Design Equation For A Batch Reactor

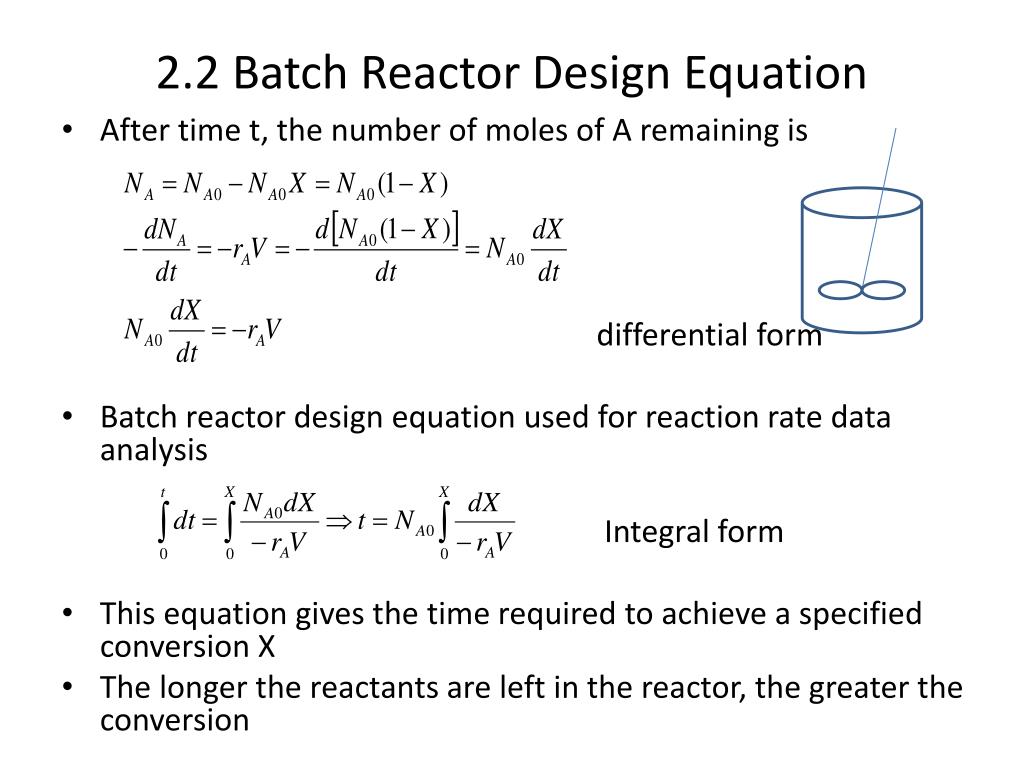

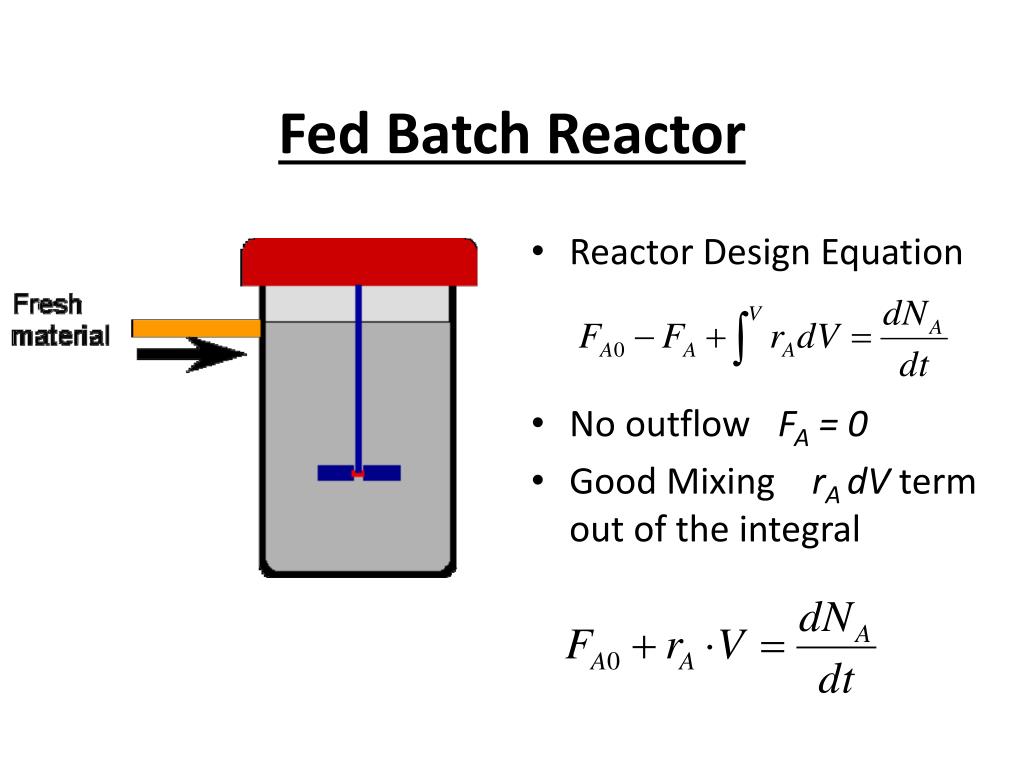

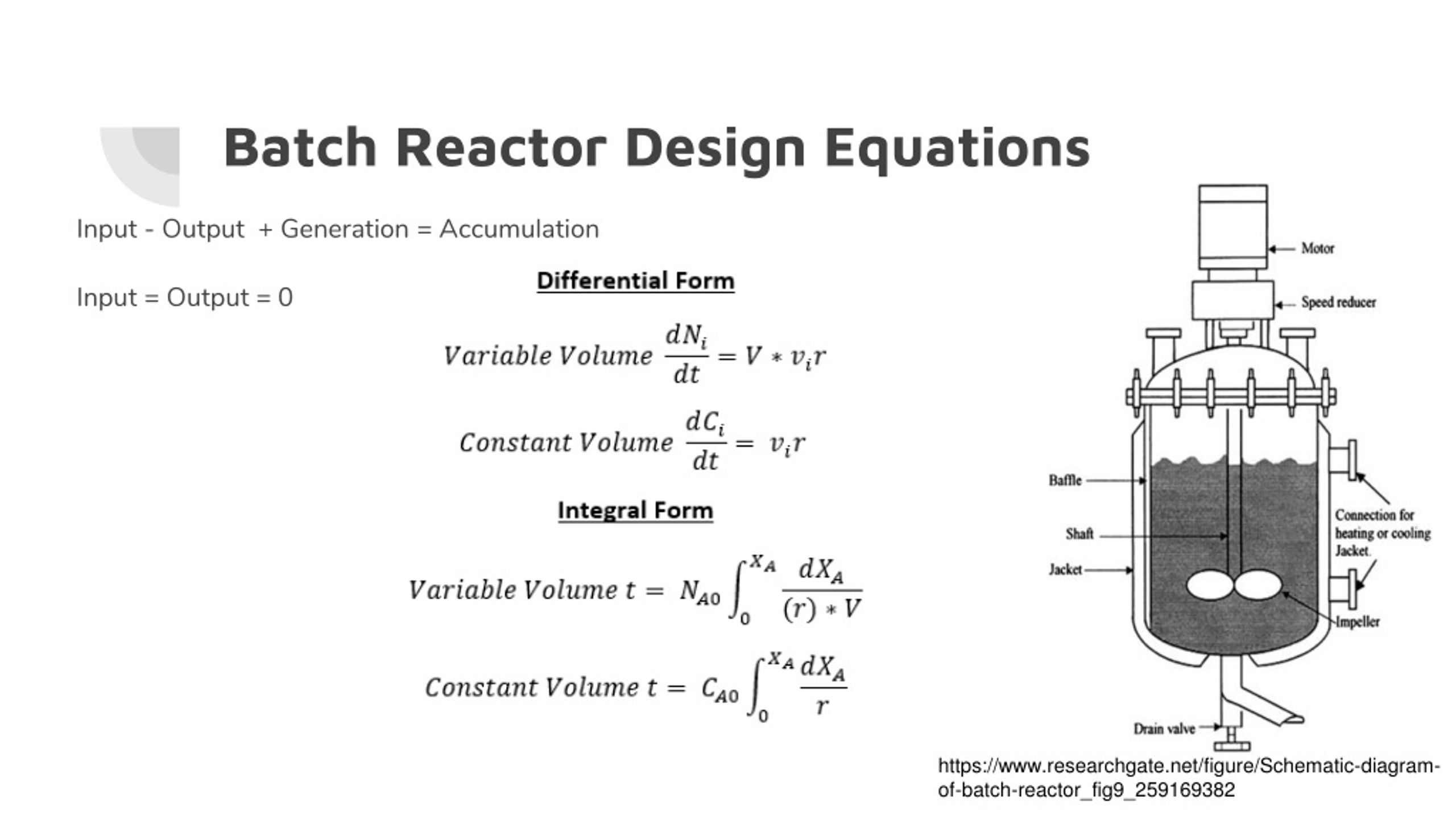

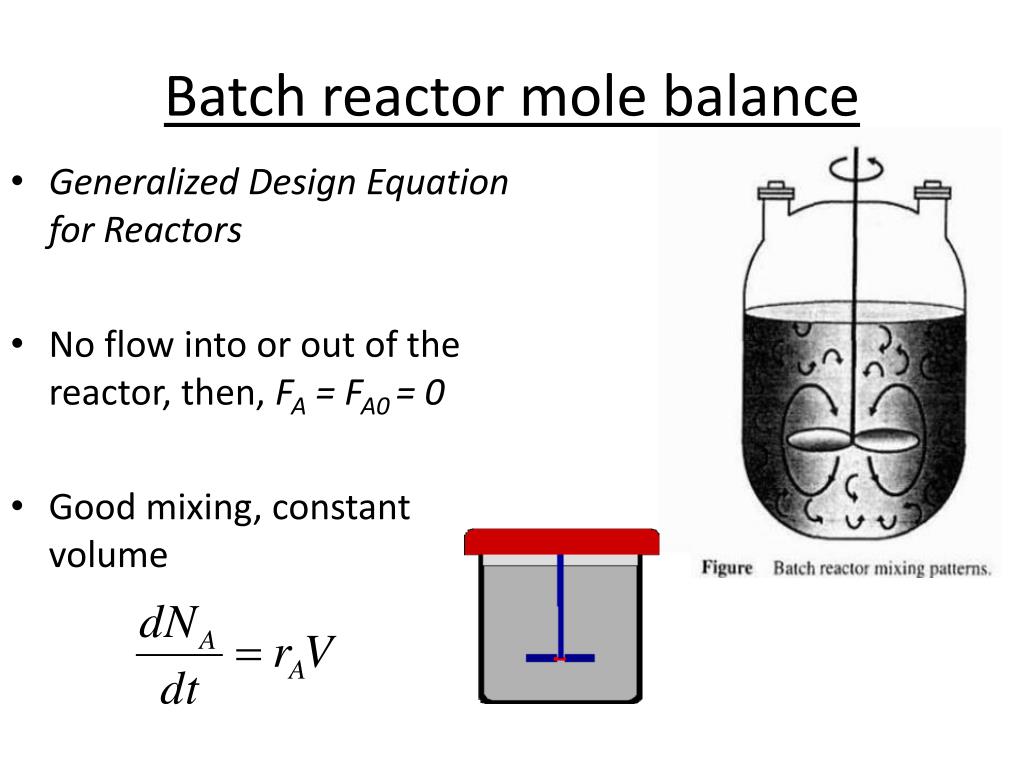

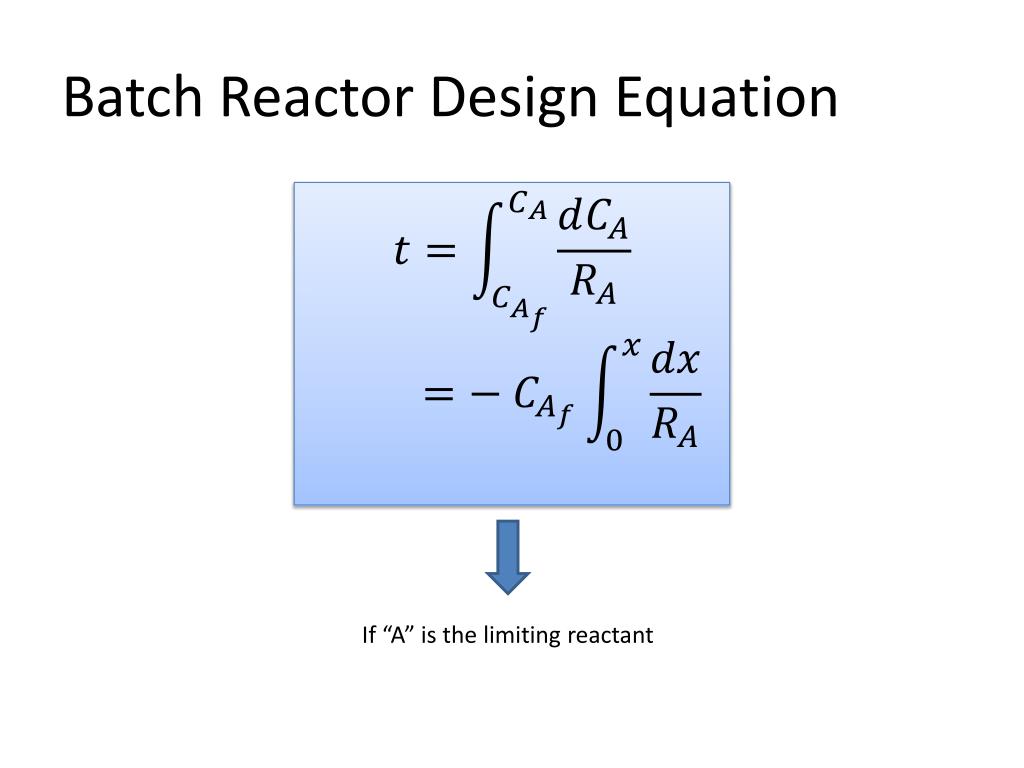

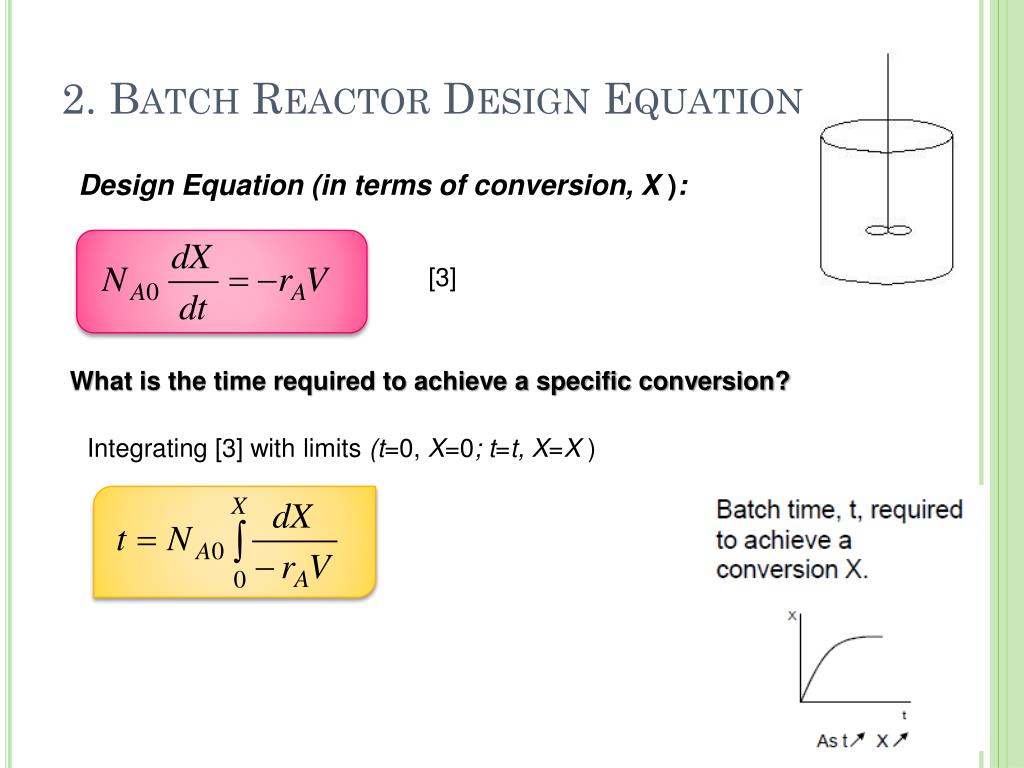

Design Equation For A Batch Reactor - This lecture covers batch reactor equations, reactor sizing for constant volume and variable volume processes. Constant volume v = v 0 (e.g. Web while batch processes comfortably accommodate slow reactions over extended timeframes (minutes to days), flow reactors are typically designed for much. When we design any reactor we have two design equations we must consider. One involves the modelling of the material using a “mass balance”,. Web this volume describes a unified methodology that applies to both single and multiple reactions (reactors with single reactions are merely simple special cases). Web reactor design is primarily concerned with the type and size of the reactor and its method of operation for the required process. Reactor models are essential for reaction engineering analyses. Web 6 reactor design equations. Web the design equations presented in chapter 1 can also be written in terms of conversion. The design of any process where. A reactor model is a set of equations that relates what goes into a reactor to. While the reaction is carried out, nothing else is put in or taken out until the reaction is. (a) batch reactor, (b) semibatch reactor, and (c) distillation reactor. We set q = 0 in the cstr material balance. Given its volume v, and the initial internal concentration c0, the total mass will be m = v·c0. This document highlights enhancements to the design and operation of sbrs that will ultimately provide more Web batch reactors are quite common in process industries, even if they are not the most performing reactors their simplicity makes it often an attractive choice. For the reaction a + b )k*1. A reactor model is a set of equations that relates what goes into a reactor to. (a) batch reactor, (b) semibatch reactor, and (c) distillation reactor. Presented by professor alan hall, university of huddersfield. Given its volume v, and the initial internal concentration c0, the total mass will be m = v·c0. Web batch reactors are quite common in process industries, even if they are not the most performing reactors their simplicity makes it often an attractive choice for small /. Web derivation of batch reactor design equations. 1.4.1 ideal batch reactors 12 1.4.2 reactor. Presented by professor alan hall, university of huddersfield. Web the general design equation. C r = k1(t ). Web the design equations presented in chapter 1 can also be written in terms of conversion. Noting that the elapsed time is the independent. Liquid phase or gas phase in a steel container) in terms of conversion. (a) batch reactor, (b) semibatch reactor, and (c) distillation reactor. Web 6 reactor design equations. (a) batch reactor, (b) semibatch reactor, and (c) distillation reactor. Web the general design equation. Web this volume describes a unified methodology that applies to both single and multiple reactions (reactors with single reactions are merely simple special cases). In general, this type of reactor is charged via ports in the top of the tank. In most batch reactors, the longer a reactant is in the reactor, the more reactant is converted to product the reactant is exhausted. Web while batch processes comfortably accommodate slow reactions over extended timeframes (minutes to days), flow reactors are typically designed for much. The design is meant to use uranium and deliver anywhere. A reactor model is a set. Web batch reactors are quite common in process industries, even if they are not the most performing reactors their simplicity makes it often an attractive choice for small /. The design of any process where. Web this volume describes a unified methodology that applies to both single and multiple reactions (reactors with single reactions are merely simple special cases). Web. Constant volume v = v 0 (e.g. Web 2.2 batch design equations. The reaction time necessary to reach a. Web this volume describes a unified methodology that applies to both single and multiple reactions (reactors with single reactions are merely simple special cases). Presented by professor alan hall, university of huddersfield. Web 2.2 batch design equations. 1.4.1 ideal batch reactors 12 1.4.2 reactor. Web formulate the batch reactor design equations for any step in the operating protocol of a specified batch reactor system. The design is meant to use uranium and deliver anywhere. Reactions take place over space (the reactor volume), and the residence time of the. Web sequencing batch reactor (sbr) wastewater treatment systems. While the reaction is carried out, nothing else is put in or taken out until the reaction is. The design of any process where. Web while batch processes comfortably accommodate slow reactions over extended timeframes (minutes to days), flow reactors are typically designed for much. One involves the modelling of the material using a “mass balance”,. Web derivation of the design and performance equations for a batch reactor with first order kinetics. In most batch reactors, the longer a reactant is in the reactor, the more reactant is converted to product the reactant is exhausted. Given its volume v, and the initial internal concentration c0, the total mass will be m = v·c0. 1) no inflow or out flow f a0 = f a = 0. Reactor models are essential for reaction engineering analyses. Reactions take place over space (the reactor volume), and the residence time of the. Liquid phase or gas phase in a steel container) in terms of conversion. C r = k1(t ). Web this volume describes a unified methodology that applies to both single and multiple reactions (reactors with single reactions are merely simple special cases). We set q = 0 in the cstr material balance to obtain d (cjvr) dt = qfcjf+ rjvr; Noting that the elapsed time is the independent.

PPT Chapter 2 PowerPoint Presentation, free download ID4008361

Performance Equation of Batch reactor Design Equation of Batch

Ideal Batch Reactor Design Equation Chemical Chemical

Chemical Reaction Engineering Lecture 4 Design Equations for

Fed batch reactor design equation YouTube

PPT Mole balance for chemical reaction engineering (Design Equations

PPT PowerPoint Presentation, free download ID8861856

PPT Mole balance for chemical reaction engineering (Design Equations

PPT Reactor Design PowerPoint Presentation, free download ID2437746

PPT ERT 316 REACTION ENGINEERING CHAPTER 2 CONVERSION & REACTOR

A Reactor Model Is A Set Of Equations That Relates What Goes Into A Reactor To.

Constant Volume V = V 0 (E.g.

Web Derivation Of Batch Reactor Design Equations.

Web 2.2 Batch Design Equations.

Related Post: