Flange Bolting Pattern

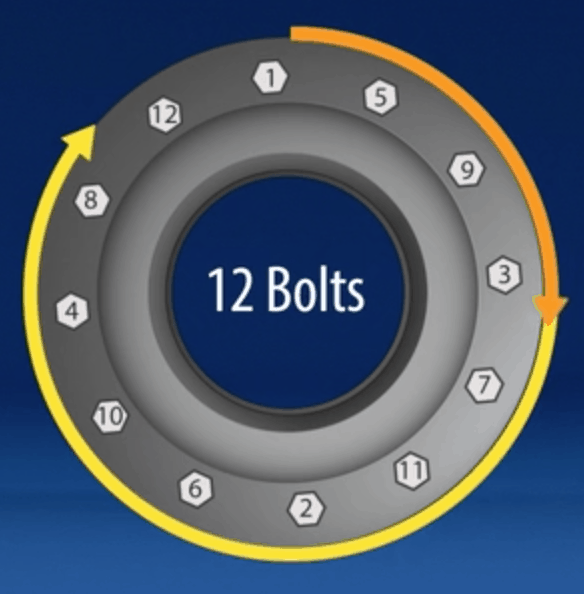

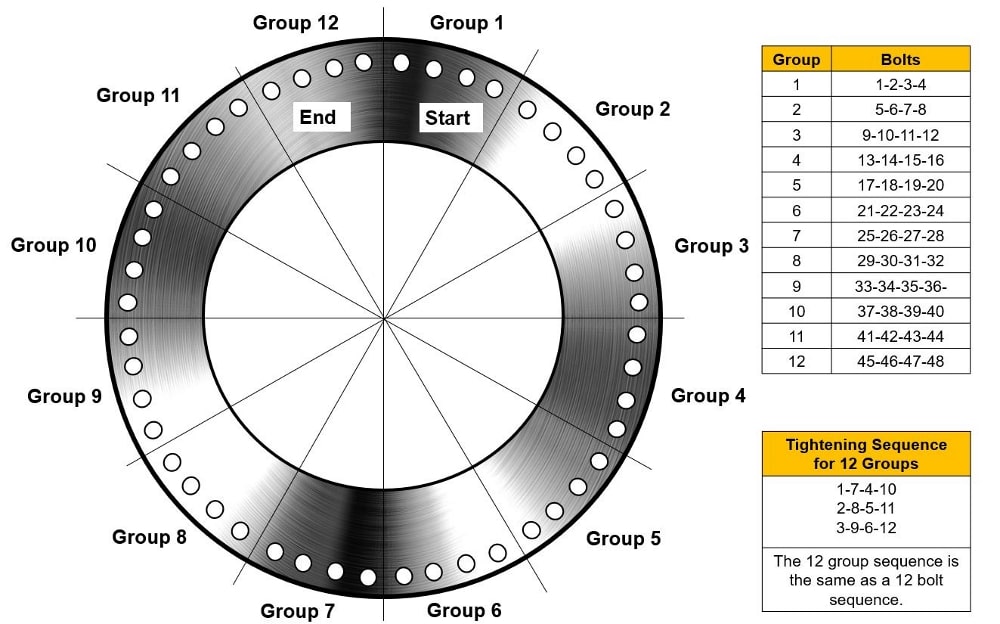

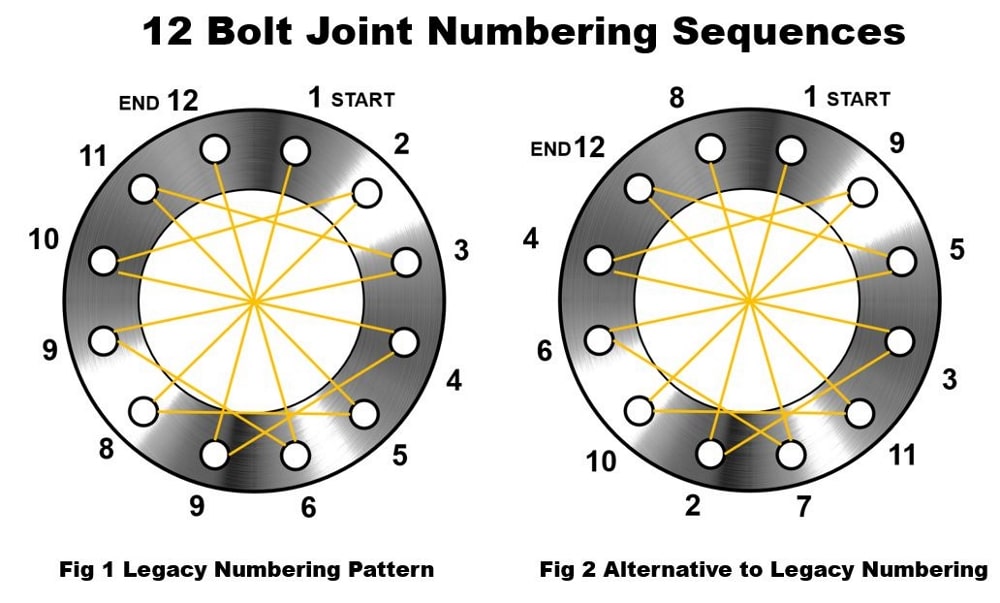

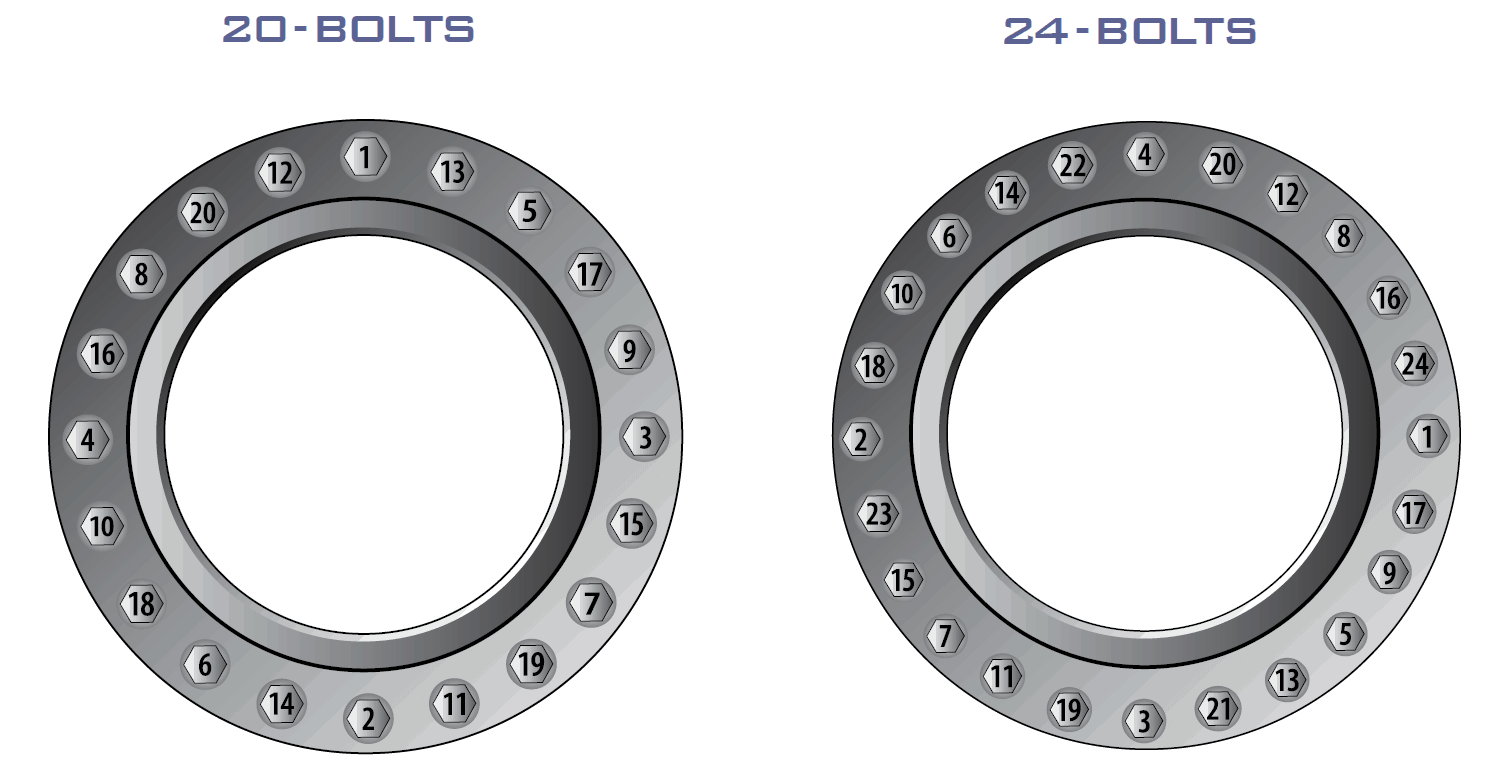

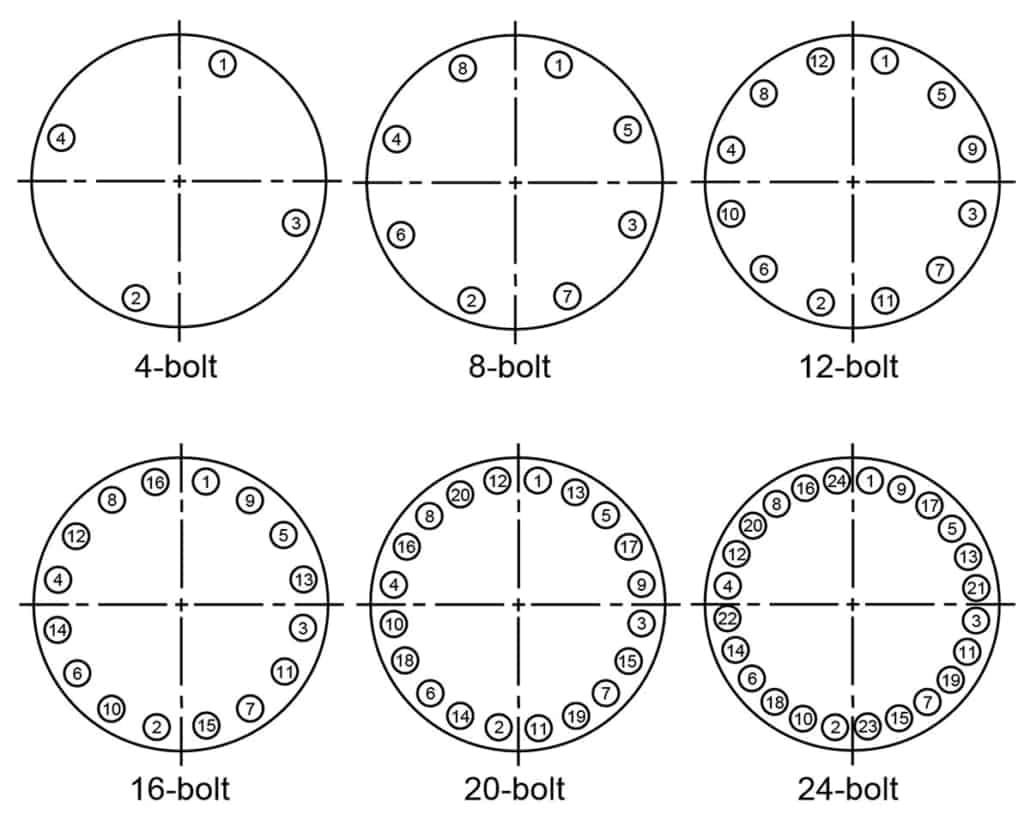

Flange Bolting Pattern - Uip supplies gaskets of all types & sizes for many industrial applications. When ordering, allow for the total length required for all components. When ordering, allow for the total length required for all components. The asme b16.5 stud lengths are specified from thread to thread. Web while the star pattern is the most common, it is certainly not the only — or necessarily the best — bolting pattern to apply when torquing a bolted flange assembly. Web the following chart shows the quantity and size of bolts or studs require for a particular flange size and class. The asme b16.5 stud lengths are specified from thread to thread. Web when ordering, allow for the total length required for all components. Web look up flange bolt sizes and torque patterns in three taps with flange bolt. Rack your orders and shipments.have reports sent right to your inbox: Web conventional way to achieve that load is by applying a measured torque to the flange bolts. Web this document provides specifications for class 150 flanges according to asme b16.5, including bolt circle diameters, bolt hole diameters, number of bolts, bolt diameters, and lengths of machine bolts and stud bolts for nominal pipe sizes from 1/2 to 24 inches. Web. Web when ordering, allow for the total length required for all components. Ase historyaccounts receivableyou can set up custom alerts to. When ordering, allow for the total length required for all components. 90 60 4 x 14. Set up your email address to receive your invoices. We measure our studs from end to. Web this document provides specifications for class 150 flanges according to asme b16.5, including bolt circle diameters, bolt hole diameters, number of bolts, bolt diameters, and lengths of machine bolts and stud bolts for nominal pipe sizes from 1/2 to 24 inches. Class 900 number of bolts. Web flange reference chart 2019.xlsx. This. We measure our studs from end to end, which includes the chamfered points. When ordering, allow for the total length required for all components. 90 60 4 x 14. In no event will south coast industrial metals or any of its affiliates be liable for any damages arising from the use of the information included in this document or that. Web all dimensions listed are given in inches. This gives multiple options for tightening sequences which if followed correctly will help to ensure a leak free flange joint. Web conventional way to achieve that load is by applying a measured torque to the flange bolts. 90 60 4 x 14. When ordering, allow for the total length required for all. Ase historyaccounts receivableyou can set up custom alerts to. The asme b16.5 stud lengths are specified from thread to thread. Web flange reference chart 2019.xlsx. Web asme b16.5 pipe flanges shall be bolted up by either machine bolts with nuts or stud bolts with nuts. Web while the star pattern is the most common, it is certainly not the only. Web 18914 east industrial parkway | new caney, tx 77357 | www.fastorq.com | main: Web when ordering, allow for the total length required for all components. Class 900 number of bolts. 90 60 4 x 14. Flange bolt torque sequence for proper gasket installation. Web flange reference chart 2019.xlsx. Web all dimensions listed are given in inches. Web this document provides specifications for class 150 flanges according to asme b16.5, including bolt circle diameters, bolt hole diameters, number of bolts, bolt diameters, and lengths of machine bolts and stud bolts for nominal pipe sizes from 1/2 to 24 inches. Web the following chart shows. When ordering, allow for the total length required for all components. We measure our studs from end to end, which includes the chamfered points. Web bolt tightening patterns. The stud bolt, either threaded at both ends or threaded full length, shall be furnished with two heavy hex nuts. Usage (down to the item level), buying trend. In this article, you will learn about the torque sequence of pipe flanges. Limitation of liability and disclaimer of warranty: Web asme b16.5 pipe flanges shall be bolted up by either machine bolts with nuts or stud bolts with nuts. Web the following chart shows the quantity and size of bolts or studs require for a particular flange size and. Web when ordering, allow for the total length required for all components. Web bolt tightening patterns. Flange bolt torque sequence for proper gasket installation. We measure our studs from end to. Web this document provides specifications for class 150 flanges according to asme b16.5, including bolt circle diameters, bolt hole diameters, number of bolts, bolt diameters, and lengths of machine bolts and stud bolts for nominal pipe sizes from 1/2 to 24 inches. 281.449.6466 | 1.800.231.1075 bolt specifications for standard ansi flanges We measure our studs from end to end, which includes the chamfered points. Web all dimensions listed are given in inches. Web class 150 steel pipe flanges bolting pattern and bolt and stud lengths. Web the following chart shows the quantity and size of bolts or studs require for a particular flange size and class. We measure our studs from end to end, which includes the chamfered points. Web a complete torque tightening sequence with charts for class 150 to 2500 flanges. Ase historyaccounts receivableyou can set up custom alerts to. Class 900 number of bolts. Web control the torque applied, the bolting pattern and the tightening sequence to avoid leaks. Rack your orders and shipments.have reports sent right to your inbox:

Bolt Tightening Sequence and Restrictions Hex Technology

Bolt Tightening Sequence Why it Matters Enerpac Blog

Asme b16.5 Class 300 Flanges Bolting Pattern and Dimensions Chart

Bolt Tightening Sequence Why it Matters Enerpac Blog

Flange Bolt Torque Sequence and Torque Table A Complete Bolt

FlangeBoltingPatterns2 Industrial Bolting and Torque Tools

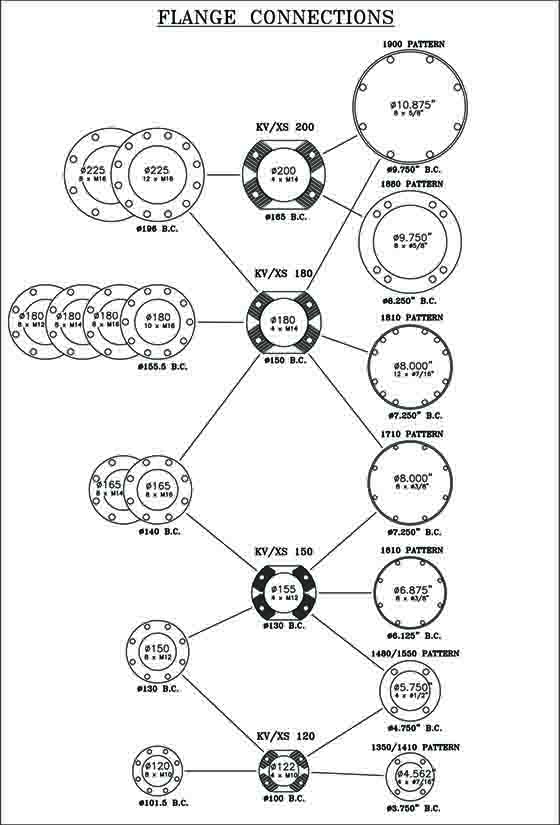

Companion Flange Bolt Patterns Machine Service, Inc.

FlangeBoltingPatterns Industrial Bolting and Torque Tools

Flange Bolt Torque Sequence UIP International Premium Industrial

Flange Nuts and Bolts Explained (Fasteners) saVRee

In This Article, You Will Learn About The Torque Sequence Of Pipe Flanges.

The Lengths Of The Machine Bolts Are Measured From Under The Head To The Top Of The Bolt.

When Ordering, Allow For The Total Length Required For All Components.

Web Welcome To This Interactive Flange Bolting Calculator From Hytorc.the Program Computes Recommended Torque Values , Bolting Patterns, Tool Selection And Pump Pressure Settings For Standard Asme B16.5 And Api 6A Flanges Under Normal Assembly Conditions.

Related Post: