Control Chart X Bar

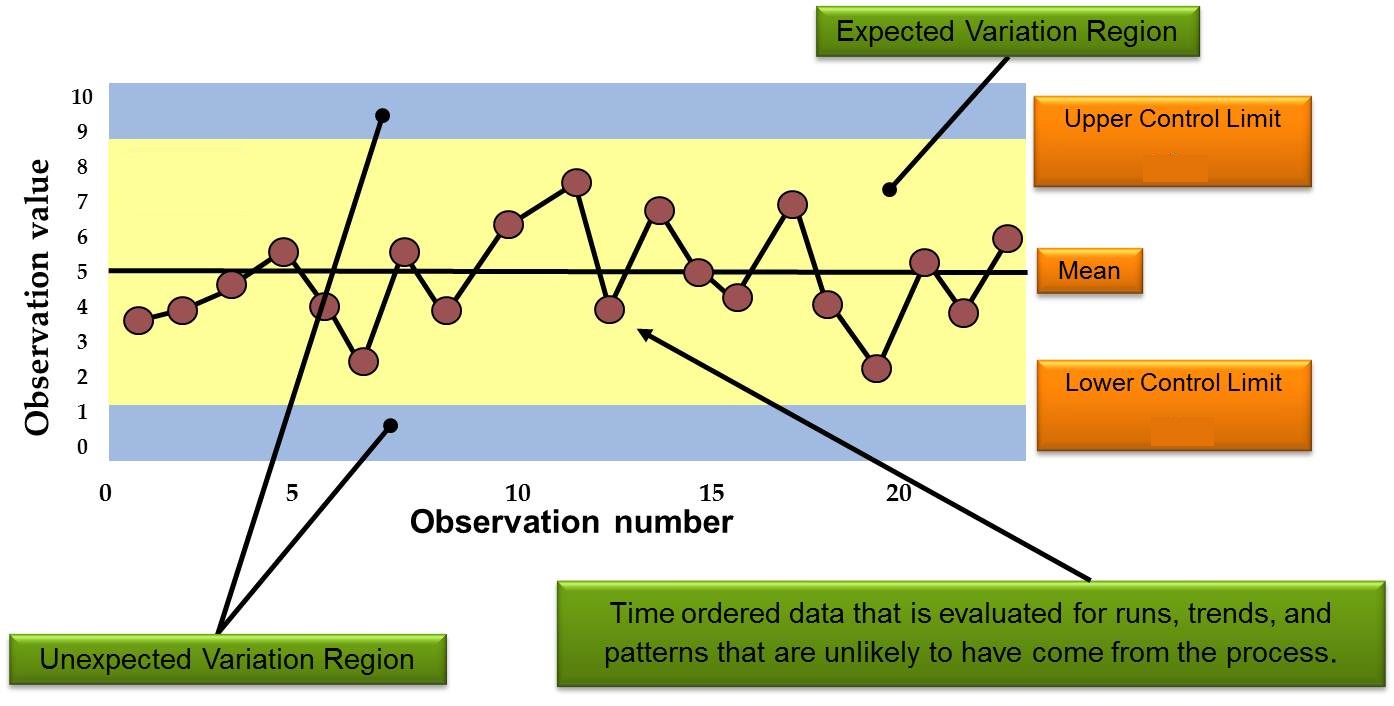

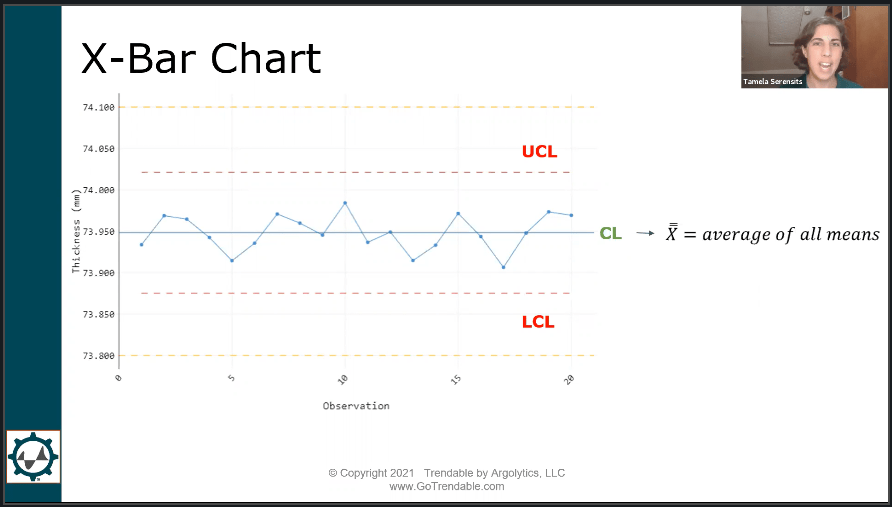

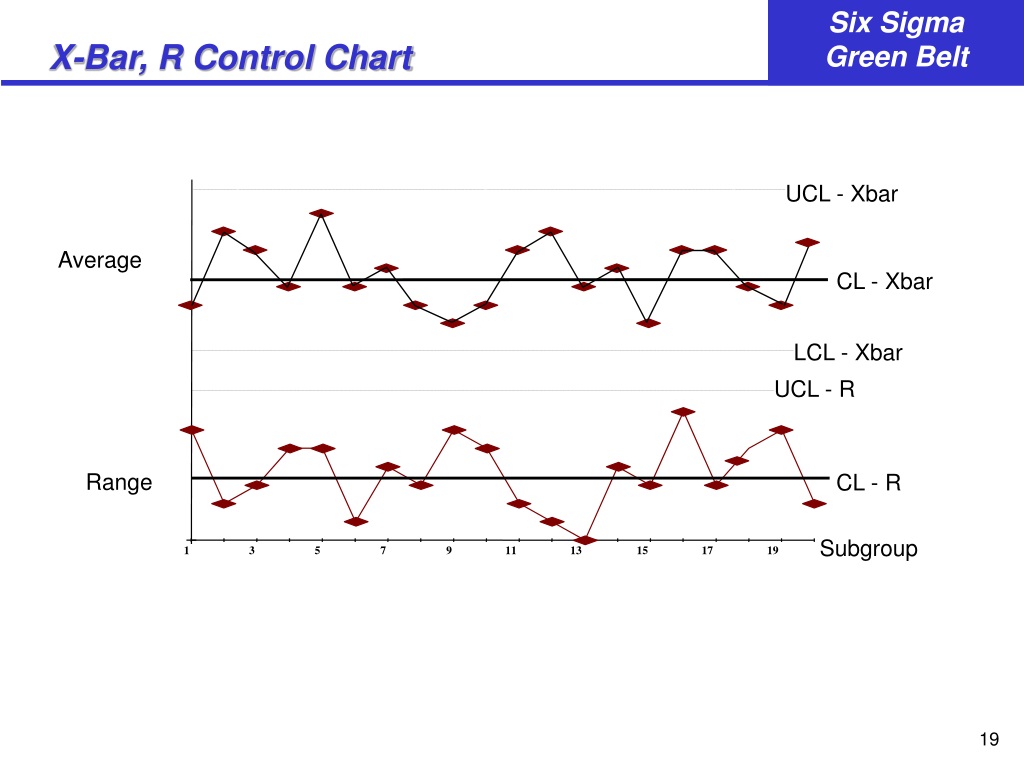

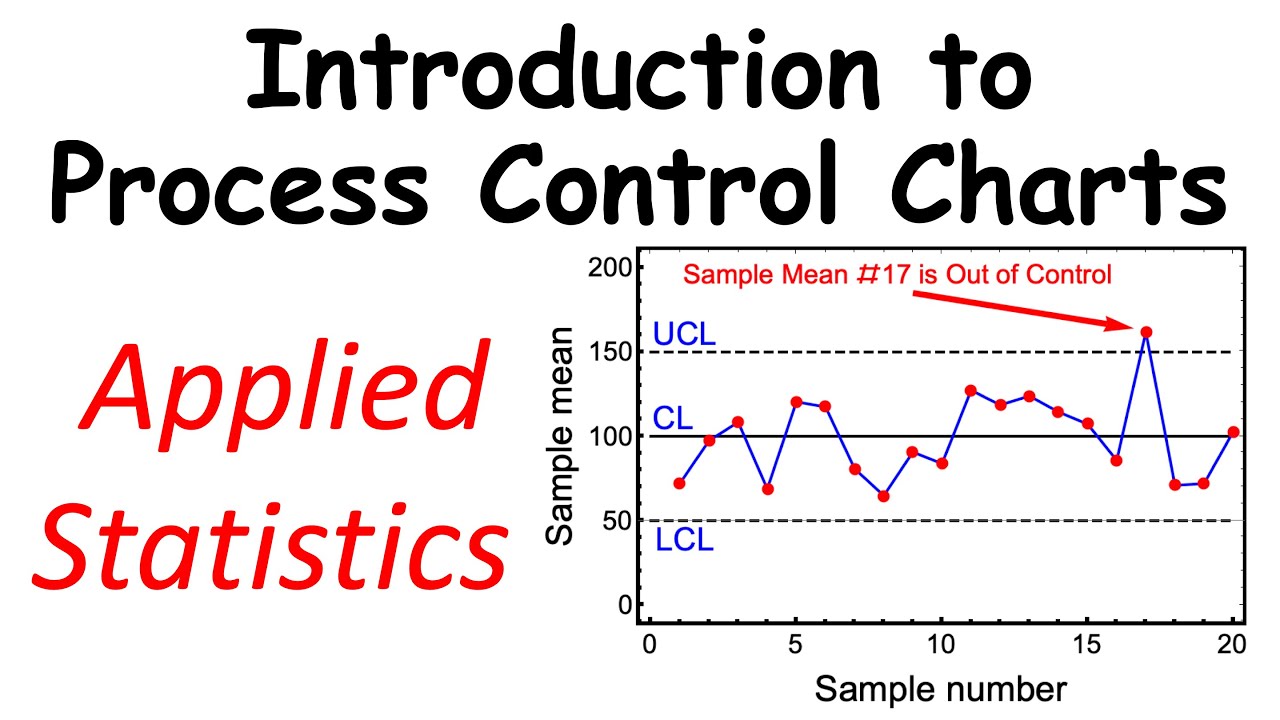

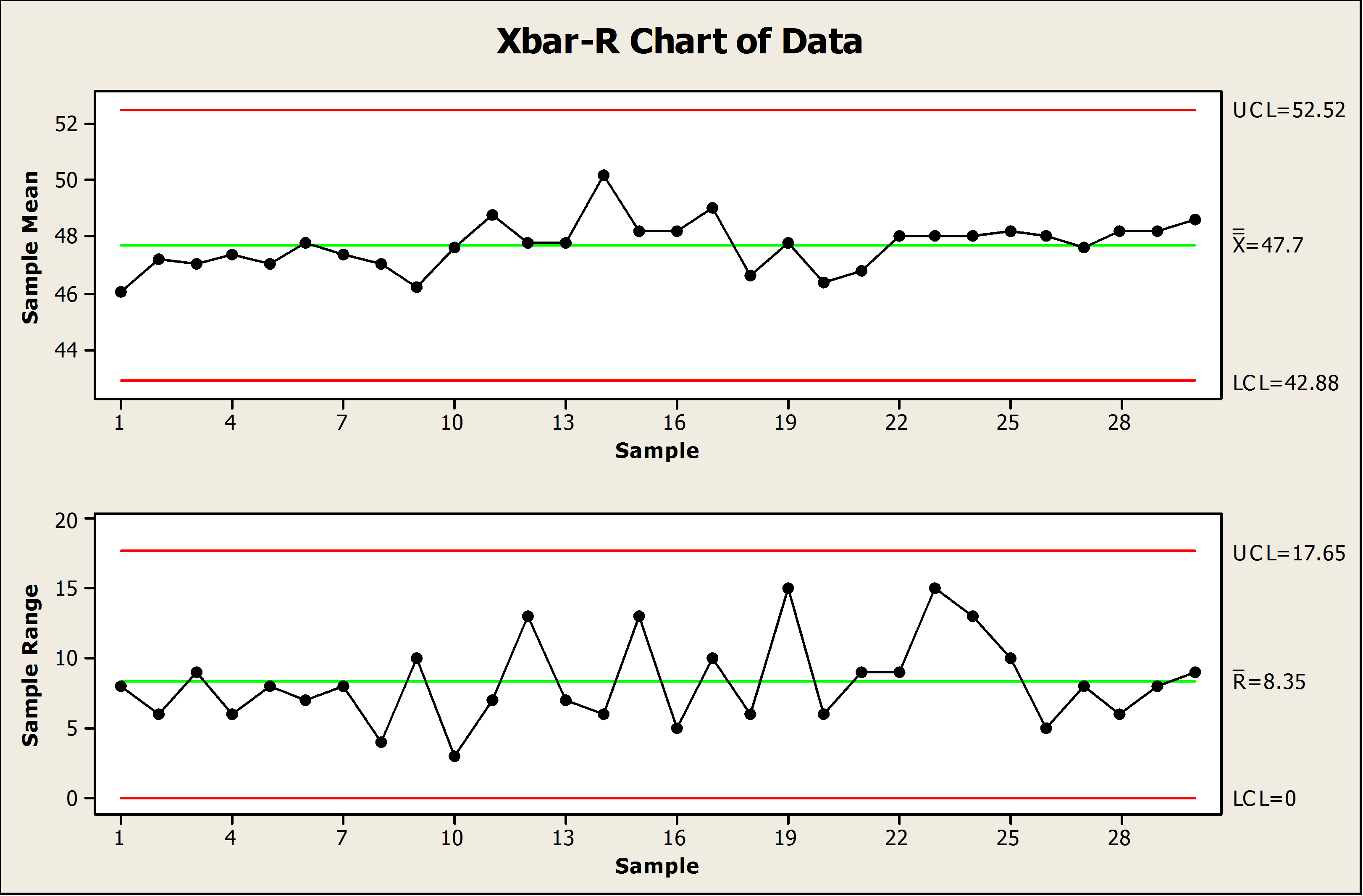

Control Chart X Bar - Web control charts are an essential tool in the six sigma methodology to monitor and control process variation. This is one of the most commonly used control charts due to its flexibility in monitoring many manufacturing processes. What is a control chart? X bar s charts often use control charts to examine the process mean and standard deviation over time. It is used for continuous data, when individual measurements are collected in subgroups at regular intervals. Analyzing the pattern of variance depicted by a quality control chart can help determine if defects are occurring randomly or systematically. If your requirement is solved, please make this answer a solution ️ and help other users find the solution quickly. This shows the process capability and helps you monitor a process to see if it is within acceptable parameters or not. The control chart includes everything a run chart does but adds upper control limits and lower control limits at a distance of 3 standard deviations away from the process mean. Web what are x bar r control charts? Process that is in statistical control is predictable, and characterized by points that fall between the lower and upper control limits. When is a control chart appropriate? Web the xbar & r chart is the most commonly used control chart. Consists of two charts displaying central tendency and variability. Full guide to six sigma control charts. Web control charts are an essential tool in the six sigma methodology to monitor and control process variation. It is used for continuous data, when individual measurements are collected in subgroups at regular intervals. Web a control chart is an extension of a run chart. It plots the mean (x bar) and range (r) of each subgroup of samples. The. Significance and objective of six sigma control chart. Web the resistance has full control of 11 of the 18 towns on the chinese border, and controls 90% of two more. Theoretical control limits for xbar charts. Full guide to six sigma control charts. Of constants for control charts. Analyzing the pattern of variance depicted by a quality control chart can help determine if defects are occurring randomly or systematically. What is a control chart? Web what are x bar s control charts? Let \(r_1, \, r_2, \, \ldots, r_k\), be the ranges of \(k\) samples. The control limits on the xbar chart, which are set at a distance. Legal trade flows into and out of myanmar are increasingly constricted, which has. Quality engineers at a manufacturing plant monitor part lengths. The range (r) chart shows the variation within each variable (called subgroups). Web x bar & r chart. Analyzing the pattern of variance depicted by a quality control chart can help determine if defects are occurring randomly or. Process that is in statistical control is predictable, and characterized by points that fall between the lower and upper control limits. Theoretical control limits for xbar charts. Web what are x bar s control charts? Analyzing the pattern of variance depicted by a quality control chart can help determine if defects are occurring randomly or systematically. Useful for identifying special. Let \(r_1, \, r_2, \, \ldots, r_k\), be the ranges of \(k\) samples. X bar s charts often use control charts to examine the process mean and standard deviation over time. The control limits on the xbar chart, which are set at a distance of 3 standard deviations above and below the center line, show the amount of variation that. Quality engineers at a manufacturing plant monitor part lengths. What is a control chart? The control limits on both chats are used to monitor the mean and variation of the process going forward. Web the resistance has full control of 11 of the 18 towns on the chinese border, and controls 90% of two more. The control limits on the. Please hit the like 👍 button if this comment helps you. Web what are x bar s control charts? Web x bar & r chart. Consists of two charts displaying central tendency and variability. Web control charts are an essential tool in the six sigma methodology to monitor and control process variation. The average range is $$ \bar{r} = \frac{r_1 + r_2 +. Legal trade flows into and out of myanmar are increasingly constricted, which has. Consists of two charts displaying central tendency and variability. Full guide to six sigma control charts. The center line is the average of all subgroup averages. These charts are used when the subgroups have large sample sizes. When is a control chart appropriate? How is a control chart used as a tool for analysis? Although theoretically possible, since we do not know either the population process mean or standard deviation, these formulas cannot be used directly and both must be estimated from the. Web what are x bar r control charts? This shows the process capability and helps you monitor a process to see if it is within acceptable parameters or not. Web control charts are an essential tool in the six sigma methodology to monitor and control process variation. Web x bar & r chart. This type of control chart is used for characteristics that can be measured on a continuous scale, such as weight, temperature, thickness etc. Legal trade flows into and out of myanmar are increasingly constricted, which has. The control chart includes everything a run chart does but adds upper control limits and lower control limits at a distance of 3 standard deviations away from the process mean. X bar and s charts. It plots the mean (x bar) and range (r) of each subgroup of samples. Significance and objective of six sigma control chart. Web the xbar chart plots the average of the measurements within each subgroup. It is used for continuous data, when individual measurements are collected in subgroups at regular intervals.

Quality Control Charts xbar chart, schart and Process Capability

Control Limits for xbar r chart show out of control conditions

Principle of Xbar (Mean) control chart. Download Scientific Diagram

X Bar Control Chart PresentationEZE

After discussing the several aspects and uses ofXbar and R Charts, we

Xbar R Control Chart Quality Gurus

What is an Xbar control chart? TRENDABLE

PPT Introduction to Control Charts PowerPoint Presentation, free

Statistical Process Control Charts for the Mean and Range X Bar Charts

Statistical Process Control (SPC) Christian Gould

The Average Range Is $$ \Bar{R} = \Frac{R_1 + R_2 +.

Full Guide To Six Sigma Control Charts.

Web A Control Chart Is An Extension Of A Run Chart.

X Bar And R Charts.

Related Post: