Chart For Cutting Crown Molding Flat

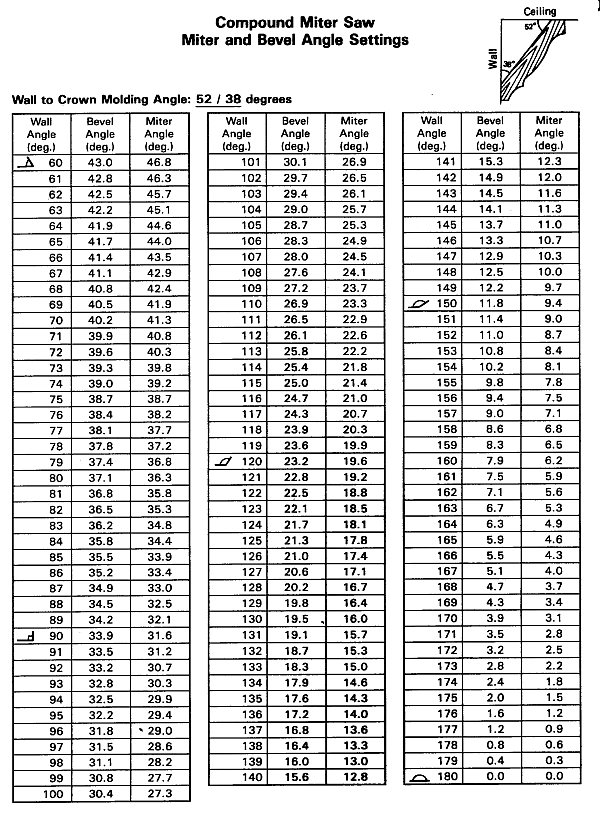

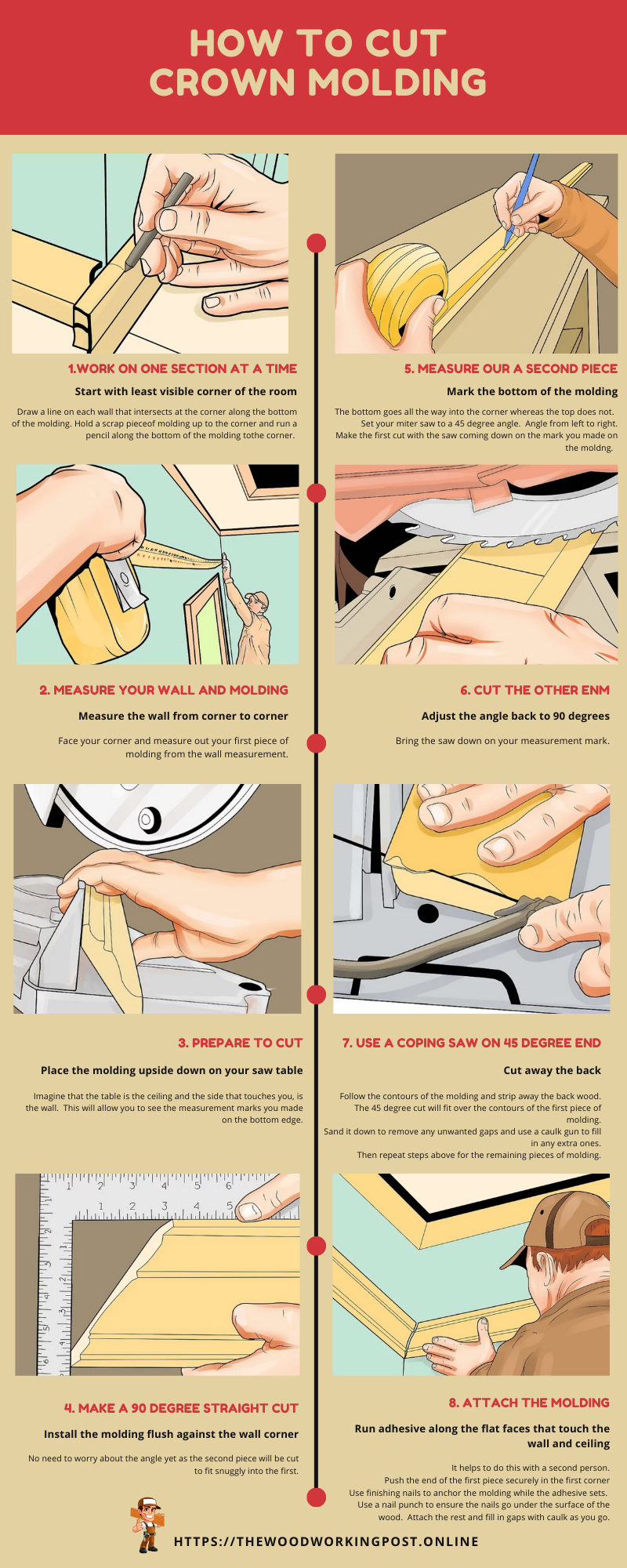

Chart For Cutting Crown Molding Flat - So print this chart and carry it in your truck. August 7, 2008 reprinted with permission from joseph fusco. Web in this example we will show you how to cut a 120 degree vaulted up and down crown molding corner for vaulted, angled, cathedral or sloped ceiling. As you learn how to cut crown moulding, practice with smaller scrap pieces to save frustration later. Compound method (flat) molding laying with broad back surface down flat on saw table. Set saw miter and bevel angles from table and diagrams below. There are no more spring angles to figure. How to cut crown molding inside corner 22.5 degrees Set the bevel to 33.9 degrees. Web the method i will go into below is a bit more precise and detailed and involves a combination of squared edges along with mitered, beveled, and coped edges and will result in a very tight fitting piece of work! No more complex compound miter cuts to make. Not many crown charts calculate miter/bevel angles for corners less than 60 degrees (even the bosch angle finder will not currently calculate miter/bevel angles for corners sharper than 60 degrees). There are no more spring angles to figure. These specific angles are usually marked on most saws for convenience. How to cut. Web no, crown molding cannot be cut laying flat. No more complex compound miter cuts to make. Before you dive in, familiarize yourself with the basics of crown molding—the styles, profiles, and the intricacies involved in cutting it flat. Once that's locked in, you're all set. Cutting crown molding on the flat. You hold your templates up in the corner you’re working in, and figure. This refers to laying the crown molding flat while cutting it. Cutting creative crown flat back foam crown moldings. Set saw miter and bevel angles from table and diagrams below. A table saw and a compound miter saw work well for the flat. Once that's locked in, you're all set. I’ll always remember him for that. Web how to cut crown molding in 9 steps. Web steps for cutting crown molding. As you learn how to cut crown moulding, practice with smaller scrap pieces to save frustration later. Start with cutting a regular inside 90 degree corner. Lay the crown molding flat and make the cut. Before you dive in, familiarize yourself with the basics of crown molding—the styles, profiles, and the intricacies involved in cutting it flat. Hold the molding at the same angle as it will be installed. Web how to cut crown molding: Set blade at 45 degrees and make cut in two lengths of molding to create a scarf joint. Web how to cut crown molding in 9 steps. Web crown moulding miter and bevel angle setting chart. Swing the table to cut the miter, tilt the blade to cut the bevel. Cutting creative crown flat back foam crown moldings. On most saws, “31.6” is specially marked. This refers to laying the crown molding flat while cutting it. See our instructional video page for more information! Web compound miter chart is for cutting all crown molding (regardless of the crown spring angle) using a compound miter saw with the crown molding lying flat and face up. You hold your templates. There are no more spring angles to figure. Web in this example we will show you how to cut a 120 degree vaulted up and down crown molding corner for vaulted, angled, cathedral or sloped ceiling. This foundational knowledge is crucial for achieving precise cuts. Just lay the crown in flat arranged for your mitre or cope cut and you're. Master the process of marking, setting up the miter saw, making the cuts, installing, and finishing touches. Web place molding in compound miter saw with broad back surface down flat on saw table (visible decorative surface up). So print this chart and carry it in your truck. Web how to cut crown molding in 9 steps. Web compound miter chart. You hold your templates up in the corner you’re working in, and figure. See our instructional video page for more information! Web in this example we will show you how to cut a 120 degree vaulted up and down crown molding corner for vaulted, angled, cathedral or sloped ceiling. Once again, this adjustment will have a special marking on most. Lay the crown flat and cut. Once again, this adjustment will have a special marking on most saws. Where can i find this information? Swing the table to cut the miter, tilt the blade to cut the bevel. Web no, crown molding cannot be cut laying flat. To find the correct bevel and miter angles, use a chart, such as this one, which was laminated for jobsite use by a carpenter named bruce abernathy: Hold the molding at the same angle as it will be installed. Set blade at 45 degrees and make cut in two lengths of molding to create a scarf joint. On most saws, “31.6” is specially marked. August 7, 2008 reprinted with permission from joseph fusco. I’ll always remember him for that. Our crown moldings cut in most positions in most miter saws. Not many crown charts calculate miter/bevel angles for corners less than 60 degrees (even the bosch angle finder will not currently calculate miter/bevel angles for corners sharper than 60 degrees). See our instructional video page for more information! Web the method i will go into below is a bit more precise and detailed and involves a combination of squared edges along with mitered, beveled, and coped edges and will result in a very tight fitting piece of work! And i’ll always remember the crown chart he prepared and allowed me to publish in my finish carpentry book.

Crown Molding Flat Cut Chart

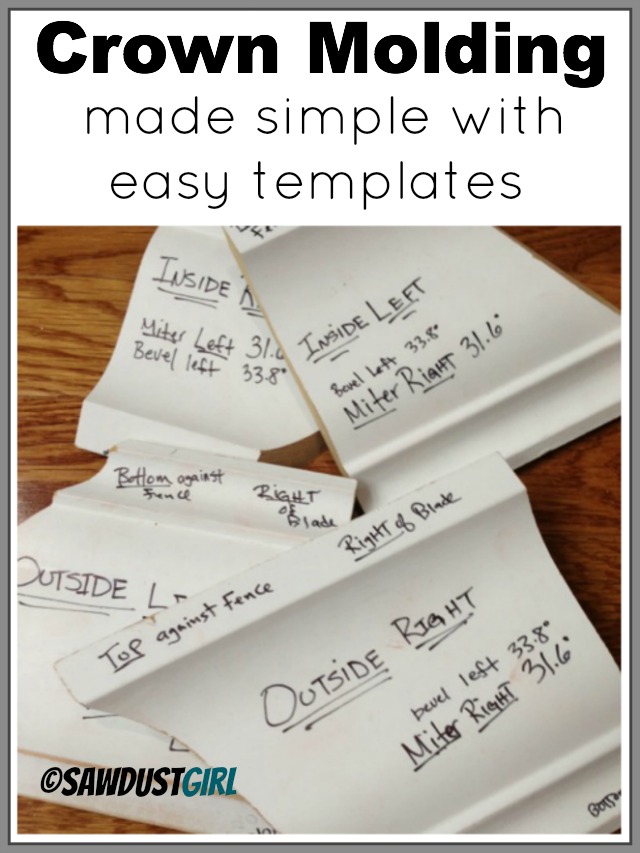

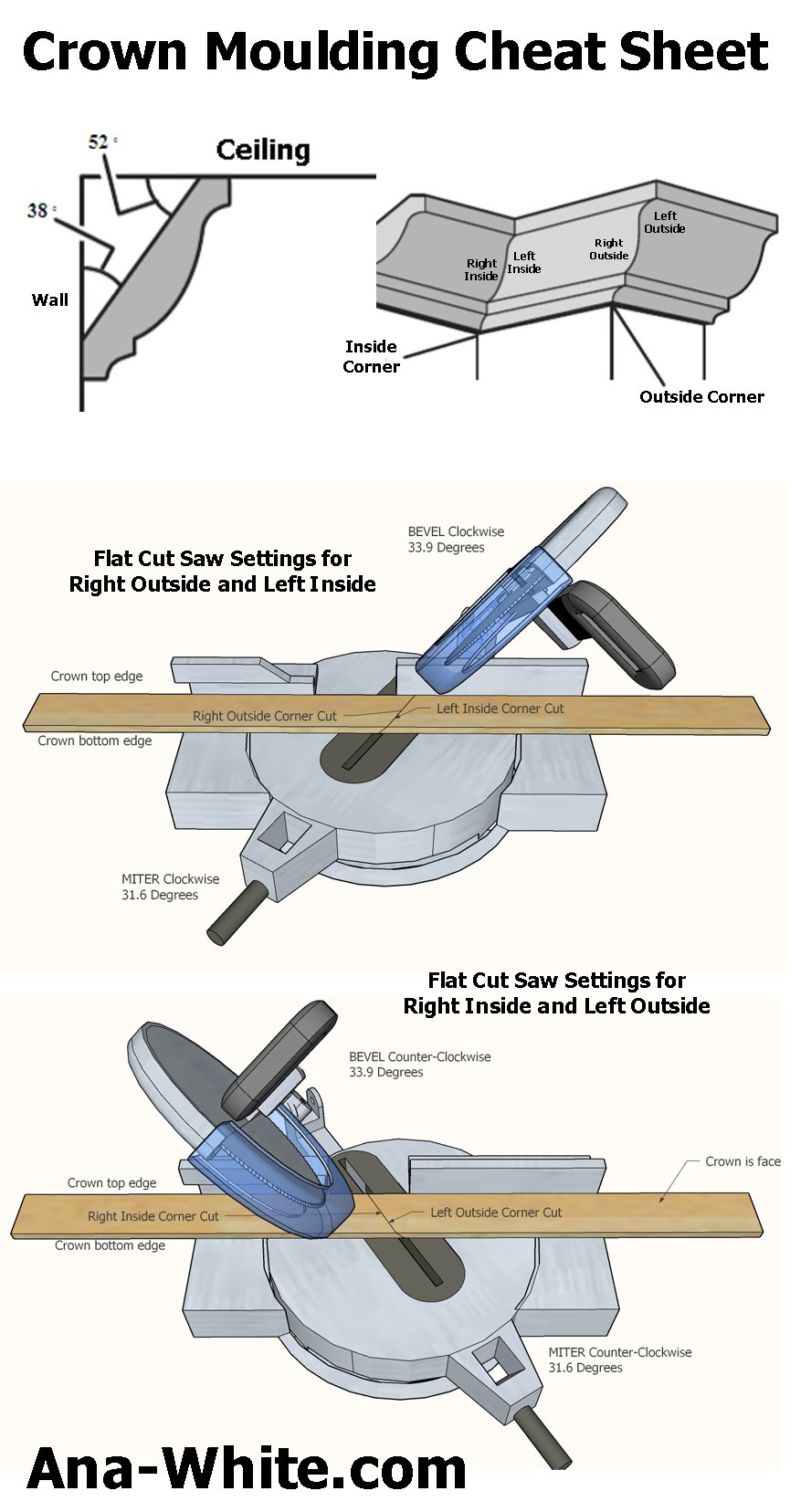

Crown Molding Cheat Sheet

Crown Molding Cut Angles Chart

Crown Molding Angle Chart Outside Corners

The Secret Numbers For Cutting Crown Flat Family Handyman

Crown Molding Cutting Angles Chart

Cutting Crown Molding Flat Angle Chart

Cutting Crown Molding Flat (and how to install it) The Woodworking Post

Chart For Cutting Crown Molding Flat

Cutting Crown Flat Chart

No More Complex Compound Miter Cuts To Make.

How Do I Determine Which Bevel And Angle I Should Set My Compound Miter Saw At When Cutting A Piece Of Crown Molding On The Flat?

To Make A Scarf Joint In The Middle Of A Long Run, Start By Placing The Crown Molding Upside Down On Miter Saw Table;

This Foundational Knowledge Is Crucial For Achieving Precise Cuts.

Related Post: