Countersink Dimensions Chart

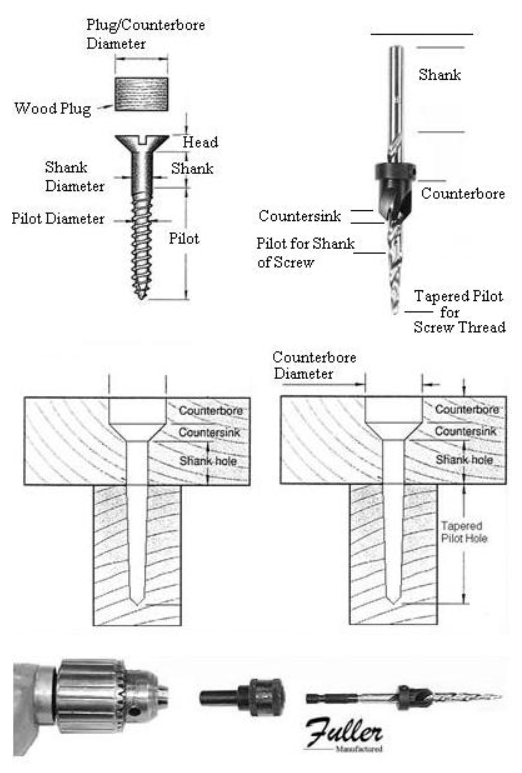

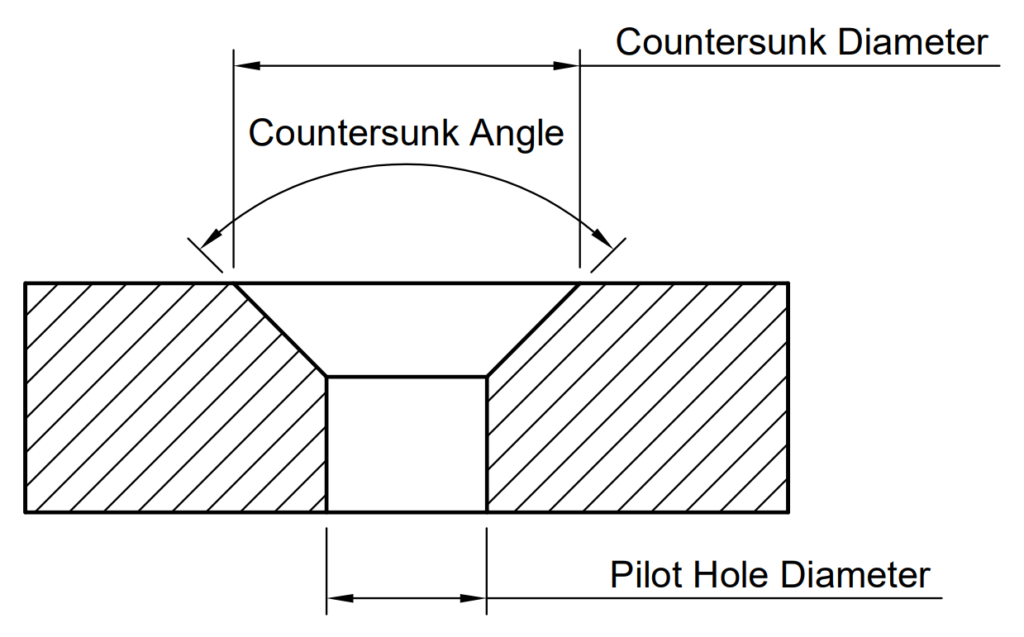

Countersink Dimensions Chart - This short post will give you the exact dimensions you need for your countersunk screws. This short post will give you the exact dimensions you need for your countersunk screws. Web how to dimension a countersink. Just as with counterbore and spotface hole features, dimensions for a countersink are also listed directly below the dimension of the smaller coaxial hole. Understand the types and use of countersink drill bit, countersink vs counterbore hole and check out the countersink size chart for. Web unsure on what size countersunk hole to use for your ansi inch socket flat head fasteners? Web choose from a variety of standard countersink options, which can either be formed or machined into sheet part parts. It is considered good practice to countersink or break the edges of holes that are smaller than f (max.) in parts having a hardness which approaches, equals, or exceeds the screw hardness. Web this chart shows the dimensions of counterbore and countersink holes for different screw sizes, in metric units (millimeters). Web unsure on what size countersunk hole to use for your ansi inch 82 degree machine fasteners? Countersink diameter (this should be larger than the diameter of the screw head) countersink angle (this is a standard per the type of fastener that is being used, more on this below) Web choose from a variety of standard countersink options, which can either be formed or machined into sheet part parts. It is considered good practice to countersink or. In the above example, the part has a 0.5 thru hole and a countersink with a diameter of 0.7 and an included angle of 82°. Just as with counterbore and spotface hole features, dimensions for a countersink are also listed directly below the dimension of the smaller coaxial hole. Web the graphic above shows how to fully define a countersink. Learn more about this type of engineering hole and its dimensions. It is considered good practice to countersink or break the edges of holes that are smaller than f (max.) in parts having a hardness which approaches, equals, or exceeds the screw hardness. In the above example, the part has a 0.5 thru hole and a countersink with a diameter. Web the graphic above shows how to fully define a countersink — the 3 dimensions needed to properly define a countersink are: Web how to dimension a countersink. Web unsure on what size countersunk hole to use for your ansi inch 82 degree machine fasteners? Understand the types and use of countersink drill bit, countersink vs counterbore hole and check. Countersink diameter (this should be larger than the diameter of the screw head) countersink angle (this is a standard per the type of fastener that is being used, more on this below) Just as with counterbore and spotface hole features, dimensions for a countersink are also listed directly below the dimension of the smaller coaxial hole. Web when determining what. Countersink diameter (this should be larger than the diameter of the screw head) countersink angle (this is a standard per the type of fastener that is being used, more on this below) Machined countersinks are created with a drill press and formed countersinks are made with punch press tooling—the best option depends on your project and part geometry. Web how. It is considered good practice to countersink or break the edges of holes that are smaller than f (max.) in parts having a hardness which approaches, equals, or exceeds the screw hardness. Learn more about this type of engineering hole and its dimensions. Web this chart shows the dimensions of counterbore and countersink holes for different screw sizes, in metric. Web unsure on what size countersunk hole to use for your ansi inch socket flat head fasteners? Web unsure on what size countersunk hole to use for your ansi metric socket flat head fasteners? Understand the types and use of countersink drill bit, countersink vs counterbore hole and check out the countersink size chart for. Web this chart shows the. Web unsure on what size countersunk hole to use for your ansi inch 82 degree machine fasteners? Just as with counterbore and spotface hole features, dimensions for a countersink are also listed directly below the dimension of the smaller coaxial hole. Understand the types and use of countersink drill bit, countersink vs counterbore hole and check out the countersink size. This short post will give you the exact dimensions you need for your countersunk screws. Web unsure on what size countersunk hole to use for your ansi inch socket flat head fasteners? Just as with counterbore and spotface hole features, dimensions for a countersink are also listed directly below the dimension of the smaller coaxial hole. This short post will. Web how to dimension a countersink. Web the graphic above shows how to fully define a countersink — the 3 dimensions needed to properly define a countersink are: Learn more about this type of engineering hole and its dimensions. Just as with counterbore and spotface hole features, dimensions for a countersink are also listed directly below the dimension of the smaller coaxial hole. A countersink is dimensioned by specifying the diameter of the countersink where it meets the surface and the included angle. Web unsure on what size countersunk hole to use for your ansi inch socket flat head fasteners? Understand the types and use of countersink drill bit, countersink vs counterbore hole and check out the countersink size chart for. Web unsure on what size countersunk hole to use for your ansi metric socket flat head fasteners? In the above example, the part has a 0.5 thru hole and a countersink with a diameter of 0.7 and an included angle of 82°. Countersink diameter (this should be larger than the diameter of the screw head) countersink angle (this is a standard per the type of fastener that is being used, more on this below) Web this chart shows the dimensions of counterbore and countersink holes for different screw sizes, in metric units (millimeters). Web choose from a variety of standard countersink options, which can either be formed or machined into sheet part parts. Machined countersinks are created with a drill press and formed countersinks are made with punch press tooling—the best option depends on your project and part geometry. It is considered good practice to countersink or break the edges of holes that are smaller than f (max.) in parts having a hardness which approaches, equals, or exceeds the screw hardness. Web unsure on what size countersunk hole to use for your ansi inch 82 degree machine fasteners?

Countersunk Hole Dimensions Chart Pdf

Standard Countersink Dimensions Chart

Metric Countersunk Hole Dimensions Chart A Pictures Of Hole 2018

Countersink drill size chart Jamestown Distributors

Countersink 90° d1=10,4mm d2=6mm DamenCNC B.V.

Standard Countersink Dimensions Chart

Standard Countersink Dimensions Chart

What Size Countersink Chart

Countersunk Hole Size for Machine Screw (ANSI Metric)

Counterbore and Countersink Dimensions Chart

Web When Determining What Are Countersink Holes, It Is Necessary To Have An Understanding Of How To Drill Them, Their Applications, Uses, And Size Charts.

This Short Post Will Give You The Exact Dimensions You Need For Your Countersunk Screws.

This Short Post Will Give You The Exact Dimensions You Need For Your Countersunk Screws.

This Short Post Will Give You The Exact Dimensions You Need For Your Countersunk Screws.

Related Post: