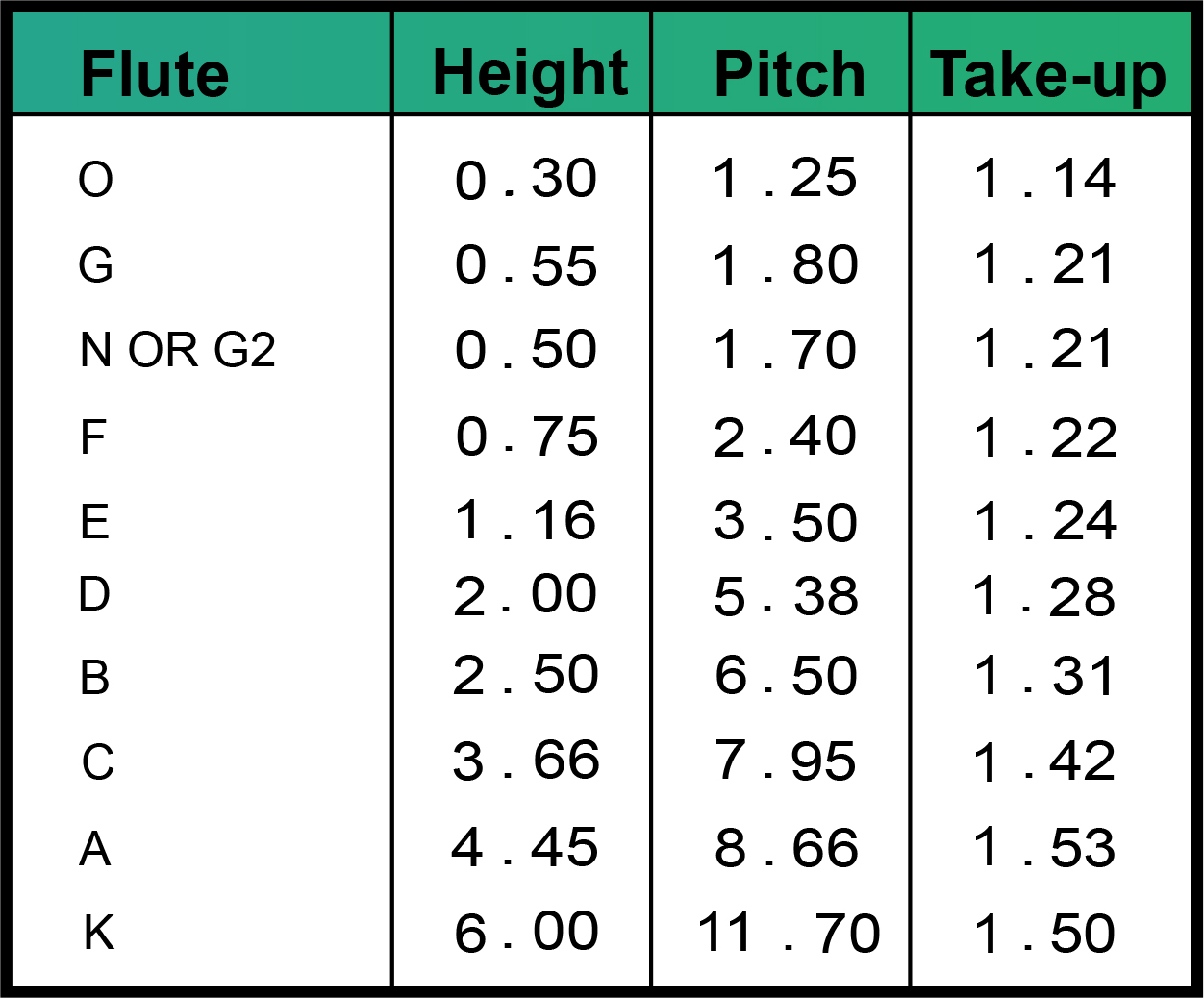

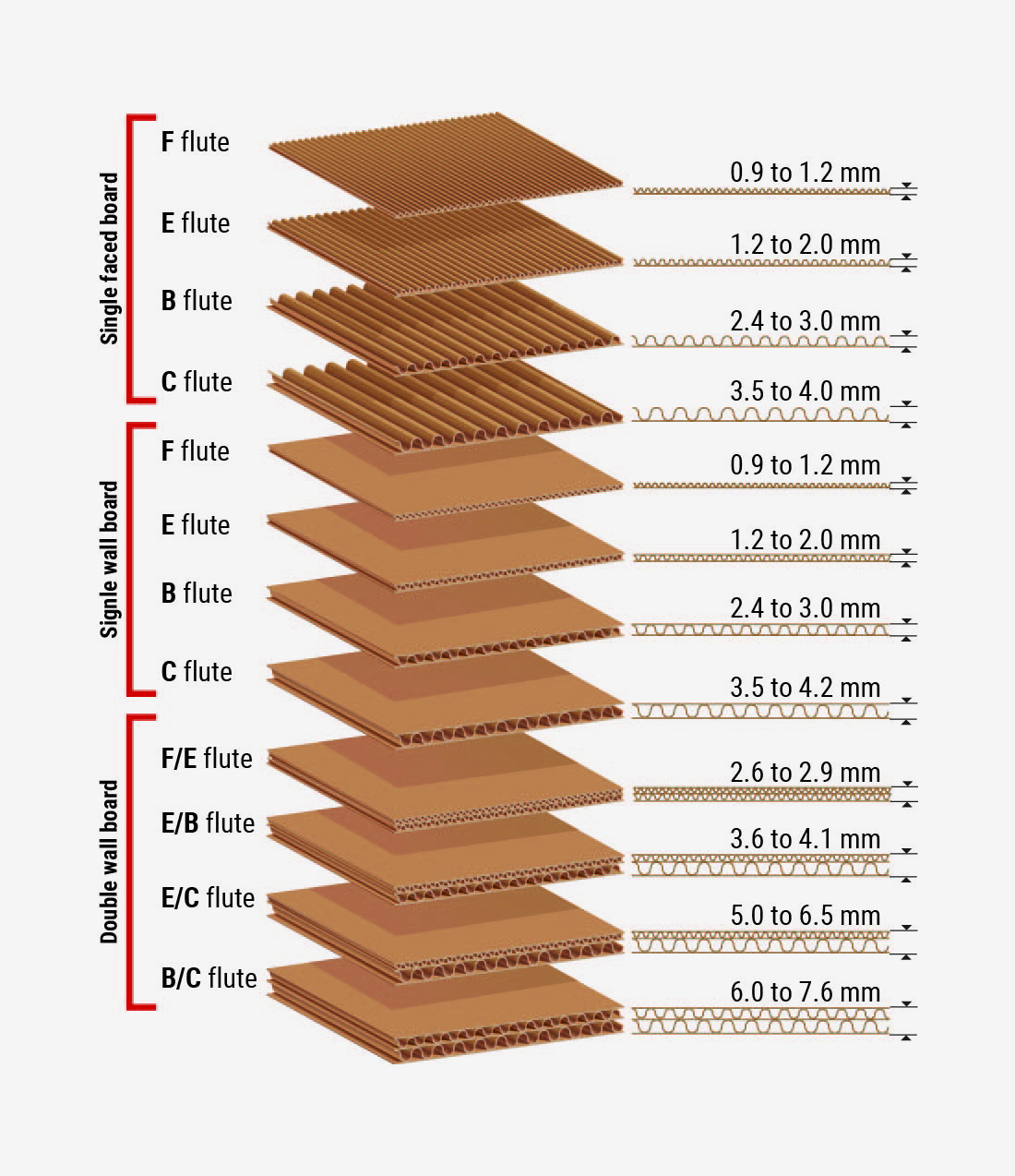

Corrugated Cardboard Flute Chart

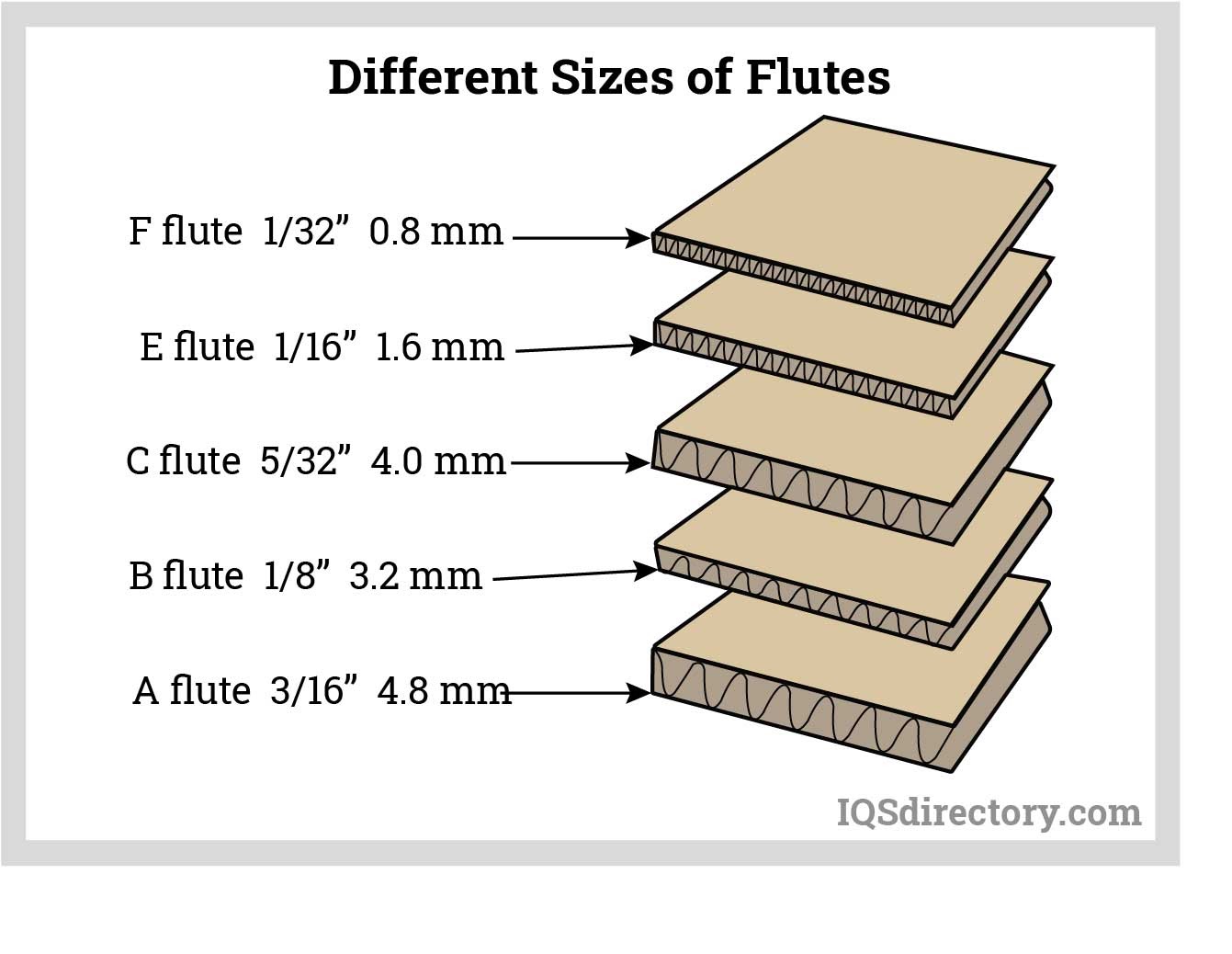

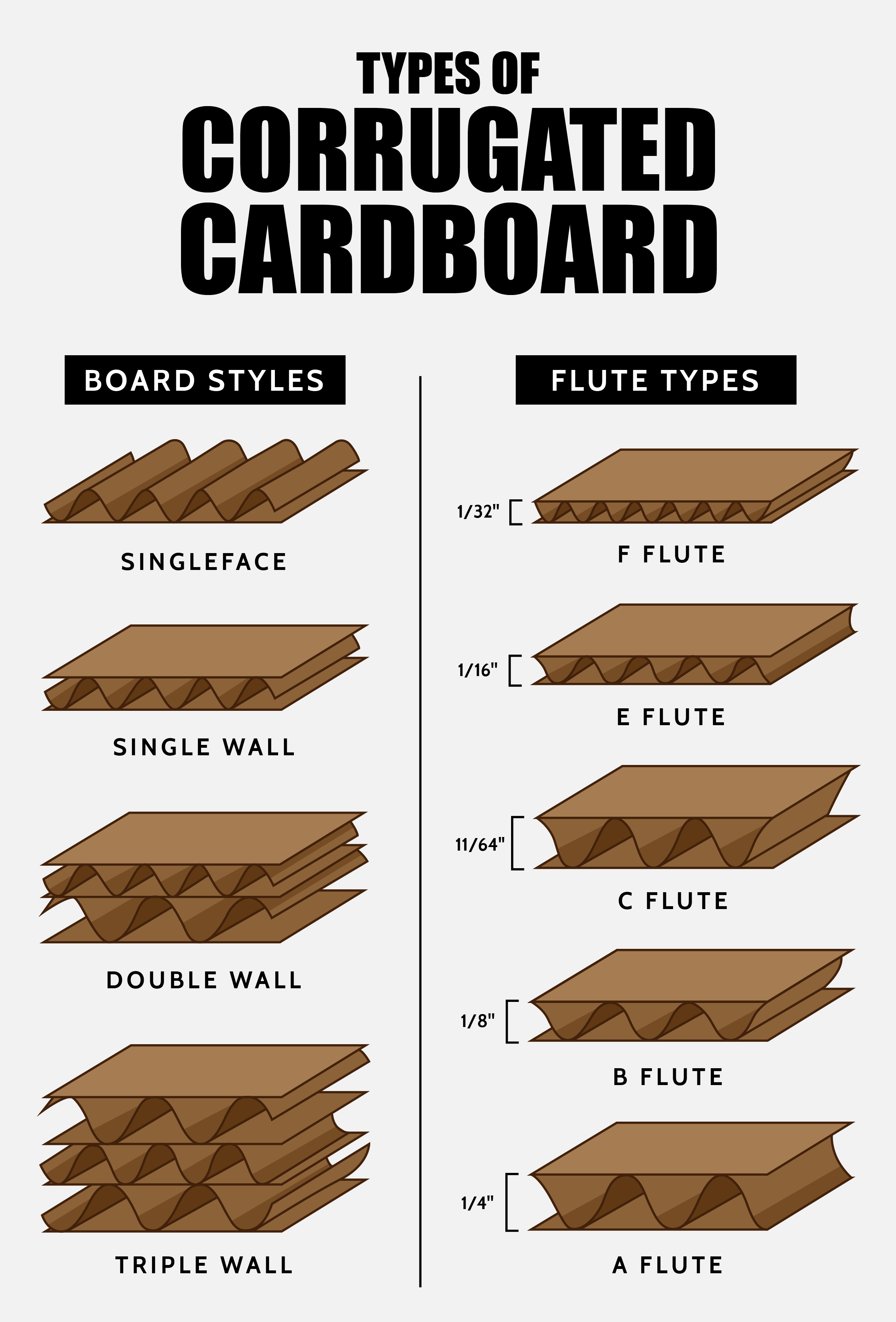

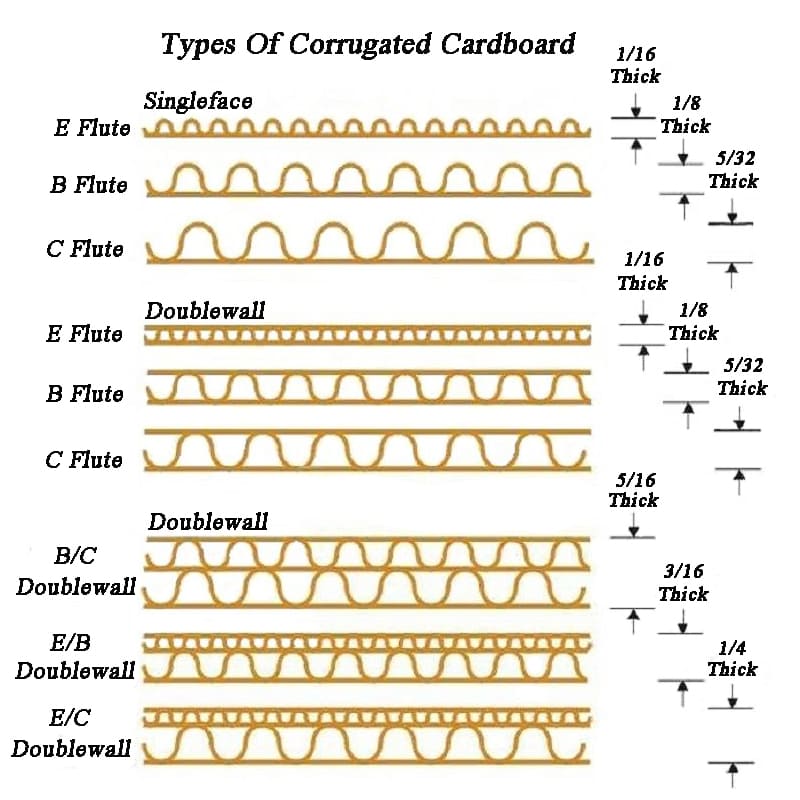

Corrugated Cardboard Flute Chart - Web pads help keep tops of products dust free during storage. Web each type of corrugated flute serves a unique purpose, and choosing the right one depends on various factors, such as the weight and fragility of the item being packaged, as well as storage and printing requirements. Feel free to print out the chart above for an easy reference to corrugated fluting profiles the next time you need to order corrugated boxes. Get imaginative with your leftovers, or simply consider these first for your packaging needs. It separates the liners and provides the strength and rigidity. Web the flute comes in different sizes resulting in different strengths and performance of the cardboard: Web corrugated cardboard sheets and boxes come in a variety of different, lettered grades, each with different weights they can withstand. Web corrugated flutes are designed to provide corrugated packaging with extra layers of insulation and protection. Flutes come in several sizes, known as flute profiles. Boxes can outfitted with foam inserts and padding or cardboard partitions and grids to accommodate a number of different product types. We specialize in small runs with quick setup and quick turnaround times. Here are descriptions and details of. Web you can get a better understanding of box type and flutes by the following cardboard flute chart: Customize your perfect corrugated box. Corrugated board is classified as follows according to the number of outer/intermediate plies and flutes: Web the most common flutes are b flutes, c flutes, and e flutes. Use our corrugated flute chart to learn the common types of corrugated board used in packaging and shipping: Each flute size has a particularly useful function, from shipping strength to reducing storage space to improved printability. Web fluted cardboard can use various flute designs to maximise strength,. Web the corrugated flute, the wavy layer between two flat paperboard sheets, is a key factor contributing to its strength. Learn about our corrugated cardboard packaging solutions today. It separates the liners and provides the strength and rigidity. Helps prevent strapping and forklift damage. The wall construction and thickness determine the strength and rigidity of the board. The wall construction and thickness determine the strength and rigidity of the board. Web pads help keep tops of products dust free during storage. Use our corrugated flute chart to learn the common types of corrugated board used in packaging and shipping: Web the corrugated flute, the wavy layer between two flat paperboard sheets, is a key factor contributing to. Helps prevent strapping and forklift damage. Web hopefully this guide has helped give you a better understanding of corrugated flutes and their purpose in the shipping process. Web each type of corrugated flute serves a unique purpose, and choosing the right one depends on various factors, such as the weight and fragility of the item being packaged, as well as. Get imaginative with your leftovers, or simply consider these first for your packaging needs. Use our corrugated flute chart to learn the common types of corrugated board used in packaging and shipping: Web the flute comes in different sizes resulting in different strengths and performance of the cardboard: Choosing the right corrugated board style, as well as the appropriate flute. Corrugated board is classified as follows according to the number of outer/intermediate plies and flutes: Feel free to print out the chart above for an easy reference to corrugated fluting profiles the next time you need to order corrugated boxes. Let’s take a closer look at each of them in our corrugated flute chart: Web pads help keep tops of. Web the most common flutes are b flutes, c flutes, and e flutes. Though each manufacturer may have slight variations (there is no strict standardization), the cardboard is graded based on the number of flutes (ridges) per linear foot, always allowing for plus/minus 3 or 4 flutes. Web corrugated material is available in different wall thicknesses, known as flutes sizes.. We specialize in small runs with quick setup and quick turnaround times. Web you can get a better understanding of box type and flutes by the following cardboard flute chart: Web the “flute” describes the structure of the wave shaped cardboard material that makes up a board’s corrugation. Web how to choose the right flute type in corrugated boxes. Web. Web fluted cardboard can use various flute designs to maximise strength, cushioning, and crush resistance. Flute = 33 flutes/linear foot. Web the most common flutes are b flutes, c flutes, and e flutes. Understanding the different types of corrugated flutes, their dimensions, and their applications is crucial for selecting the right packaging solution for various products. Use our corrugated flute. Helps prevent strapping and forklift damage. Web corrugated flutes are designed to provide corrugated packaging with extra layers of insulation and protection. Though each manufacturer may have slight variations (there is no strict standardization), the cardboard is graded based on the number of flutes (ridges) per linear foot, always allowing for plus/minus 3 or 4 flutes. Web the flute comes in different sizes resulting in different strengths and performance of the cardboard: Web the corrugated flute, the wavy layer between two flat paperboard sheets, is a key factor contributing to its strength. Here are the most common flute designs: We specialize in small runs with quick setup and quick turnaround times. Here are descriptions and details of. Corrugated board is classified as follows according to the number of outer/intermediate plies and flutes: What box thickness and flute type is best for your product or application? It separates the liners and provides the strength and rigidity. Flutes come in several sizes, known as flute profiles. Web corrugated cardboard comes in various styles, each designed to meet specific packaging requirements. Boxes can outfitted with foam inserts and padding or cardboard partitions and grids to accommodate a number of different product types. Web you can get a better understanding of box type and flutes by the following cardboard flute chart: Web the most common flutes are b flutes, c flutes, and e flutes.

Corrugated Flutes and How They Improve Packaging

Corrugated Box Sizes & Thicknesses Guide

Corrugated Flute Chart Dinastindo Pratama

Corrugated Box What Is It? How Is It Used? Types, Shipping

Corrugated Board Thickness Chart

What Are The Major Types Of Flutes Used For Corrugated Boxes

Buffalo Packaging in Costa Mesa, CA provides its customers with a

Understanding The Different Types Of Corrugated Flutes , 54 OFF

How to Determine the Right Flute Packaging 101 WCP Solutions

How to choose the right corrugated flute

Choosing The Right Corrugated Board Style, As Well As The Appropriate Flute Size, Allows You To Create Custom Boxes Tailored To The Needs Of Different Products.

Feel Free To Print Out The Chart Above For An Easy Reference To Corrugated Fluting Profiles The Next Time You Need To Order Corrugated Boxes.

Finally, Corrugated Flutes Help Provide Structure To Corrugated Boxes, So They Support Heavier Items Without Folding Or Breaking.

Web Flute (36 Flutes / Foot) Flute, The Original Flute, Is The Highest Flute Size, And Therefore, When Combined With An Inner And Outer Facing, Is The Thickest.

Related Post: