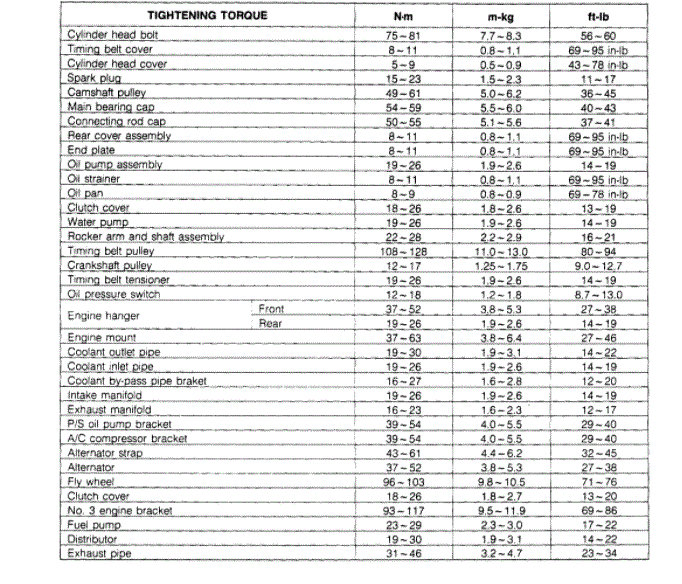

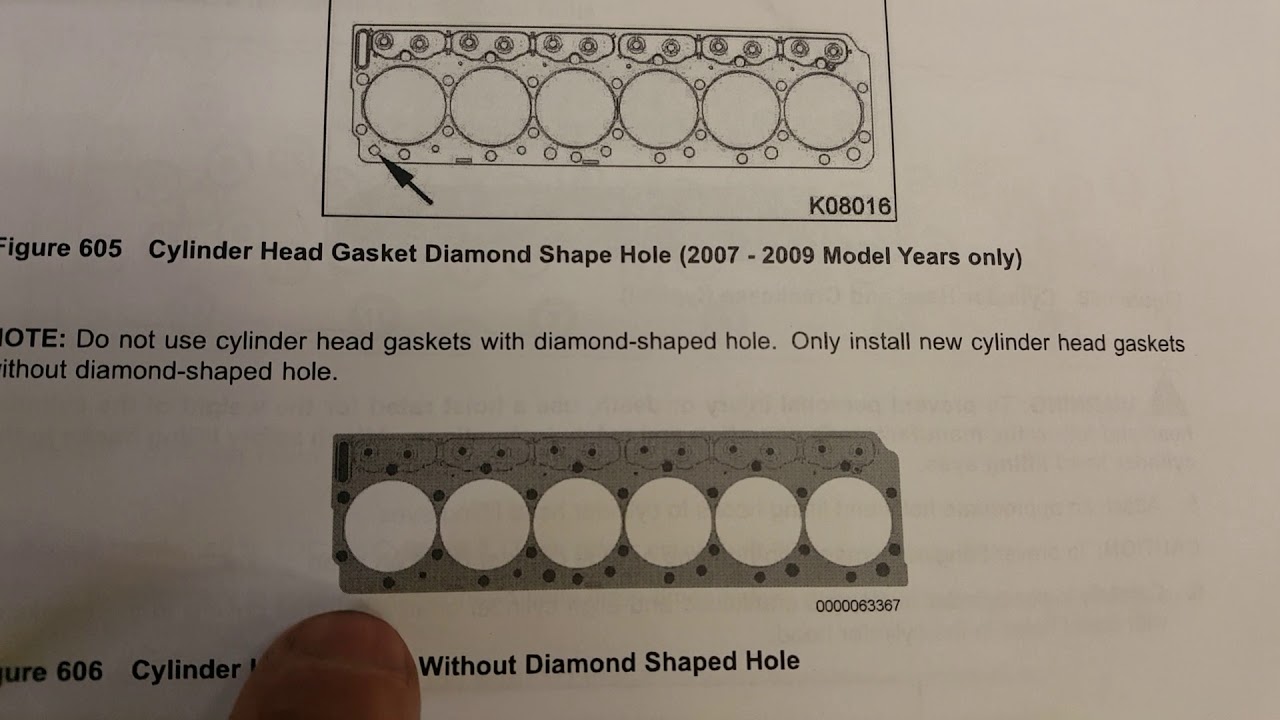

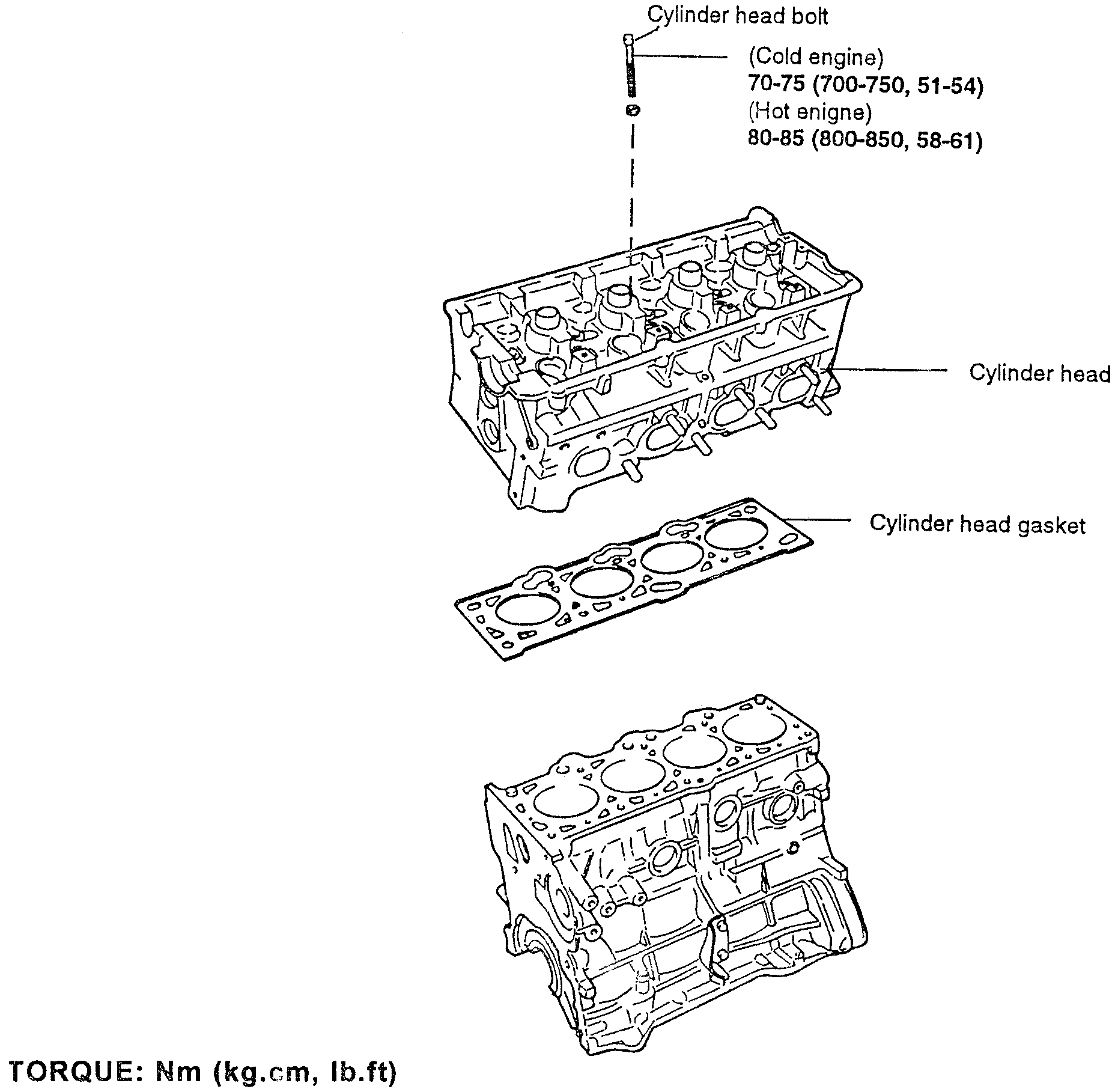

Cylinder Head Bolt Torque Chart

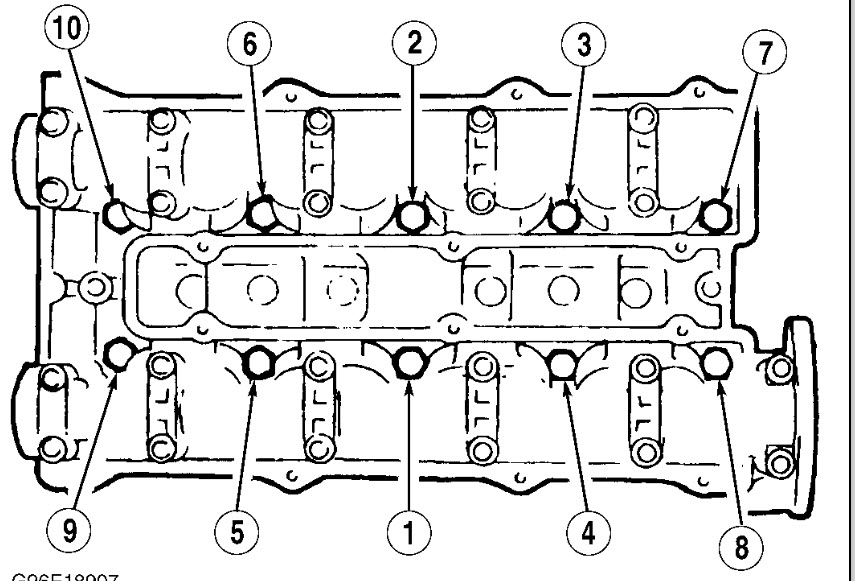

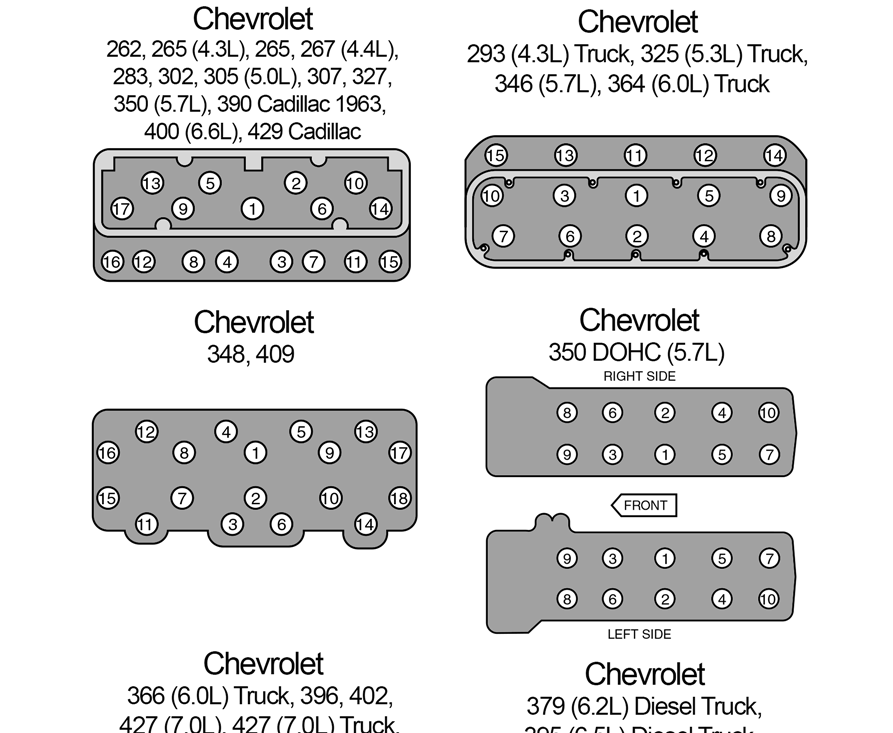

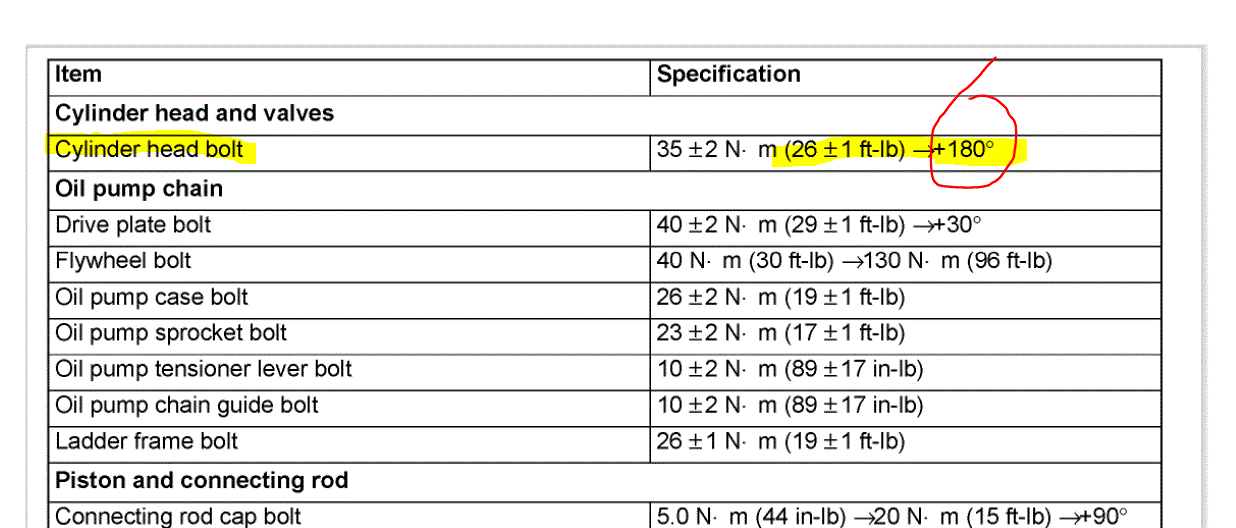

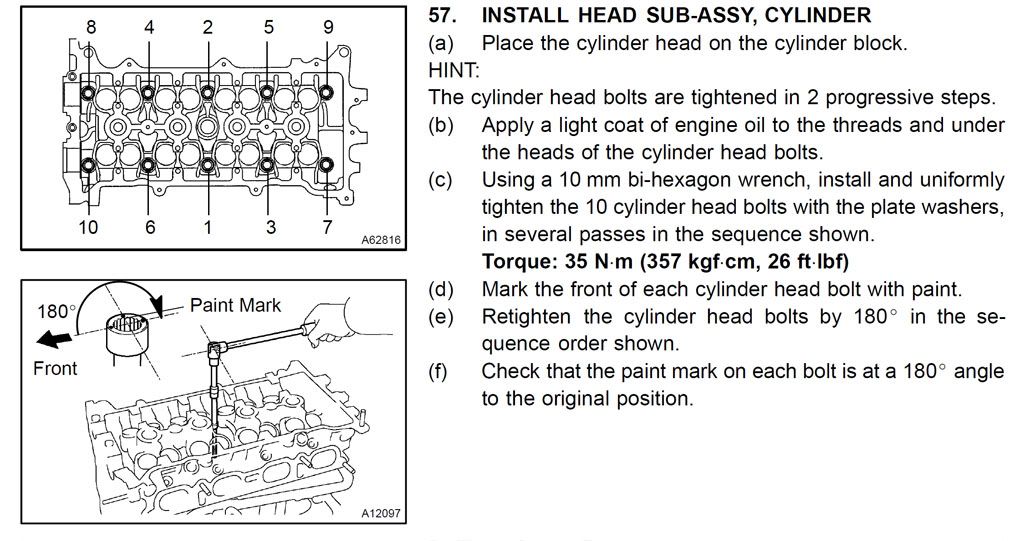

Cylinder Head Bolt Torque Chart - Do a first round hand tight, second round at. Bolts, nuts, plugs, fittings, and clamps. When following the torque sequences below, wait approximately 15 minutes between torque steps. Web head stud torque specifications. For each cylinder head, start with head bolt numbered one. Tighten the cylinder head bolts to 44 ft.lbs. Hereby, and in combination with the applied torquing method, the bolts have a strong effect on surface pressure quality. Always use a smooth pull for torque. Torque wrenches must be used properly in order to ensure that the correct torque is applied. First, here are few things to keep in mind: Damage to engine and cylinder heads can occur. Web ses 75% of the yield strength. Torque the m14 cylinder head bolts 1, 3, 5, 7, & 9 to 85 lbf/ft (115 nm) in the numerical sequence shown. • ensure that the joint surfaces are clean and free of oil. For help with installing cylinder heads and valves on your perkins,. The updated sequence and specification is as follows: Web to properly torque the cylinder head bolts on a 21 hp briggs and stratton engine, it is important to follow the manufacturer’s specifications. For help with installing cylinder heads and valves on your perkins, deutz, or other industrial engine, take a look at tech tip #10: Different styles depending on heads. For each cylinder head, start with head bolt numbered one. 50% torque (ok, let's just say 35 ft/lbs) then final round at specs. • ensure that the joint surfaces are clean and free of oil. Torque wrenches must be used properly in order to ensure that the correct torque is applied. Web cylinder head bolts • step 1: Be sure to follow this procedure for best results. • ensure that the joint surfaces are clean and free of oil. Do a first round hand tight, second round at. Web cylinder head bolt torque specifications. Web we have listed below torque values by size of bolts for bolts without lubricant applied. Hereby, and in combination with the applied torquing method, the bolts have a strong effect on surface pressure quality. Use a reduced torque value if the bolt has been lubricated. When following the torque sequences below, wait approximately 15 minutes between torque steps. First, here are few things to keep in mind: The updated sequence and specification is as follows: Web we have listed below torque values by size of bolts for bolts without lubricant applied. Use a reduced torque value if the bolt has been lubricated. Web to properly torque the cylinder head bolts on a 21 hp briggs and stratton engine, it is important to follow the manufacturer’s specifications. Web torque settings for the following: • ensure that. Some people do only 1 or 2 steps to reach the final torque. Be sure to use a torque wrench that has the proper range. Bolts, nuts, plugs, fittings, and clamps. Hereby, and in combination with the applied torquing method, the bolts have a strong effect on surface pressure quality. Torque values and valve settings and tech tip #30: Bolts, nuts, plugs, fittings, and clamps. 58 y (43lbft) engine oil cooler hose connector. The prevailing torque lock nut clamp loads are listed at 75% of the proof loads specified for the appropriate grade bolt: Web head stud torque specifications. For help with installing cylinder heads and valves on your perkins, deutz, or other industrial engine, take a look at. A crucial component of engine building is setting the torque on head bolts. Web search for your part by vehicle year, make and model. Torque refers to how tight a bolt should be. The prevailing torque lock nut clamp loads are listed at 75% of the proof loads specified for the appropriate grade bolt: I would also add make sure. Web to properly torque the cylinder head bolts on a 21 hp briggs and stratton engine, it is important to follow the manufacturer’s specifications. Different styles depending on heads and stud diameters. Lbs.) and newton meters (nm) for the cylinder head bolts: Always use a smooth pull for torque. A crucial component of engine building is setting the torque on. Torque the m14 cylinder head bolts 1, 3, 5, 7, & 9 to 85 lbf/ft (115 nm) in the numerical sequence shown. Hereby, and in combination with the applied torquing method, the bolts have a strong effect on surface pressure quality. Web small block chevy head bolt torque specifications. Torque refers to how tight a bolt should be. Different styles depending on heads and stud diameters. Web torque settings for the following: For help with installing cylinder heads and valves on your perkins, deutz, or other industrial engine, take a look at tech tip #10: Lbs.) and newton meters (nm) for the cylinder head bolts: Web today, we’ll look at cylinder head torque sequences for general motors l8 and v8 engines. • torque the bolts using the recommended sequence. First, here are few things to keep in mind: Web search for your part by vehicle year, make and model. When torquing the cylinder head bolts, the bolt force generates a. Damage to engine and cylinder heads can occur. Torque wrenches must be used properly in order to ensure that the correct torque is applied. Web • blind bolt holes should be dry at the bottom.

Mack MP8 Manuals, Engine Specs, Bolt Torques

Cylinder Head Bolt Torque Chart

Cylinder Head Bolt Torque Chart

Cylinder Head Bolt Torque Chart

Cylinder Head Bolt Torque Specifications Manual

Cylinder Head Bolt Torque Chart

Cylinder Head Bolt Torque Chart

Torque Setting for Cylinder Head Specs I Need to Know Torque

MaxxForce DT Cylinder Head Torque Specs YouTube

Cylinder Head Bolt Torque Chart

• Properly Torque For Best Results.

This Allows Time For The Studs To Stretch And Settle Completely Before The Next Torque Application.

When Following The Torque Sequences Below, Wait Approximately 15 Minutes Between Torque Steps.

The Updated Sequence And Specification Is As Follows:

Related Post: