Flare Fitting Size Chart

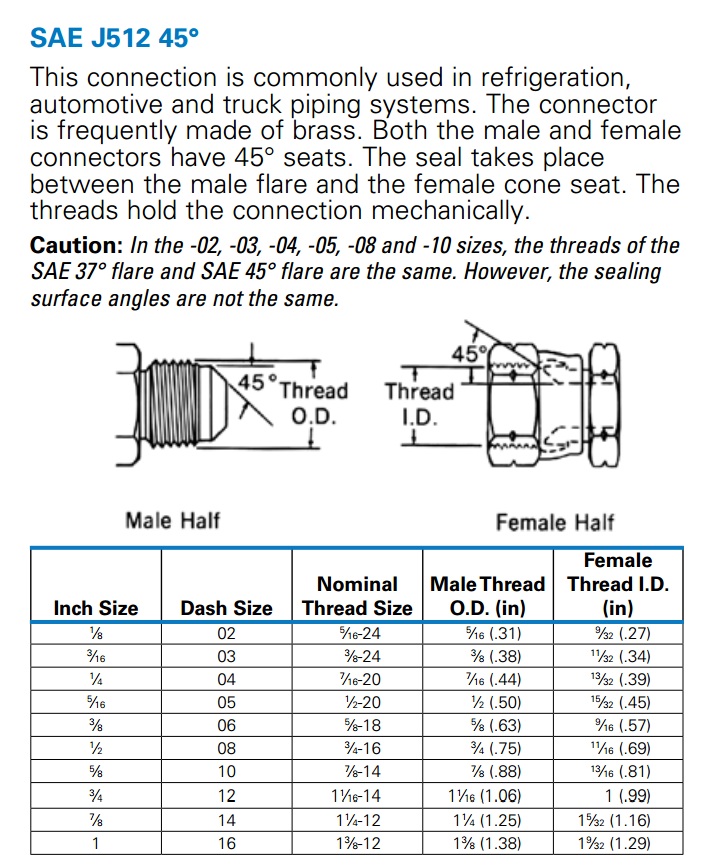

Flare Fitting Size Chart - Precision made punch and smooth bore die blocks grip and form flare without damaging the tubing. Two of the most common types are the jic 37° flare fittings and the sae 45° flare fittings. Carefully measure the seat angle to differentiate sae 45° flare fitting the sae 45° flare male will mate with an sae 45° flare. Check the detail for inverted flare fitting size chart. The tube end is flared at a 37° angle (74°included angle) Web press perfect flares in seconds, with fast cam and lever action. Sae 45° flare connections are commonly used in automotive applications as well as for refrigeration and air conditioning. Up to 2000 psi depending on tube size. The fitting consists of three pieces: Making aircraft quality flares for sae 45 degree double (inverted) on american or metric size tubing. Web these flare sae 45° fittings may be used with copper, brass, aluminium, steel and plastic tube provided an acceptable flare can be generated with the material. Two of the most common types are the jic 37° flare fittings and the sae 45° flare fittings. Some sizes have the same threads as the sae 45° flare. Vacuum to pressures of. Check the detail for inverted flare fitting size chart. Precision made punch and smooth bore die blocks grip and form flare without damaging the tubing. It uses an easily produced flare at the tube end to seal and hold fluid under high pressure. The seal is made on the 37° flare seat. Web download a pdf copy of our complete. Sae 45° flare connections are commonly used in automotive applications as well as for refrigeration and air conditioning. Check the detail for inverted flare fitting size chart. Web the most common flare fitting standards in use today are the 45° sae flare, the 37° jic flare, and the 37° an flare. Web the sae 37° flared tube fittings design is. Making aircraft quality flares for sae 45 degree double (inverted) on american or metric size tubing. Web sae inverted flare fitting features with a 42° seat, and a flared male tubing with a 45°seat. Web the sae 37° flared tube fittings design is simple. Up to 2000 psi depending on tube size. Vacuum to pressures of 350 bar (5000 psi). Vacuum to pressures of 350 bar (5000 psi) can be handled dependent upon. *please note, this catalog is 126 pages so the file may take a minute or two to download depending on your computer speed and. It uses an easily produced flare at the tube end to seal and hold fluid under high pressure. Web download a pdf copy. The jic female has straight threads and a 37° flare seat. Web press perfect flares in seconds, with fast cam and lever action. *please note, this catalog is 126 pages so the file may take a minute or two to download depending on your computer speed and. The tube end is flared at a 37° angle (74°included angle) Sae 45°. Precision made punch and smooth bore die blocks grip and form flare without damaging the tubing. Check the detail for inverted flare fitting size chart. Web sae inverted flare fitting features with a 42° seat, and a flared male tubing with a 45°seat. Web these flare sae 45° fittings may be used with copper, brass, aluminium, steel and plastic tube. Web the sae 37° flared tube fittings design is simple. Up to 2000 psi depending on tube size. Web the jic male has straight threads and wa 37° flare seat. It uses an easily produced flare at the tube end to seal and hold fluid under high pressure. The seal is made on the 37° flare seat. Web the jic male has straight threads and wa 37° flare seat. Web download a pdf copy of our complete catalog this catalog includes every fitting on our website. Some sizes have the same threads as the sae 45° flare. Web sae inverted flare fitting features with a 42° seat, and a flared male tubing with a 45°seat. Vacuum to. Web press perfect flares in seconds, with fast cam and lever action. The fitting consists of three pieces: Web the jic male has straight threads and wa 37° flare seat. Vacuum to pressures of 350 bar (5000 psi) can be handled dependent upon. Making aircraft quality flares for sae 45 degree double (inverted) on american or metric size tubing. Web press perfect flares in seconds, with fast cam and lever action. Web the jic male has straight threads and wa 37° flare seat. It uses an easily produced flare at the tube end to seal and hold fluid under high pressure. Two of the most common types are the jic 37° flare fittings and the sae 45° flare fittings. Web these flare sae 45° fittings may be used with copper, brass, aluminium, steel and plastic tube provided an acceptable flare can be generated with the material. Web download a pdf copy of our complete catalog this catalog includes every fitting on our website. Carefully measure the seat angle to differentiate sae 45° flare fitting the sae 45° flare male will mate with an sae 45° flare. *please note, this catalog is 126 pages so the file may take a minute or two to download depending on your computer speed and. The jic female has straight threads and a 37° flare seat. The tube end is flared at a 37° angle (74°included angle) Web the sae 37° flared tube fittings design is simple. Web sae inverted flare fitting features with a 42° seat, and a flared male tubing with a 45°seat. Vacuum to pressures of 350 bar (5000 psi) can be handled dependent upon. Sae 45° flare connections are commonly used in automotive applications as well as for refrigeration and air conditioning. Web the most common flare fitting standards in use today are the 45° sae flare, the 37° jic flare, and the 37° an flare. Making aircraft quality flares for sae 45 degree double (inverted) on american or metric size tubing.

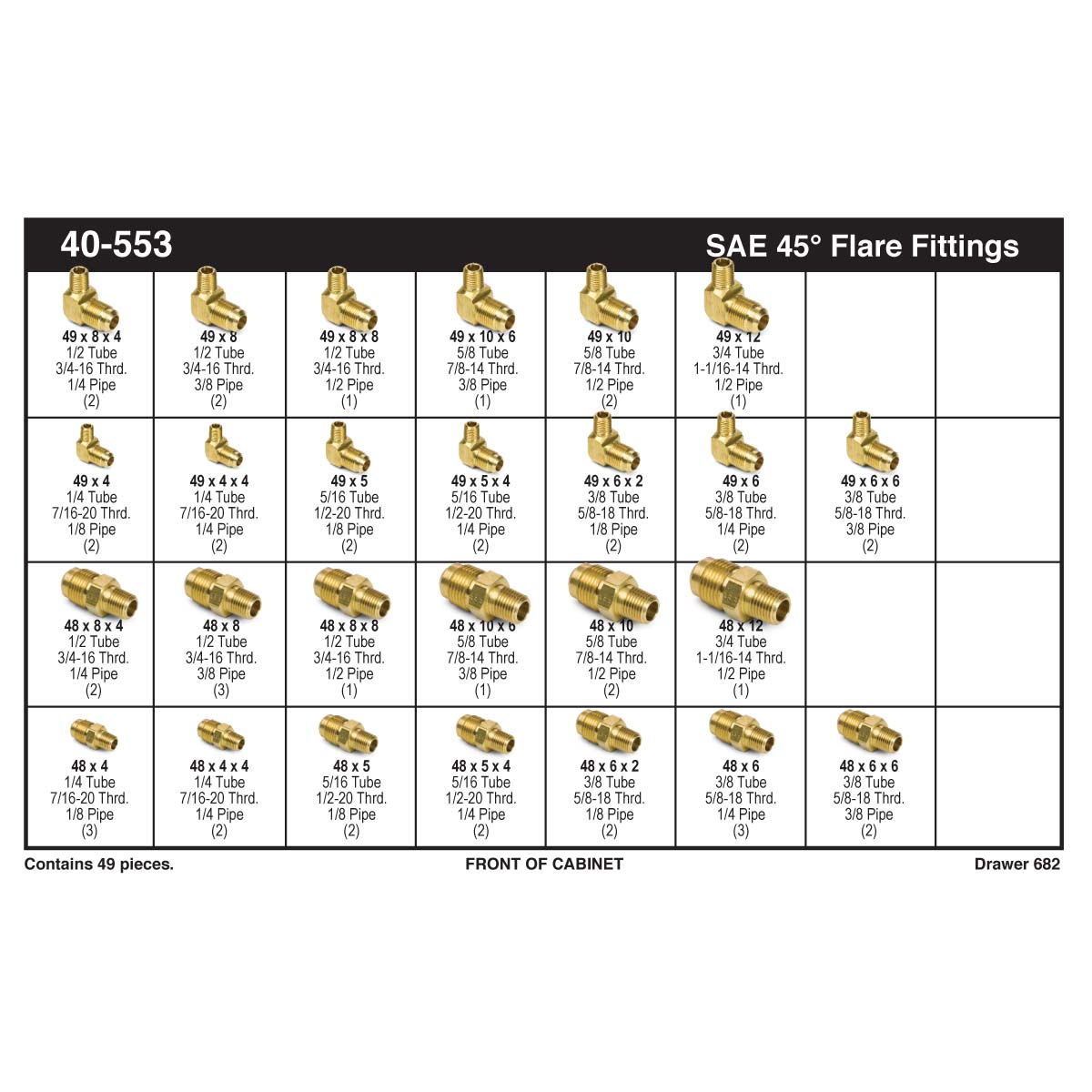

SAE 45° Flare Fittings Assortment (1/4" x 3/4") Kimball Midwest

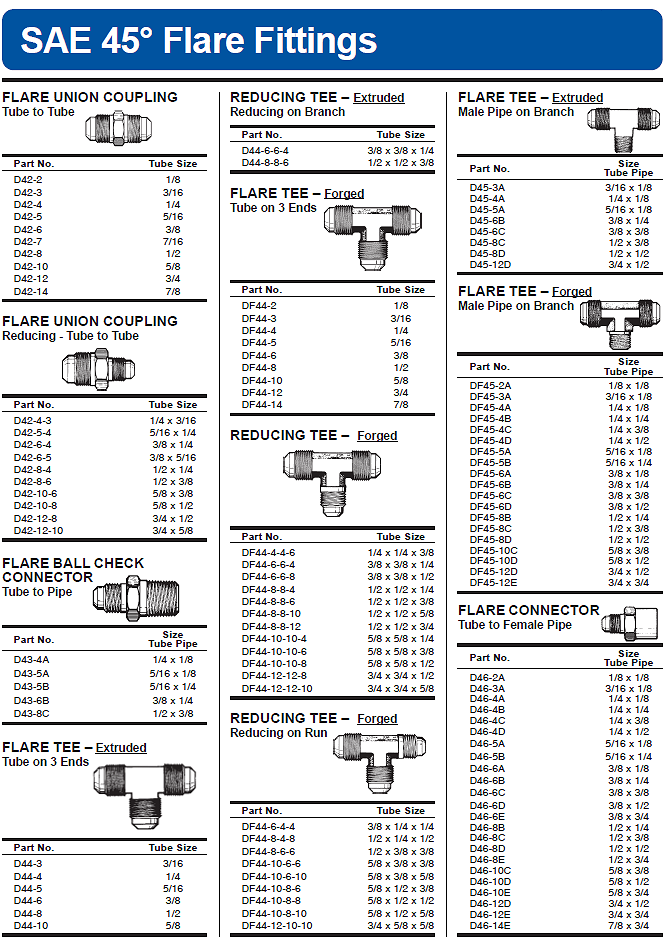

SAE 45 Flare Brass Fittings

Flare Tube Fittings IBLS

02 Flare Fittings LPG Ventures

Inverted Flare Fitting Size Chart

How to Measure Gas Pipe Size for your Fire Pit

Inverted Flare Thread Chart

Npt Pipe and Garden Hose thread size guide

Brake line fitting sizes — Ricks Free Auto Repair Advice Ricks Free

Flares for Tubing AirWay Manufacturing

The Seal Is Made On The 37° Flare Seat.

The Fitting Consists Of Three Pieces:

Check The Detail For Inverted Flare Fitting Size Chart.

Up To 2000 Psi Depending On Tube Size.

Related Post: