Design Control Process

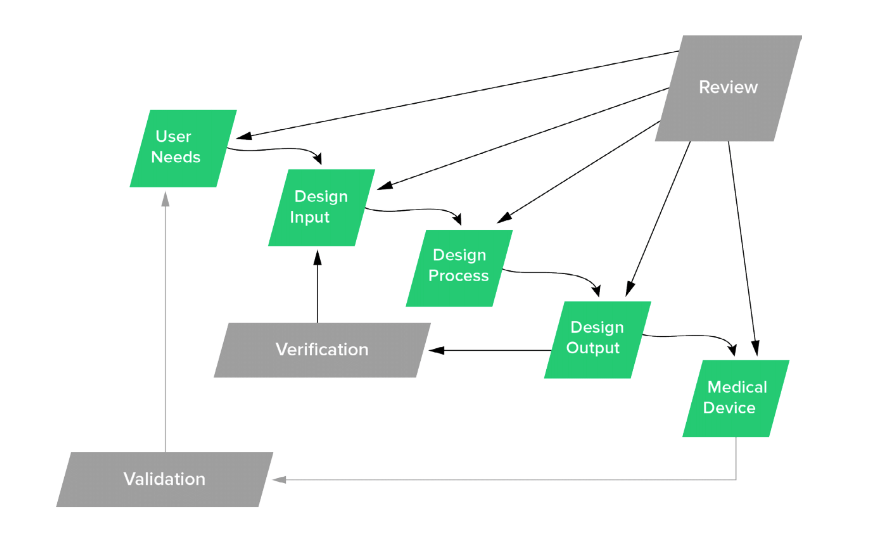

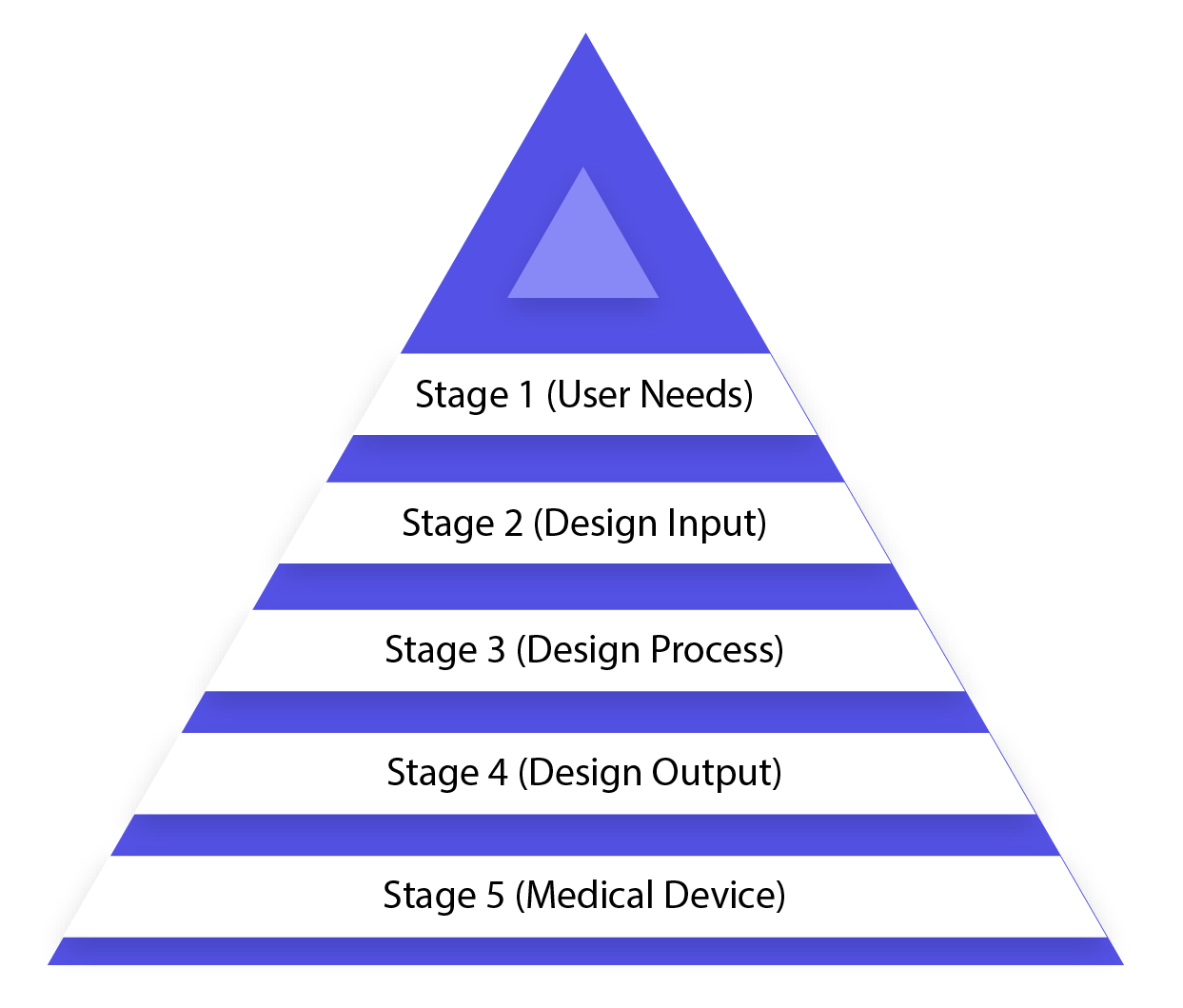

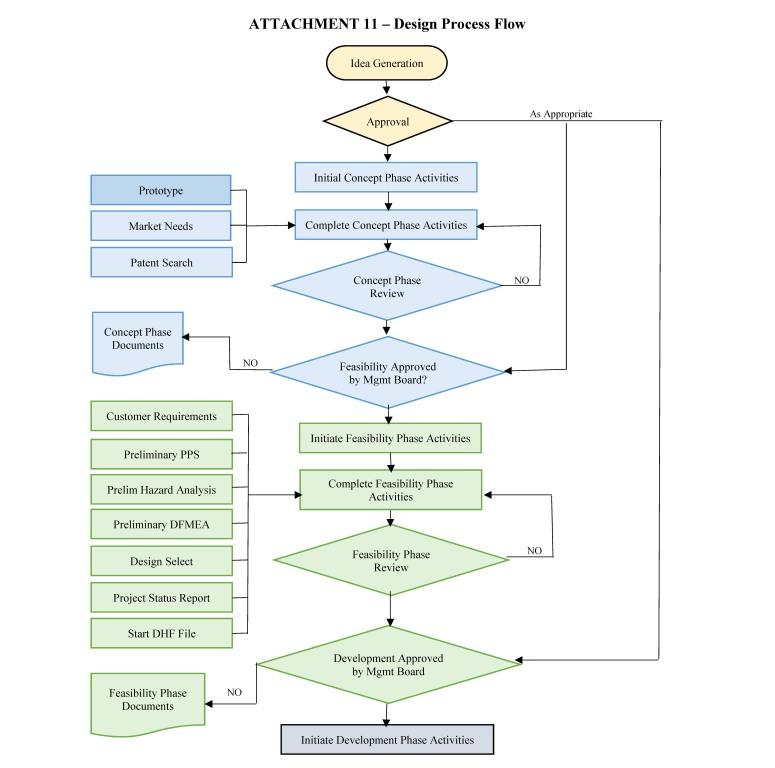

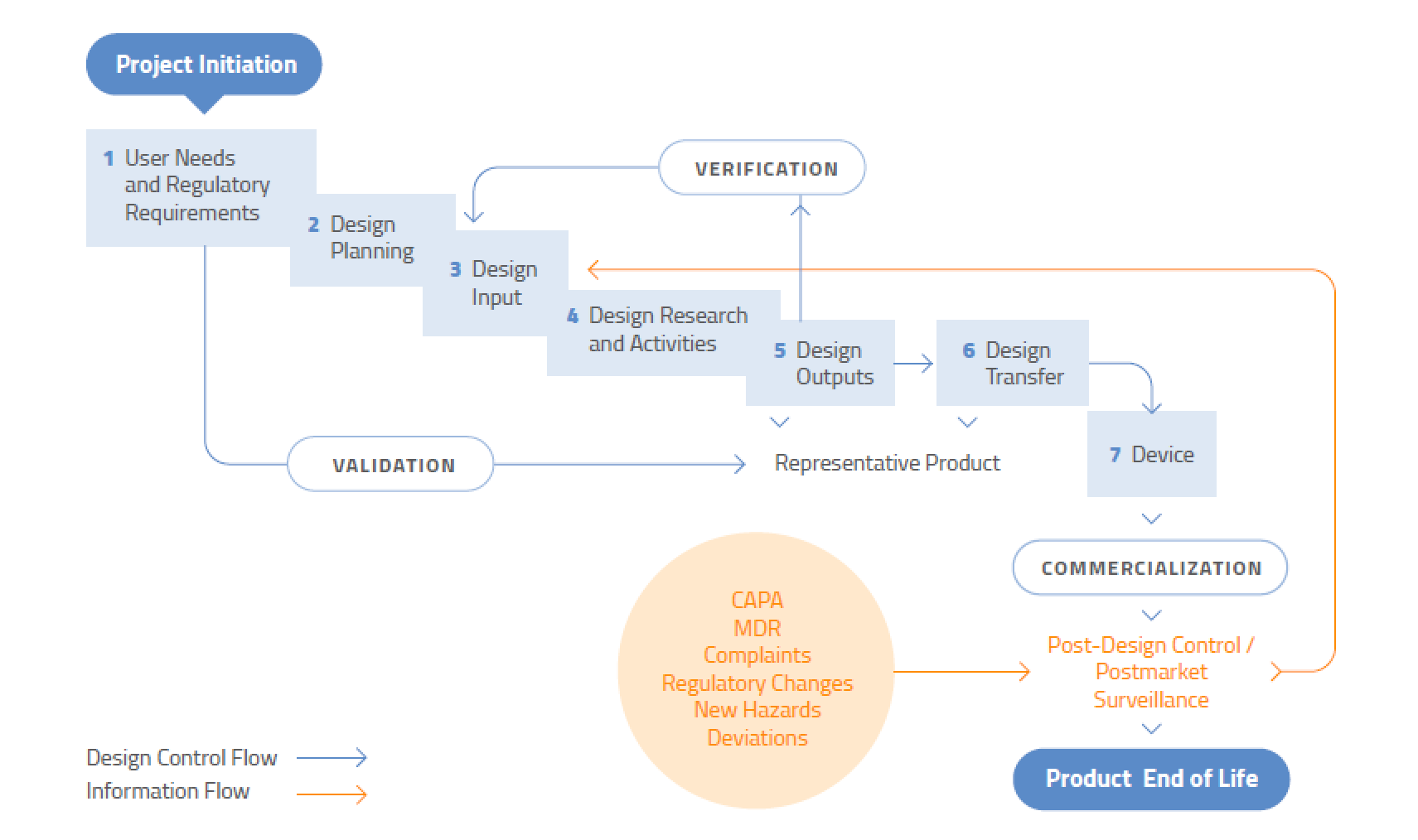

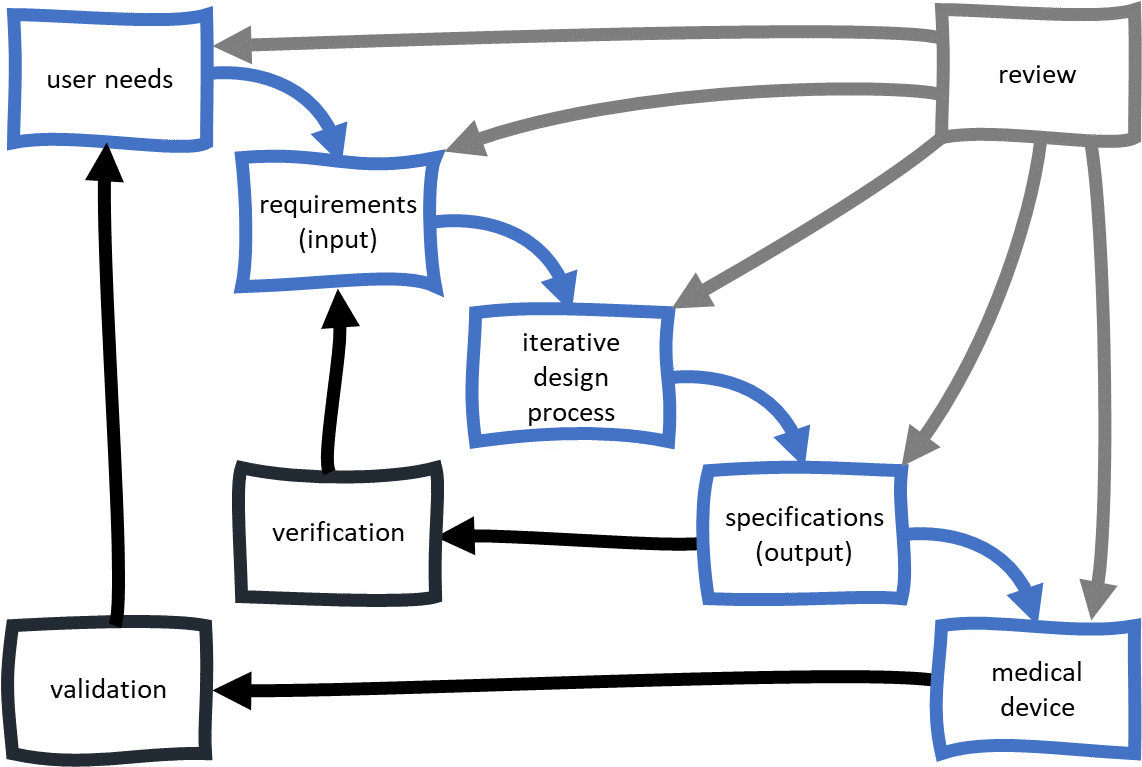

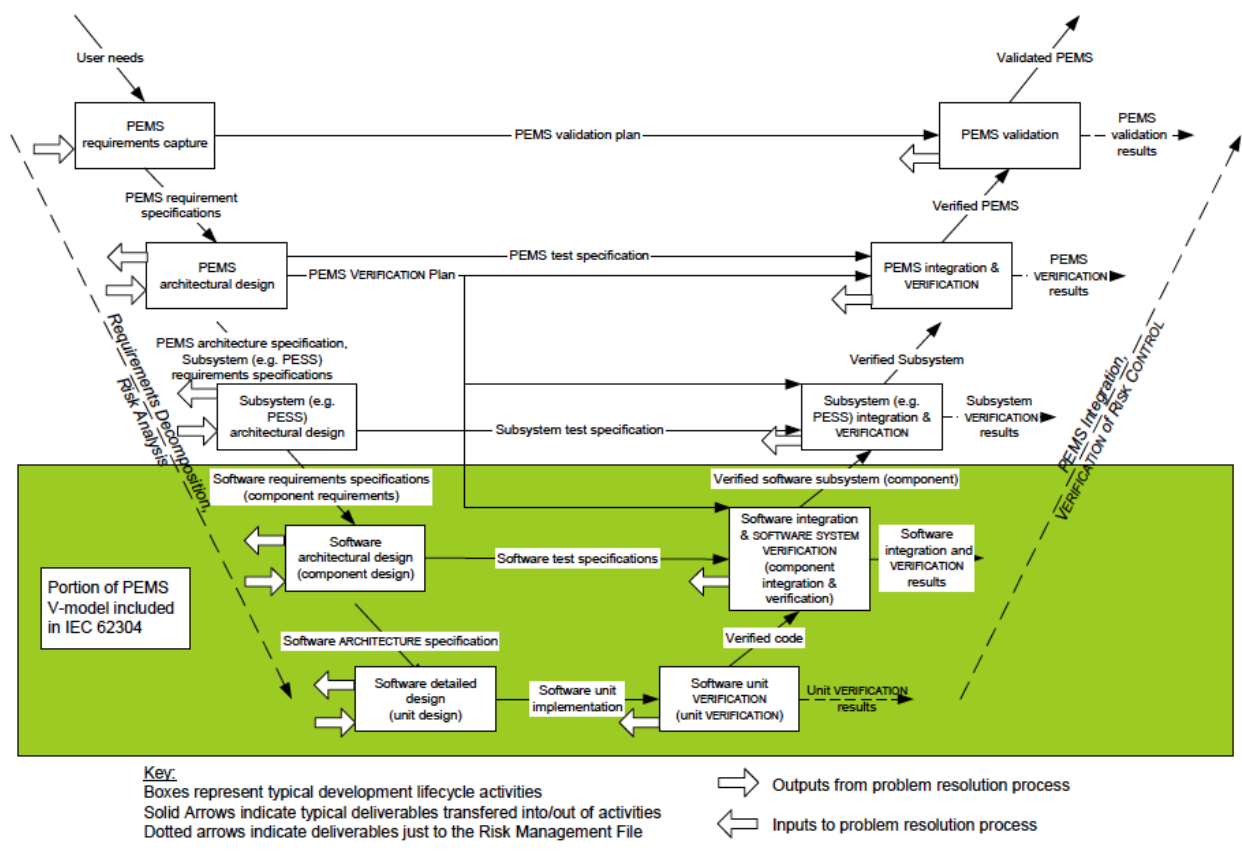

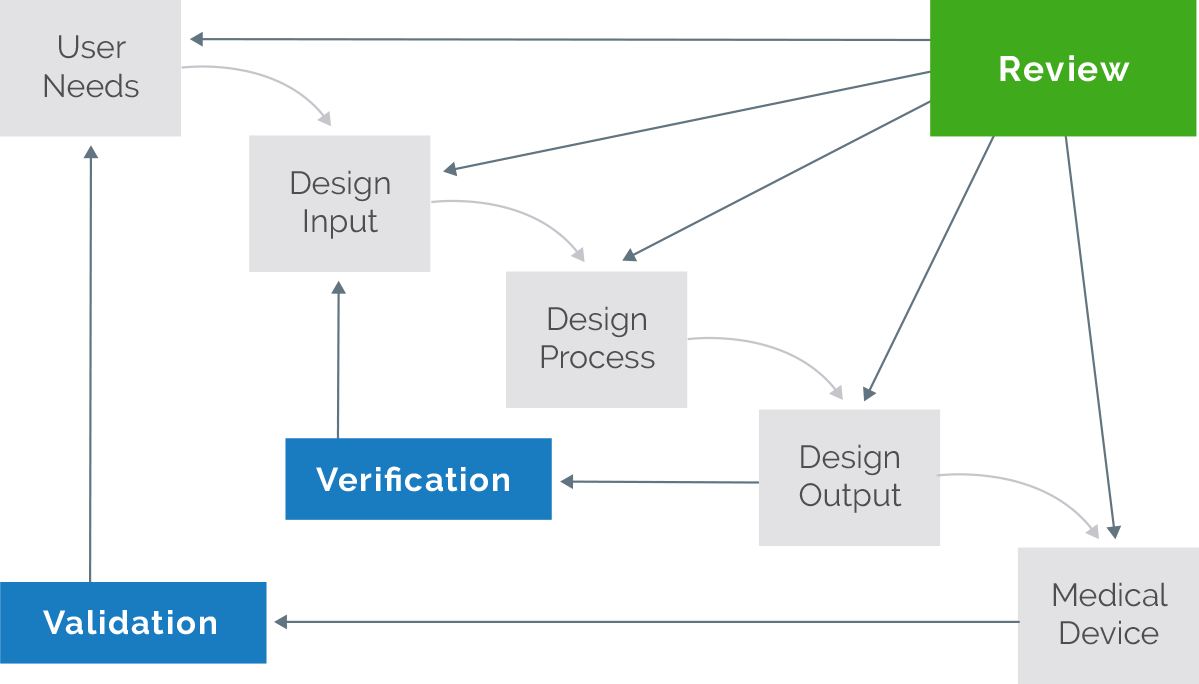

Design Control Process - This study is novel in its examination of. Web the design control process follows a set of practices and procedures that help medical product developers: (1) each manufacturer of any class iii or class ii device, and the class i devices listed in paragraph (a) (2) of this section, shall establish and. Web there are three types of workflows in sap process control: By implementing robust design controls, developers can: Pat not only enhances predictive maintenance (pdm) by detecting issues early and. Ensure each product meets all requirements. These workflows are usually associated with a schedule or frequency set up by a user using the planner application. Every product meets quality and safety requirements. Web the first step of implementing design controls is to create and design controls procedure. Web the design control process helps medical device manufacturers follow a set of practices and procedure to. Web design controls demonstrate our medical devices are safe, effective, and meet the indications for use. They are a systematic way to assure that medical devices meet user needs,. 8.1 ), the design process is a simple sequence of unidirectional phases or stages. Prevent recalls in the future. Web the design control process follows a set of practices and procedures that help medical product developers: With this guide, i plan to share valuable insights to explain what design controls are, how to address them, and how they benefit your medical device product development efforts. Every product meets quality and safety requirements. Web the. 8.1 ), the design process is a simple sequence of unidirectional phases or stages which provide assurance that each activity or phase has been completed in an acceptable manner before the next activity or phase can begin. Web design controls are a set of quality practices and procedures incorporated into the design and development process. Web looking at the introductory. Ensure each product meets all requirements. Web understand controls and evaluate design includes the following planning forms, each a component of internal control as identified by coso: Web § 820.30 design controls. This study is novel in its examination of. Web looking at the introductory statements of fda’s 21cfr820.30 regulation for design controls: The simple example shown in figure 1 illustrates the influence of design controls on a design process. Can improve and prevent future issues. Web design controls demonstrate our medical devices are safe, effective, and meet the indications for use. They are a systematic way to assure that medical devices meet user needs,. Web § 820.30 design controls. Clearly actionable data generated by process analytical technology (pat) makes this paradigm shift possible. Web the first step of implementing design controls is to create and design controls procedure. Web this documentation process is widely known as “design controls” and its purpose is to ensure that medical devices meet user needs, intended uses, and specified requirements. Web the design control. Numerical simulation of raw material effects in ironmaking blast furnaces. Web the design control process follows a set of practices and procedures that help medical product developers: Web design controls designates the application of a formal methodology to the conduct of product development activities. Web design controls play a crucial role in the development process by providing a systematic approach. The term design controls originates from the fda regulations, but is also mentioned in a modified form in iso 13485. Design controls apply to the design of the product and associated manufacturing processes. Web design controls are a set of quality practices and procedures incorporated into the design and development process. Web the design control process for medical devices breaks. Web in the waterfall approach (see fig. Web looking at the introductory statements of fda’s 21cfr820.30 regulation for design controls: Ensure each product meets all requirements. Fda design controls for medical device. Each manufacturer of any class iii or class ii device.shall establish and maintain procedures to control the design of the device in order to ensure that specified design. This study is novel in its examination of. Web design controls are a set of quality practices and procedures that are incorporated into the product design and development process to ensure that a device is appropriate for its intended use. With improved visibility, managers are empowered to more effectively direct the design process—that is, to recognize problems earlier, make corrections,. Understand controls and evaluate design includes each component of internal control as identified by coso, and provides a description of each control objective to indicate how the applicable control principle has been achieved: With this guide, i plan to share valuable insights to explain what design controls are, how to address them, and how they benefit your medical device product development efforts. The planner dictates when certain actions or processes run based on the defined parameters like timeframes, rules, or tasks. Prevent recalls in the future. Can improve and prevent future issues. Web the first step of implementing design controls is to create and design controls procedure. Pat not only enhances predictive maintenance (pdm) by detecting issues early and. Web therefore, design controls are a set of quality methods and procedures to control the process and ensure that the device meets the user needs, intended purpose and specific requirements. By implementing robust design controls, developers can: Web the design control process helps medical device manufacturers follow a set of practices and procedure to. Web the design control process for medical devices breaks down into 5 general sections which are typically outlined in a design matrix and/or other documentation. ( 1) each manufacturer of any class iii or class ii device, and the class i devices listed in paragraph (a) (2) of this section, shall establish and maintain procedures to control the design of the device in order to ensure that specified design requirements are met. Web the purpose of the design control subsystem is to control the design process to assure that devices meet user needs, intended uses, and specified requirements. Web design controls play a crucial role in the development process by providing a systematic approach to manage risks, design requirements, and verification and validation activities, and ensuring that devices are designed, developed, and manufactured in a consistent and controlled manner. It is often mandatory (by regulation) to implement such practice when designing and developing products. Web understand controls and evaluate design includes the following planning forms, each a component of internal control as identified by coso:

Design Control Process

Design Controls Need to Start With User Needs

Design Controls Digest 5 Phases of Design Controls You Need to Know

FDA Design Control The Ultimate Guide For Medical Device Companies

Design Control Procedure

Design Control and Risk Management Medical Device Approvals. Kathleen

Basics FDA Medical Design Controls Oriel STAT A MATRIX

Design Controls Process Design Talk

The Ultimate Guide To Design Controls For Medical Device Companies

Design Controls Definition Arena

Clearly Actionable Data Generated By Process Analytical Technology (Pat) Makes This Paradigm Shift Possible.

The Term Design Controls Originates From The Fda Regulations, But Is Also Mentioned In A Modified Form In Iso 13485.

Web Design Controls Designates The Application Of A Formal Methodology To The Conduct Of Product Development Activities.

Fda Design Controls For Medical Device.

Related Post: