Drill Bit Angle Chart

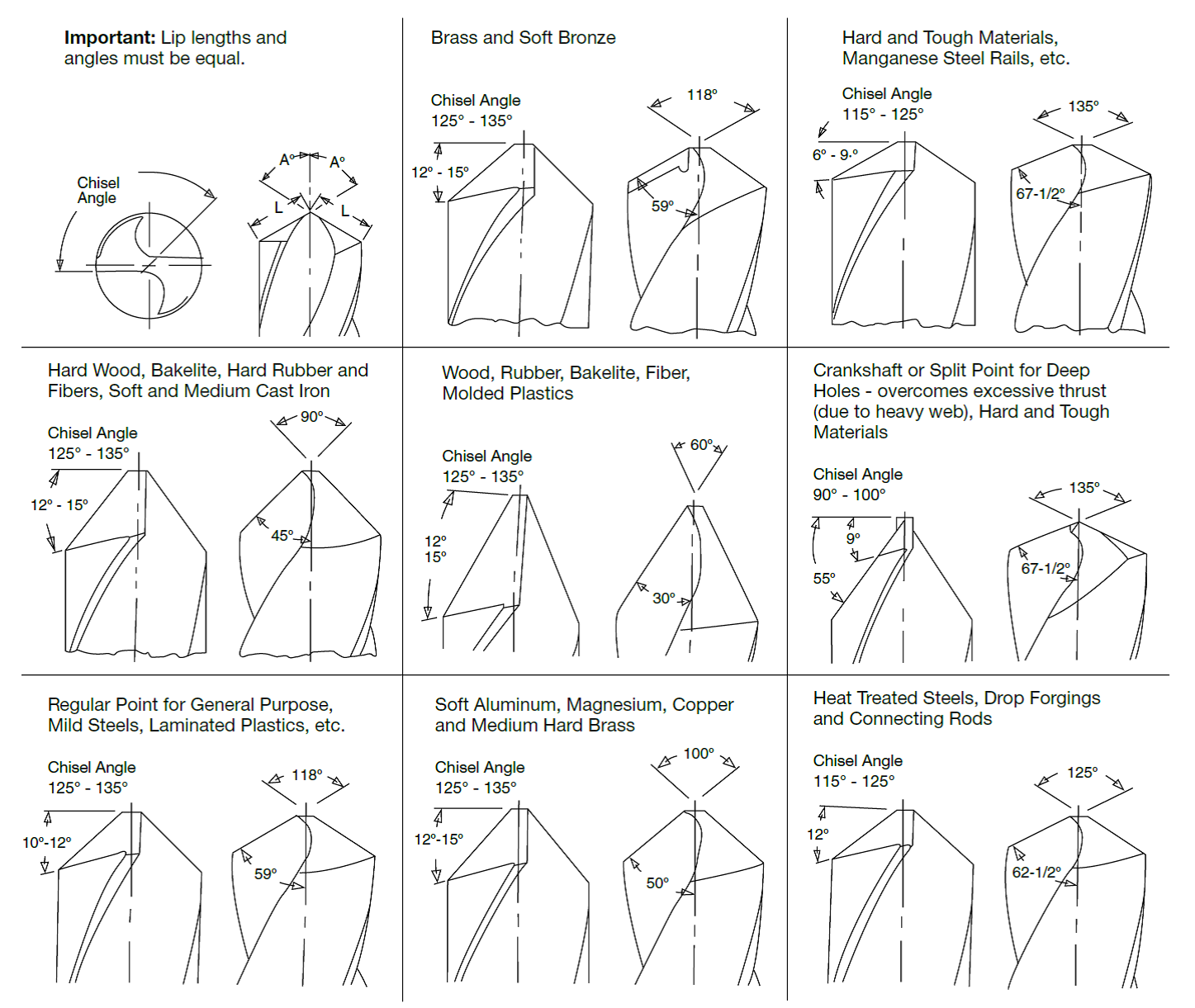

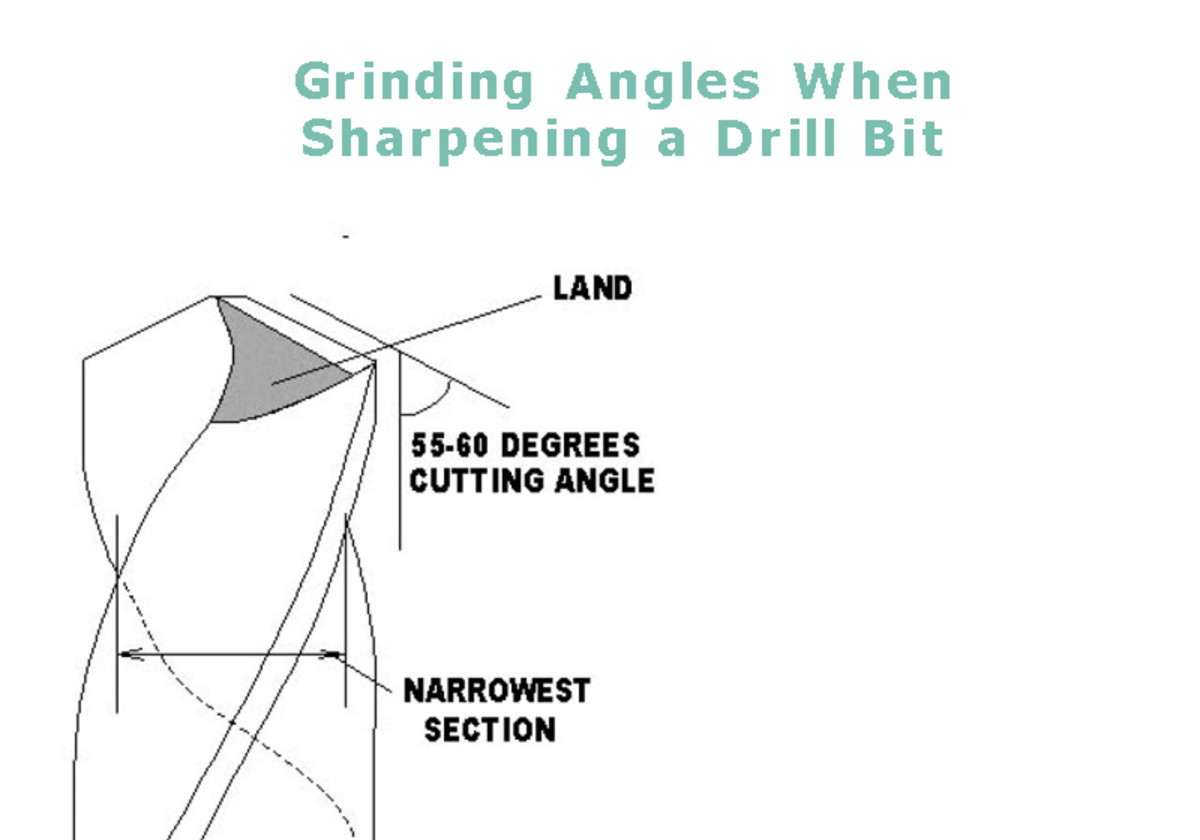

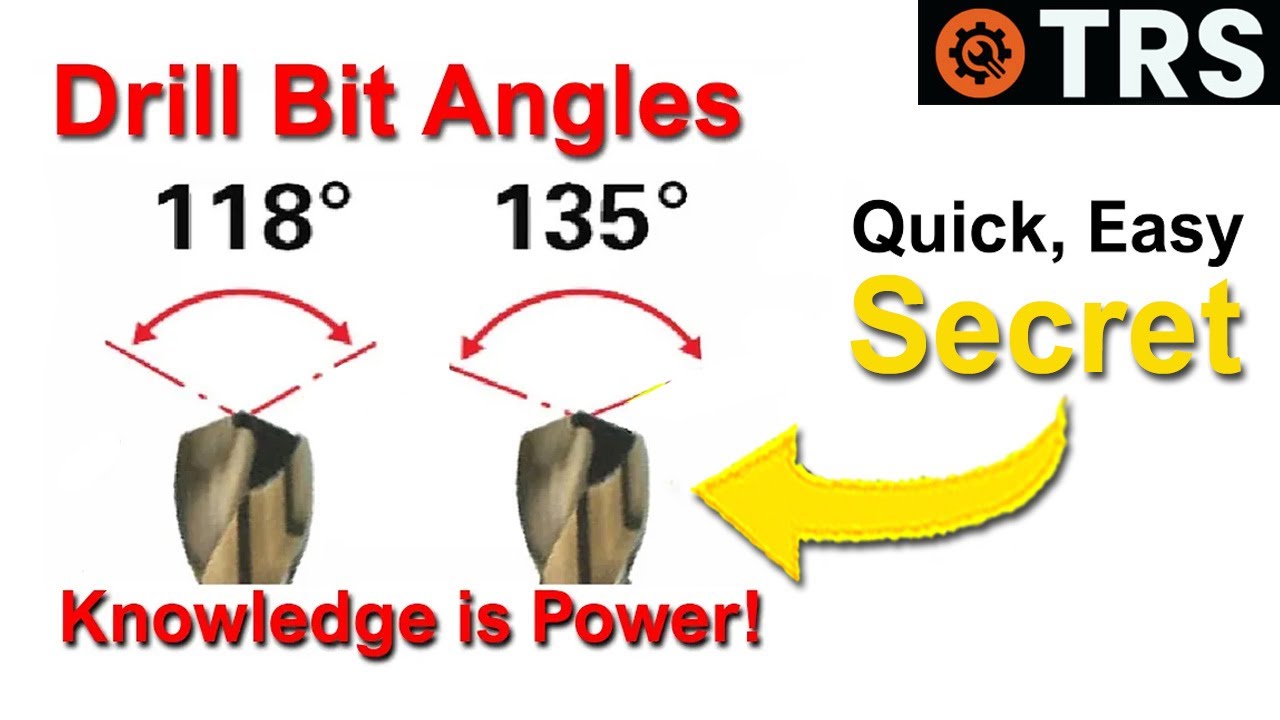

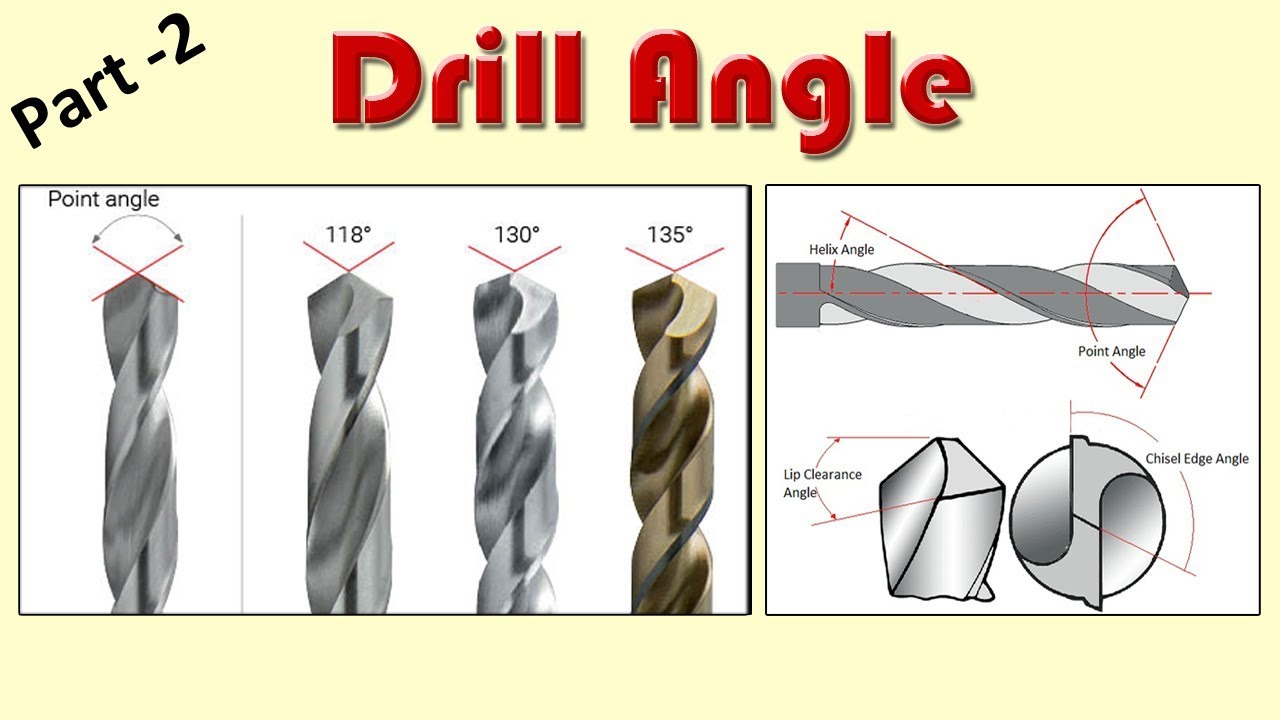

Drill Bit Angle Chart - The drill size chart contains the standard. The 5th and 6th facets form secondary drill point angles. Drill bit’s axis should intersect with the axis of the imaginary cone at an angle of approximately 45°. Web how the geometry of a drill influences tool life and hole tolerance. The difference between the two is the shape; These specialist drill bits are used for drilling centre. If you start to rotate the. Web the 6 faceted drill with secondary point angles (spa) is the most durable of points, but least understood and utilized. Web define any drill by its diameter (d) and the included tip angle (a). Web fractional sizes are measured in inches, while metric sizes are measured in millimeters. Web the 6 faceted drill with secondary point angles (spa) is the most durable of points, but least understood and utilized. However, when drilling deeper holes, it is recommended to. Enhance your woodworking, metalworking, construction,. The tip length (l) is given by a formula which can be written several ways. Drill bit’s axis should intersect with the axis of the. Web a drill bit size chart and tap size chart are often required to determine the proper drill bit for the accurate size of the hole. Web primary facet angles is determined by the nature of the material being drilled while secondary facet angles are at 20°. Enhance your woodworking, metalworking, construction,. Web the two most common drill bit point. Web drill bit size chart. Web the 6 faceted drill with secondary point angles (spa) is the most durable of points, but least understood and utilized. Web what are drill charts? These specialist drill bits are used for drilling centre. Web how the geometry of a drill influences tool life and hole tolerance. Web there are two main drill bit point angles: Web what are drill charts? Web in this case, the angle at the tip should be equal to 26°. The drill size chart contains twist drill data for up to 1.0 inches in diameter. Web a drill bit size chart and tap size chart are often required to determine the proper. The drill size chart contains the standard. Sharpening your drill bits to the correct angle can. The tip length (l) is given by a formula which can be written several ways. More simply, it is the angle between the lips in. The point angle, or cutting angle, is the angle between two lips when it is projected onto a plane. The 5th and 6th facets form secondary drill point angles. Web the drill bit sharpening angle chart provides recommended angles for sharpening different types of drill bits. Web in this case, the angle at the tip should be equal to 26°. Web a drill bit size chart and tap size chart are often required to determine the proper drill bit. Web in this case, the angle at the tip should be equal to 26°. Web discover the best angle for drill bits and master the optimal drilling angle for efficient and precise results. The tip length (l) is given by a formula which can be written several ways. Web primary facet angles is determined by the nature of the material. Web primary facet angles is determined by the nature of the material being drilled while secondary facet angles are at 20°. The point angle, or cutting angle, is the angle between two lips when it is projected onto a plane parallel to the axis. Web define any drill by its diameter (d) and the included tip angle (a). More simply,. Enhance your woodworking, metalworking, construction,. Web primary facet angles is determined by the nature of the material being drilled while secondary facet angles are at 20°. However, when drilling deeper holes, it is recommended to. The point angle, or cutting angle, is the angle between two lips when it is projected onto a plane parallel to the axis. Web discover. The drill size chart contains the standard. The 5th and 6th facets form secondary drill point angles. The 6 faceted drill with secondary point angles. The drill geometry is the number and position of the drill cutting edges, chip flutes and the angle used. A drill bit with a 118° angle cuts more aggressively and is best used for cutting. Drill bit’s axis should intersect with the axis of the imaginary cone at an angle of approximately 45°. Sharpening your drill bits to the correct angle can. Web define any drill by its diameter (d) and the included tip angle (a). If you start to rotate the. Web the typical value of the point angle is 118°. Web there are two main drill bit point angles: The 6 faceted drill with secondary point angles. The tip length (l) is given by a formula which can be written several ways. These specialist drill bits are used for drilling centre. Web what are drill charts? The drill bit size chart provides equivalent sizes for letter, metric, wire gauge, and fractional drill bit sizes, allowing the user to select the correct drill bit for their. Web the drill size chart below gives fractional sizes and their metric conversions up to 1 inch. Web for most drill bit types, the angle of the point helps determine what type of material the bit can drill. Web the drill bit sharpening angle chart provides recommended angles for sharpening different types of drill bits. Enhance your woodworking, metalworking, construction,. The point angle, or cutting angle, is the angle between two lips when it is projected onto a plane parallel to the axis.

Drill Bit Sharpening Angle Chart

Drill Bit Sharpening Angle Chart

Drill Bit Sharpening Angle Chart

Drill Bit Sharpening Angle Chart

Drill bit angles 'Easily Explained', angles for materials

Drill Point Angle Chart

Drill Bit Guide Best Types Chart Hand Tool Essentials

Standard Drill Bit Size Chart

Drill Bit Angle Guide

Drill Bit Angles Easily Explained Angles For Materials My

A Drill Bit With A 118° Angle Cuts More Aggressively And Is Best Used For Cutting Into Soft Materials Such As Wood.

Web Drill Bit Size Chart.

Web In This Case, The Angle At The Tip Should Be Equal To 26°.

Web Primary Facet Angles Is Determined By The Nature Of The Material Being Drilled While Secondary Facet Angles Are At 20°.

Related Post: