Design Pressure Vs Working Pressure

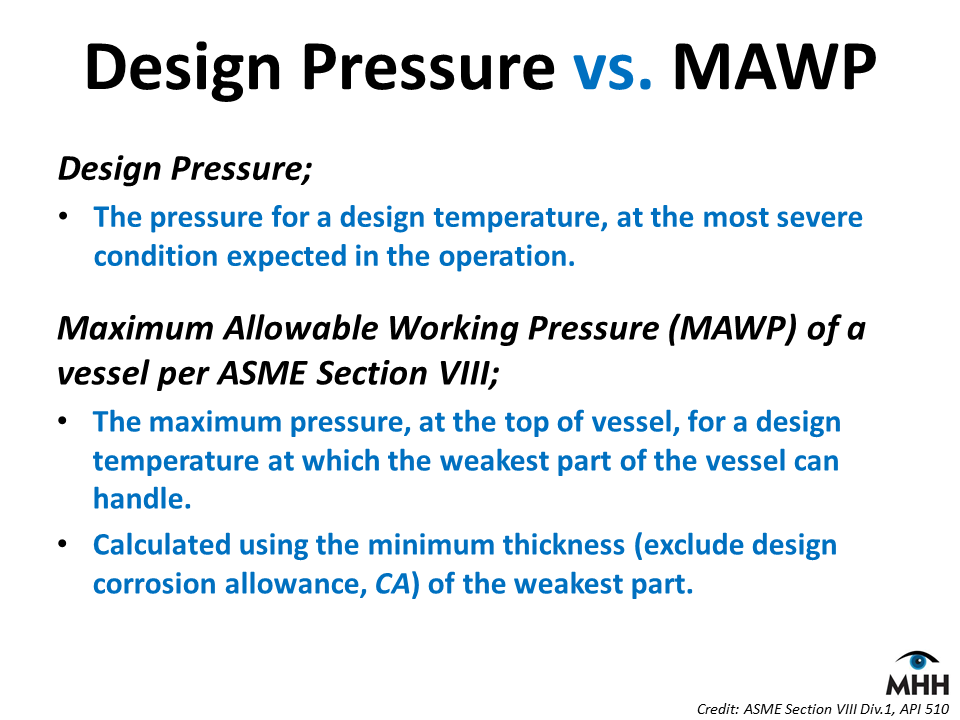

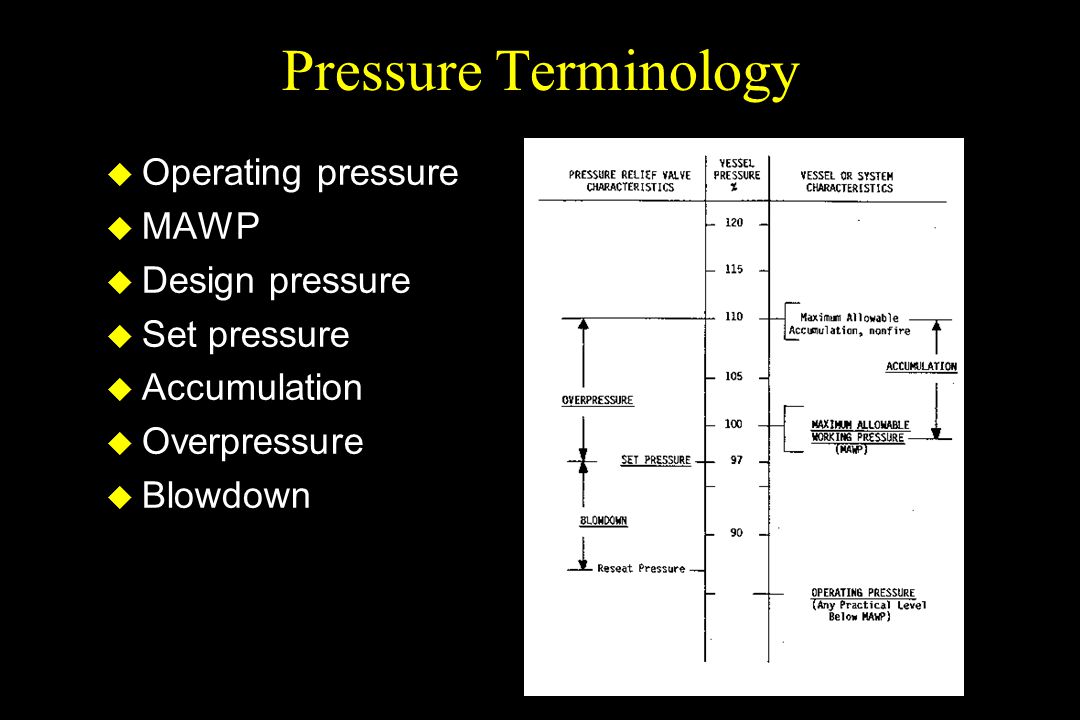

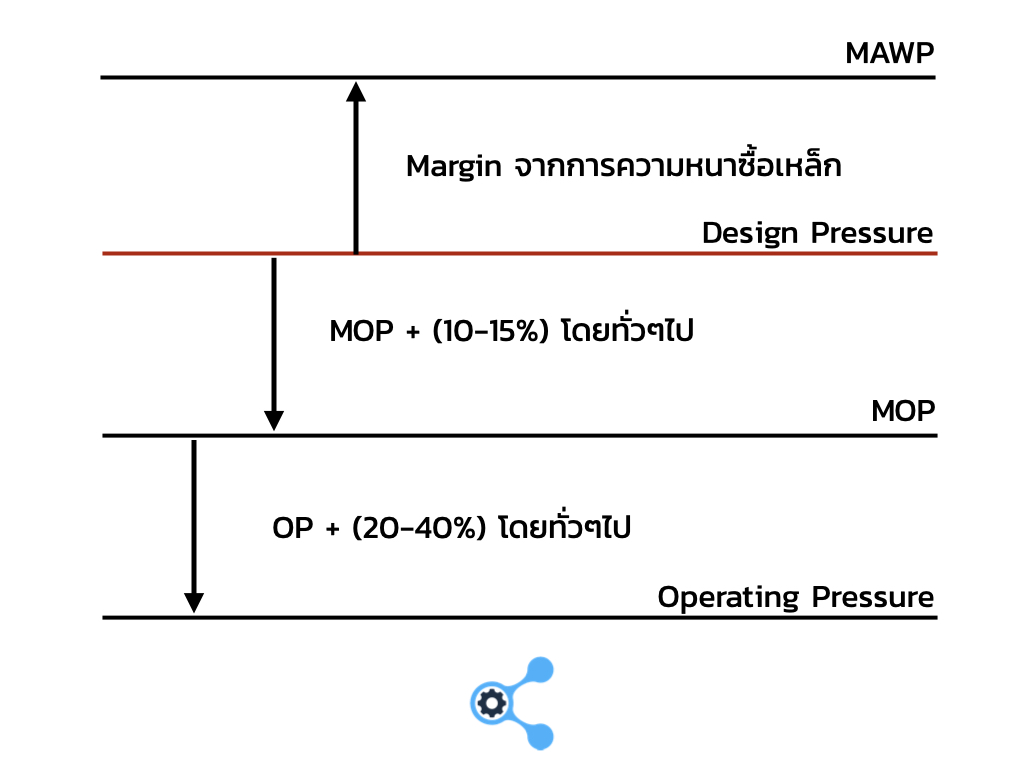

Design Pressure Vs Working Pressure - Web design pressure is what is specified, the equipment must be safely designed to contain that pressure. Web the main difference between mawp and design pressure is that the design pressure is always calculated while designing the equipment, whereas mawp is. Web the design pressure, which is the maximum pressure the vessel can be exposed to, is typically between 10 and 25 percent above the maximum operating. Mawp is normally equal to or greater than the design pressure. Web a design pressure is a design pressure. The maop is less than the mawp (maximum allowable working pressure). Web this article explains about maximum allowable working pressure and its difference with design pressure in the asme pressure vessel. Web per the original cammar article, mawp and design pressure are not synonymous and, if mistakenly used interchangeably, the difference can compromise. Web design pressure is normally less than the maximum allowable working pressure (mawp). Mawp, or maximum allowable working pressure, is the maximum pressure at a specific temperature at which a. Maximum allowable operating pressure (maop) is a pressure limit set, usually by a government body, which applies to compressed gas pressure vessels, pipelines, and storage tanks. Web the main difference between mawp and design pressure is that the design pressure is always calculated while designing the equipment, whereas mawp is. Mawp is normally equal to or greater than the design. Web design pressure is normally less than the maximum allowable working pressure (mawp). Web main differences between mawp and design pressure. For a vessel, design pressure is called maximum allowable working. Web working pressure or maximum allowable pressure. Web design pressure refers to the pressure that a vessel is designed to withstand, while mawp is the maximum pressure that the. Web the design pressure should be equal to or higher than the maximum pressure of the working medium that is possible for the given detail (the tube) under normal operating. Web design pressure is normally less than the maximum allowable working pressure (mawp). Web therefore, the key difference between the two is that design pressure is the maximum pressure equipment. If a piping system is built according to a design pressure, this is the pressure all mechanical components must be calculated. Web design pressure is what is specified, the equipment must be safely designed to contain that pressure. Mawp is normally equal to or greater than the design pressure. Mawp is the maximum pressure the the equipment can. Web per. For a vessel, design pressure is called maximum allowable working. For pipelines, this value is derived from barlow's formula, which takes into account wall thickness, diameter, allowable stress (which is a function of the material used), and a safety factor. Mawp is normally equal to or greater than the design pressure. Web a design pressure is a design pressure. Web. Web mula sa pagkarera, paglalaro ng flag football hanggang sa pagiging isang certified plantita, isa na namang masayang kuwentuhan ang meron tayo this. Mawp is normally equal to or greater than the design pressure. Web the design pressure, which is the maximum pressure the vessel can be exposed to, is typically between 10 and 25 percent above the maximum operating.. Web the design pressure, which is the maximum pressure the vessel can be exposed to, is typically between 10 and 25 percent above the maximum operating. Mawp is normally equal to or greater than the design pressure. Web design pressure is what is specified, the equipment must be safely designed to contain that pressure. Mawp, or maximum allowable working pressure,. Web design pressure for a pressure vessel comes from a variety of places and overall philosophy. Web per the original cammar article, mawp and design pressure are not synonymous and, if mistakenly used interchangeably, the difference can compromise. Mawp, or maximum allowable working pressure, is the maximum pressure at a specific temperature at which a. The maop is less than. Web design pressure is what is specified, the equipment must be safely designed to contain that pressure. Web the design pressure, which is the maximum pressure the vessel can be exposed to, is typically between 10 and 25 percent above the maximum operating. For pipelines, this value is derived from barlow's formula, which takes into account wall thickness, diameter, allowable. Web mula sa pagkarera, paglalaro ng flag football hanggang sa pagiging isang certified plantita, isa na namang masayang kuwentuhan ang meron tayo this. Web a design pressure is a design pressure. Web design pressure is what is specified, the equipment must be safely designed to contain that pressure. Web the main difference between mawp and design pressure is that the. In conversation this is sometimes referred to simply as the vessel’s “working. Web the design pressure, which is the maximum pressure the vessel can be exposed to, is typically between 10 and 25 percent above the maximum operating. Web design pressure for a pressure vessel comes from a variety of places and overall philosophy. The maop is less than the mawp (maximum allowable working pressure). Web per the original cammar article, mawp and design pressure are not synonymous and, if mistakenly used interchangeably, the difference can compromise. You start with normal operating pressure. Web a design pressure is a design pressure. If a piping system is built according to a design pressure, this is the pressure all mechanical components must be calculated. Web the design pressure for a vessel is called its “maximum allowable working pressure” (mawp). Web the main difference between mawp and design pressure is that the design pressure is always calculated while designing the equipment, whereas mawp is. Web therefore, the key difference between the two is that design pressure is the maximum pressure equipment is designed to withstand. Web the design pressure should be equal to or higher than the maximum pressure of the working medium that is possible for the given detail (the tube) under normal operating. Mawp is the maximum pressure the the equipment can. In contrast, mawp is the. Mawp, or maximum allowable working pressure, is the maximum pressure at a specific temperature at which a. For a vessel, design pressure is called maximum allowable working.

What Is The Difference Between Design Pressure And Maximum Allowable

CRNs, MAWP & Design Pressure Cammar Corporation

MAWP vs Design Pressure Overpressure & Accumulation Operating P

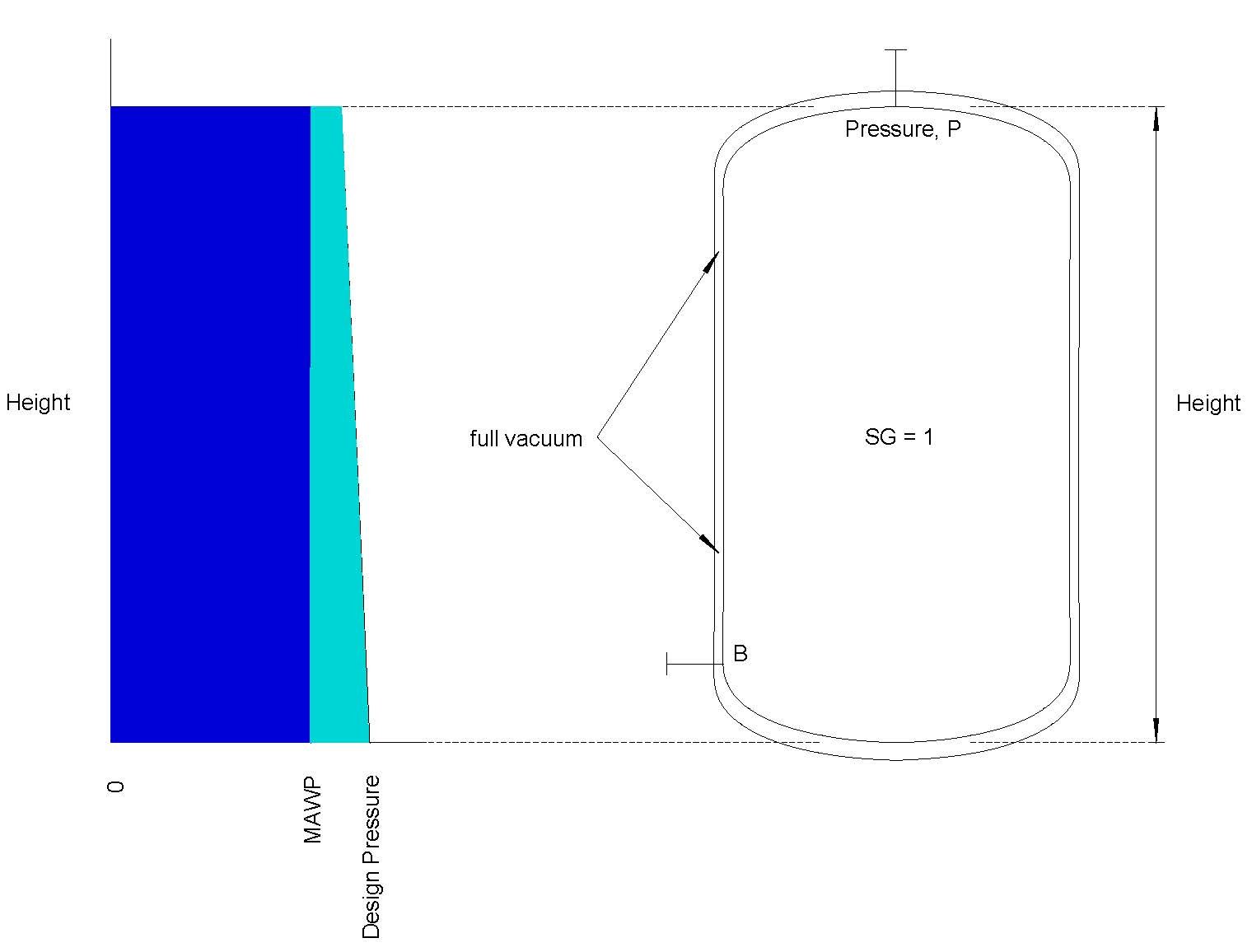

Design and Working Pressure Download Scientific Diagram

What is Operating pressure, Design Pressure, MAWP,MOP Design Hub

Difference Between MAWP and Design Pressure in short YouTube

MHH Place for Knowledge Sharing with Happiness

What is Operating pressure, Maximum operating pressure, Design pressure

Fundamentals of Pressure Relief Devices ppt download

ข้อแตกต่างของ MAWP, Design pressure, และ Operating pressure

Web Working Pressure Or Maximum Allowable Pressure.

For Pipelines, This Value Is Derived From Barlow's Formula, Which Takes Into Account Wall Thickness, Diameter, Allowable Stress (Which Is A Function Of The Material Used), And A Safety Factor.

Maximum Allowable Operating Pressure (Maop) Is A Pressure Limit Set, Usually By A Government Body, Which Applies To Compressed Gas Pressure Vessels, Pipelines, And Storage Tanks.

Web This Article Explains About Maximum Allowable Working Pressure And Its Difference With Design Pressure In The Asme Pressure Vessel.

Related Post: