Design For Manufacturing Principles

Design For Manufacturing Principles - Web the design for manufacturability (dfm) process works by examining five key principles: 3) maintain or improve product quality. Web the principles of design for manufacturing (dfm) are as follows: Web the five principles of design for manufacturing are as follows: Dfm focuses on anticipating potential fabrication issues and proactively modifying chip layouts and circuits to mitigate their i… Web general principles of dfm include designing objects for efficient assembly, the standardisation of materials and components, reducing the number of parts, and. Process, design, material, environment and compliance and testing. Web the 5 principles of dfm. Web 3d scanning technology for advanced manufacturing, design, and construction provides a comprehensive introduction to 3d scanning and its applications in both the aec and. This guide covers the categories, benefits, and key principles of dfm, such as. Web learn how to design products that are easy to manufacture, especially for pcbs. Web learn what design for manufacturing and assembly (dfma) is and how it can optimise the manufacturing and assembly aspects of a product. Web the five principles of design for manufacturing are as follows: Selecting the appropriate manufacturing process based on factors such as: Web dfma. Web learn what design for manufacturing and assembly (dfma) is and how it can optimise the manufacturing and assembly aspects of a product. Optimizing the manufacturing process for each component while taking tolerances and necessary. Web learn how to design products that are easy to manufacture, especially for pcbs. Web in this guide, we provide an overview of design for. Web the 5 principles of dfm. Process, design, material, environment and compliance and testing. Web design for manufacturing is a product design philosophy that stresses the importance of designing prototypes and parts in a way that suits the manufacturing. As a result, a product’s design can be improved to enable faster,. Web the five principles of design for manufacturing are. Web updated july 29th, 2024. Create products fasterautomate tasksconnect your teamsgenerative design Web learn how to design products that are easy to manufacture, especially for pcbs. Using the right manufacturing process is important. Web what is design for manufacturing? 25m+ parts manufacturedus & overseas suppliersunlimited capacity Web general principles of dfm include designing objects for efficient assembly, the standardisation of materials and components, reducing the number of parts, and. Web the design for manufacturability (dfm) process works by examining five key principles: Web the 3 goals of dfm. Web the five principles of design for manufacturing are as follows: Create products fasterautomate tasksconnect your teamsgenerative design Web design for manufacturability, also known as dfm or dfma (assembly), is a guiding engineering design principle that has many advantages when incorporated into. The process comprises all physical manufacturing operations, such as cnc machining,. Web learn what design for manufacturing and assembly (dfma) is and how it can optimise the manufacturing and. Dfm focuses on anticipating potential fabrication issues and proactively modifying chip layouts and circuits to mitigate their i… Web dfma is a design methodology that emphasises manufacturing simplicity and assembly efficiency. As a result, a product’s design can be improved to enable faster,. Web in this guide, we provide an overview of design for manufacturability (dfm), a crucial methodology utilized. Web in this guide, we provide an overview of design for manufacturability (dfm), a crucial methodology utilized by designers and engineers to avoid costly mistakes in the early. Web the 3 goals of dfm. Web the design for manufacturability (dfm) process works by examining five key principles: Web design for manufacturability, also known as dfm or dfma (assembly), is a. Using the right manufacturing process is important. As a result, a product’s design can be improved to enable faster,. Web design for manufacturing (dfm) refers to design activity that is based on minimizing the cost of production and/or time to market for a product, while maintaining an appropriate. Web design for manufacturability (dfm) is a set of engineering principles and. 3) maintain or improve product quality. The process comprises all physical manufacturing operations, such as cnc machining,. Web updated july 29th, 2024. Web dfma is a design methodology that emphasises manufacturing simplicity and assembly efficiency. Selecting the appropriate manufacturing process based on factors such as: Web the 5 principles of dfm. Web the 3 goals of dfm. Web key principles and concepts behind dfm: Web the principles of design for manufacturing (dfm) are as follows: Web general principles of dfm include designing objects for efficient assembly, the standardisation of materials and components, reducing the number of parts, and. Intuitive user interfacetrack sop trainingsefficient training Learn how to optimize product design and manufacturing processes using dfm principles. Dfm focuses on anticipating potential fabrication issues and proactively modifying chip layouts and circuits to mitigate their i… Create products fasterautomate tasksconnect your teamsgenerative design 1) streamline and simplify the manufacturing process. Web dfma is a design methodology that emphasises manufacturing simplicity and assembly efficiency. Web design for manufacturing is a product design philosophy that stresses the importance of designing prototypes and parts in a way that suits the manufacturing. As a result, a product’s design can be improved to enable faster,. 3) maintain or improve product quality. Web 3d scanning technology for advanced manufacturing, design, and construction provides a comprehensive introduction to 3d scanning and its applications in both the aec and. The process comprises all physical manufacturing operations, such as cnc machining,.

PPT ME317 Design For Manufacturing PowerPoint Presentation, free

9 Best Practices When Following Design for Manufacturing Principles

Episode 12 Design for Manufacturing and Assembly YouTube

What Is Design for Manufacturing? Chapter 2 Incorporated

Design for Manufacturing (DFM) Everything You Need to Know

Technical Engineering Drawing Manual Following ISO and BSI standards

Design For Manufacturing and assembly Overviews, Steps, Advantages

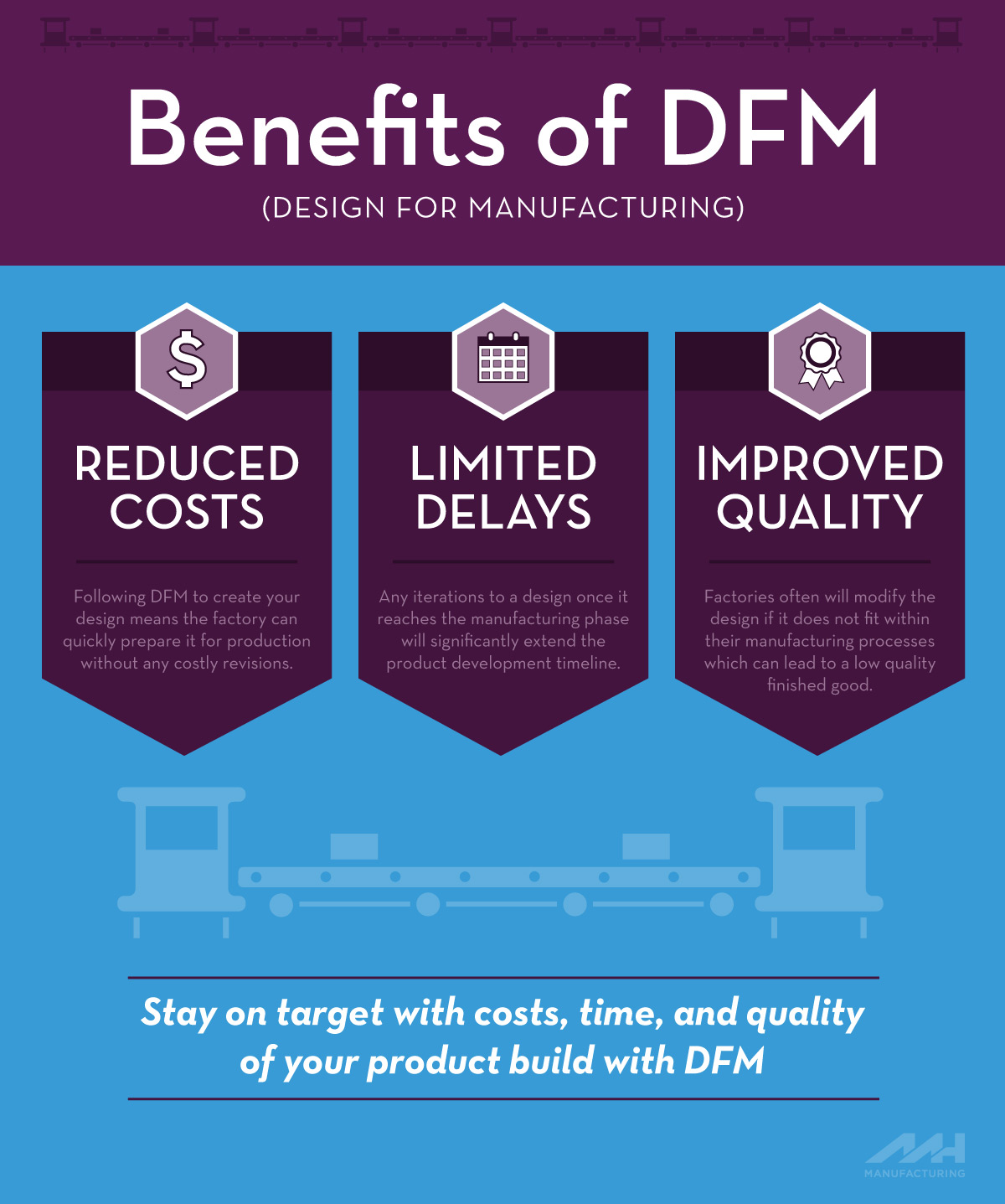

DFM What It Is and Why It's Important

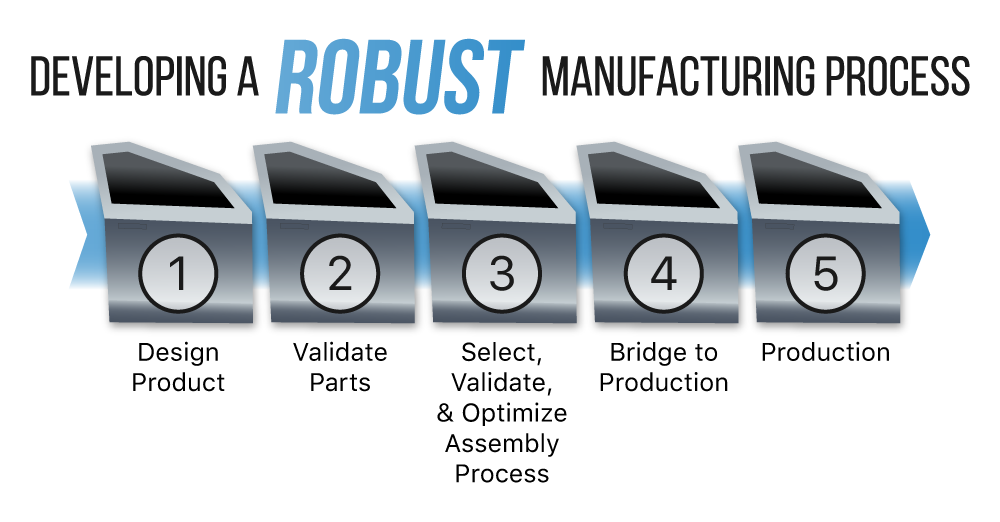

How to develop a robust manufacturing process for a new product

Design For Manufacturability Design for Manufacturing(DFM) GUIDELINES

Web What Is Design For Manufacturing?

Web In This Guide, We Provide An Overview Of Design For Manufacturability (Dfm), A Crucial Methodology Utilized By Designers And Engineers To Avoid Costly Mistakes In The Early.

Web Design For Manufacturability, Also Known As Dfm Or Dfma (Assembly), Is A Guiding Engineering Design Principle That Has Many Advantages When Incorporated Into.

Design For Manufacturing (Dfm) Is The Systematic Method Of Designing Parts, Components, Or Products With The Primary Objective Of.

Related Post: