End Mill Rpm Chart

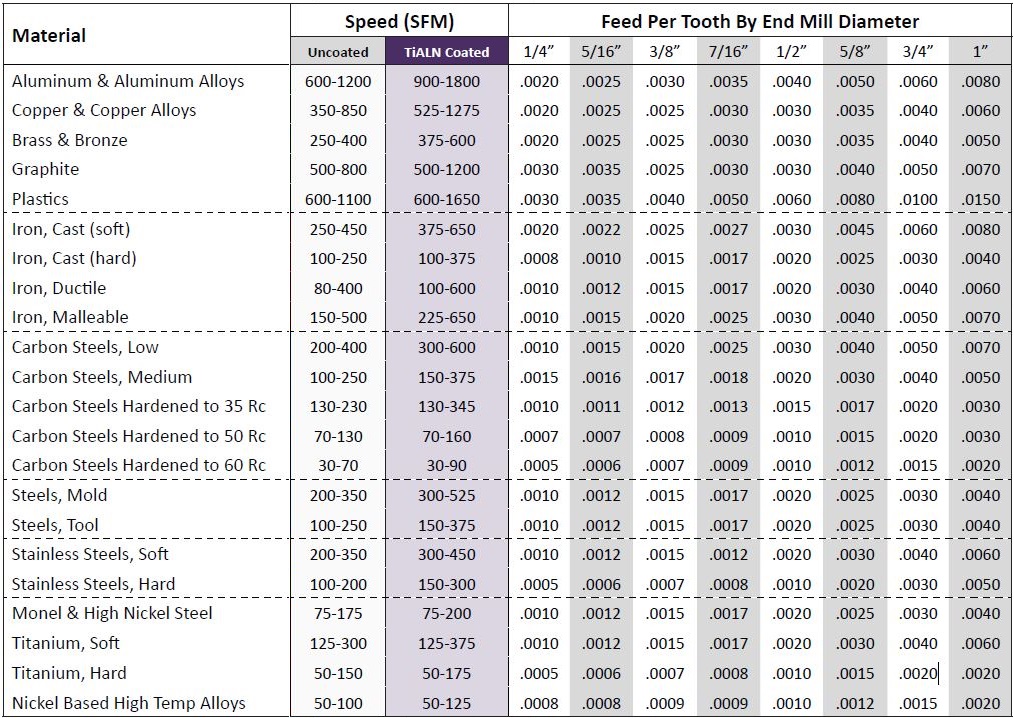

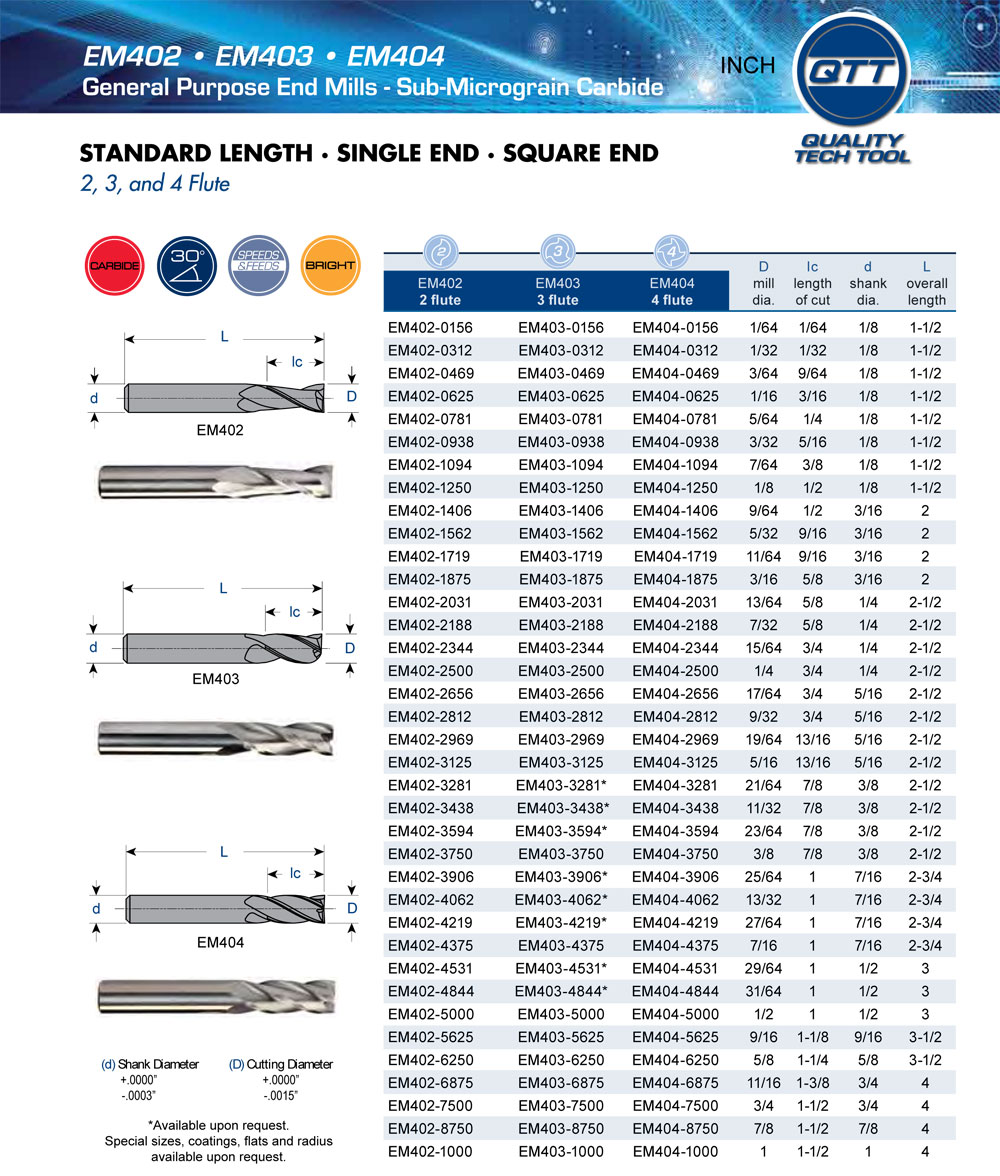

End Mill Rpm Chart - Zillow has 2 photos of this 4 beds, 3 baths, 2,569 square feet single family home with a list price of $343,990. Web speeds & feeds library. Web calculate the speeds and feeds of carbide end mills, diamond end mills, and plastic cutting carbide end mills with these general machining guidelines. It differs from other online calculators because it is an optimizing calculator. Web enter cutter diameter and surface speed to calculate the r.p.m. Web enjoy this simple to use feed and speed calculator for end milling processes. Web the most important aspect of milling with end mills is to run the tool at the proper rpm (revolutions per minute or spindle speed) and ipm (inches per minute or feed rate). Web the simple guidance given for cutting steel with hss was 100sfm at the largest diameter. Web milling speed and feed calculator. Web 214 happywell ln, caddo mills, tx 75135 is pending. Web speeds and feeds for carbide endmills. Web suggested speed & feed data for high speed steel end mills. Exclusively distributed by industrial supply co. Web 214 happywell ln, caddo mills, tx 75135 is pending. Web enjoy this simple to use feed and speed calculator for end milling processes. Web 1) select your material in the iso colored chart with respect to material description. Web the most important aspect of milling with end mills is to run the tool at the proper rpm (revolutions per minute or spindle speed) and ipm (inches per minute or feed rate). Web calculate rpm, ipm, sfm, ipt and more. Web the best online. Find sfm, ipm, rpm, and more here. All posted parameters are suggested starting values. Web the vertical lines on the left and right indicate the rated torque and horsepower; Web the simple guidance given for cutting steel with hss was 100sfm at the largest diameter. Let’s unpack what we see in the. Calculate the sfm, then use the rpm calculator, and feed rate calculator. Web the simple guidance given for cutting steel with hss was 100sfm at the largest diameter. A challenge of getting a good cnc cut is in selecting the best cutting speed (feed rate) and router/ spindle rpm (speed of rotation). Web suggested speed & feed data for high. A challenge of getting a good cnc cut is in selecting the best cutting speed (feed rate) and router/ spindle rpm (speed of rotation). Below are variable abbreviations and formulas for many common milling operations. Torque level is on the left while the hp levels are read on the right. Web suggested speed & feed data for high speed steel. Feed per tooth (ipt) ×. Web suggested speed & feed data for high speed steel end mills. Zillow has 2 photos of this 4 beds, 3 baths, 2,569 square feet single family home with a list price of $343,990. Feeds and speeds are a critical. Approximating pi allows the simple formula of 4 x cutting speed (sfm) /. Web this calculator will determine speeds and feed rates for machining operations on mill or lathes. Torque level is on the left while the hp levels are read on the right. Web suggested speed & feed data for high speed steel end mills. Click here to download a printable pdf file. Web 214 happywell ln, caddo mills, tx 75135 is. Web the vertical lines on the left and right indicate the rated torque and horsepower; Web 1) select your material in the iso colored chart with respect to material description. Web calculate rpm, ipm, sfm, ipt and more. Torque level is on the left while the hp levels are read on the right. Feeds and speeds are a critical. Web enjoy this simple to use feed and speed calculator for end milling processes. Web if this conditions exists, conventional milling should be used and feed per tooth should be reduced by 50%. Below are variable abbreviations and formulas for many common milling operations. Web speeds & feeds library. Web the simple guidance given for cutting steel with hss was. Cutting speeds are usually given in feet or meters per minute and these speeds. Web the vertical lines on the left and right indicate the rated torque and horsepower; Torque level is on the left while the hp levels are read on the right. For milling, turning, drilling, grooving, and parting off. Web 214 happywell ln, caddo mills, tx 75135. Click here to download a printable pdf file. A challenge of getting a good cnc cut is in selecting the best cutting speed (feed rate) and router/ spindle rpm (speed of rotation). Approximating pi allows the simple formula of 4 x cutting speed (sfm) /. Web enjoy this simple to use feed and speed calculator for end milling processes. All posted parameters are suggested starting values. Web if this conditions exists, conventional milling should be used and feed per tooth should be reduced by 50%. Web the most important aspect of milling with end mills is to run the tool at the proper rpm (revolutions per minute or spindle speed) and ipm (inches per minute or feed rate). Torque level is on the left while the hp levels are read on the right. Web calculate the speeds and feeds of carbide end mills, diamond end mills, and plastic cutting carbide end mills with these general machining guidelines. Let’s unpack what we see in the. Web speeds and feeds for carbide endmills. Web the vertical lines on the left and right indicate the rated torque and horsepower; Web the speeds and feeds calculator may be employed for calculations of estimated speeds and feeds (rpm and ipm) values on the basis of the parameters you have currently set. Feed per tooth (ipt) ×. Web determine the spindle speed for turning, milling, drilling, and reaming with these charts and cutting speed calculators. Web the simple guidance given for cutting steel with hss was 100sfm at the largest diameter.

End Mill Speed Chart

End Mill Rpm Chart

End Mill Speed Chart

End Mill Speed Chart

Carbide End Mill Speed And Feed Chart

End Mill Rpm Chart

End Mill Speed And Feed Chart

WI Machining Drill and Tap Charts

End Mill Speed Chart

End Mill Speed Chart

Web This Calculator Will Determine Speeds And Feed Rates For Machining Operations On Mill Or Lathes.

Web Calculate Rpm, Ipm, Sfm, Ipt And More.

Web Enter Cutter Diameter And Surface Speed To Calculate The R.p.m.

Web 1) Select Your Material In The Iso Colored Chart With Respect To Material Description.

Related Post: