Control Chart Limits

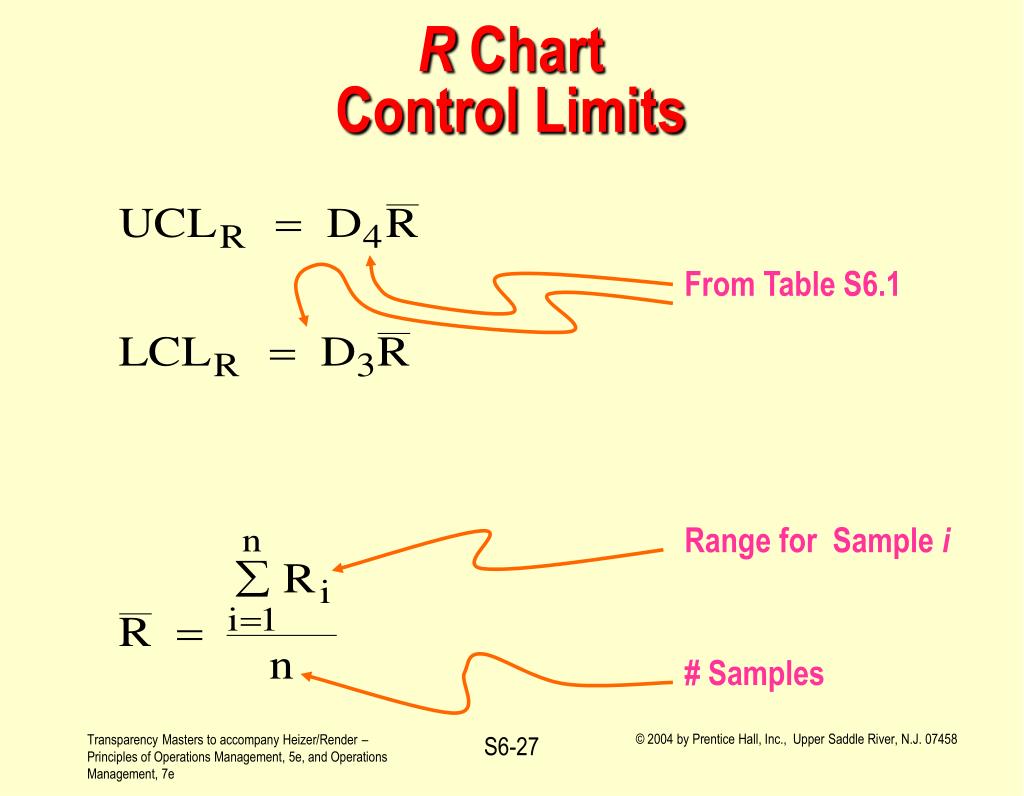

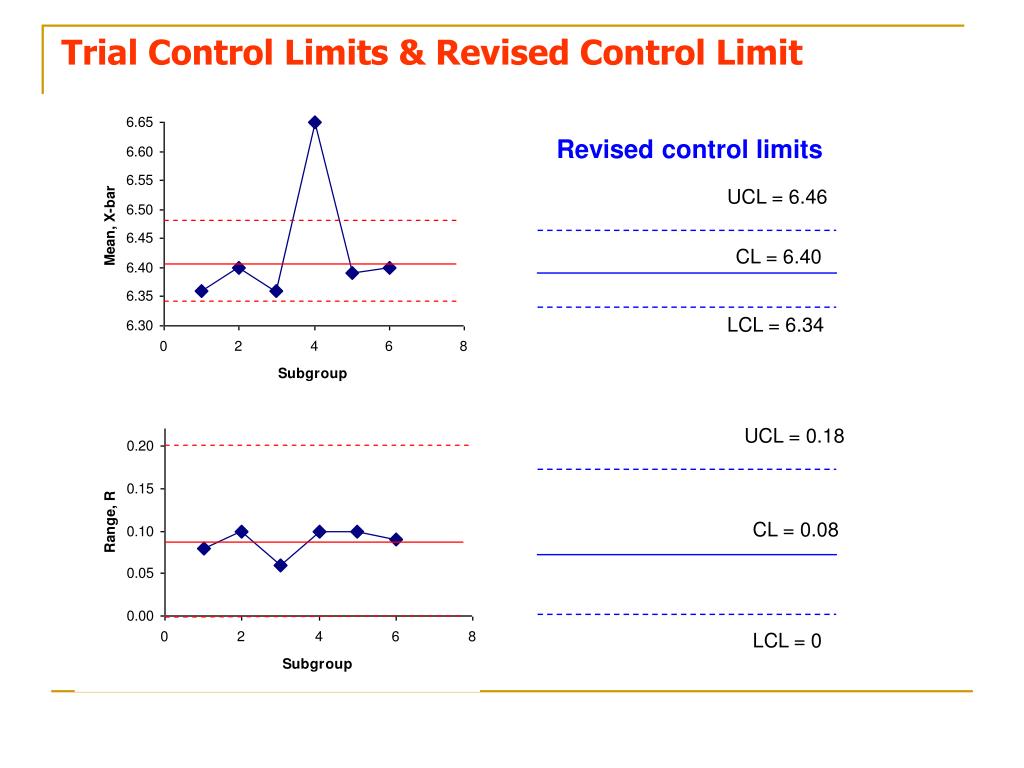

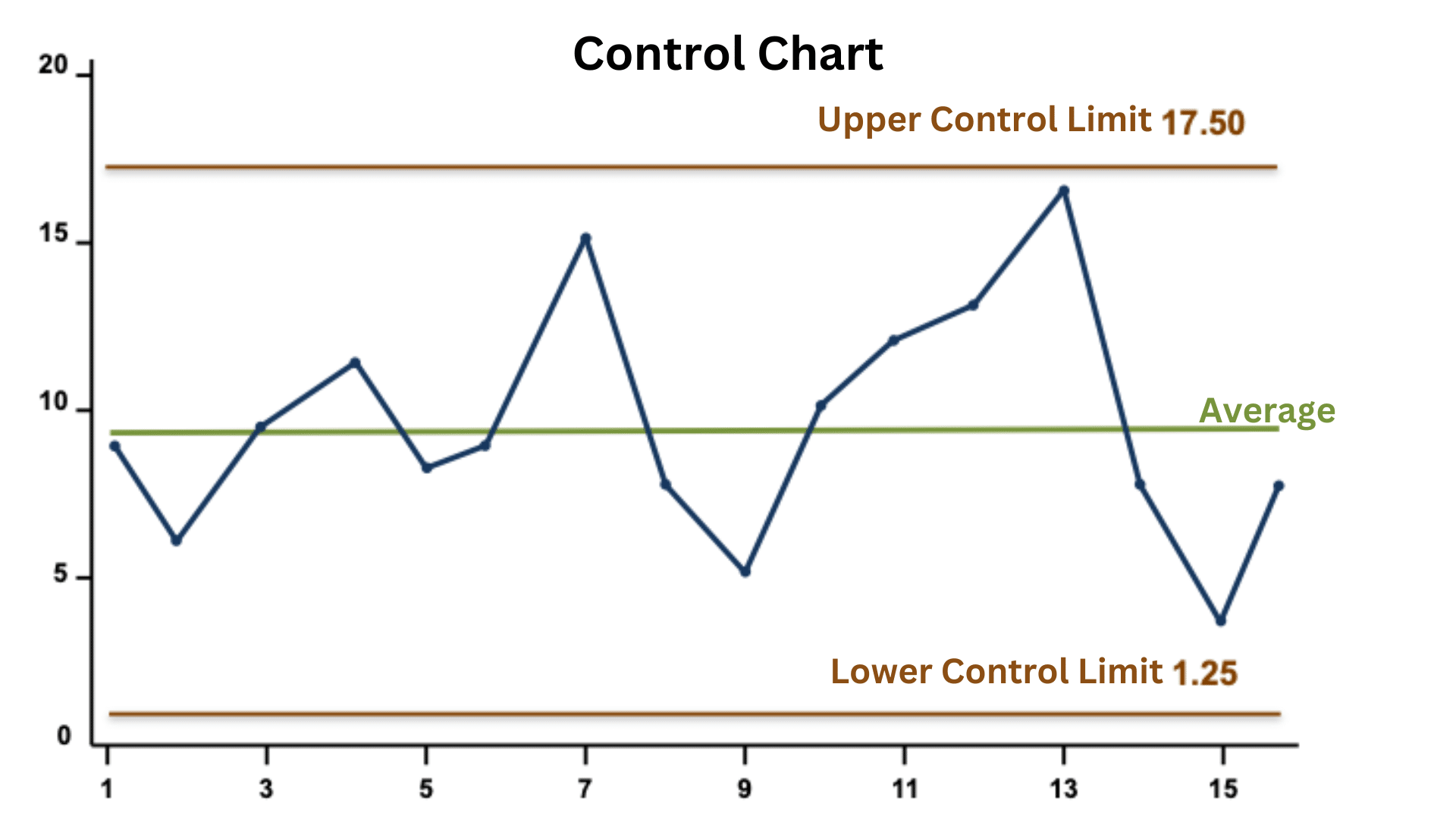

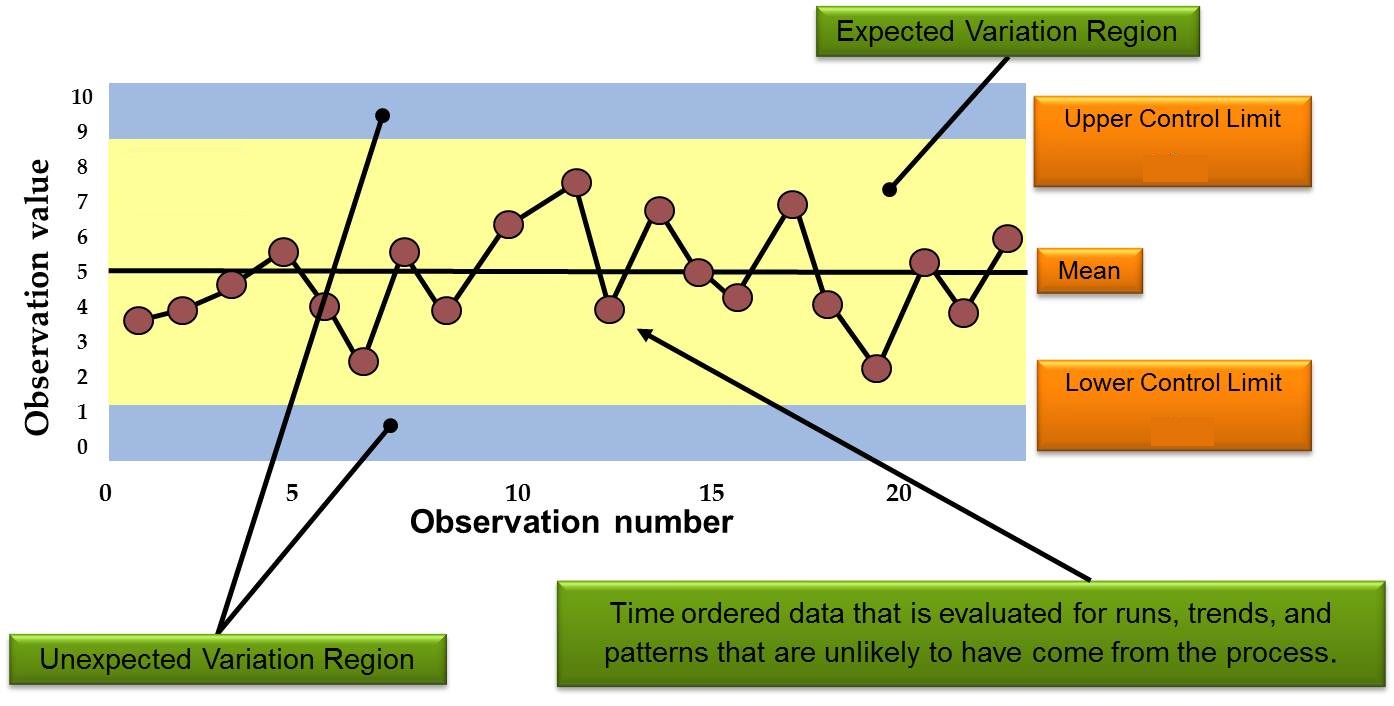

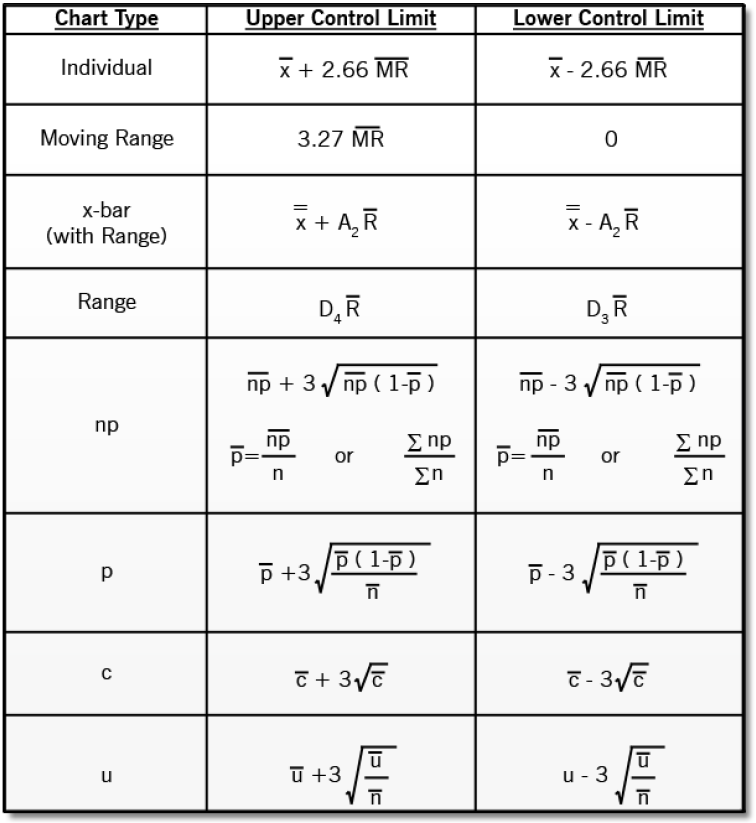

Control Chart Limits - Trump and his allies are planning a sweeping expansion of presidential power over the machinery of government if voters. Web the control chart includes everything a run chart does but adds upper control limits and lower control limits at a distance of 3 standard deviations away from the process mean. The control limits are ±3σ from the. Web in a july 18 campaign event in fayetteville, north carolina, vice president kamala harris, democrats’ presumptive presidential nominee, warned that project 2025. Control limits are the horizontal lines above and. U c l = x ¯ + 3 m r ― 1.128 center line = x ¯ l c. Web the control limits are usually set at three standard deviations from the mean, encompassing about 99.7 percent of the process data. You can start calculating the control limits after five data points. Web by plotting data points, establishing a center line, setting control limits, and interpreting the resulting chart, these tools enable the detection of special cause variations and the. Web control limits are one part of a control chart that allows you to identify common and special cause variation. Web admin — december 13, 2012. Web doug mills/the new york times. Web the control limits as pictured in the graph might be 0.001 probability limits. Most control charts include a center line, an upper control limit, and a lower control limit. Web a control chart displays process data by time, along with upper and lower control limits that delineate. The control limits are ±3σ from the. Web to establish upper and lower control limits on control charts, there are a number of methods. Web the two main components of a control chart are: Web what are control chart limits? Control limits are the horizontal lines above and. Web the control limits are usually set at three standard deviations from the mean, encompassing about 99.7 percent of the process data. Web to establish upper and lower control limits on control charts, there are a number of methods. The control charts in this publication were made using the spc for excel software. Web what are control chart limits? Web. If so, and if chance causes alone were present, the probability of a point falling above the upper limit. The following formulas are used to compute the upper and lower control limits for statistical process control (spc) charts. Web the control chart includes everything a run chart does but adds upper control limits and lower control limits at a distance. Most control charts include a center line, an upper control limit, and a lower control limit. The following formulas are used to compute the upper and lower control limits for statistical process control (spc) charts. These limits let you know. Trump and his allies are planning a sweeping expansion of presidential power over the machinery of government if voters. Picture. If you’re looking to keep your processes on track, control charts are your best buddy. The ucl and lcl establish natural boundaries for variation in the process. For the control chart for individual measurements, the lines plotted are: Control limits are the horizontal lines above and. Web in a july 18 campaign event in fayetteville, north carolina, vice president kamala. Control limits distinguish control charts from a simple line graph or run chart. U c l = x ¯ + 3 m r ― 1.128 center line = x ¯ l c. Web individuals control limits for an observation. Control limits are the horizontal lines above and. Web what are control chart limits? Web doug mills/the new york times. Web this newsletter has examined when to calculate control limits when you first start a control chart. Most control charts include a center line, an upper control limit, and a lower control limit. Control charts are a valuable tool for monitoring process performance. You can start calculating the control limits after five data points. Web what are control chart limits? These lines are determined from. Web admin — december 13, 2012. The control charts in this publication were made using the spc for excel software. If you understand how control limits were. Control limits distinguish control charts from a simple line graph or run chart. Web in a july 18 campaign event in fayetteville, north carolina, vice president kamala harris, democrats’ presumptive presidential nominee, warned that project 2025. Web the two main components of a control chart are: The control limits are ±3σ from the. These lines are determined from. If you understand how control limits were. Web doug mills/the new york times. These lines are determined from. The ucl and lcl establish natural boundaries for variation in the process. Web this newsletter has examined when to calculate control limits when you first start a control chart. Web control charts limit specification limits or targets because of the tendency of those involved with the process (e.g., machine operators) to focus on performing to. Control limits are the horizontal lines above and. Most control charts include a center line, an upper control limit, and a lower control limit. We will discuss the method for the number of components in a. You can start calculating the control limits after five data points. If you’re looking to keep your processes on track, control charts are your best buddy. Web the control limits are usually set at three standard deviations from the mean, encompassing about 99.7 percent of the process data. Web if you are plotting individual values (e.g., the x control chart for the individuals control chart), the control limits are given by: If the process data falls within. Web to establish upper and lower control limits on control charts, there are a number of methods. Web a control chart always has a central line for the average, an upper line for the upper control limit, and a lower line for the lower control limit.

PPT Operations Management Statistical Process Control Supplement 6

PPT Control Charts for Variables PowerPoint Presentation, free

6 Sigma Control Chart Introduction Toolkit from Leanscape

The 7 QC Tools Control Charts Enhancing Your Business Performance

An Introduction to Process Behavior Charts

A Beginner's Guide to Control Charts The W. Edwards Deming Institute

After discussing the several aspects and uses ofXbar and R Charts, we

Statistical Process Control PresentationEZE

Control Chart Construction Formulas for Control Limits

Control Limit Chart In Excel Labb by AG

The Following Formulas Are Used To Compute The Upper And Lower Control Limits For Statistical Process Control (Spc) Charts.

Web The Control Limits Of Your Control Chart Represent Your Process Variation And Help Indicate When Your Process Is Out Of Control.

The Control Charts In This Publication Were Made Using The Spc For Excel Software.

Web Admin — December 13, 2012.

Related Post: