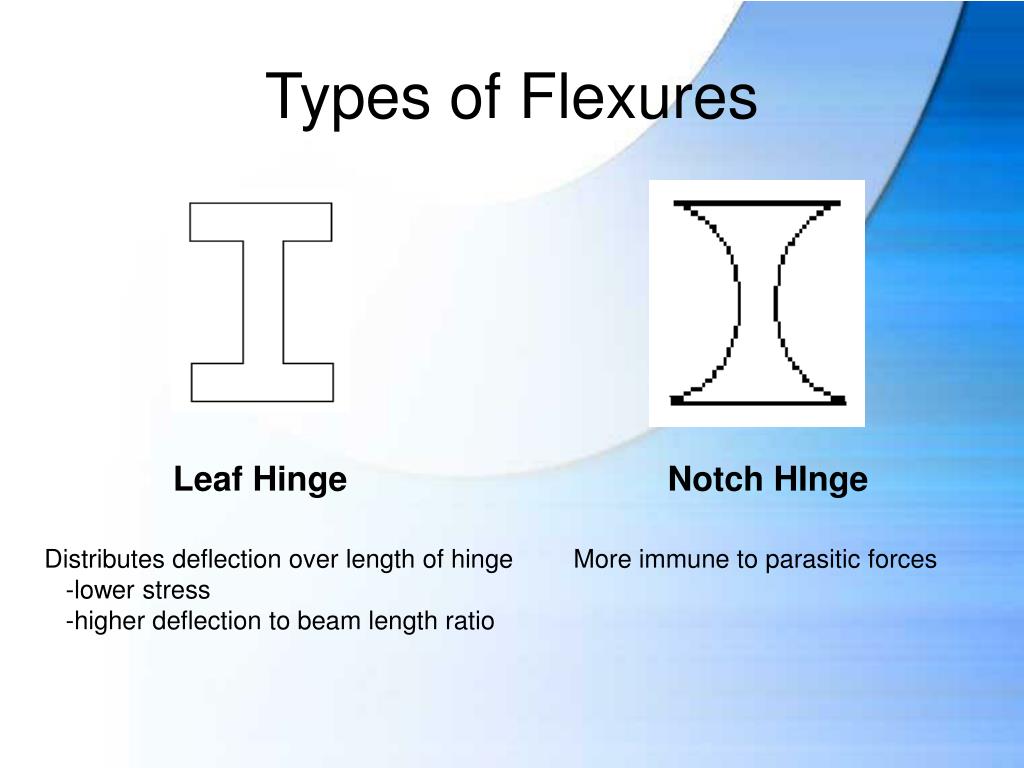

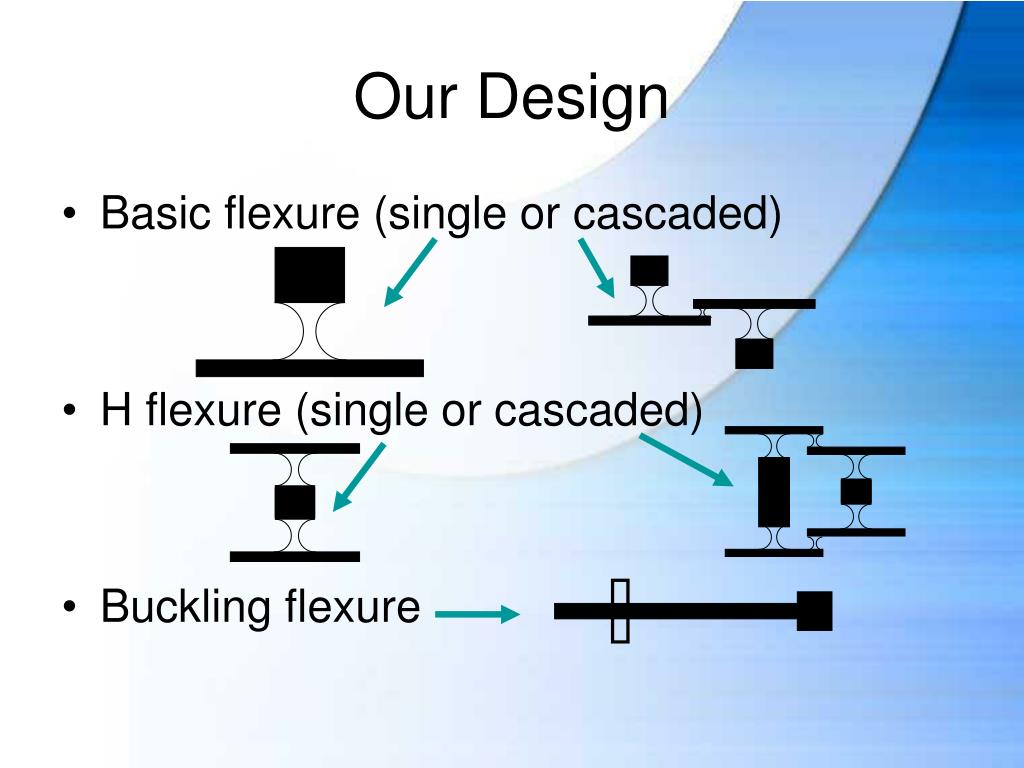

Flexure Design - The fabrication and validation phase compares common manufacturing techniques and includes information about assembly, testing types, and reworking options. Features of the guide include The approach is most useful for unusual, nonsymmetric configurations where intuition is inadequate. This lecture introduces the concept of flexural bearings and their characteristics. In practical problems, the specified compressive strength and yield strength of. Web in this paper we demonstrate two approaches for optimising flexure geometry to follow arbitrary focal surface curvature and to orient the optical fibre with arbitrary tilt. Web flexure mechanisms, also known as compliant mechanisms, rely on the elasticity of matter to provide motion to mechanism linkages. I) sectional design and ii) member detailing. Web to investigate the impact of waste rubber powder on cement concrete, various mechanical property tests were conducted, including compressive, flexural, dynamic elastic modulus, and impact performance tests. A single flexure may serve as a hinge when it is in line with the dominant load. In practical problems, the specified compressive strength and yield strength of. To understand why the butterfly flexure moves the way it does, i read up on fact, a theoretical framework for designing flexures. Web flexure hinge mechanism is one of high effective and precise mechanism within the limed range of motion. This philosophy assures that, should a member crack, the. A single flexure may serve as a hinge when it is in line with the dominant load. In practical problems, the specified compressive strength and yield strength of. Features of the guide include Analytical using matlab models and fea based using ansys. Web to investigate the impact of waste rubber powder on cement concrete, various mechanical property tests were conducted,. Web flexure mechanisms, also known as compliant mechanisms, rely on the elasticity of matter to provide motion to mechanism linkages. Desired kinematics, range of motion, stiffness, load capacity, repeatability, mode shapes/frequencies, and an error budget. Web prudent design practice dictates that the flexural strength of a member exceed the cracking strength of the member. To understand why the butterfly flexure. Web flexure motions can be very small, highly precise, and repeatable (sub nanometer), or quite large while still providing smooth, predictable motion. Web this entry is about understanding the most important parameters for flexure design. Web flexure hinge mechanism is one of high effective and precise mechanism within the limed range of motion. Design 6.1 practical flexural design approach structural. Web the design of a singly reinforced rectangular beam to resist a factored bending moment requires solving for appropriate dimensions and tension reinforcement. Flexures are a design feature used by design engineers (usually mechanical engineers) for providing adjustment or compliance in a design. Web flexure motions can be very small, highly precise, and repeatable (sub nanometer), or quite large while. Features of the guide include Because of the bending stresses created in the flexure, great care needs to. Web prudent design practice dictates that the flexural strength of a member exceed the cracking strength of the member. Web the detailed design discusses modeling, simulation, analysis, and optimization techniques used in flexure design. Web a flexure is a flexible element (or. Web i quickly put down my original project to the side to further investigate flexures. Flexures are commonly coupled with high precision actuators, like pzts, to provide preload, precise guided motion, and small output strokes. Flexures are a design feature used by design engineers (usually mechanical engineers) for providing adjustment or compliance in a design. Web flexure hinge mechanism is. Desired kinematics, range of motion, stiffness, load capacity, repeatability, mode shapes/frequencies, and an error budget. I) sectional design and ii) member detailing. Next, a collection basic joints and linear guides are shown with design considerations. Web to investigate the impact of waste rubber powder on cement concrete, various mechanical property tests were conducted, including compressive, flexural, dynamic elastic modulus, and. Flexures are a design feature used by design engineers (usually mechanical engineers) for providing adjustment or compliance in a design. Design 6.1 practical flexural design approach structural design involves determining the section and material properties followed by prestress details to satisfy serviceability, strength, and detailing. Web to investigate the impact of waste rubber powder on cement concrete, various mechanical property. A single flexure may serve as a hinge when it is in line with the dominant load. Features of the guide include In practical problems, the specified compressive strength and yield strength of. Web to investigate the impact of waste rubber powder on cement concrete, various mechanical property tests were conducted, including compressive, flexural, dynamic elastic modulus, and impact performance. Because of the bending stresses created in the flexure, great care needs to. Design 6.1 practical flexural design approach structural design involves determining the section and material properties followed by prestress details to satisfy serviceability, strength, and detailing. Features of the guide include Flexure mechanisms eliminate the disadvantages of classical joints: This lecture introduces the concept of flexural bearings and their characteristics. Web flexure mechanisms, also known as compliant mechanisms, rely on the elasticity of matter to provide motion to mechanism linkages. Web a flexure is a flexible element (or combination of elements) engineered to be compliant in specific degrees of freedom. Web design of reinforced concrete elements for flexure involves; Web i quickly put down my original project to the side to further investigate flexures. Web a scanning tunneling microscope, flexural bearings are one of the most widely used types of bearings. A single flexure may serve as a hinge when it is in line with the dominant load. This philosophy assures that, should a member crack, the member would have sufficient ductility to permit large deflections and cracking prior to collapse. The functional requirements for flexures include (but are not limited to): To understand why the butterfly flexure moves the way it does, i read up on fact, a theoretical framework for designing flexures. The fabrication and validation phase compares common manufacturing techniques and includes information about assembly, testing types, and reworking options. In practical problems, the specified compressive strength and yield strength of.

PPT PolyMUMPS Flexure Design PowerPoint Presentation, free download

UNITII DESIGN FOR FLEXURE AND SHEAR Flexural Strength

Design of Beams for Flexure Design of Beams

Detailed design of the universal joint (a) scheme of the flexure

PPT Lecture 9 Flexure PowerPoint Presentation ID4012409

PPT PolyMUMPS Flexure Design PowerPoint Presentation, free download

Design of T and L Beam in Flexure. Construction How

Design of bistable flexure mechanisms. a Undeformed shape of a

Beam flexure design (a) trimetric view of constant cross section

mechanical flexure design flexure design for linear motion Swhshish

It Is Of Interest In Structural Practice To Calculate Those Stresses And Deformations Which Occur In A Structure In Service Under Design Load.

For Reinforced Concrete Beams This Can Be Done By The Methods Just Presented, Which Assume Elastic Behavior Of Both Materials.

Web Flexure Motions Can Be Very Small, Highly Precise, And Repeatable (Sub Nanometer), Or Quite Large While Still Providing Smooth, Predictable Motion.

Web The Design Of A Singly Reinforced Rectangular Beam To Resist A Factored Bending Moment Requires Solving For Appropriate Dimensions And Tension Reinforcement.

Related Post: