Dust Collector Design

Dust Collector Design - Powerful, compact and low noise It is advisable to place machines requiring the largest cubic feet per minute (cfm) of airflow closest to. The first consideration is the limitation of workshop space (ceiling height, obstructions, electrical service, etc.). Web this project helps to understand as a design guide which provides information that will help to achieve optimum performance and energy efficiency in commercial dust collection systems by. The blower system, the ducting, the dust collector unit, the cleaning system, and the discharge mechanism. Web a dust collector should suck most of the dust and wood chips away from machines such as tablesaws, thickness planers, bandsaws, and drum sanders and then store that waste to be disposed of later. Web dust collectors capture, convey, and collect dust for various manufacturing and industrial processes. Adaptable to your existing ductwork. Layout the machinery of your shop. Web need to design a dust collection system? Web sdc engineering has the capability and experience to assist in the design of your system and ducting. The blower system, the ducting, the dust collector unit, the cleaning system, and the discharge mechanism. Web dust collection systems consist of five basic components: Web to design your own system, you'll have to consider many factors, such as what machines you'll. Web need to design a dust collection system? All of our engineers are well versed on the acgih ® industrial ventilation: A manual of recommended practice for design and have designed many successfully balanced ducting systems. Web to design your own system, you'll have to consider many factors, such as what machines you'll connect, where to place them, what size. Web a dust collector should suck most of the dust and wood chips away from machines such as tablesaws, thickness planers, bandsaws, and drum sanders and then store that waste to be disposed of later. The dusty airstream is forced to flow in a tangential path. A manual of recommended practice for design and have designed many successfully balanced ducting. Web discover the essential dust collection system design considerations to meet your facility's needs & compliance standards. This article will focus on the best practices of effective hood design. Our product line includes fittings and pipes that range from 3 to 24 in diameter, accommodating various sizes and capacities. Web a dust collector should suck most of the dust and. Web dust collectors are designed and constructed to filter airborne dust and debris that can cause injury or illness to employees, damage or degrade equipment, and negatively impact plant production. Web a dust collector should suck most of the dust and wood chips away from machines such as tablesaws, thickness planers, bandsaws, and drum sanders and then store that waste. Layout the machinery of your shop. Web your dust collection system design should begin with mapping out and identifying the areas and processes within the facility generating dust and centering your system around it. It is advisable to place machines requiring the largest cubic feet per minute (cfm) of airflow closest to. Web from shop design through installation, oneida air. Web need to design a dust collection system? Our product line includes fittings and pipes that range from 3 to 24 in diameter, accommodating various sizes and capacities. Consider these pointers to keep your shop and your lungs in great shape. Layout the machinery of your shop. The blower system, the ducting, the dust collector unit, the cleaning system, and. By dominick dalsanto sales director & baghouse expert baghouse.com phone: Placement is the first design consideration of any dust collection system. Web your dust collection system design should begin with mapping out and identifying the areas and processes within the facility generating dust and centering your system around it. Typical operations within a dust collection unit proceed as follows: Easy. The blower system, the ducting, the dust collector unit, the cleaning system, and the discharge mechanism. Consider these pointers to keep your shop and your lungs in great shape. All of our engineers are well versed on the acgih ® industrial ventilation: Web discover the essential dust collection system design considerations to meet your facility's needs & compliance standards. It. Consider these pointers to keep your shop and your lungs in great shape. This article will focus on the best practices of effective hood design. When it comes to industrial dust collection, it’s important to take a “system design” engineering approach versus the more common “component selection” method. By dominick dalsanto sales director & baghouse expert baghouse.com phone: Web to. Web two main components are critical to dust collection system performance: Web your dust collection system design should begin with mapping out and identifying the areas and processes within the facility generating dust and centering your system around it. Web dust collectors are designed and constructed to filter airborne dust and debris that can cause injury or illness to employees, damage or degrade equipment, and negatively impact plant production. All of our engineers are well versed on the acgih ® industrial ventilation: We cater to a diverse range of industries, including woodworking, aerospace, paper, pharmaceutical, chemical, plastics, and hvac. By dominick dalsanto sales director & baghouse expert baghouse.com phone: Our product line includes fittings and pipes that range from 3 to 24 in diameter, accommodating various sizes and capacities. Web from shop design through installation, oneida air systems is with you every step of the way. The first consideration is the limitation of workshop space (ceiling height, obstructions, electrical service, etc.). Web a dust collector should suck most of the dust and wood chips away from machines such as tablesaws, thickness planers, bandsaws, and drum sanders and then store that waste to be disposed of later. Web dust collection systems consist of five basic components: Easy & fast to install, just clamp together, no rivets, screws or welding needed. It is advisable to place machines requiring the largest cubic feet per minute (cfm) of airflow closest to. On a dust collection system, hoods are canopies or covers located at the end of ducting branches. Placement is the first design consideration of any dust collection system. Typical operations within a dust collection unit proceed as follows:

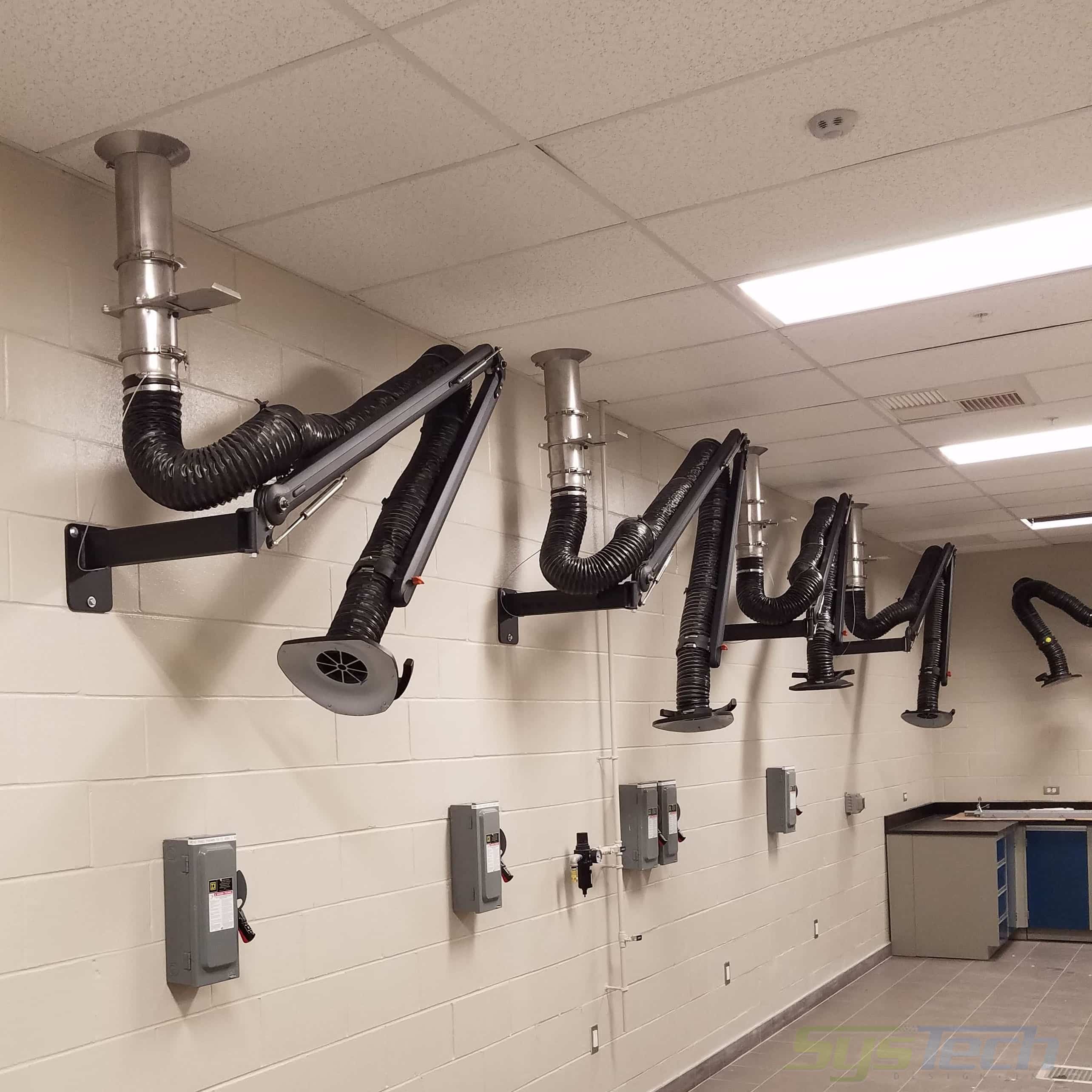

Industrial Dust Collection Dust Collectors Collection Systems

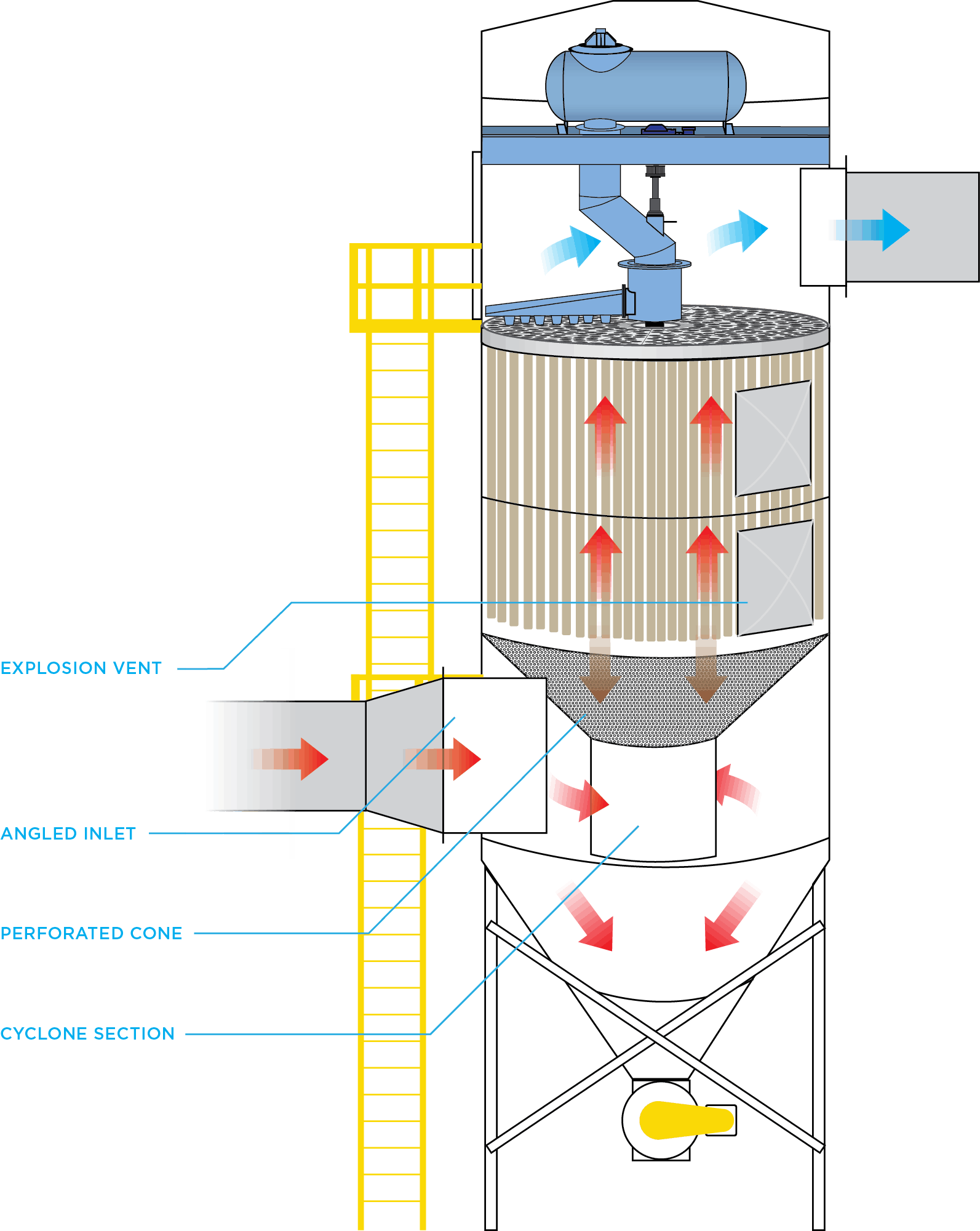

15. Typical design of a cyclone dust collector. Download Scientific

BRF Baghouse Dust Collector Imperial Systems, Inc.

Dust Collection Systems Combustible Dust Explosions SysTech Design

BRF Baghouse Dust Collector Imperial Systems, Inc.

Dust Collection Systems Combustible Dust Explosions SysTech Design

Dust Collection System Design and Equipment Shop dust collection

25 Ideas for Diy Cyclone Dust Collector Plans Home, Family, Style and

Cyclone Dust Collector Dust Collection Services LLC

Dust Collection Systems Combustible Dust Explosions SysTech Design

Layout The Machinery Of Your Shop.

Web How To Design A Dust Collection System.

Our Blog Offers Best Practices And Tips For Creating Effective And Efficient Industrial Dust Collection Systems.

Web Sdc Engineering Has The Capability And Experience To Assist In The Design Of Your System And Ducting.

Related Post: