Design Wind Turbine Blade

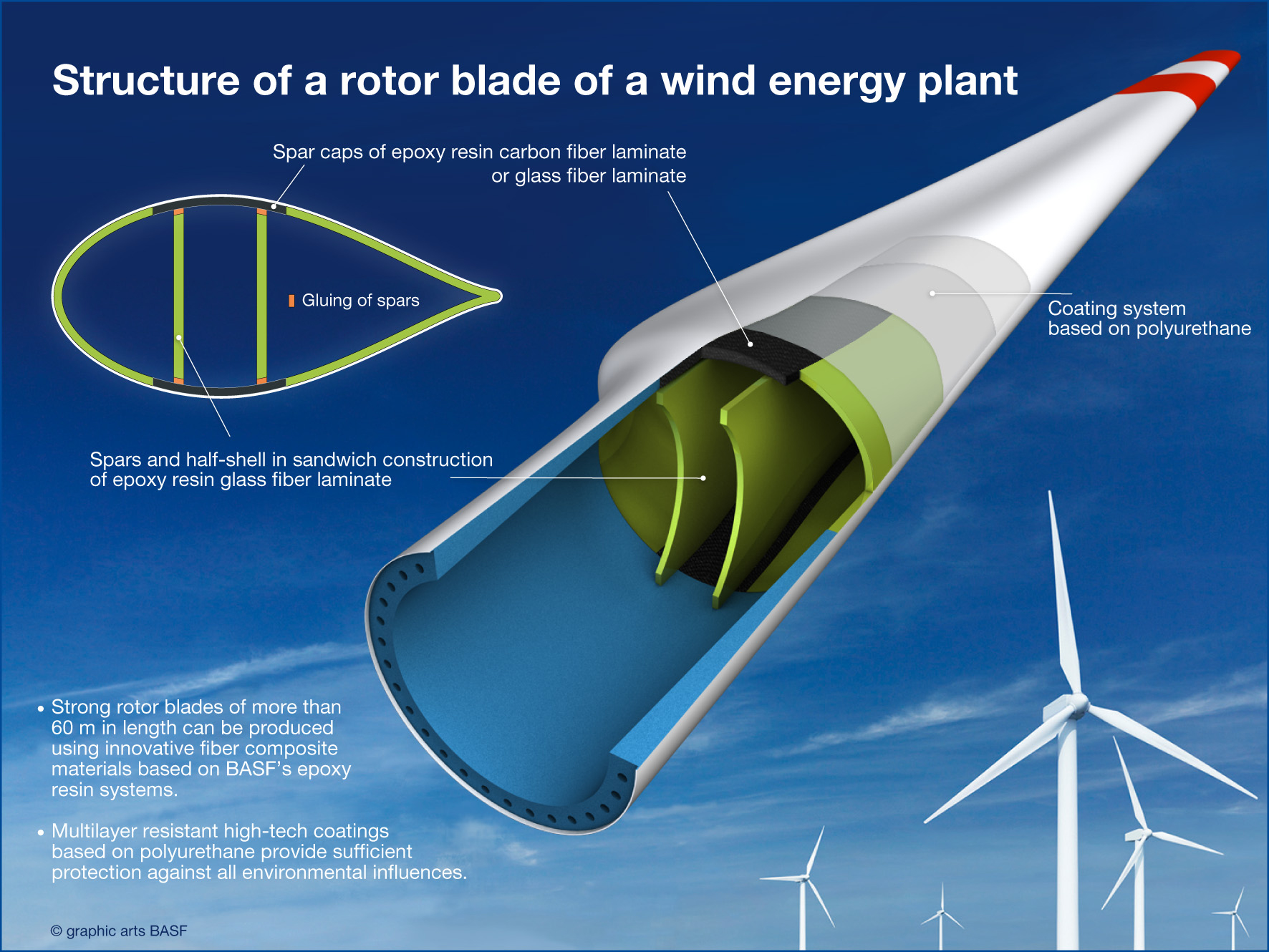

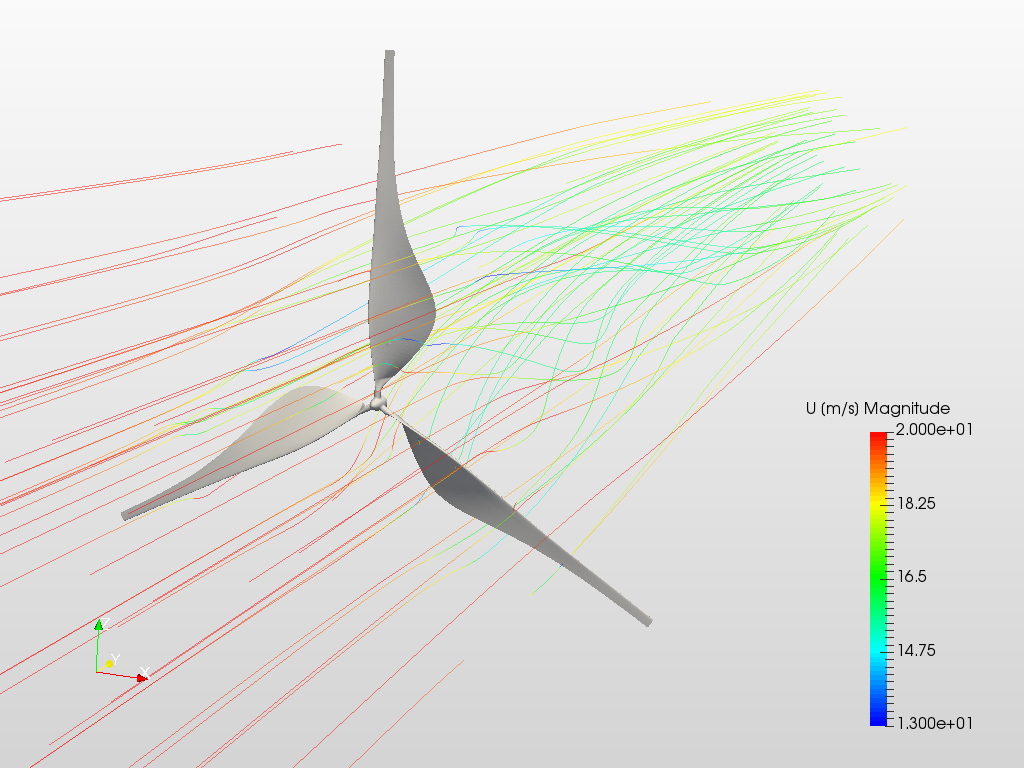

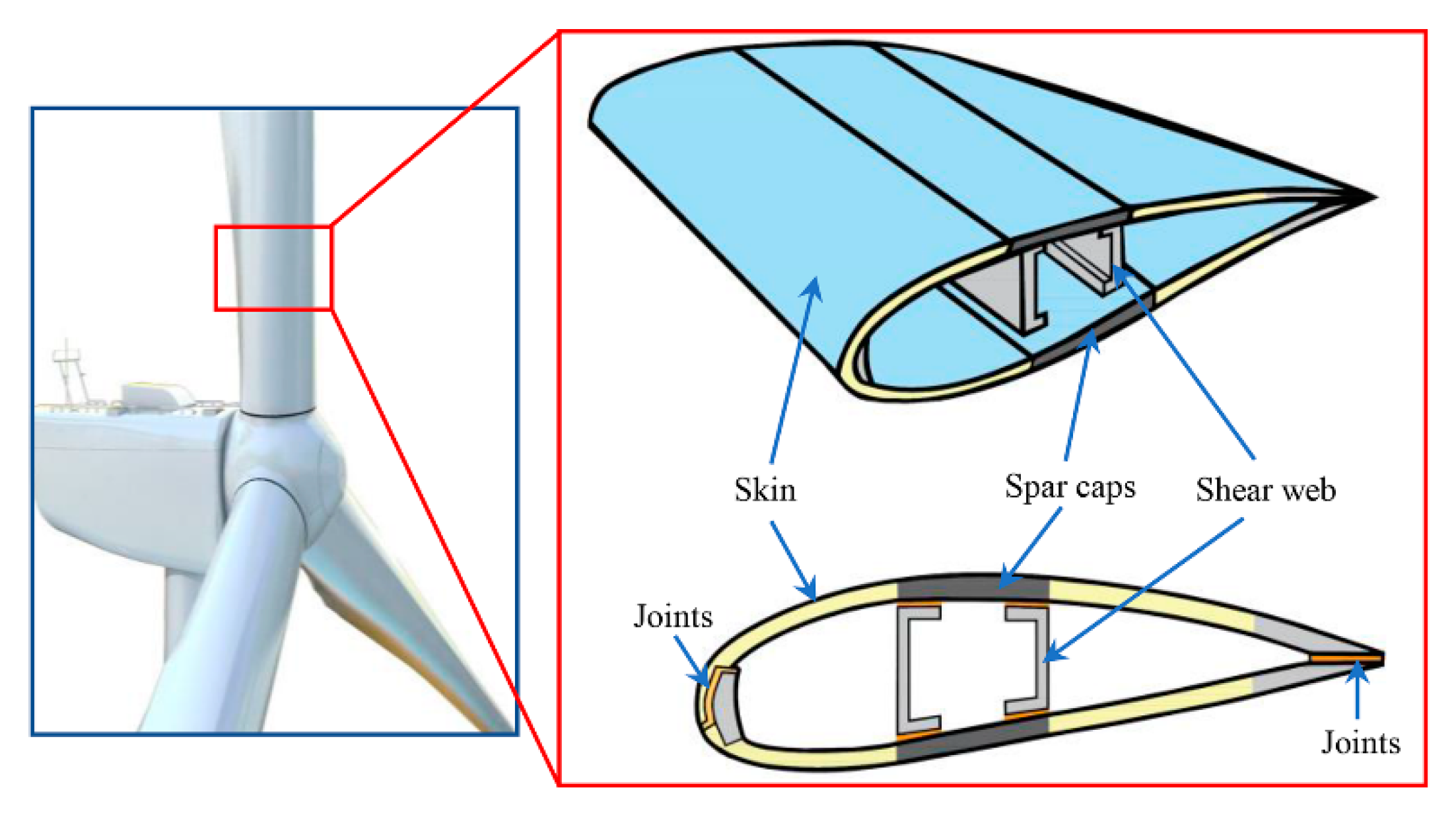

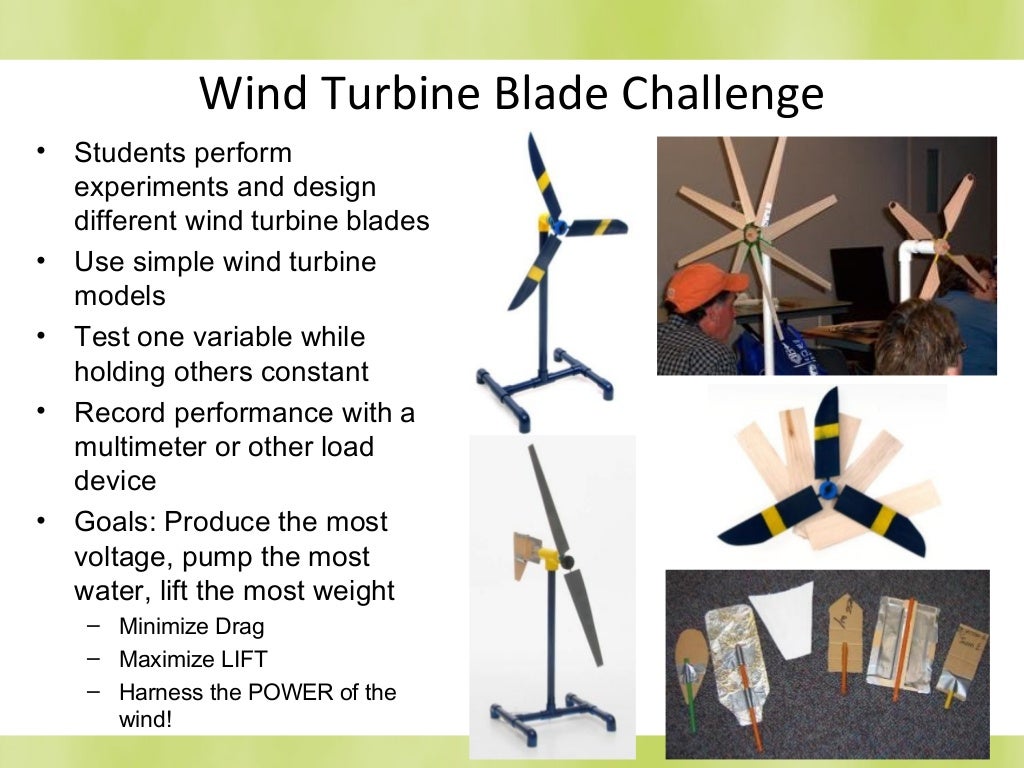

Design Wind Turbine Blade - As a result, the company will reinspect all 150 blades that had been made at the. The main design principles and failure mechanisms of blades in operation are assessed and explained through an industry point of. Web wind turbine blade design has evolved significantly over the years, resulting in improved energy capture, efficiency, and reliability. Wind turbine blades transform the wind’s kinetic energy into rotational energy, which is then used to produce power. The overall goal of our project was to gain an understanding of wind turbine blades sufficient to develop figures of merit analyzing the tradeoffs between structure, material, cost, and other qualities in order to optimize the design of a large wind turbine blade. Web for much more on material and structure requirements for wind turbine blades see brøndsted and nijssen (2013). Web the debris had fallen from a damaged turbine blade at the nearby vineyard wind project. Web we create new, reliable wind turbine blade designs by developing and testing the best materials for wind turbine blades. Web the maker of a massive wind turbine blade that broke apart off nantucket island says a manufacturing problem was responsible. Web wind turbine blade design. Web in this comprehensive guide, we will delve into the intricate details of wind turbine blade shape, exploring the various parameters that define its design and their impact on the overall performance of the turbine. Higher tower ⇒ higher wind speed because of vertical shear. Web central to the effectiveness of a wind turbine is its blade design and the. We then combine these using our advanced design tools. Web the maker of a massive wind turbine blade that broke apart off nantucket island says a manufacturing problem was responsible. Web the idea that a wind turbine blade could break apart and spread thousands of pieces of foam and fiberglass across the south shore never came to mind for members. Web zhu, shen, and sørensen ( 2014) presented an integrated method of designing the aerofoil families of large wind turbine blades using the bemt. Web in order to give a context for the effort undertaken by the individual researchers this section gives a general background for wind turbine blades identifying the trends and issues of importance for these structures as. Web we create new, reliable wind turbine blade designs by developing and testing the best materials for wind turbine blades. As a result, the company will reinspect all 150 blades that had been made at the. Web the blade design from 1948, shown in fig. Web for much more on material and structure requirements for wind turbine blades see brøndsted. Web an overview of the current and future trends in wind turbine blade structural design process is presented. Higher tower ⇒ higher wind speed because of vertical shear. Blog energy wind turbine blade design optimization with simscale. Discover the role of blade length, aerodynamics, materials, and ongoing challenges in harnessing wind energy. The company has said the damage was caused. Size grows more than power rating. An example of a wind turbine, this 3 bladed turbine is the classic design of modern wind turbines. Larger swept area ⇒ larger power capture. Web the aerodynamic design principles for a modern wind turbine blade are detailed, including blade plan shape/quantity, aerofoil selection and optimal attack angles. We then combine these using our. Web central to the effectiveness of a wind turbine is its blade design and the materials used in their construction. Web the maker of a massive wind turbine blade that broke apart off nantucket island says a manufacturing problem was responsible. Web the aerodynamic design principles for a modern wind turbine blade are detailed, including blade plan shape/quantity, aerofoil selection. Web the maker of a massive wind turbine blade that broke apart off nantucket island says a manufacturing problem was responsible. Larger swept area ⇒ larger power capture. A detailed review of design loads on wind turbine blades is offered, describing aerodynamic, gravitational, centrifugal, gyroscopic and operational conditions. A dutch design and engineering firm hired by ge vernova to assess. A preliminary investigation by ge found that the vineyard wind blade that broke off, falling into the ocean and littering nearby beaches, was due to a “manufacturing deviation. The main design principles and failure mechanisms of blades in operation are assessed and explained through an industry point of. Web for much more on material and structure requirements for wind turbine. Web we create new, reliable wind turbine blade designs by developing and testing the best materials for wind turbine blades. An example of a wind turbine, this 3 bladed turbine is the classic design of modern wind turbines. Web the blade design from 1948, shown in fig. We then combine these using our advanced design tools. The blade was manufactured. Web in order to give a context for the effort undertaken by the individual researchers this section gives a general background for wind turbine blades identifying the trends and issues of importance for these structures as well as concepts for “smarter” blades that address these issues. The design philosophy for rotor blades (as with all fibre reinforced polymer structures) began with large safety factors and addressing simple issues of linear elastic behaviour. Web wind turbine blade design has evolved significantly over the years, resulting in improved energy capture, efficiency, and reliability. Web the debris had fallen from a damaged turbine blade at the nearby vineyard wind project. This comprehensive review aims to explore the various blade designs used in wind turbines, ranging from traditional to. Web zhu, shen, and sørensen ( 2014) presented an integrated method of designing the aerofoil families of large wind turbine blades using the bemt. Web the idea that a wind turbine blade could break apart and spread thousands of pieces of foam and fiberglass across the south shore never came to mind for members of town administration and the. The part, made and installed by ge vernova, had broken three days earlier, and no one really knew why. The main design principles and failure mechanisms of blades in operation are assessed and explained through an industry point of. Larger swept area ⇒ larger power capture. Web the design process for wind turbine blades involves the use of computational fluid dynamics (cfd) codes, such as windse, to simulate wind turbine or wind farm performance, optimize designs, and quantify uncertainty. Web table of contents. A preliminary investigation by ge found that the vineyard wind blade that broke off, falling into the ocean and littering nearby beaches, was due to a “manufacturing deviation. Web an overview of the current and future trends in wind turbine blade structural design process is presented. The company has said the damage was caused by a manufacturing issue and was not related to the turbine’s design or. Web wind turbine blade design.wind,,turbine,,blade,,design wind,,turbine,,blade,,design Wind

Wind Turbine Blade Design Engineering's Advice

Wind Turbine Blade Design Considerations

All Things Wind Turbine Blade Inspection

Fibreglass wind turbine blade design

Wind turbine blade design calculations Renewable energy

Turbine Blade

World's biggest wind turbine blade design unveiled by German engineers

Lightweight rotor blades made from plastic foams for offshore wind turbines

Wind turbine blade design

Web In This Comprehensive Guide, We Will Delve Into The Intricate Details Of Wind Turbine Blade Shape, Exploring The Various Parameters That Define Its Design And Their Impact On The Overall Performance Of The Turbine.

The Overall Goal Of Our Project Was To Gain An Understanding Of Wind Turbine Blades Sufficient To Develop Figures Of Merit Analyzing The Tradeoffs Between Structure, Material, Cost, And Other Qualities In Order To Optimize The Design Of A Large Wind Turbine Blade.

We Then Combine These Using Our Advanced Design Tools.

Web We Create New, Reliable Wind Turbine Blade Designs By Developing And Testing The Best Materials For Wind Turbine Blades.

Related Post: