Design Of Windmill Blades

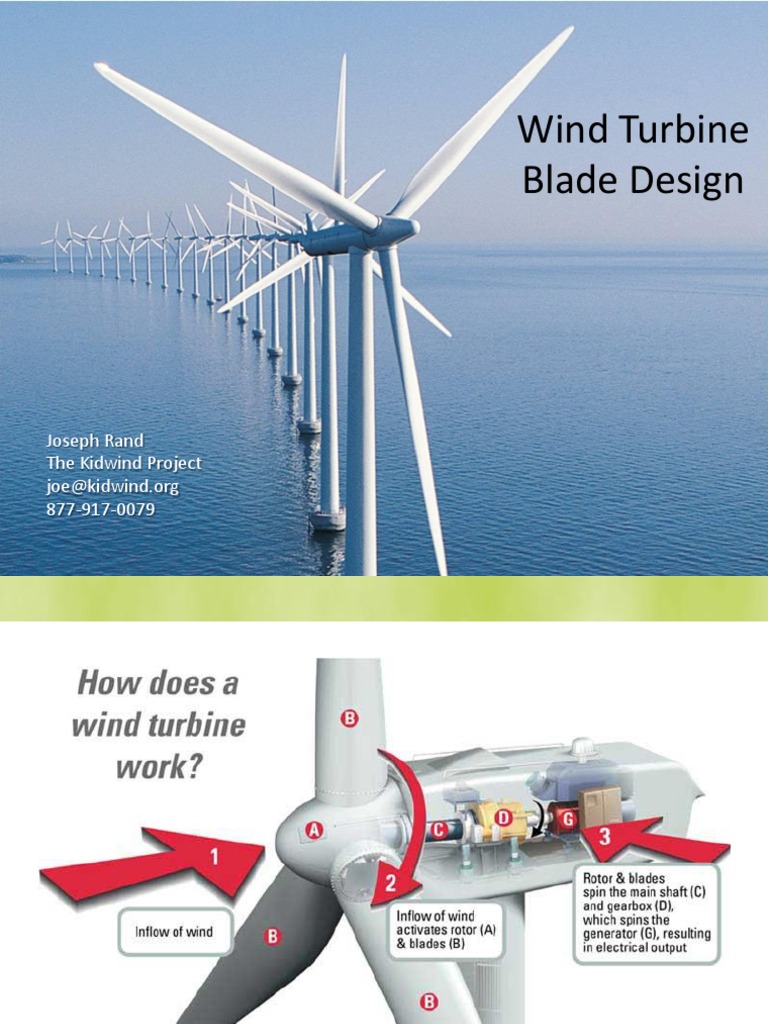

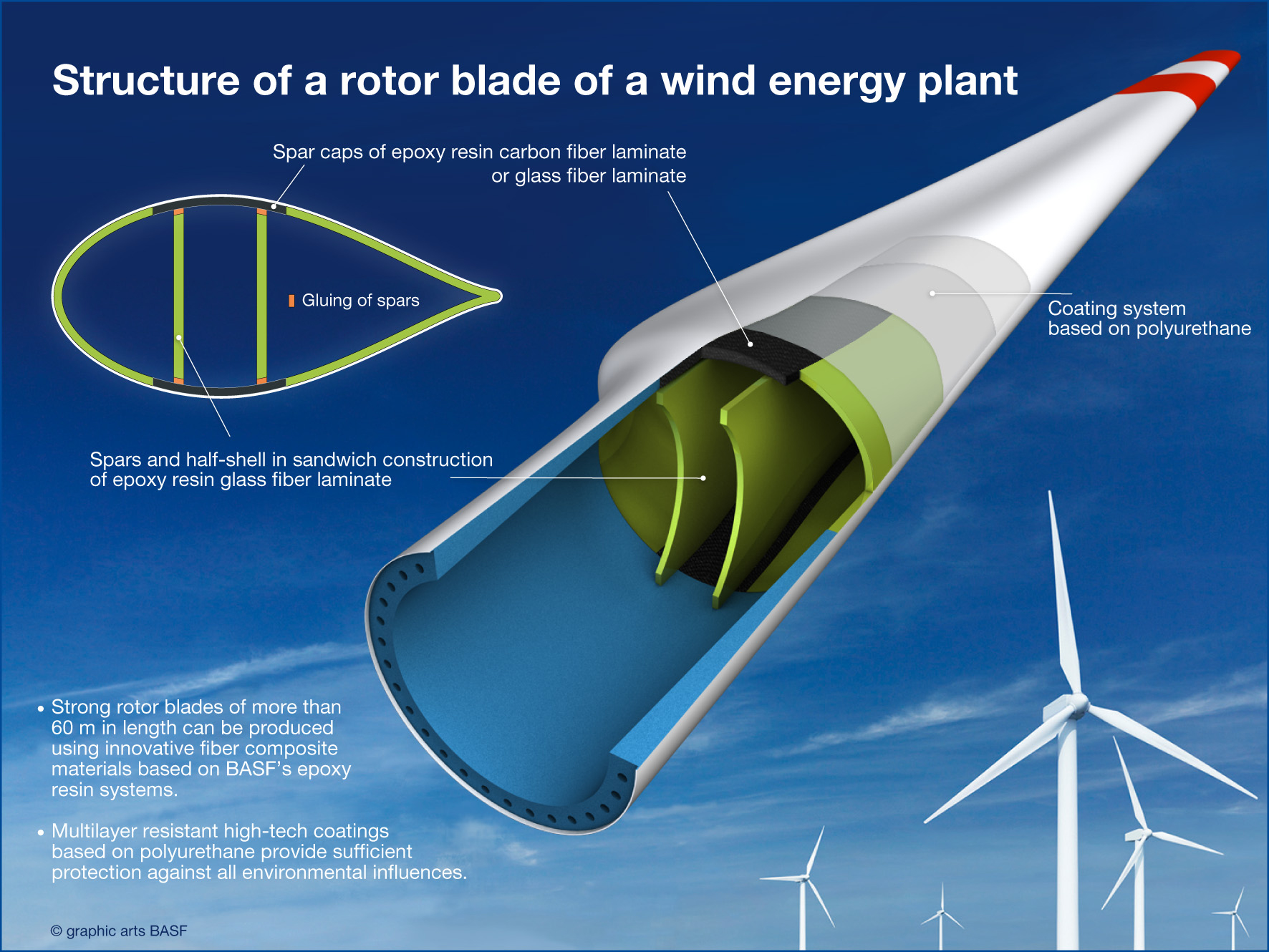

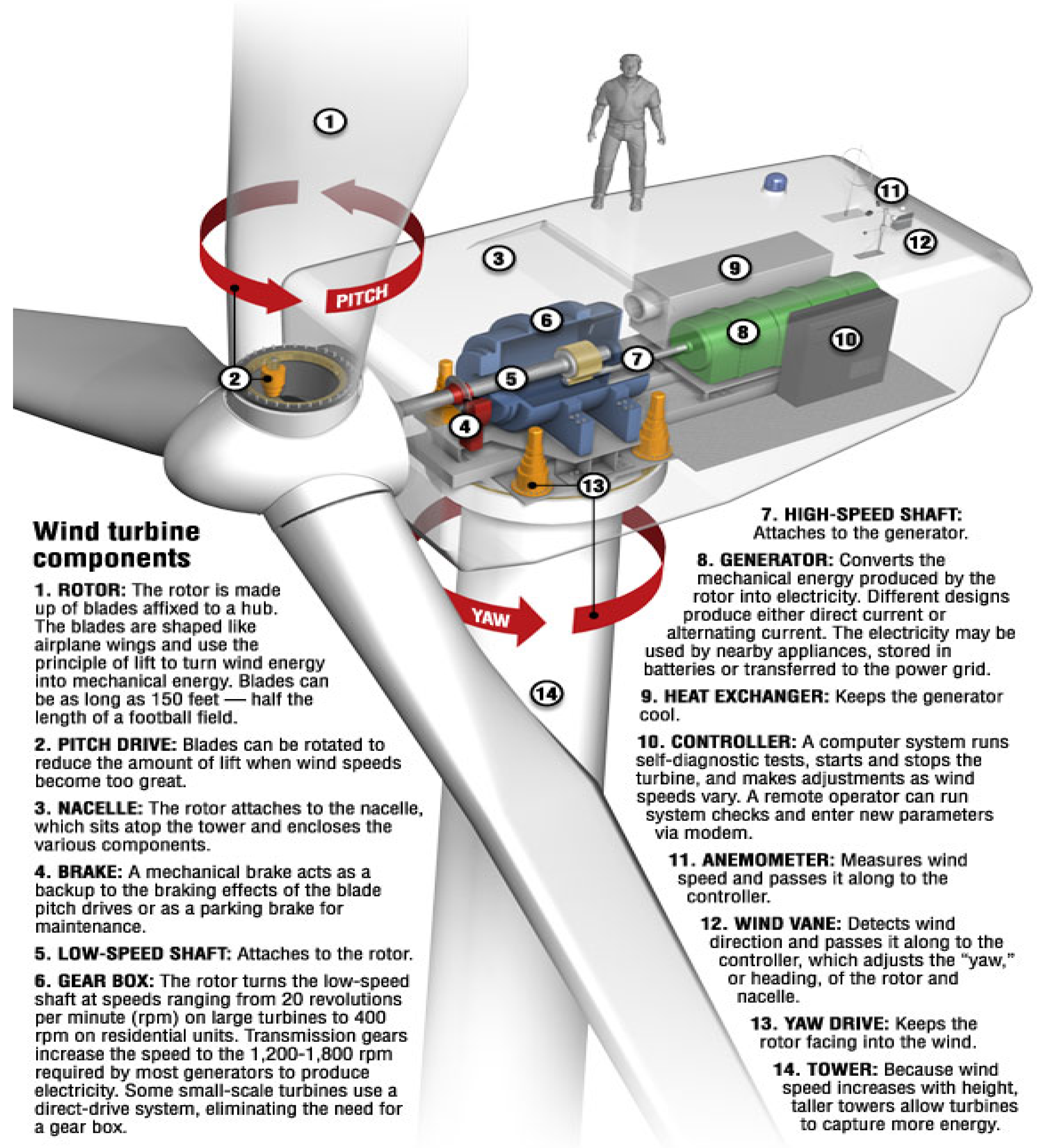

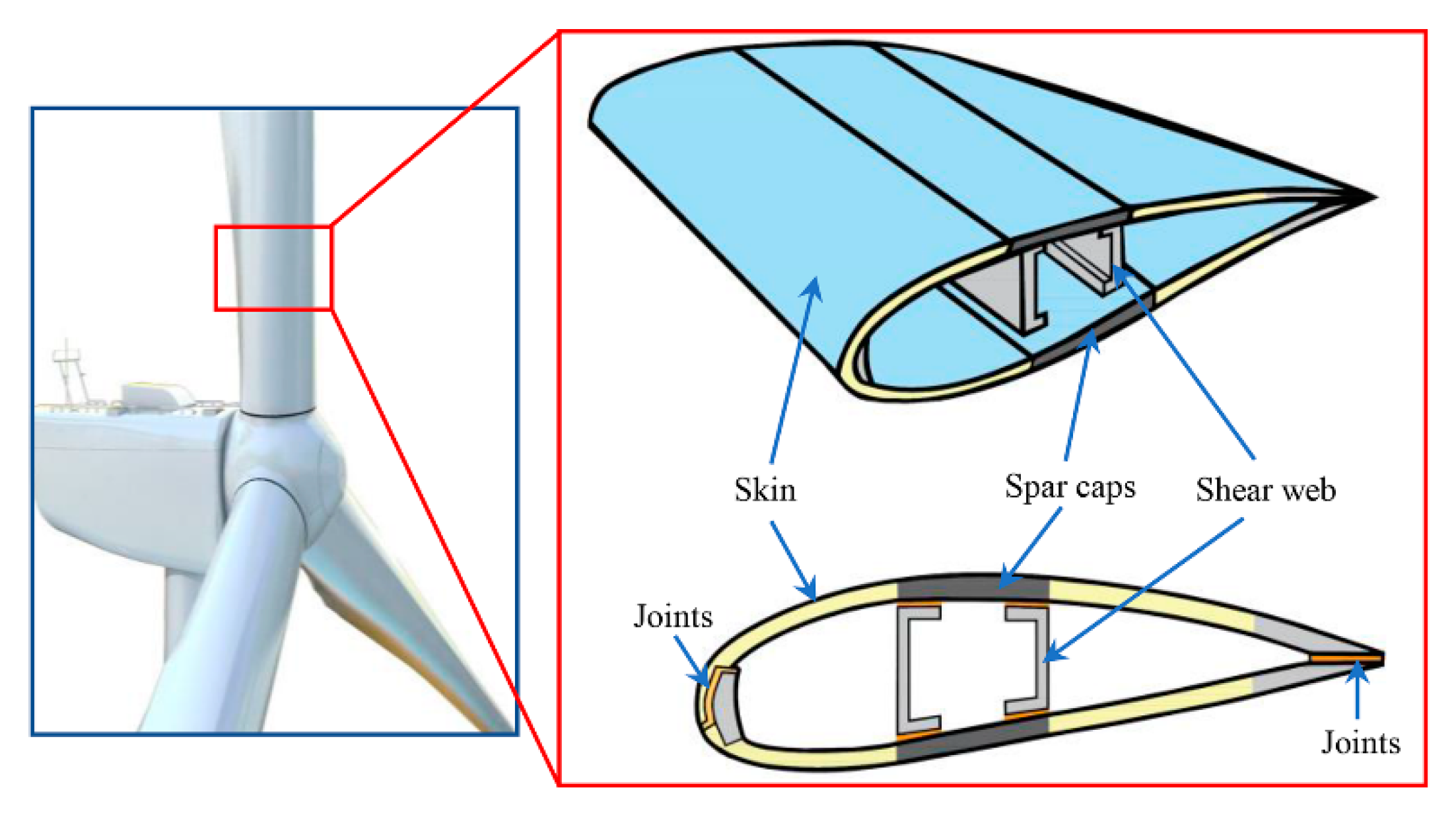

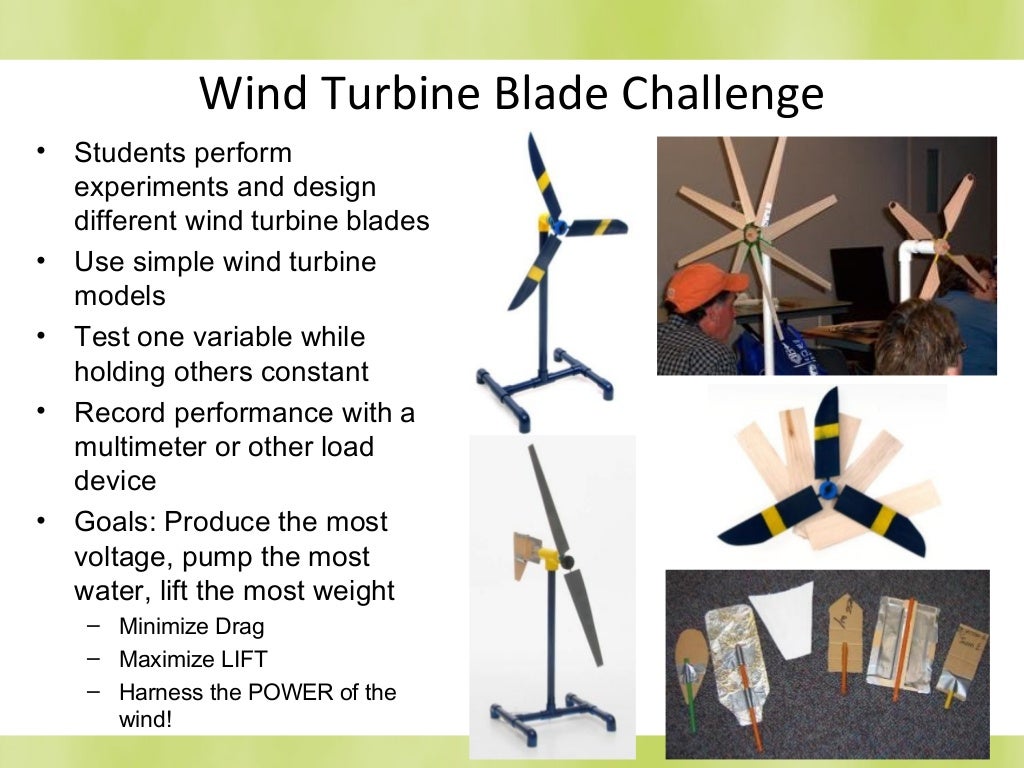

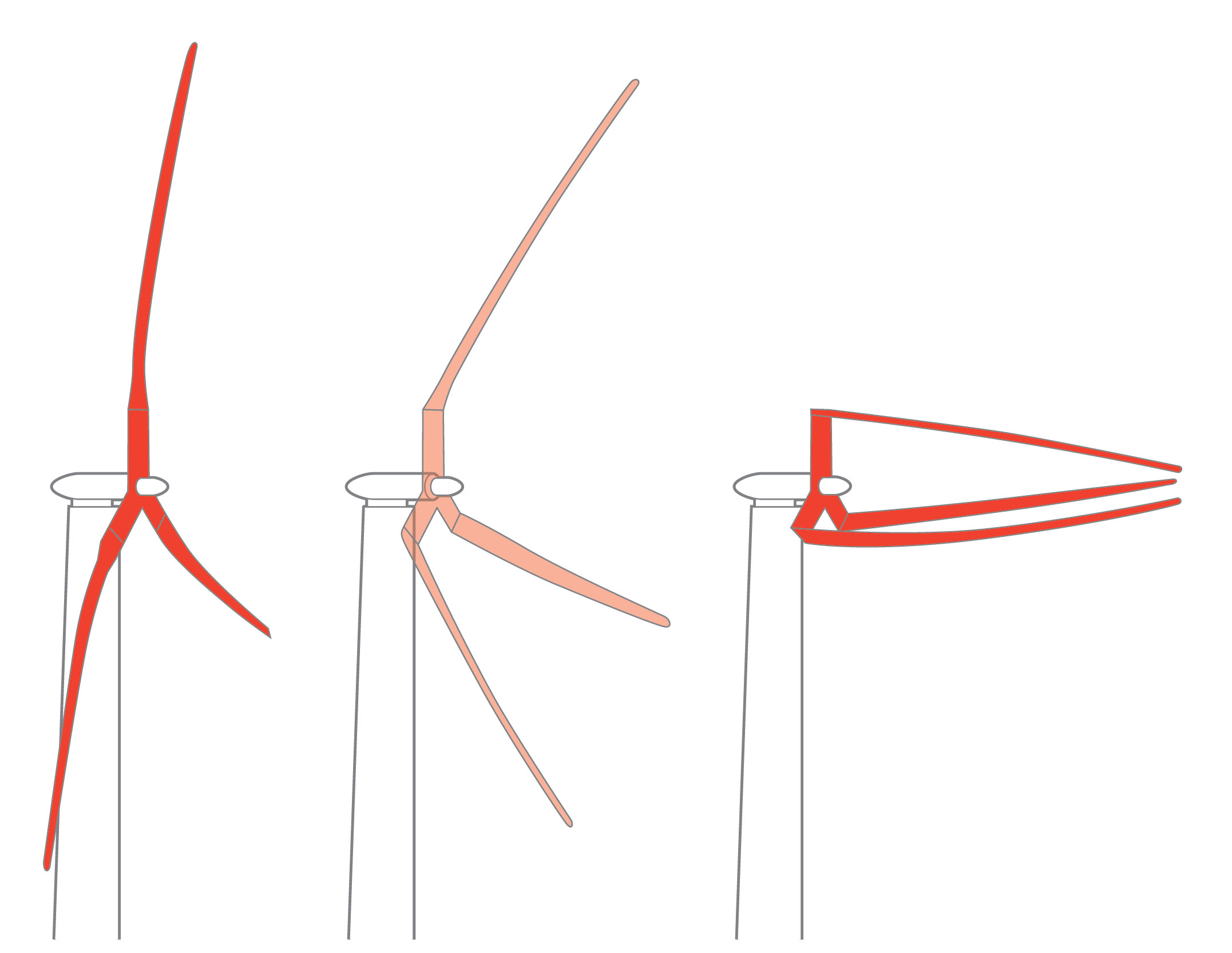

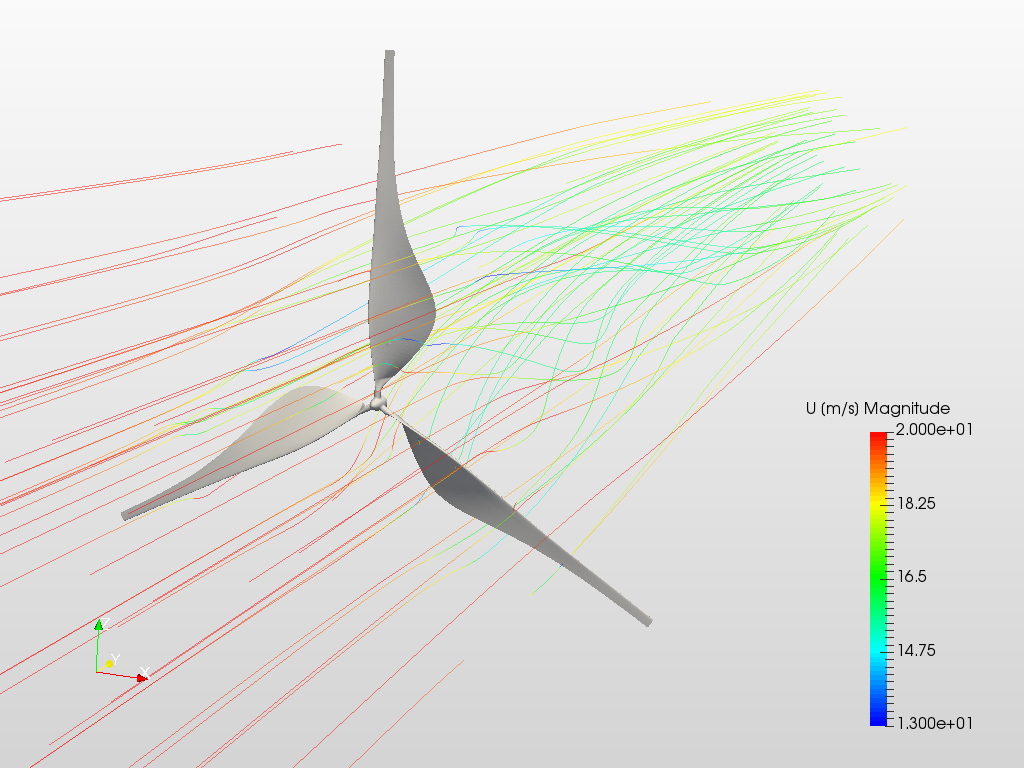

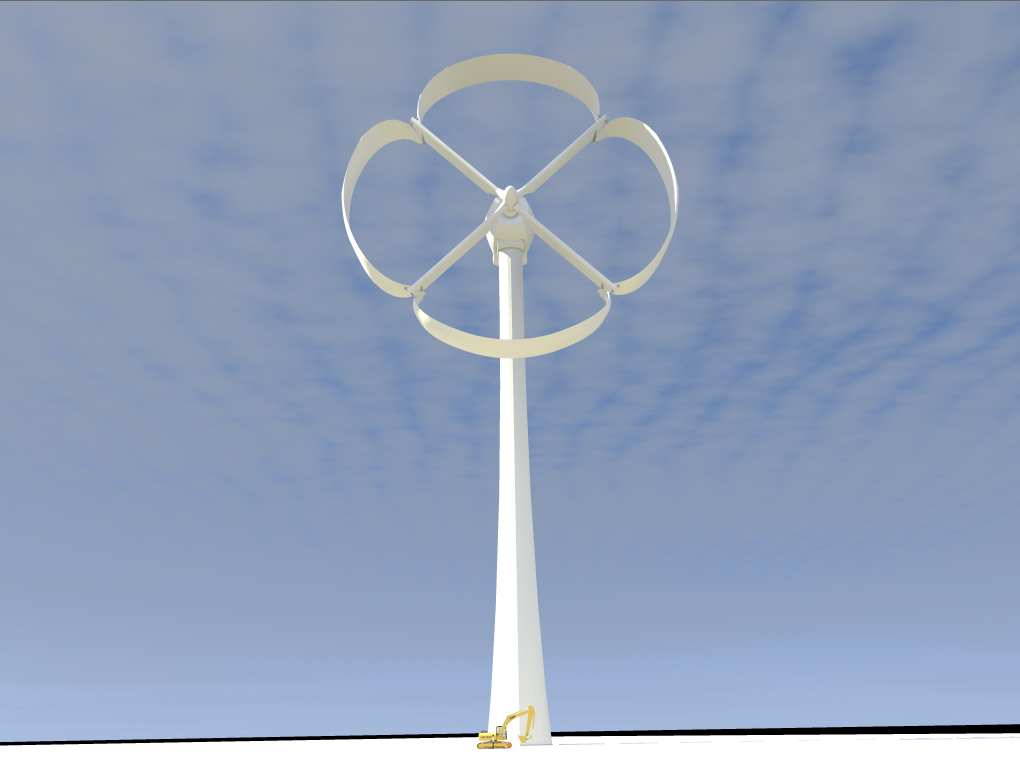

Design Of Windmill Blades - • define a parametric composite material model (mechanical properties vs. I will even provide you with a pdf drawing that you can print out, and use as a template. This design consideration has to do with aerodynamics (drag), stability of the turbine, and cost efficiency. When wind flows across the blade, the air pressure on one side of the blade decreases. Web optimized blade design for homemade windmills. 5 shows the design case of retired wind turbine blades used as structural materials in the marine field. The maker of a massive wind turbine blade that broke apart. A detailed review of design loads on wind turbine blades is offered, describing aerodynamic, gravitational, centrifugal, gyroscopic and operational conditions. Web design of wind turbine blades. July 24, 2024 at 8:21 p.m. 5 shows the design case of retired wind turbine blades used as structural materials in the marine field. Wind turbine blades generate lift with their curved shape. Having fewer blades reduces drag, but a two blade design results in wobble when motors turn the nacelle to face the wind (yaw). Web the best in wind turbine blade design. The airfoil. Web a wind turbine turns wind energy into electricity using the aerodynamic force from the rotor blades, which work like an airplane wing or helicopter rotor blade. Web through the grading of blades, the processed materials can be used in offshore platforms and marine ranches, fig. I will even provide you with a pdf drawing that you can print out,. Generating lift and drag when they move through the air, airfoils play a key role in improving the aerodynamic performance. Ge vernova is pointing to a “manufacturing deviation” and not an engineering design flaw in the failure of its wind turbine off the coast of nantucket. Pick closest existing material within market products Wind turbine blades generate lift with their. The intent of this project, created in collaboration with mech425, is to identify the best angle for flat, uniform blades in relationship to the air stream. Wind turbine blades generate lift with their curved shape. I promise you it is easier then you think. The blade of a modern wind turbine is now much lighter than older wind turbines so. Web vineyard wind’s catastrophic blade failure earlier this month is believed to have been caused by a manufacturing error, ge vernova, the company that supplies vineyard wind with its turbine. A detailed review of design loads on wind turbine blades is offered, describing aerodynamic, gravitational, centrifugal, gyroscopic and operational conditions. Generating lift and drag when they move through the air,. Web design of wind turbine blades. I will even provide you with a pdf drawing that you can print out, and use as a template. Web vineyard wind’s catastrophic blade failure earlier this month is believed to have been caused by a manufacturing error, ge vernova, the company that supplies vineyard wind with its turbine. Pick closest existing material within. Web the design process for wind turbine blades involves the use of computational fluid dynamics (cfd) codes, such as windse, to simulate wind turbine or wind farm performance, optimize designs, and quantify uncertainty. Generating lift and drag when they move through the air, airfoils play a key role in improving the aerodynamic performance. Wind turbine blades generate lift with their. Pick closest existing material within market products This design consideration has to do with aerodynamics (drag), stability of the turbine, and cost efficiency. However, a number of different styles/types of turbines exist and the way in which they harness kinetic energy from the wind is quite different. The airfoil shape is characterized by a curved upper surface and a flatter. A detailed review of design loads on wind turbine blades is offered, describing aerodynamic, gravitational, centrifugal, gyroscopic and operational conditions. The maker of a massive wind turbine blade that broke apart. Web wind turbine blade design is a complicated procedure that combines engineering, aerodynamics, and materials science. The airfoil shape is characterized by a curved upper surface and a flatter. Web this was designed by me, a real aerospace engineer, using real airfoils, and optimized for a small wind turbine at lower starting wind speeds. At the last section of the wt blade, i.e., between section 9 and section 10, the pitch angle is adjusted to 5°, and the other blades remain the same. Web a stereotypical wind turbine is. Lm wind power’s technology plays a central role in the creation of each wind turbine blade type. Web explore the world of wind turbine blade technology and how design choices impact efficiency. Ge vernova is pointing to a “manufacturing deviation” and not an engineering design flaw in the failure of its wind turbine off the coast of nantucket. Pick closest existing material within market products Web a wind turbine turns wind energy into electricity using the aerodynamic force from the rotor blades, which work like an airplane wing or helicopter rotor blade. However, a number of different styles/types of turbines exist and the way in which they harness kinetic energy from the wind is quite different. Web wind turbine blade design. This makes full use of the characteristics of lightweight, high strength, and strong corrosion resistance of thermosetting. Web the best in wind turbine blade design. The airfoil shape is characterized by a curved upper surface and a flatter lower surface. Web vineyard wind’s catastrophic blade failure earlier this month is believed to have been caused by a manufacturing error, ge vernova, the company that supplies vineyard wind with its turbine. Web the most common blade shape for wind turbines is the airfoil design, which is optimized to maximize lift and minimize drag. The design method starts with determining the wind turbine’s particular needs, such as the intended power output and operating circumstances. A detailed review of design loads on wind turbine blades is offered, describing aerodynamic, gravitational, centrifugal, gyroscopic and operational conditions. • define a parametric composite material model (mechanical properties vs. The blade of a modern wind turbine is now much lighter than older wind turbines so they can accelerate quickly at lower wind speeds.

All Things Wind Turbine Blade Inspection

Energies Free FullText Wind Turbine Blade Design

Homemade Wind Turbine Blade Design Homemade Ftempo

wind,,turbine,,blade,,design wind,,turbine,,blade,,design Wind

Wind turbine blade design

Folding Blade Design Could Allow For 50 MW Turbines North American

Wind turbine blade design calculations Renewable energy

Wind Turbine Blade Design slidesharetrick

Turbine Blade Design

PPT Wind turbine blade design using FEM PowerPoint Presentation, free

July 24, 2024 At 8:21 P.m.

5 Shows The Design Case Of Retired Wind Turbine Blades Used As Structural Materials In The Marine Field.

Web Wind Turbine Blades Have Been Designed In Many Shapes And Styles Throughout The Evolution Of Wind Energy Technology.

I Will Even Provide You With A Pdf Drawing That You Can Print Out, And Use As A Template.

Related Post: