Flange Rating Chart

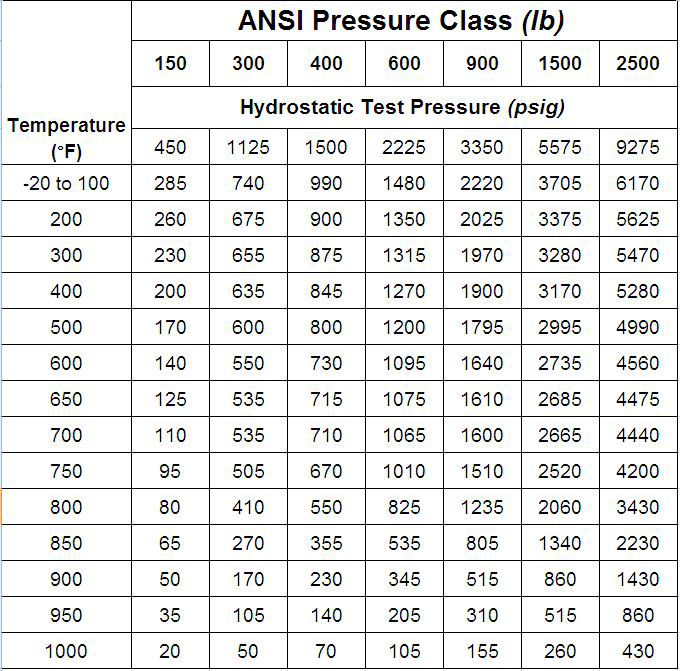

Flange Rating Chart - These ratings are established based on the prime factor of hydro testing of the flanged fittings to the bursting and by adding a factor of safety of 3.0 at the rated working pressure and ambient temperature. Web carbon steel (astm a105n & a350 lf2) limitations > 425°c. From the chart below you can easily find out if your system requirement matches with flange class or not. From the chart below you can easily find out if your system requirement matches with flange class or not. Web carbon steel (astm a105n & a350 lf2) limitations > 425°c. These ratings are established based on the prime factor of hydro testing of the flanged fittings to the bursting and by adding a factor of safety of 3.0 at the. Web carbon steel (astm a105n & a350 lf2) limitations > 425°c. These ratings are established based on the prime factor of hydro testing of the flanged fittings to the bursting and by adding a factor of safety of 3.0 at the rated working pressure and ambient temperature. From the chart below you can easily find out if your system requirement. Web carbon steel (astm a105n & a350 lf2) limitations > 425°c. From the chart below you can easily find out if your system requirement matches with flange class or not. These ratings are established based on the prime factor of hydro testing of the flanged fittings to the bursting and by adding a factor of safety of 3.0 at the. From the chart below you can easily find out if your system requirement matches with flange class or not. Web carbon steel (astm a105n & a350 lf2) limitations > 425°c. These ratings are established based on the prime factor of hydro testing of the flanged fittings to the bursting and by adding a factor of safety of 3.0 at the. From the chart below you can easily find out if your system requirement matches with flange class or not. These ratings are established based on the prime factor of hydro testing of the flanged fittings to the bursting and by adding a factor of safety of 3.0 at the rated working pressure and ambient temperature. Web carbon steel (astm a105n. Web carbon steel (astm a105n & a350 lf2) limitations > 425°c. These ratings are established based on the prime factor of hydro testing of the flanged fittings to the bursting and by adding a factor of safety of 3.0 at the rated working pressure and ambient temperature. From the chart below you can easily find out if your system requirement. These ratings are established based on the prime factor of hydro testing of the flanged fittings to the bursting and by adding a factor of safety of 3.0 at the rated working pressure and ambient temperature. Web carbon steel (astm a105n & a350 lf2) limitations > 425°c. From the chart below you can easily find out if your system requirement. From the chart below you can easily find out if your system requirement matches with flange class or not. These ratings are established based on the prime factor of hydro testing of the flanged fittings to the bursting and by adding a factor of safety of 3.0 at the rated working pressure and ambient temperature. Web carbon steel (astm a105n. From the chart below you can easily find out if your system requirement matches with flange class or not. These ratings are established based on the prime factor of hydro testing of the flanged fittings to the bursting and by adding a factor of safety of 3.0 at the rated working pressure and ambient temperature. Web carbon steel (astm a105n. From the chart below you can easily find out if your system requirement matches with flange class or not. Web carbon steel (astm a105n & a350 lf2) limitations > 425°c. These ratings are established based on the prime factor of hydro testing of the flanged fittings to the bursting and by adding a factor of safety of 3.0 at the. Web carbon steel (astm a105n & a350 lf2) limitations > 425°c. From the chart below you can easily find out if your system requirement matches with flange class or not.

Flange Pressure Rating Chart

Flange Rating Pressure Temperature Chart A Visual Reference of Charts

Use of ASME B16.5 Standards for Flange Pressure Ratings

ASME B16.5 Class 900 Flanges, ANSI B16.5 class 900 flange dimensions

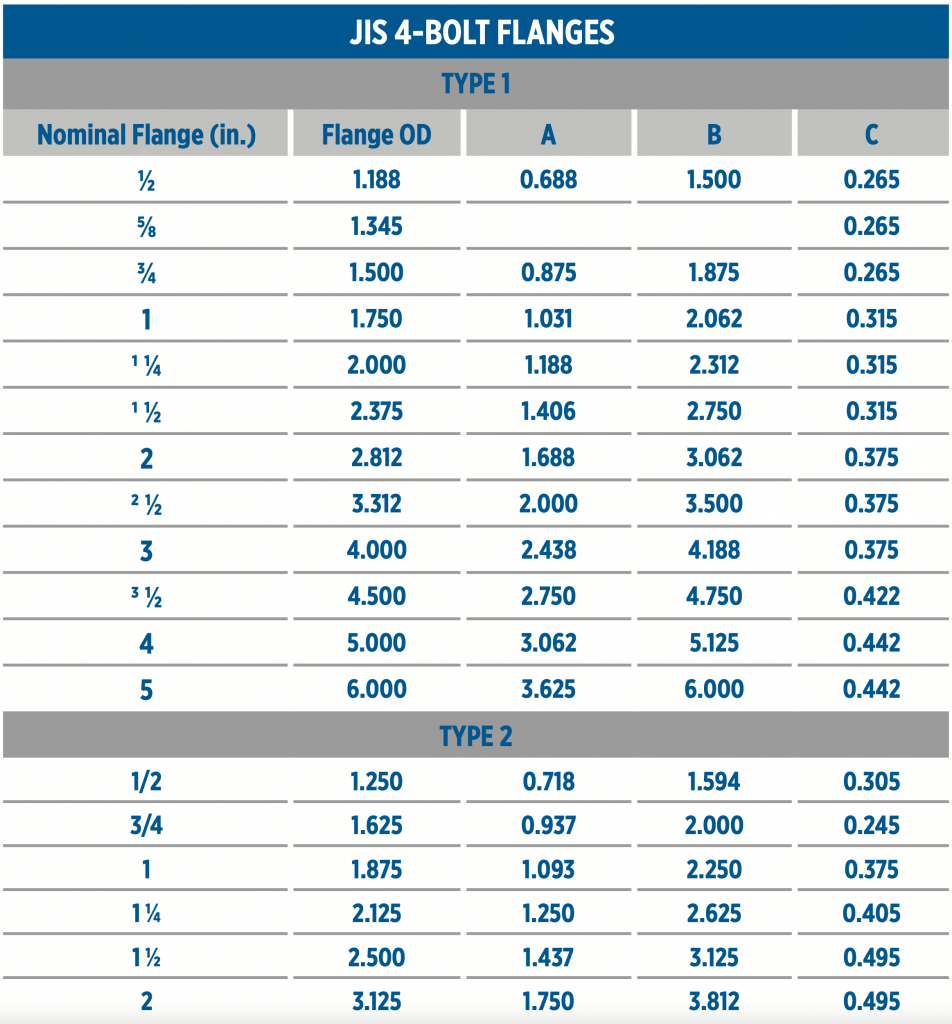

Distinguishing the Different Types of International Flanges

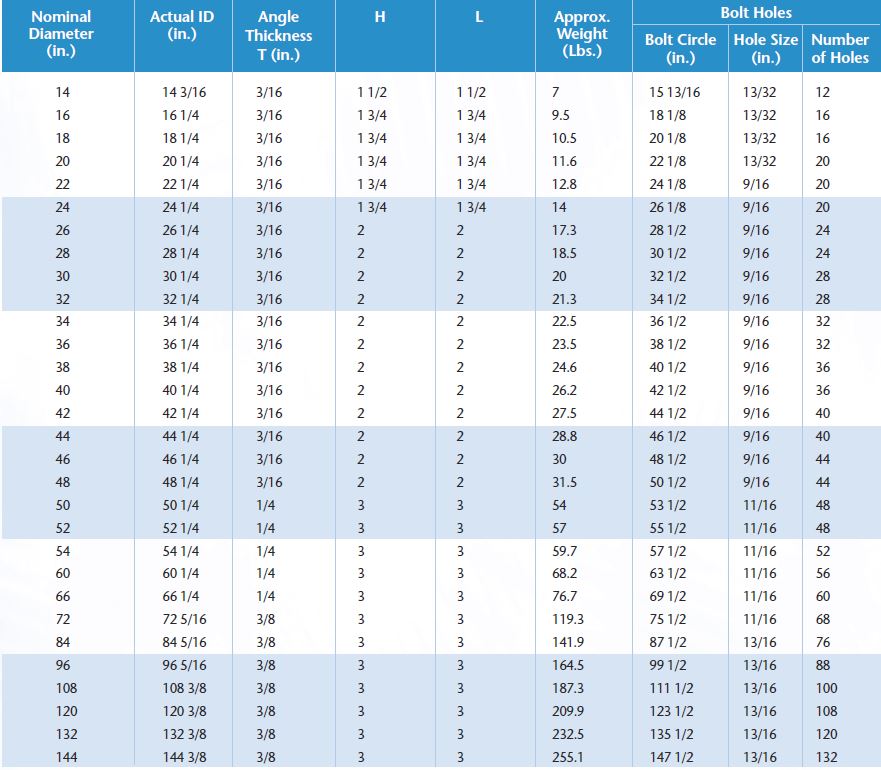

Flange Size Guide Printable

ANSI Flange Rating Chart

ASME B16.5 Class 400 Flanges Dimensions In MM And Thickness

Flange Rating Selection Chart A Visual Reference of Charts Chart Master

Use of ASME B16.5 Standards for Flange Pressure Ratings

These Ratings Are Established Based On The Prime Factor Of Hydro Testing Of The Flanged Fittings To The Bursting And By Adding A Factor Of Safety Of 3.0 At The Rated Working Pressure And Ambient Temperature.

Related Post: