Electric Motor Greasing Chart

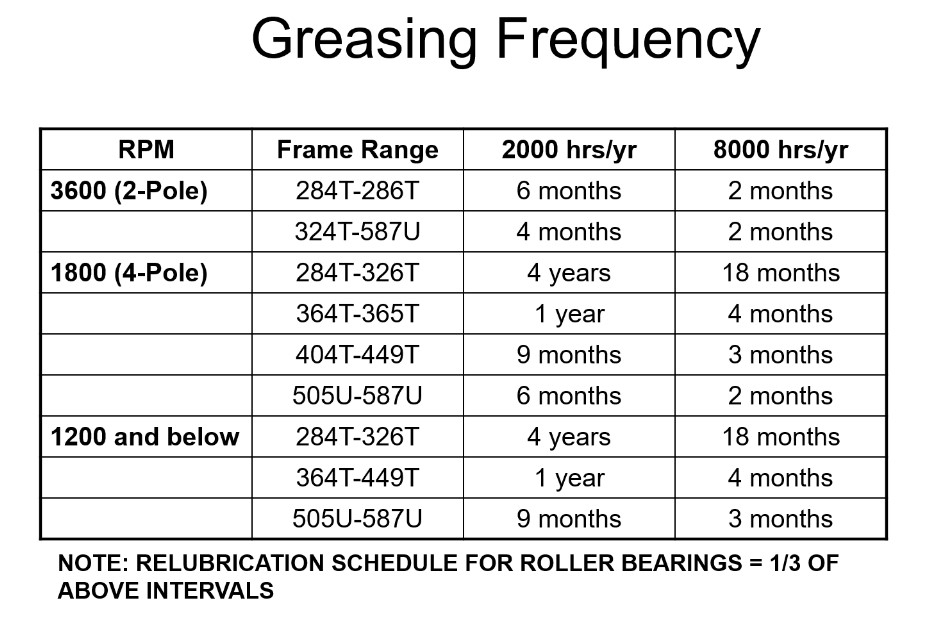

Electric Motor Greasing Chart - Keep your electric motors and your operation running smoothly by following best practices in grease lubrication. Bearing size, hours of operation, rpm, bearing type, etc. Web electric motor bearing lubrication guide. Reduce friction and prevent wear. Web electric motor lubrication guide. Web this bulletin, for thermal fluids hub customers, is intended to serve as a practical guide to the proper lubrication of electric motor bearings utilizing grease as a lubricant. The general procedure for greasing is as follows: Wipe grease from the pressure fitting, clean dirt, debris and paint around the grease relief plug. It is also good practice to let your motor repair center know the type of grease in case the standard grease used by Web this article is focusing on some factors to consider when greasing ball bearing motors. General guidelines for typical greases. This recording is intended for mechanical technicians, field service technicians, shop supervisors and engineering staff. It is also good practice to let your motor repair center know the type of grease in case the standard grease used by Web it is recommended that the type of grease used on each motor is recorded in order. How to get the most from your electric motors lubrication. Match the electric motor application information to the graph below for proper simalube sizing. The general procedure for greasing is as follows: Lock and tag out the electric motor. This article explains the typical lubrication requirement for for motors found on hvac equipment in buildings such as air conditioners, furnace. Wipe grease from the pressure fitting, clean dirt, debris and paint around the grease relief plug. Web the primary functions of an electric motor bearing grease are to: Bearing size, hours of operation, rpm, bearing type, etc. Lock and tag out the electric motor. Operating conditions within evs can be severe compared to standard combustion powertrains, and the risk of. Web it is recommended that the type of grease used on each motor is recorded in order to avoid premature bearing failure. This recording is intended for mechanical technicians, field service technicians, shop supervisors and engineering staff. Web electric motor lubrication schedule: It is also good practice to let your motor repair center know the type of grease in case. Reduce friction and prevent wear. Match the electric motor application information to the graph below for proper simalube sizing. General guidelines for typical greases. Web determining the correct amount of grease for an electric motor bearing is one of the most important steps in initial greasing and in regreasing of the bearings. Act as a seal to prevent entry of. General guidelines for typical greases. Web electric motor lubrication schedule: Reduce friction and prevent wear. Excess grease is eventually forced out of the bearing housings and begins dripping on the motor windings, resulting in early winding failure. Match the electric motor application information to the graph below for proper simalube sizing. Web lubeselect for skf greases provides you a user friendly tool to select the right grease and suggest frequency and quantity, while taking into account the particular conditions of your application. Match the electric motor application information to the graph below for proper simalube sizing. Wipe grease from the pressure fitting, clean dirt, debris and paint around the grease relief. Web determining the correct amount of grease for an electric motor bearing is one of the most important steps in initial greasing and in regreasing of the bearings. Operating conditions within evs can be severe compared to standard combustion powertrains, and the risk of electrical arcing across mechanical surfaces. Web the primary functions of an electric motor bearing grease are. Web this bulletin, for thermal fluids hub customers, is intended to serve as a practical guide to the proper lubrication of electric motor bearings utilizing grease as a lubricant. General guidelines for typical greases. The general procedure for greasing is as follows: Web lubeselect for skf greases provides you a user friendly tool to select the right grease and suggest. Keep your electric motors and your operation running smoothly by following best practices in grease lubrication. How to get the most from your electric motors lubrication. Web determining the correct amount of grease for an electric motor bearing is one of the most important steps in initial greasing and in regreasing of the bearings. In many cases, you may be. Wipe grease from the pressure fitting, clean dirt, debris and paint around the grease relief plug. In many cases, you may be able to standardize the type of grease used in a majority of your motors. Web this article is focusing on some factors to consider when greasing ball bearing motors. It is also good practice to let your motor repair center know the type of grease in case the standard grease used by Web the primary functions of an electric motor bearing grease are to: This recording is intended for mechanical technicians, field service technicians, shop supervisors and engineering staff. Web it is recommended that the type of grease used on each motor is recorded in order to avoid premature bearing failure. The general procedure for greasing is as follows: Web determining the correct amount of grease for an electric motor bearing is one of the most important steps in initial greasing and in regreasing of the bearings. Web as public attention is increasingly drawn toward more sustainable transportation methods, the popularity of electric vehicles (evs) as part of the solution is rapidly expanding. Web in electric motors, several factors determine how often a bearing should be greased: Bearing size, hours of operation, rpm, bearing type, etc. Web lubeselect for skf greases provides you a user friendly tool to select the right grease and suggest frequency and quantity, while taking into account the particular conditions of your application. This article explains the typical lubrication requirement for for motors found on hvac equipment in buildings such as air conditioners, furnace or air handler blower fans, oil burner motors, well pumps, and condensate return pumps. Too much lubricant is a major cause of premature motor failure. Operating conditions within evs can be severe compared to standard combustion powertrains, and the risk of electrical arcing across mechanical surfaces.

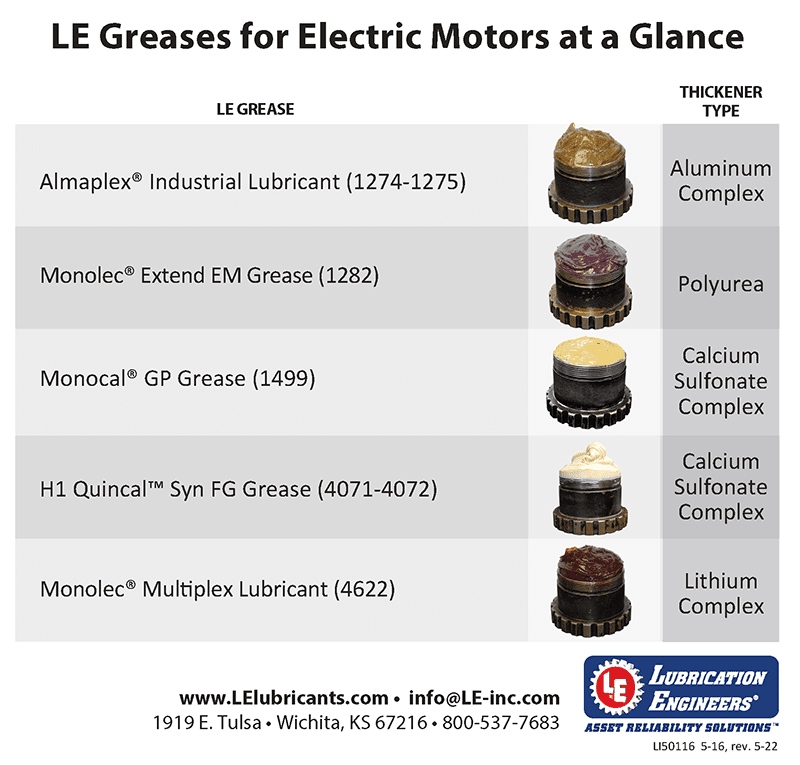

Electric Motor Lubrication Lubrication Engineers

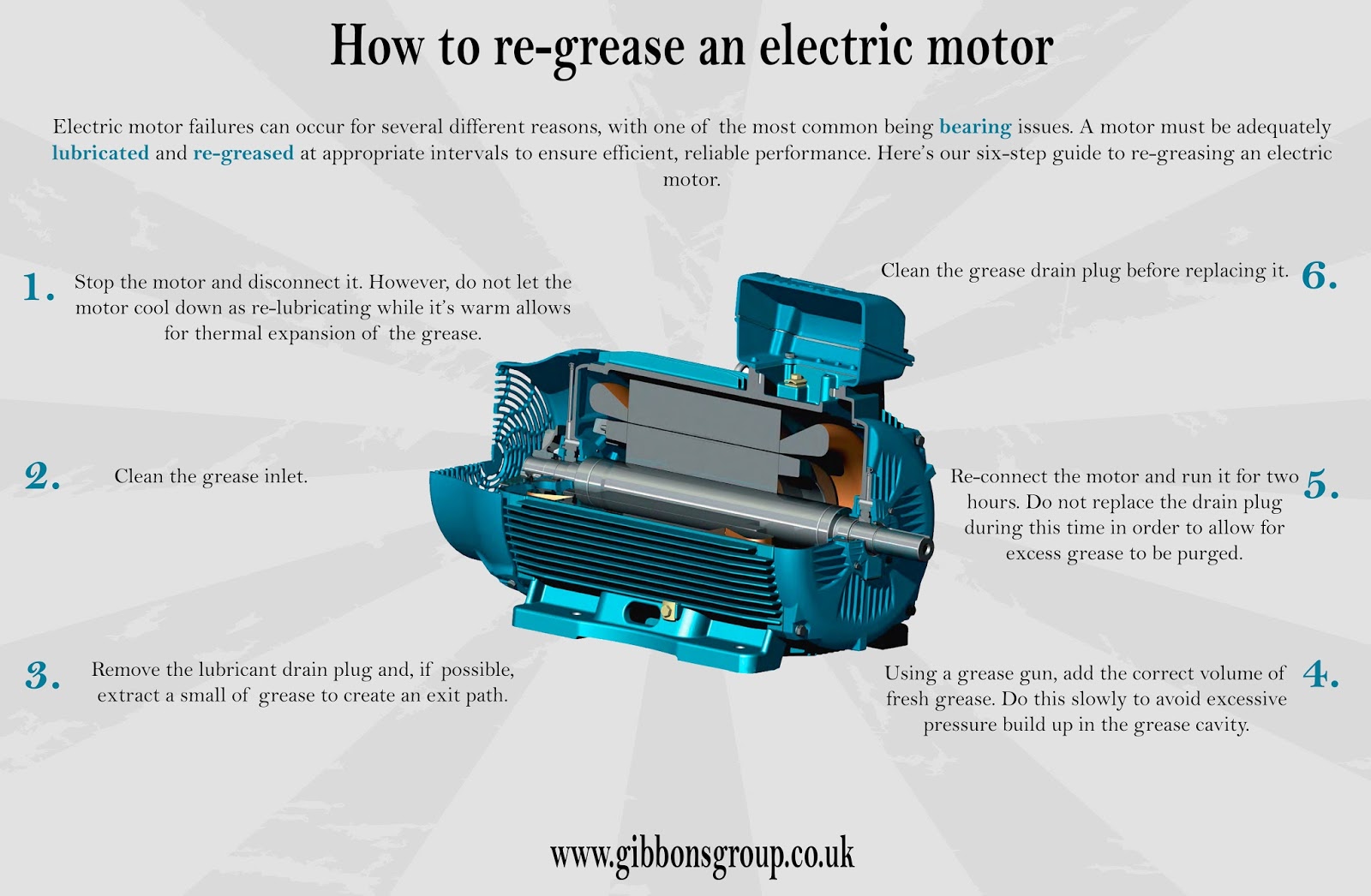

How to regrease an electric motor The Gibbons Group

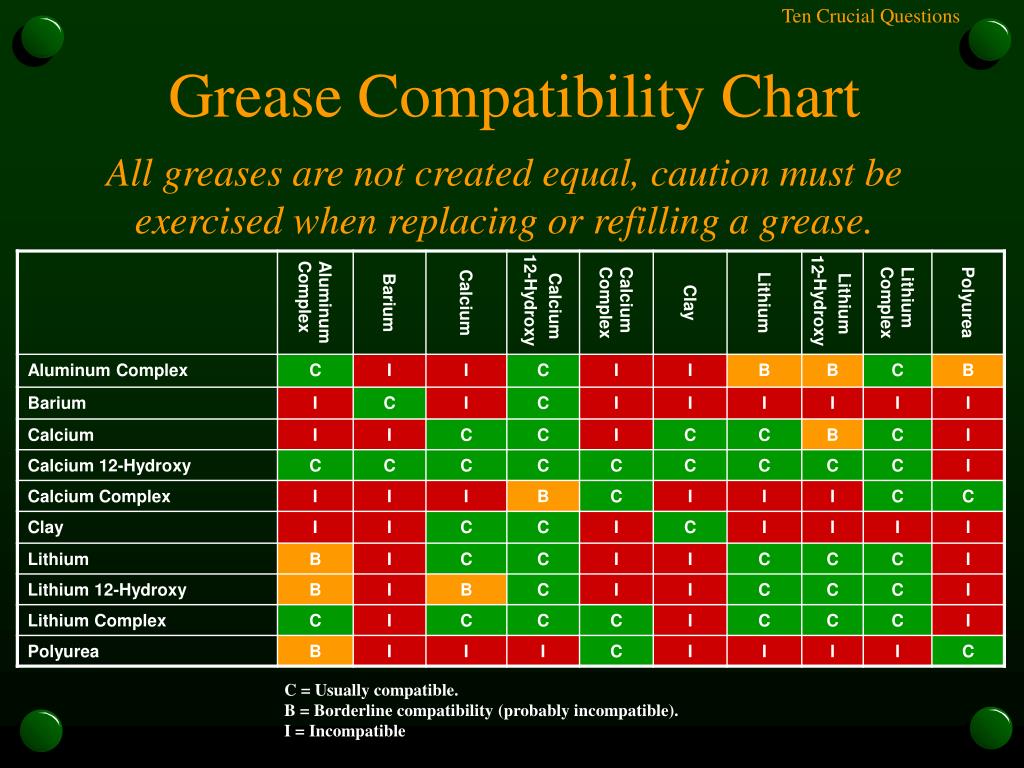

Electric Motor Grease Compatibility Chart

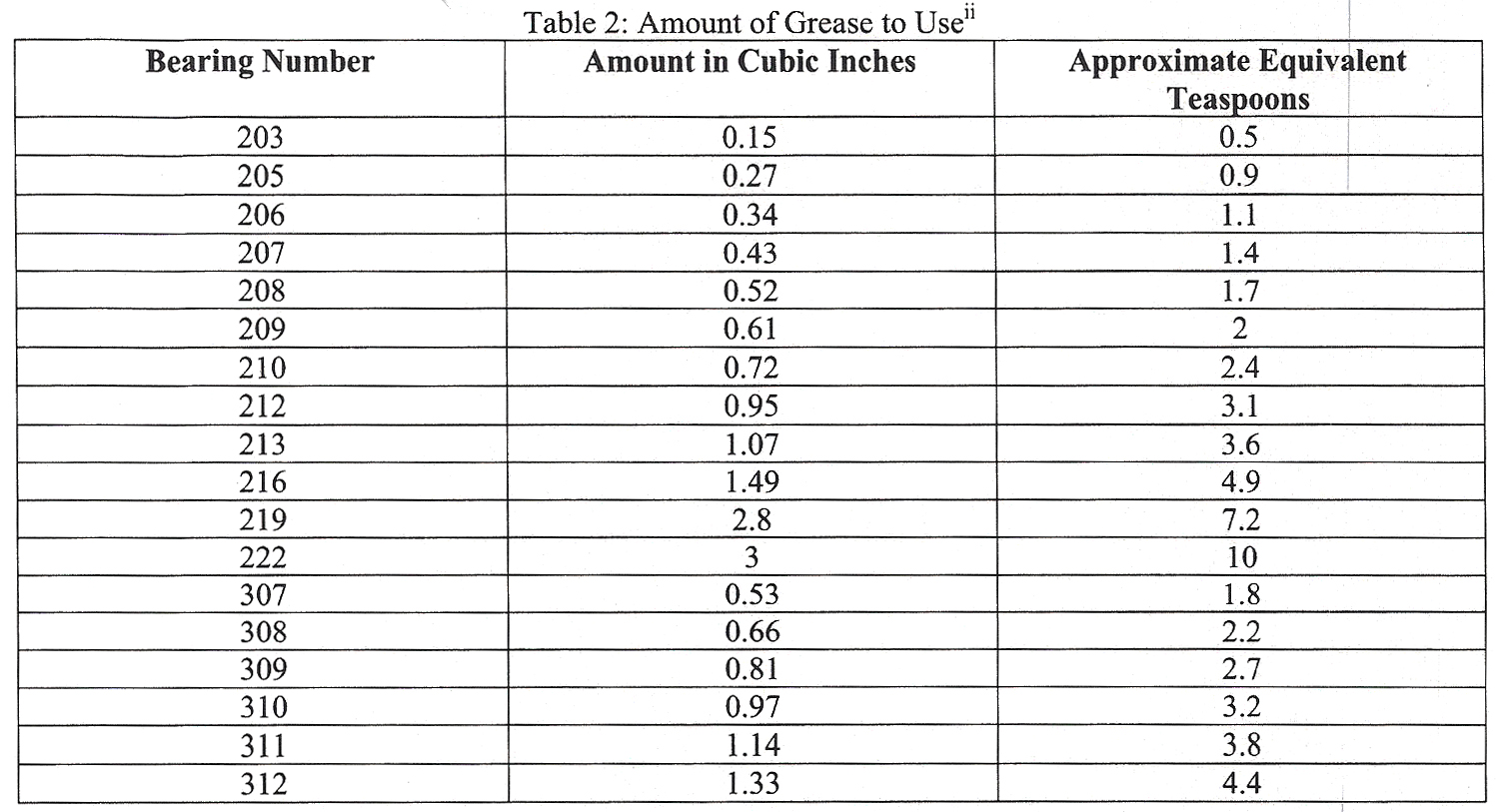

Electric Motor Bearing Lubrication

Electric Motor Greasing Chart

Proper Greasing Of Electric Motors

UNO GREASE MAX How to Design an Electric Motor Regreasing Program

Electric Motor Greasing Chart

Electric Motor Greasing Chart

Greasing Electric Motor Ball Bearings HECO

Match The Electric Motor Application Information To The Graph Below For Proper Simalube Sizing.

There Is A Variety Of Useful Information In This Article, But Please Be Sure To Check With The Manufacturer Of The Motor On Their Recommended Greasing Frequency, Amount Of Grease, And Type Of Lubricant To Use.

Web Electric Motor Bearing Lubrication Guide.

General Guidelines For Typical Greases.

Related Post: