Electrical Wire Harness Design

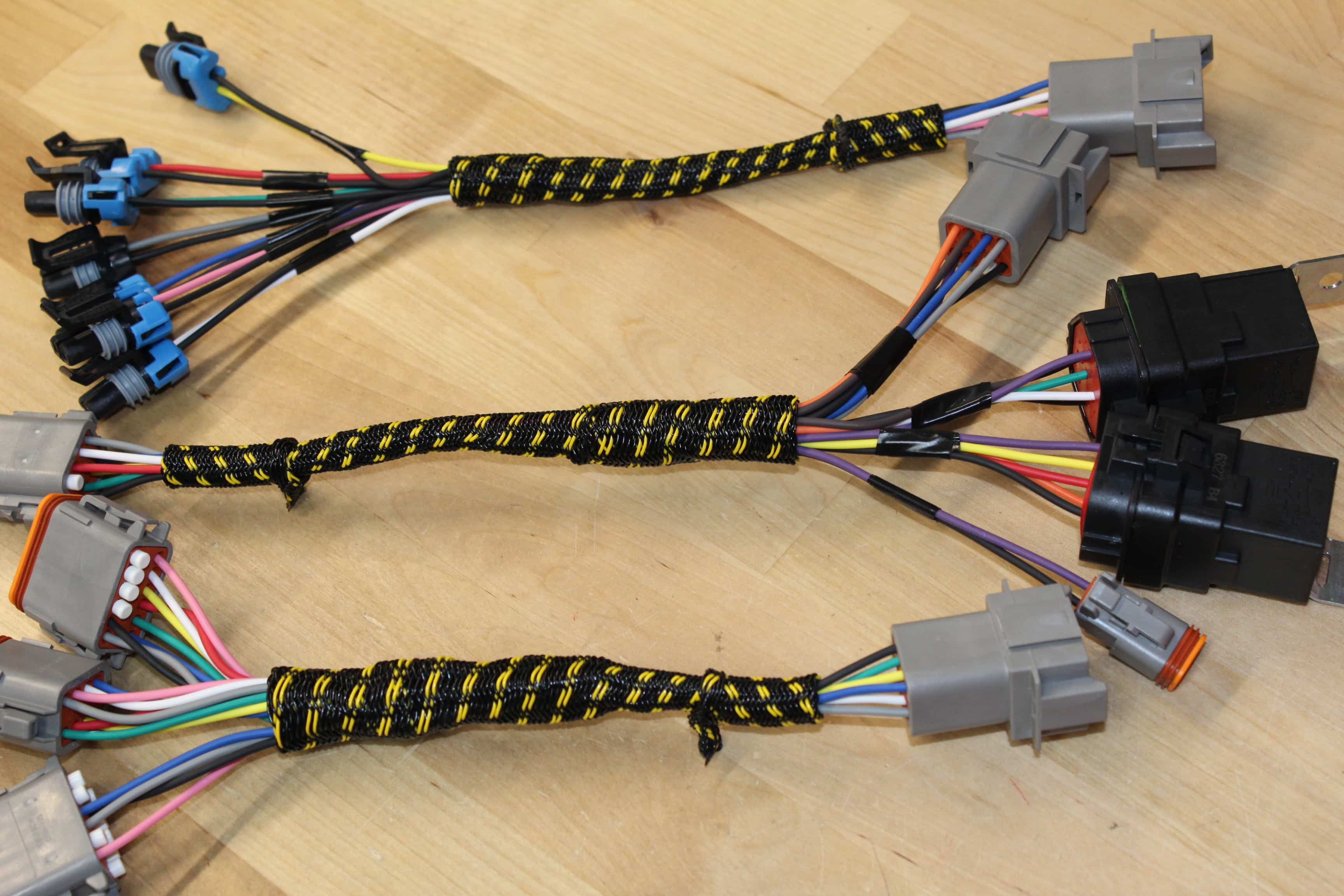

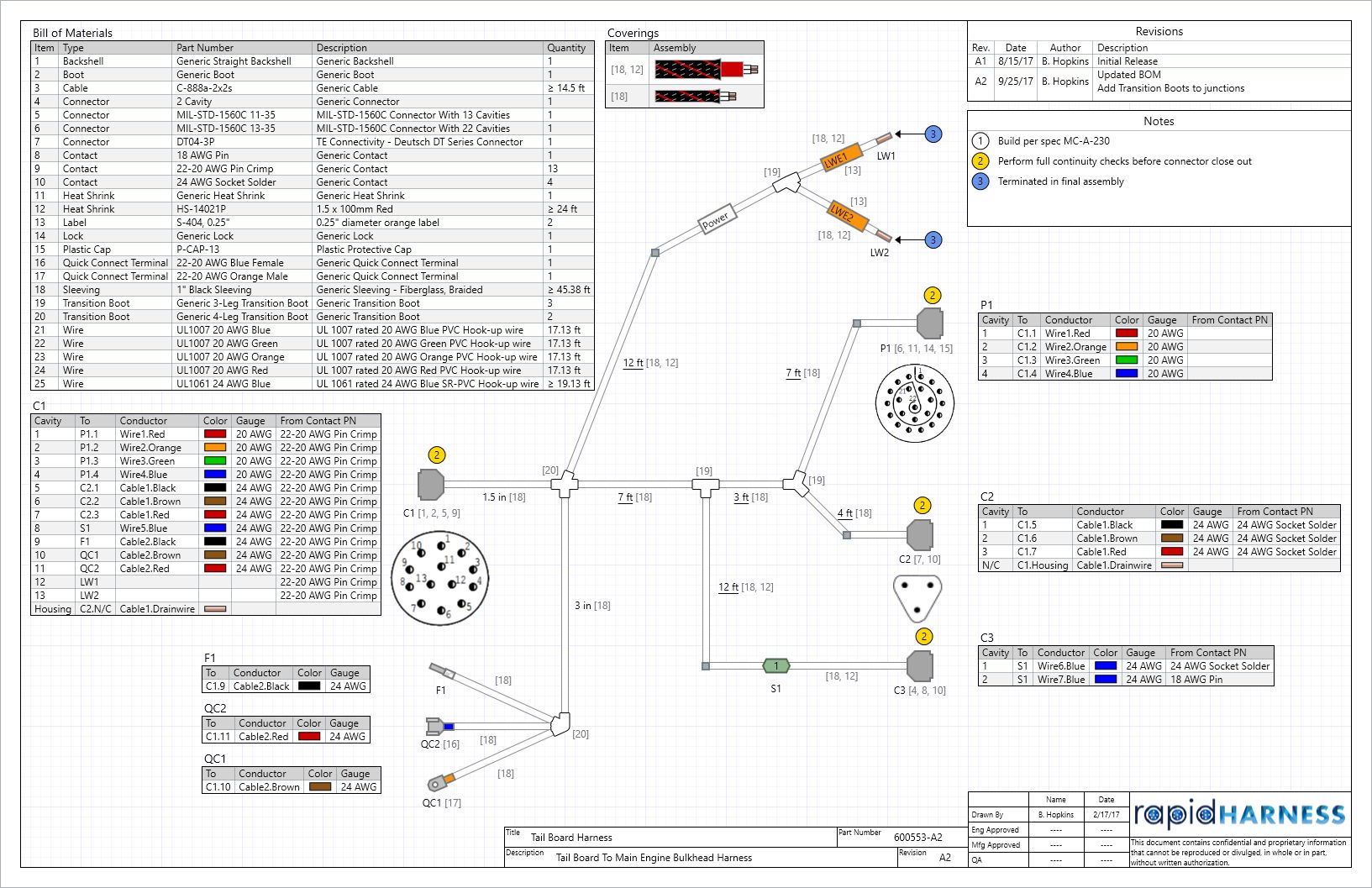

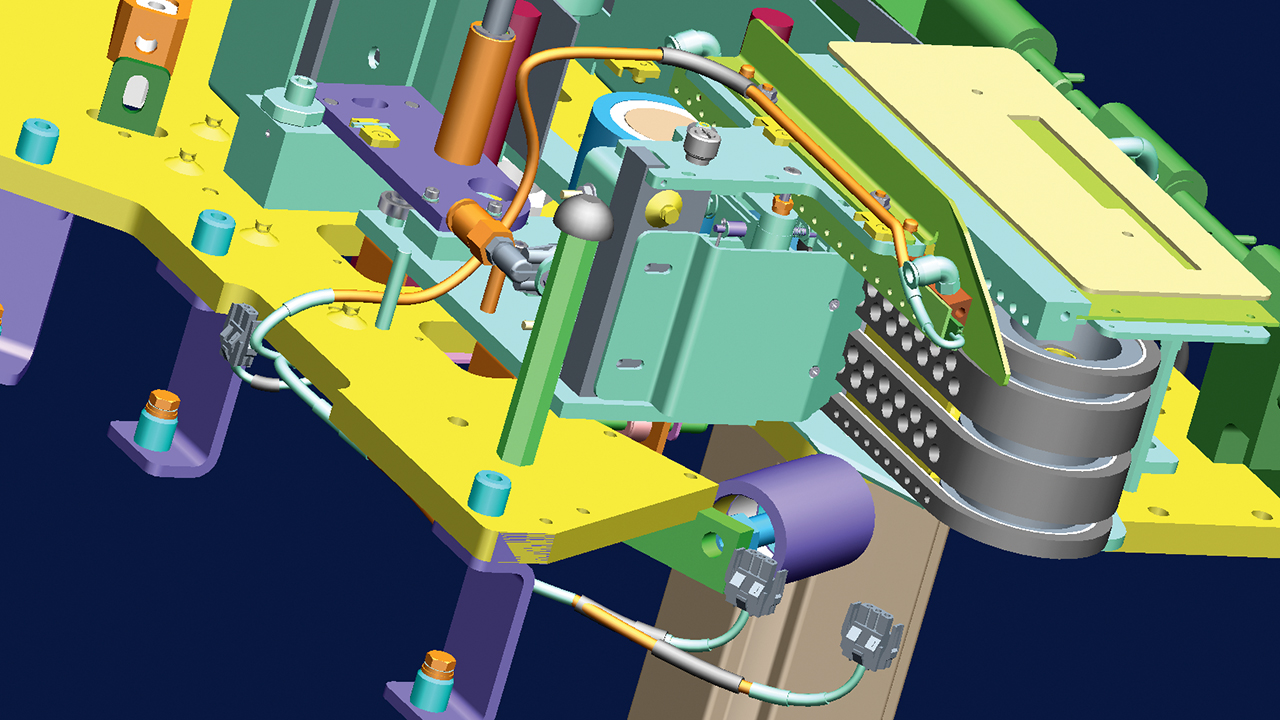

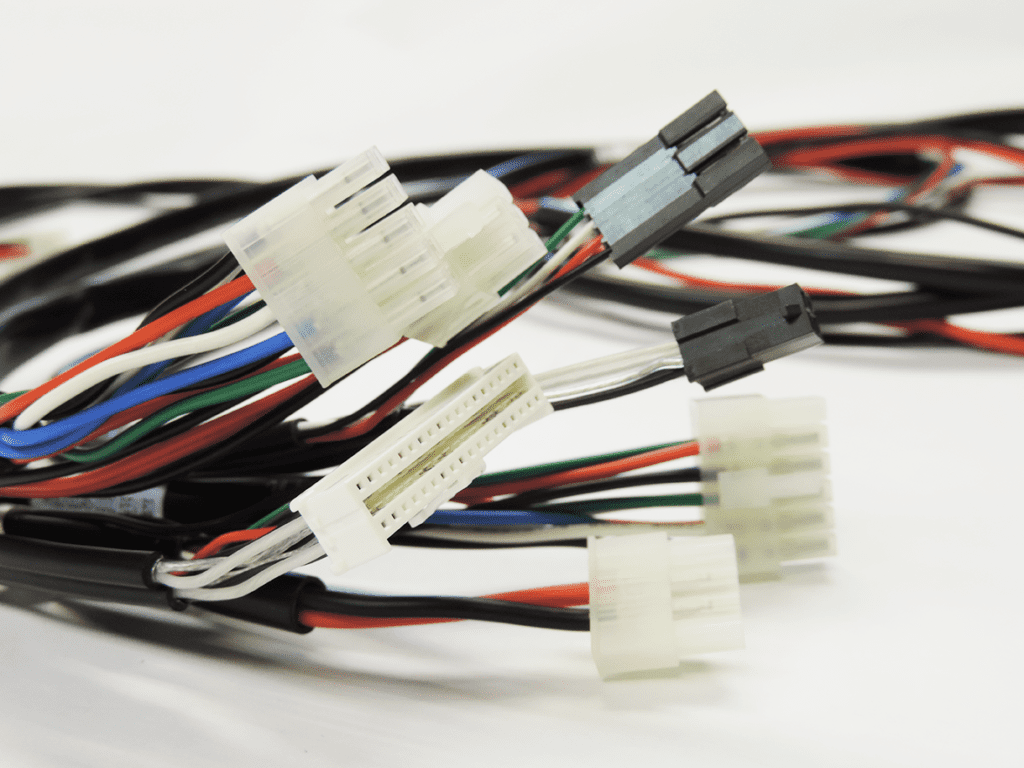

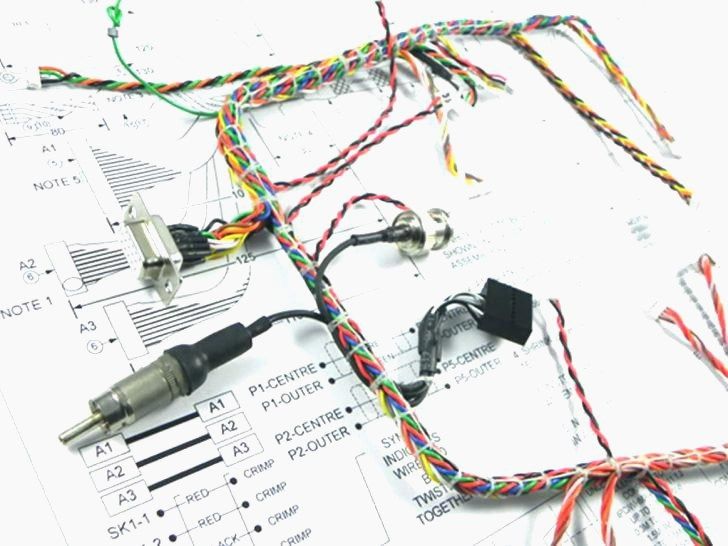

Electrical Wire Harness Design - You must first define the required connectors and connection points. This helps harness manufacturers improve harness. Web a wire harness assembly is the collection of various wires (single electrical conductors), cables (group of insulated wires), connectors, terminations, sleeves, and other infrastructure needed to provide a safe and efficient means for organizing wires within a. This way, the harness is laid out to the exact dimensions that are required. Web wiring harness design and engineering with capital software helps harness engineers cut costs, improve product quality and boost efficiency. Create comprehensive models that ensure realistic wiring harness costing and enable wiring harness product engineers to efficiently prepare product data. Reducing harness design cycle time and cost. Lastly, we’ll how automation is influencing wire. Improving product and process quality. Web first, understand what a wire harness is, then we’ll discuss the steps involved in designing a wire harness. Laying out the connectors, wires, and other elements in the required configuration. We’ll review components and materials, followed by a discussion of the options for purchasing wire harnesses. So there’s plenty more we can tell you about wire harnesses, but in the article, we’re going to give you a basic overview, the steps to guide you on design and construction.. Not having the proper training in college you ask yourself, “where do i start?”. Laying out the connectors, wires, and other elements in the required configuration. Optimizing formboard layout and design. So there’s plenty more we can tell you about wire harnesses, but in the article, we’re going to give you a basic overview, the steps to guide you on. Web arcadia wire harness design software helps electrical engineers create validated wiring diagrams, wire & cable harness layouts, formboards and manufacturing documentation quickly & accurately, like never before. Web wire harness design is a complex but fascinating field, blending electrical knowledge with practical design skills. We’ll review components and materials, followed by a discussion of the options for purchasing wire. Web arcadia wire harness design software helps electrical engineers create validated wiring diagrams, wire & cable harness layouts, formboards and manufacturing documentation quickly & accurately, like never before. Web a wire harness assembly is the collection of various wires (single electrical conductors), cables (group of insulated wires), connectors, terminations, sleeves, and other infrastructure needed to provide a safe and efficient. Whether you’re working on quick test articles or aerospace grade drawings, rapidharness will revolutionize the way you work. Defining an electrical harness requires two steps. This helps harness manufacturers improve harness. Web a wire harness assembly is the collection of various wires (single electrical conductors), cables (group of insulated wires), connectors, terminations, sleeves, and other infrastructure needed to provide a. Optimizing formboard layout and design. Web in this detailed guide, we will go through the basics of electrical wire harness design and discuss its multiple applications as well as complex designing procedures along with essential tools, major pitfalls & prospects. Web arcadia wire harness design software helps electrical engineers create validated wiring diagrams, wire & cable harness layouts, formboards and. Web first, understand what a wire harness is, then we’ll discuss the steps involved in designing them. Web as complexity rises, current harness manufacturing methods struggle to keep pace due to manual data exchanges and the inability to capture tribal knowledge. Selecting appropriate materials and components. You get hired at a large oem to design electrical wiring harnesses and wired. This helps harness manufacturers improve harness. Optimizing formboard layout and design. They are engineered assemblies of cables or wires that transmit electrical power and signals. Web design and assembly from the drawing board to finished wire harness requires step by step planning and a good amount of manual production. Web zuken’s powerful and versatile wire harness design platform caters to. You must first define the required connectors and connection points. We’ll review components and materials, followed by a discussion of the options for purchasing them. Whether you’re working on quick test articles or aerospace grade drawings, rapidharness will revolutionize the way you work. Web wire harnesses are laid out and built on a panel that has pegs positioned strategically where. Gathering specifications and requirements of the wire harness. So there’s plenty more we can tell you about wire harnesses, but in the article, we’re going to give you a basic overview, the steps to guide you on design and construction. Even though wire harnesses might seem simple, designing a wire harness does take consideration and is a major part of. Wire harness design is the process by which an engineer evaluates the requirements of an electrical part of system, given available physical space to create an assembly of wires to deliver power and information as needed. Web arcadia wire harness design software helps electrical engineers create validated wiring diagrams, wire & cable harness layouts, formboards and manufacturing documentation quickly & accurately, like never before. Optimizing formboard layout and design. Even though wire harnesses might seem simple, designing a wire harness does take consideration and is a major part of the overall manufacturing process. Defining an electrical harness requires two steps. Web it’s the wire harness that ensures the reliability of effective energy and information transmission in an application. Selecting appropriate materials and components. Web wiring harness design and engineering with capital software helps harness engineers cut costs, improve product quality and boost efficiency. We’ll review components and materials, followed by a discussion of the options for purchasing them. Once you have these connections, you are ready to begin defining the geometric bundle that links the various connection points. Web wire harness design is a complex but fascinating field, blending electrical knowledge with practical design skills. Create comprehensive models that ensure realistic wiring harness costing and enable wiring harness product engineers to efficiently prepare product data. Web design and assembly from the drawing board to finished wire harness requires step by step planning and a good amount of manual production. The capabilities of nx cad wire harness routing enable you to produce a wire harness. Web first, understand what a wire harness is, then we’ll discuss the steps involved in designing a wire harness. Creating a schematic diagram of the wire harness.

catia electrical harness design tutorials

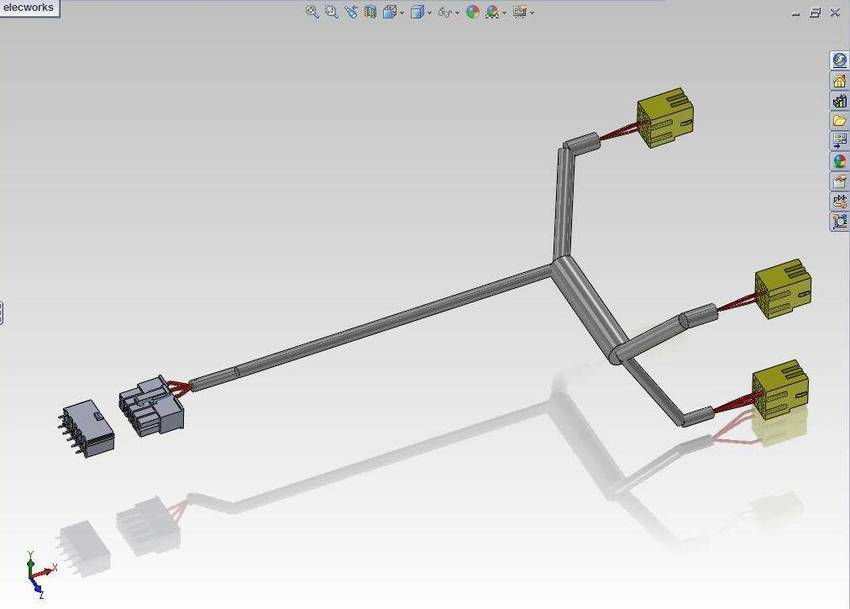

Elecworks Introduces Integrated Wire Harness Design within SolidWorks

Design your Harness your way with SOLIDWORKS Electrical Schematic

Wire Harness

RapidHarness A CAD solution built for designing productionready wire

3D Electrical Wiring & Harness Design Siemens Software

what is wire harness design Wiring Diagram and Schematics

Cable & Wire Harnesses Consolidated Electronic Wire & Cable

PRAXIEN KNOWLEDGE AND SKILLS UNLIMITED

Wiring Harness Design Basics Pdf

Whether You’re Working On Quick Test Articles Or Aerospace Grade Drawings, Rapidharness Will Revolutionize The Way You Work.

Laying Out The Connectors, Wires, And Other Elements In The Required Configuration.

Lastly, We’ll How Automation Is Influencing Wire Harness Manufacturing.

Web Wire Harnesses Are Laid Out And Built On A Panel That Has Pegs Positioned Strategically Where The Wires Will Branch Out Into Different Directions, Or Connectors Need To Be Added.

Related Post: