Drawing Chamfer Callout

Drawing Chamfer Callout - In this article, you will learn the proper way to do a chamfer callout, as well as how to do the callout in popular software programs. Standards allow for a common language to be used between you and the optician so there is no confusion regarding the features desired in the final part. Is it to call out the note with a leader (.25 x 45°) or to add two seperate dimensions (one linear and one angle)? Web character height on a drawing. See figure 2 for chamfer dimensioning examples. Y14.5 clearly says a note 1 x 1 or 1 x 45° is allowed. If a symbol dimension is shown as 1.5h, and the predominant character height on the drawing is to be 3mm, then the symbol dimension is 4.5mm (1.5 x 3mm). Is this correct or do i have it backwards? Web what is the correct way to call out a 45 degree chamfer? Web chamfers, rounds, fillets, and “break edges” are edge features that you may commonly see on your part drawings. Chamfers can be dimensioned in two ways, either by calling out the length by angle, or calling out the length by length. Web character height on a drawing. They are used for a variety of reasons, which typically include: In this article, you will learn the proper way to do a chamfer callout, as well as how to do the. Y14.5 clearly says a note 1 x 1 or 1 x 45° is allowed. Web chamfers, rounds, fillets, and “break edges” are edge features that you may commonly see on your part drawings. If an angle other than 45 degrees is dimensioned, the surface to which the angle is measured must be made clear on the drawing. Web when using. Standards allow for a common language to be used between you and the optician so there is no confusion regarding the features desired in the final part. Y14.5 clearly says a note 1 x 1 or 1 x 45° is allowed. Web chamfers, rounds, fillets, and “break edges” are edge features that you may commonly see on your part drawings.. Is it to call out the note with a leader (.25 x 45°) or to add two seperate dimensions (one linear and one angle)? Part strength, burr removal, ease of assembly, and aesthetics. Optical drawings provide a precise definition of your optic for fabrication. Chamfers can also be specified by giving both legs of the chamfer such as: Web when. Is this correct or do i have it backwards? Chamfers can be dimensioned in two ways, either by calling out the length by angle, or calling out the length by length. Is it to call out the note with a leader (.25 x 45°) or to add two seperate dimensions (one linear and one angle)? See figure 2 for chamfer. Solidwork has a dimension style that is c1 for 45 degree chamfers. Web you can dimension chamfers in drawings. Some companies find it desirable to vary from the If a symbol dimension is shown as 1.5h, and the predominant character height on the drawing is to be 3mm, then the symbol dimension is 4.5mm (1.5 x 3mm). Web what is. Web when using a leader to call out a chamfer (ie. If a symbol dimension is shown as 1.5h, and the predominant character height on the drawing is to be 3mm, then the symbol dimension is 4.5mm (1.5 x 3mm). Is this correct or do i have it backwards? Some companies find it desirable to vary from the Solidwork has. Web chamfers, rounds, fillets, and “break edges” are edge features that you may commonly see on your part drawings. Web what is the standard for a callout of a chamfer feature? Web a chamfer is a slope at the edge of a part and a chamfer callout refers to how to dimension chamfers on drawings. Web dimensioning chamfers is done. Web chamfers, rounds, fillets, and “break edges” are edge features that you may commonly see on your part drawings. Part strength, burr removal, ease of assembly, and aesthetics. Some companies find it desirable to vary from the Chamfers can also be specified by giving both legs of the chamfer such as: Y14.5 clearly says a note 1 x 1 or. Is it to call out the note with a leader (.25 x 45°) or to add two seperate dimensions (one linear and one angle)? Part strength, burr removal, ease of assembly, and aesthetics. Web character height on a drawing. They are used for a variety of reasons, which typically include: In addition to the usual dimension display properties, chamfer dimensions. See figure 2 for chamfer dimensioning examples. Is it to call out the note with a leader (.25 x 45°) or to add two seperate dimensions (one linear and one angle)? If no angle is given the chamfer is assumed to be at 45 degrees. In this article, you will learn the proper way to do a chamfer callout, as well as how to do the callout in popular software programs. Solidwork has a dimension style that is c1 for 45 degree chamfers. Chamfers can also be specified by giving both legs of the chamfer such as: Web character height on a drawing. Web when using a leader to call out a chamfer (ie. Web what is the correct way to call out a 45 degree chamfer? Part strength, burr removal, ease of assembly, and aesthetics. Standards allow for a common language to be used between you and the optician so there is no confusion regarding the features desired in the final part. Web dimensioning chamfers is done with a call out that specifies the length of the chamfer along with the angle of the chamfer. Y14.5 clearly says a note 1 x 1 or 1 x 45° is allowed. Web you can dimension chamfers in drawings. If a symbol dimension is shown as 1.5h, and the predominant character height on the drawing is to be 3mm, then the symbol dimension is 4.5mm (1.5 x 3mm). Web chamfers, rounds, fillets, and “break edges” are edge features that you may commonly see on your part drawings.Inventor Ability to change the decimal places in the call out of the

Create the model shown on the next page. NOTE You may needto play

SOLVED Please Model This Image And Calculate Its Volume In, 57 OFF

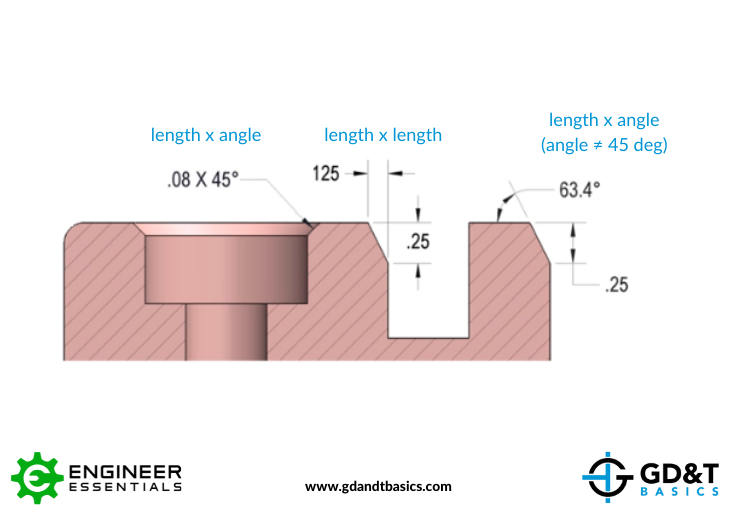

Chamfer Dimensioning GD&T Basics

Customizing your Hole Callouts in SOLIDWORKS Drawings Part 2

SOLIDWORKS 2018 Advanced Hole & Callout Tutorial Innova Systems

Dimensioning standards

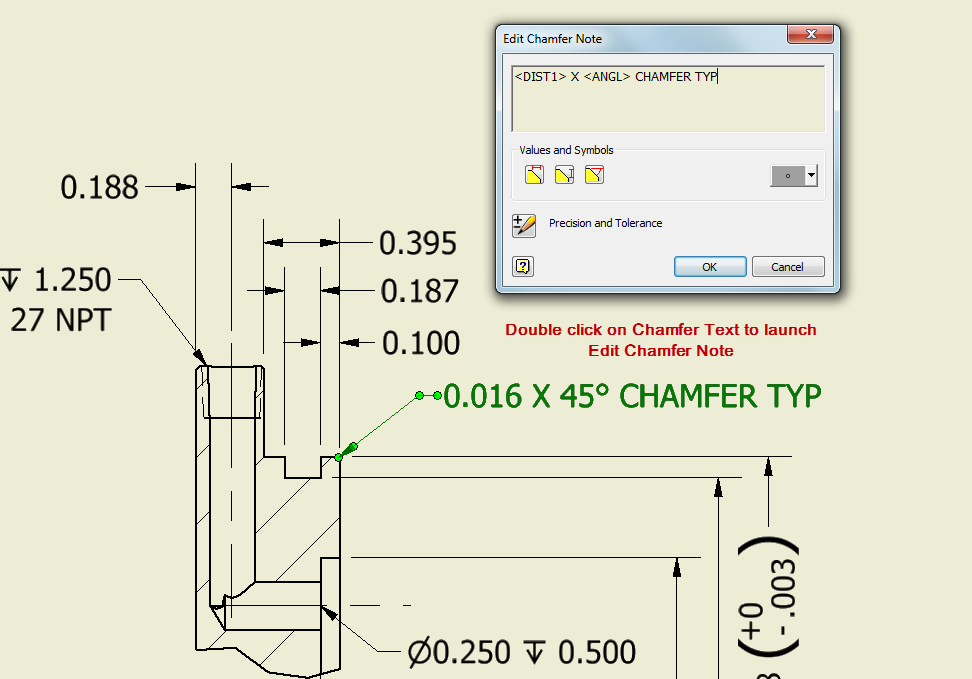

SolidWorks Tutorial How to Add Chamfer Dimension In Solidworks Drawing

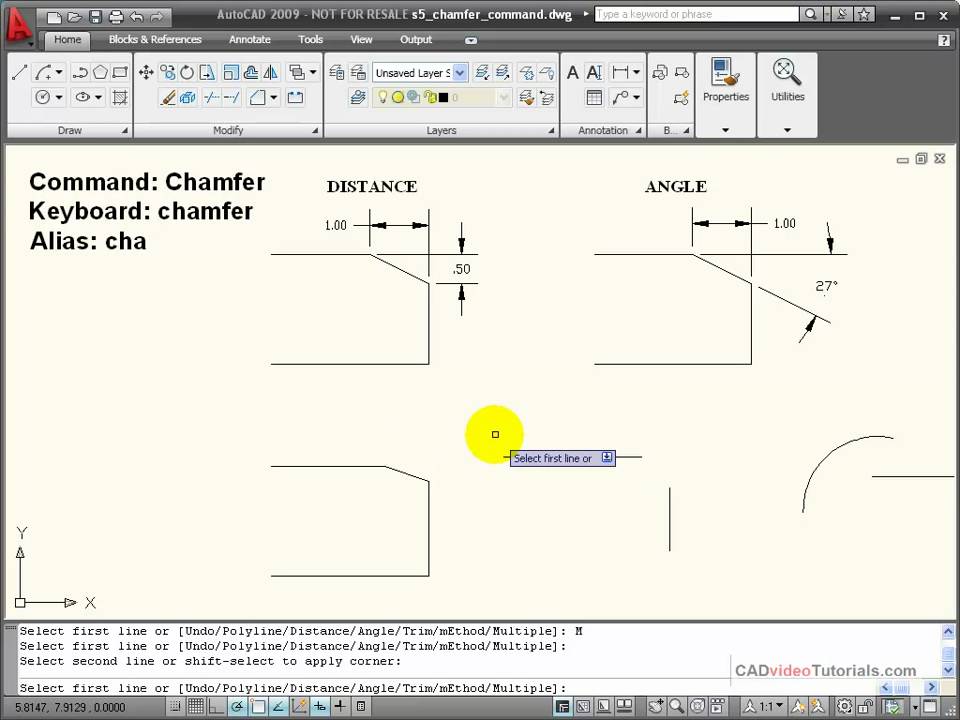

AutoCAD Tutorial Using the CHAMFER Command YouTube

Dimension Guidelines ViBaDirect

Chamfers Can Be Dimensioned In Two Ways, Either By Calling Out The Length By Angle, Or Calling Out The Length By Length.

.040 X 30) To My Knowledge The.040 Be The Depth Into The Material And The 30 Degrees Is The Angle From The Centerline.

Web What Is The Standard For A Callout Of A Chamfer Feature?

If An Angle Other Than 45 Degrees Is Dimensioned, The Surface To Which The Angle Is Measured Must Be Made Clear On The Drawing.

Related Post: