Cpk Chart

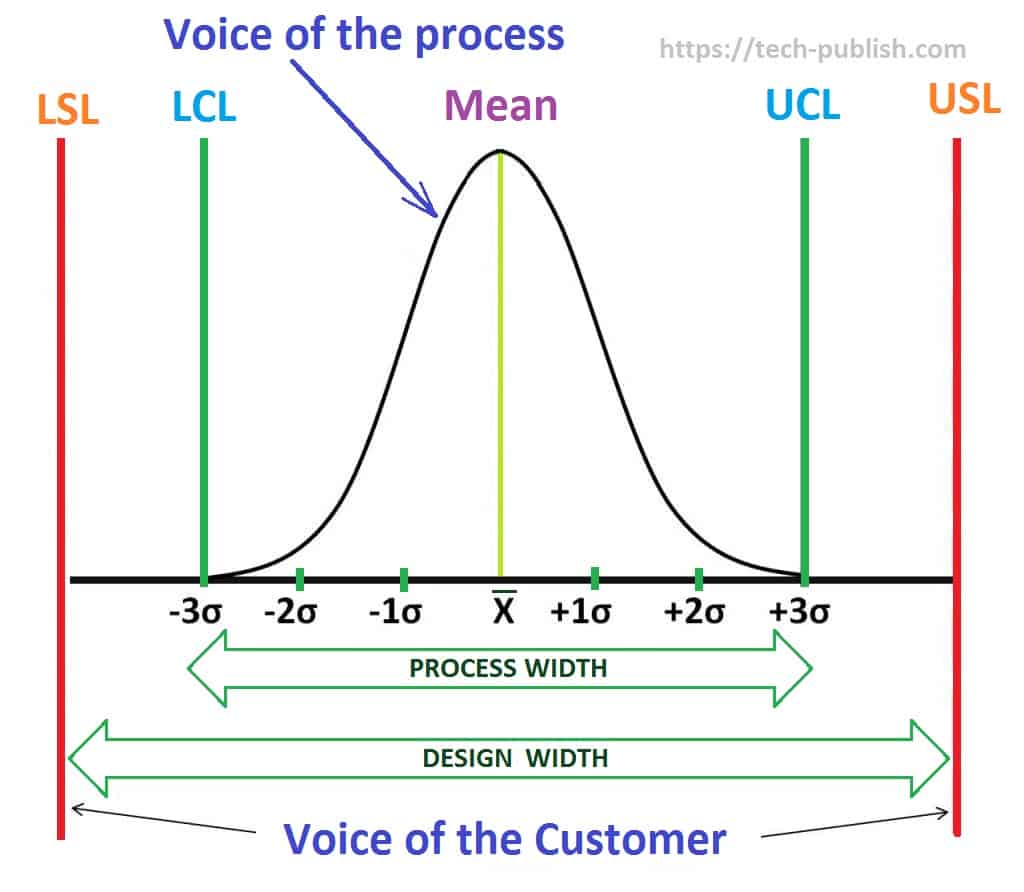

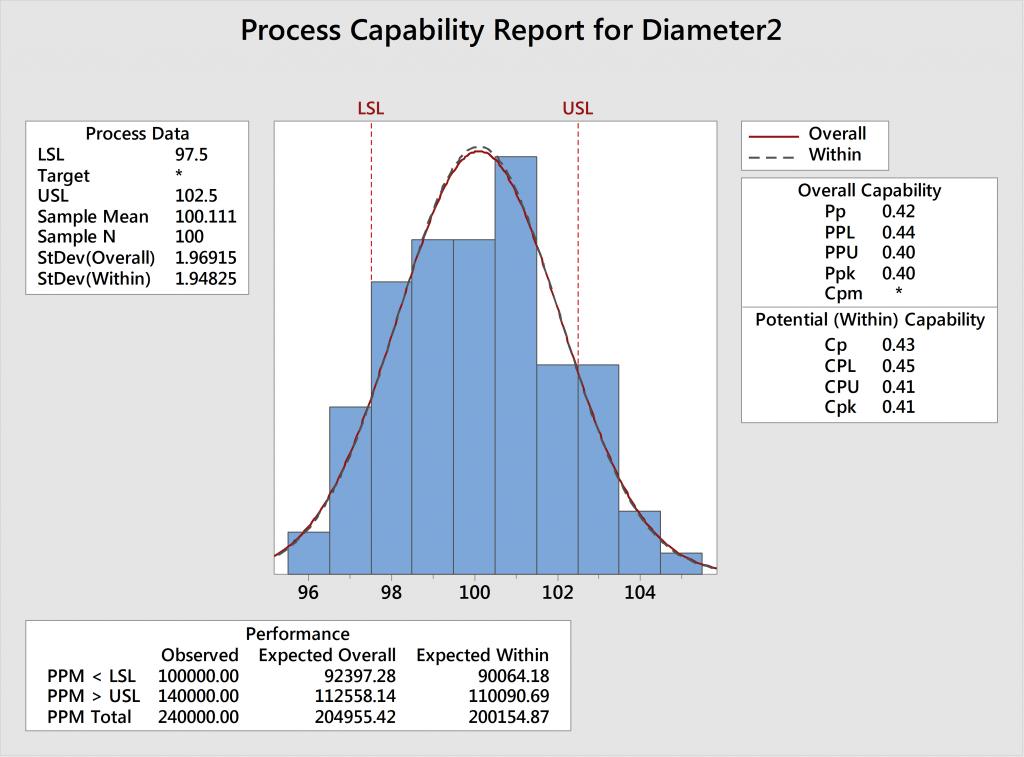

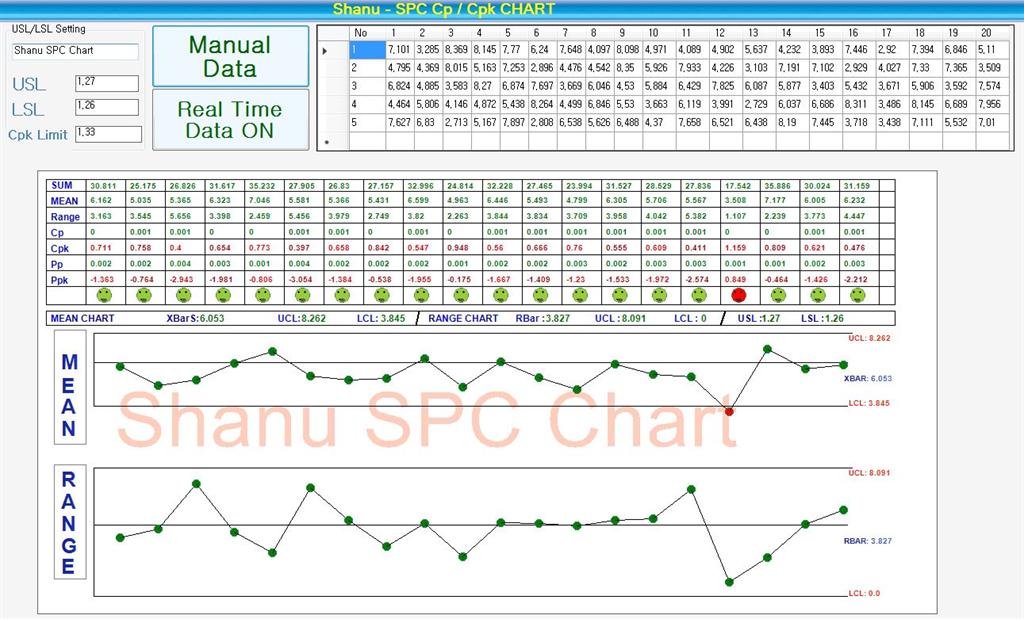

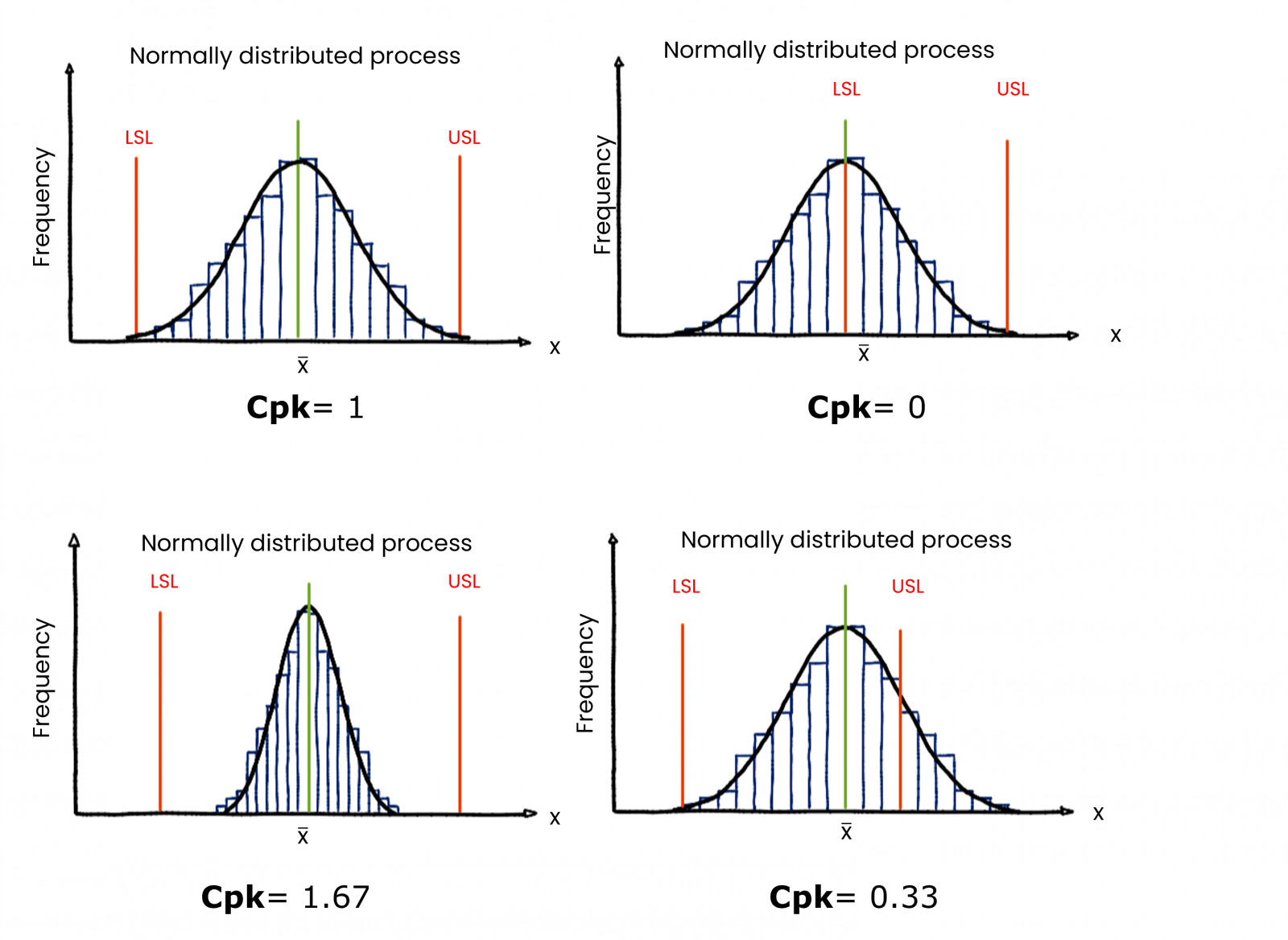

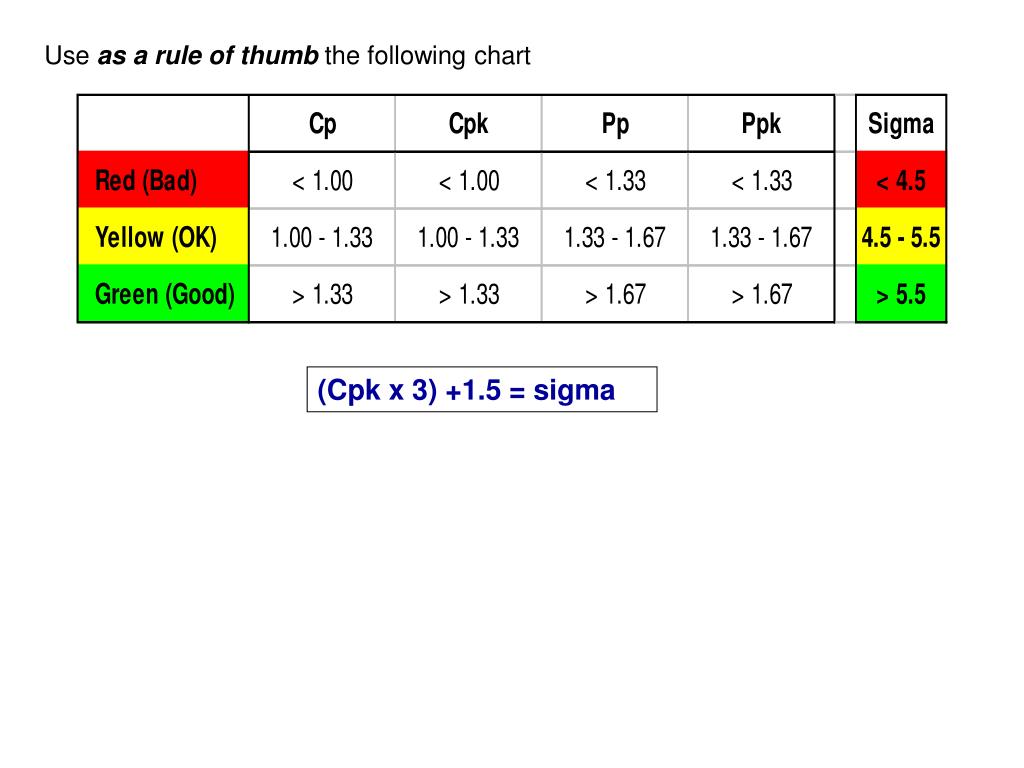

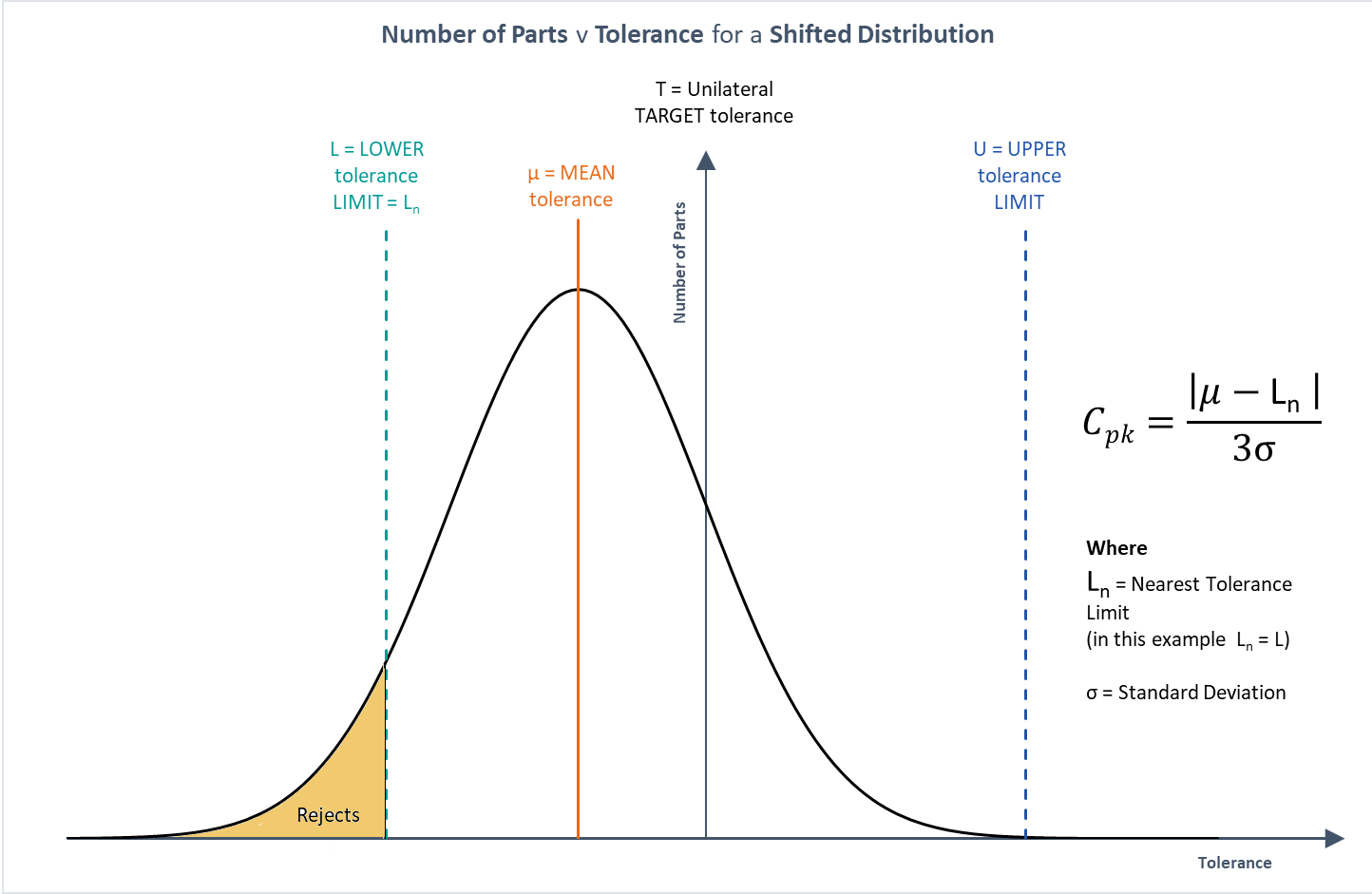

Cpk Chart - Web process capability uses the process sigma value determined from either the moving range, range, or sigma control charts. This is the capability index that accounts for the centering of the process and is defined as the minimum of cpk upper and cpk lower. Web a process capability study uses data from a sample to predict the ability of a manufacturing process to produce parts conforming to specifications. Cpk is one commonly applied metric to measure how a process (aka voice of the process vop) is performing relative to the customer specifications. Web assess process capability with cpk chart. Web process capability index (cpk) is a statistical tool, to measure the ability of a process to produce output within customer’s specification limits. Web improve cpk by moving the upper and lower limits closer to the mean. Don't understand cpk confidence intervals? Web this spreadsheet calculates the process capability index and process performance index given process sample and performance specification input. Web cpk measures how close you are to the optimal area of your process and how consistent your process is. Web cpk measures how close you are to the optimal area of your process and how consistent your process is. The larger the cpk index of your process is, the less likely it is that any unit manufactured in your process will be outside the defined limits. Cpk is a measure of process performance capability. Our calculator generates accurate capability. Cp and cpk consider the deviation mean within rational subgroups, while pp and ppk set. Web what are process capability indices? Web improve cpk by moving the upper and lower limits closer to the mean. The cpk calculator will evaluate and display the process capability index of those values. Web assess process capability with cpk chart. Cpk is a measure of process capability that helps you identify and correct defects. Web by decoding the significance and interplay of cp, cpk, pp, and ppk, businesses can elevate their quality standards, reduce waste, and enhance customer satisfaction. This index is crucial for understanding both the variability and the centrality of the process. The ability of an engineering process. This is the capability index that accounts for the centering of the process and is defined as the minimum of cpk upper and cpk lower. Don't understand cpk confidence intervals? Web cpk is a common measure used in process capability analysis that allows you to know how well your process is meeting your customers’ expectations and specifications. Web cpk is. Cpk indicates shifting or closeness of process average from the target or mean value. Web the process capability cp and cpk index calculator is a useful tool for assessing the performance and stability of business processes. Web the process capability index is a statistical measure used to quantify how capable a process is of producing output within specification limits. Cpk. In simple words, it measures producer’s capability to produce a product within customer’s tolerance range. Web what are process capability indices? Web cpk is a common measure used in process capability analysis that allows you to know how well your process is meeting your customers’ expectations and specifications. Web process capability index (cpk) is a statistical tool, to measure the. Enter the upper specification limit, lower specification limit, standard deviation, and process mean into the calculator. Cpk is a measure of process capability that helps you identify and correct defects. This post aims to demystify these vital indices, offering a comprehensive insight into their relevance and application in today’s manufacturing landscape. Web cpk is a short term process index that. Web cpk is a short term process index that numerically describes the within subgroup or potential capability (ppk is a long term indicator) of a process assuming it was analyzed and stays in control. Pp and ppk are used for process performance. This index is crucial for understanding both the variability and the centrality of the process. How it theoretically. Cp and cpk consider the deviation mean within rational subgroups, while pp and ppk set. Learn to gauge meeting specifications, assuming control and normal distribution. Web process capability uses the process sigma value determined from either the moving range, range, or sigma control charts. It involves understanding the capability of the process to estimate product output by analyzing the distribution. Enter the upper specification limit, lower specification limit, standard deviation, and process mean into the calculator. In simple words, it measures producer’s capability to produce a product within customer’s tolerance range. Web improve cpk by moving the upper and lower limits closer to the mean. This article will explain how cpk is calculated and interpreted. Cpk is a measure of. This prediction enables us to qualify a new manufacturing process as being fit for use in production. Web assess process capability with cpk chart. This index is crucial for understanding both the variability and the centrality of the process. Web cpk is a short term process index that numerically describes the within subgroup or potential capability (ppk is a long term indicator) of a process assuming it was analyzed and stays in control. Don't understand cpk confidence intervals? Enter the upper specification limit, lower specification limit, standard deviation, and process mean into the calculator. Learn how the number of samples and sample size impacts cp and cpk. This article will explain how cpk is calculated and interpreted. This post aims to demystify these vital indices, offering a comprehensive insight into their relevance and application in today’s manufacturing landscape. Pp and ppk are used for process performance. Web this spreadsheet calculates the process capability index and process performance index given process sample and performance specification input. Web what are process capability indices? In simple words, it measures producer’s capability to produce a product within customer’s tolerance range. Cpk is a measure of process capability that helps you identify and correct defects. How it theoretically could be behaving? It involves understanding the capability of the process to estimate product output by analyzing the distribution of data, control chart analysis, and production conditions.

Process Capability Indices Cp Cpk Techpublish

.png)

What is Critical Process Capability Cpk? Examples

How to Improve Cpk

Cpk Chart In Excel A Visual Reference of Charts Chart Master

SPC CP and Cpk Chart in C Windows Forms

What is Critical Process Capability Cpk? Examples

How To Make A Process Capability Calculation Cp Cpk vrogue.co

PPT Process Capability PowerPoint Presentation, free download ID

Cp and Cpk Process Capability Analysis Example & Interpretations

Cpk, Ppk, PPM and Tolcap Why and how Tolcap predicts Cpk

Cpk, Or The Corrected Process Capability Index, Improves The Cp Measure By Incorporating The Mean’s Position Relative To The Specification Limits.

Web The Process Capability Index, Or Process Capability Ratio, Is A Statistical Measure Of Process Capability:

Web Improve Cpk By Moving The Upper And Lower Limits Closer To The Mean.

Web Cpk Is A Common Measure Used In Process Capability Analysis That Allows You To Know How Well Your Process Is Meeting Your Customers’ Expectations And Specifications.

Related Post: