Cfm Pipe Size Chart

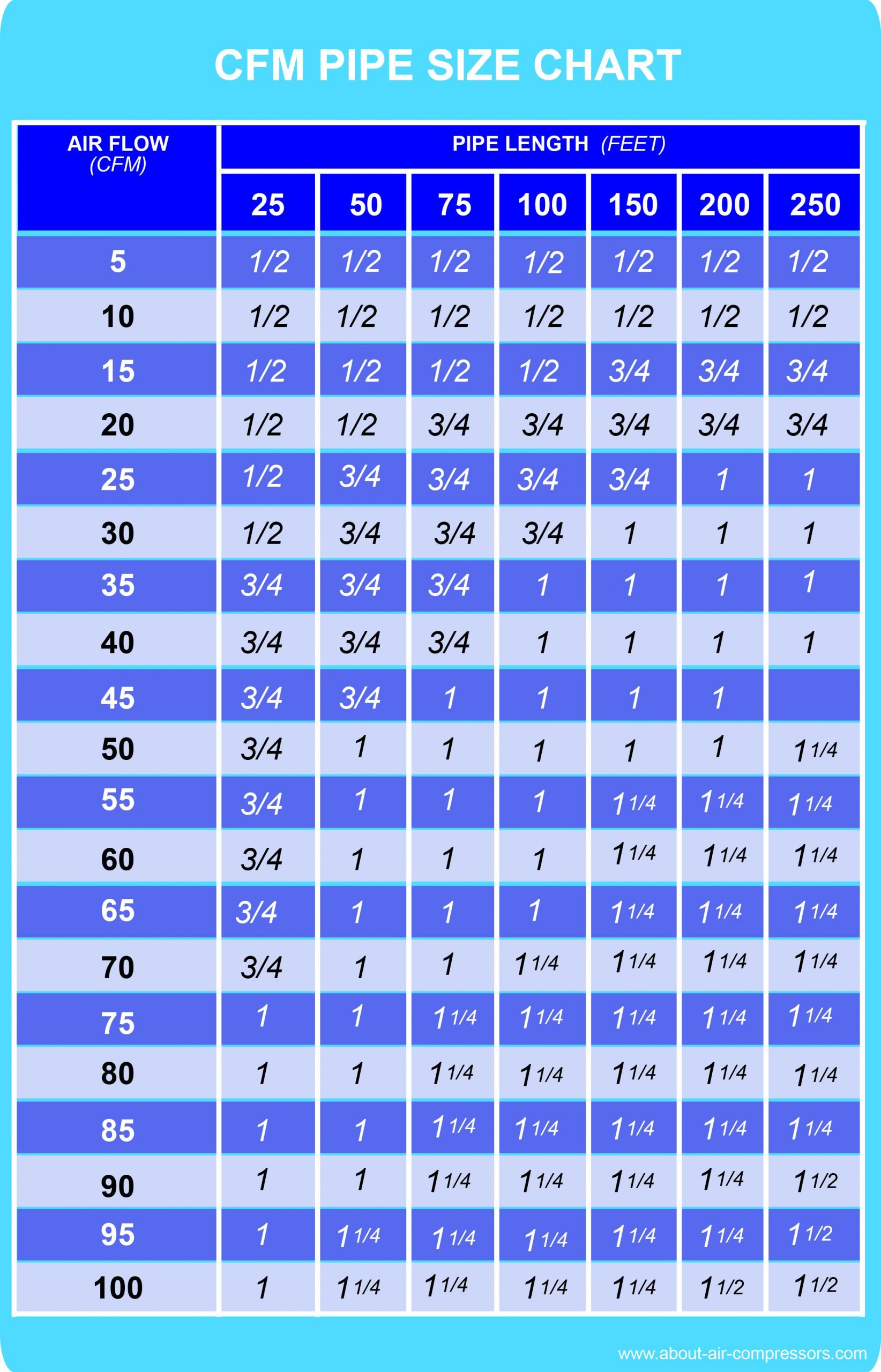

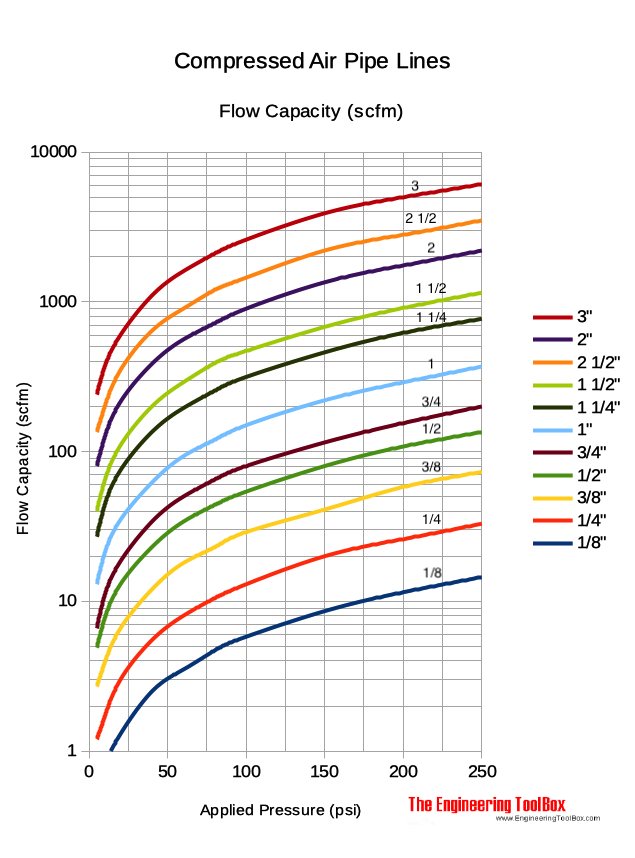

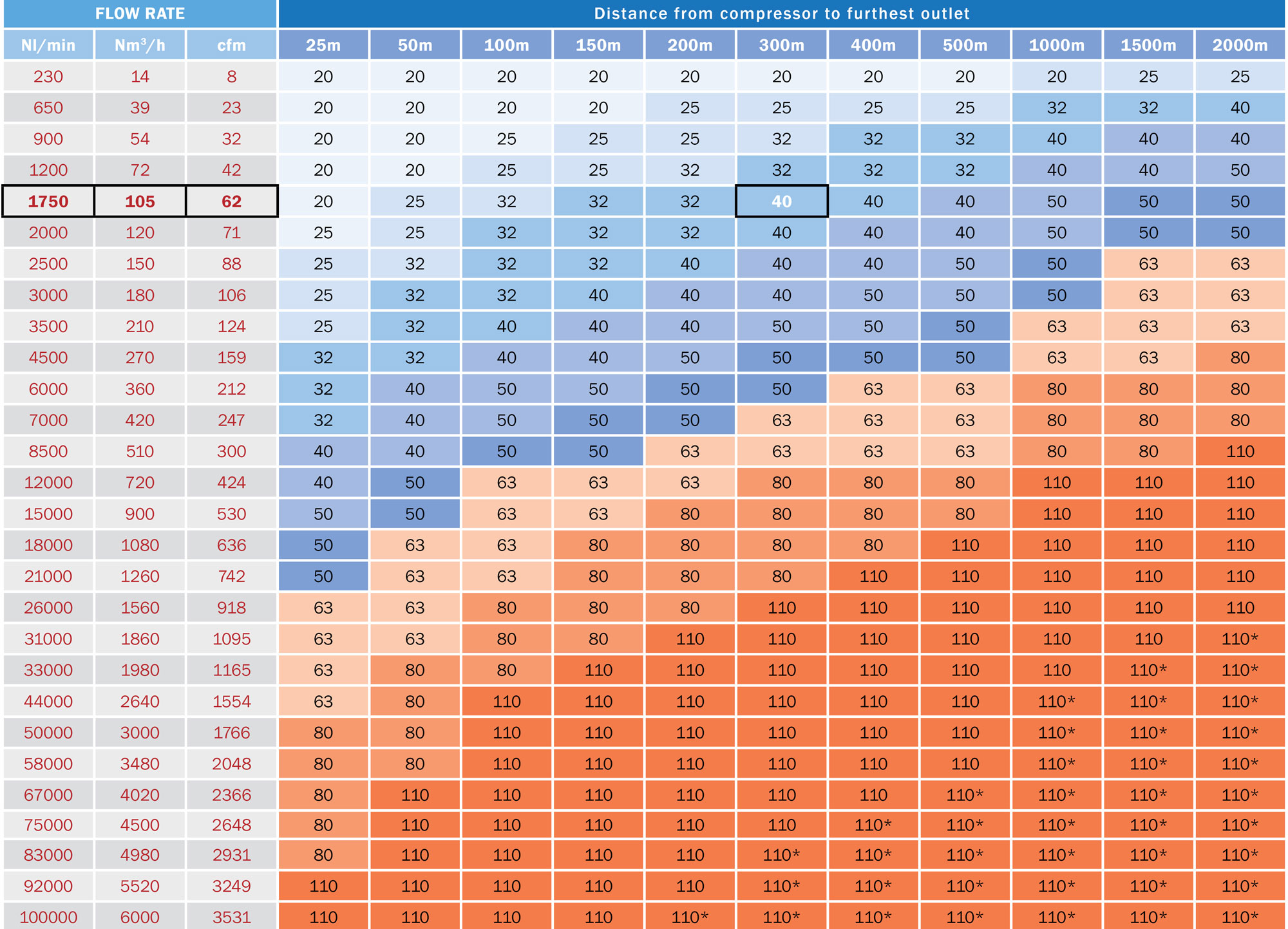

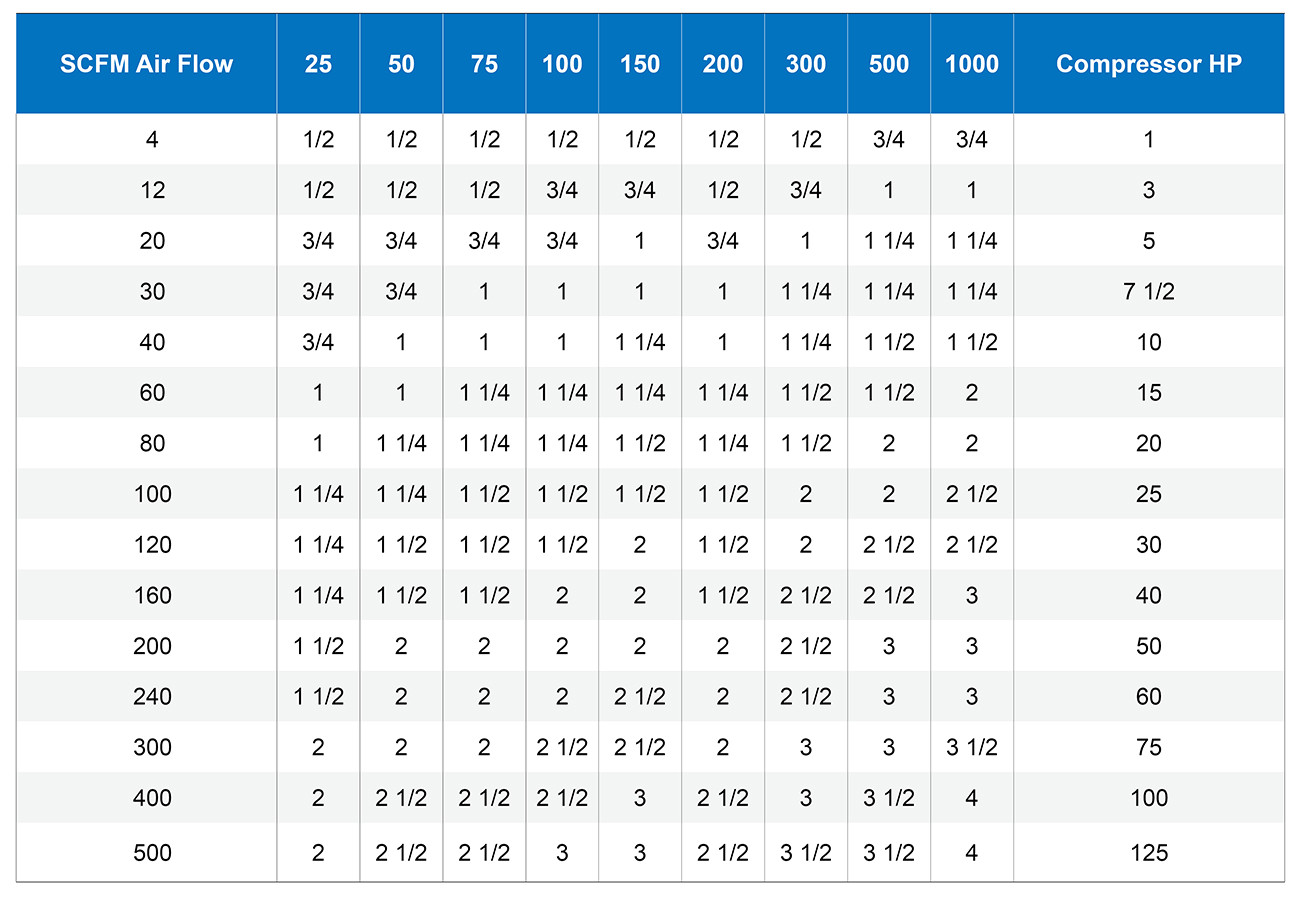

Cfm Pipe Size Chart - This chart is applicable for designing compressed air systems. Web thus, for the example 160 cfm, 40 hp compressor, piping size of 1.5 in. On steady pumping, a compressor will produce a. Based on line presssure 90 psig (620 kpa, 6.2 bar). Application knowledgefull range of productsmultiple technologies160 years of expertise Calculate the correct pipe size for your. Web typically, velocities between 20 and 30 feet per second (6 to 9 meters per second) are recommended for compressed air systems. Web in general it is common to set. Web to make a realistic estimate of air flow volume, the far right column of the chart showing compressor hp may be used. 1 psig = 6.9 kpa = 0.069 bar. Web to make a realistic estimate of air flow volume, the far right column of the chart showing compressor hp may be used. 1 psig = 6.9 kpa = 0.069 bar. Application knowledgefull range of productsmultiple technologies160 years of expertise Would be recommended at an operating pressure of 100 psi (see table). Equations displayed for easy reference. Lower pressure drop by installing the right compressed air pipe size. Calculate the correct pipe size for your. Flex duct =.05 on most metal duct calculator round metal pipe =.06 on most metal. 1 ft (foot) = 0.3048 m. Compressed air pipe sizing calculation. Determine your air compressor’s maximum cfm. Draw a piping schematic and show all pipe fittings,. On steady pumping, a compressor will produce a. 1 cfh = 1 mbh (mbh is thousands of btus per hour) related mobile apps from the engineering. Application knowledgefull range of productsmultiple technologies160 years of expertise Calculate the correct pipe size for your. Web to size your compressed air piping system correctly, you must consider your application’s required operating pressure, maximum cfm (cubic feet/minute), and the distance from. Web we can help determine the correct pipe size and configuration that will supply the flow you need. Based on line presssure 90 psig (620 kpa, 6.2 bar).. 1 cfh = 1 mbh (mbh is thousands of btus per hour) related mobile apps from the engineering. Calculate the correct pipe size for your. This chart is applicable for designing compressed air systems. Web thus, for the example 160 cfm, 40 hp compressor, piping size of 1.5 in. On steady pumping, a compressor will produce a. Calculate the correct pipe size for your. Web thus, for the example 160 cfm, 40 hp compressor, piping size of 1.5 in. Determine your air compressor’s maximum cfm. 1 inch = 25.4 mm. Based on line presssure 90 psig (620 kpa, 6.2 bar). Web cfm 4 cfm 6 cfm 8 cfm 10 cfm 12 60 6x4 60 4x6 90 4x8 120 4x10 150 4x12. Web to make a realistic estimate of air flow volume, the far right column of the chart showing compressor hp may be used. Web aluminium compressed air pipe sizing chart aids to determine the correct diameter (mm) of the. Flex duct =.05 on most metal duct calculator round metal pipe =.06 on most metal. Web to make a realistic estimate of air flow volume, the far right column of the chart showing compressor hp may be used. Web to choose the correct diameter of pipe for your system, you need to know how much flow rate (cfm) will travel. Would be recommended at an operating pressure of 100 psi (see table). Web to make a realistic estimate of air flow volume, the far right column of the chart showing compressor hp may be used. Web online calculator to quickly determine pipe sizing by velocity for air. Calculate the correct pipe size for your. Compressed air pipe sizing calculation. Web steps to figuring what size piping your compressed air system needs: Web in general it is common to set. 1 cfh = 1 mbh (mbh is thousands of btus per hour) related mobile apps from the engineering. Web typically, velocities between 20 and 30 feet per second (6 to 9 meters per second) are recommended for compressed air systems.. 1 cubic foot (ft3, cf) = approx 1000 btus. Application knowledgefull range of productsmultiple technologies160 years of expertise Draw a piping schematic and show all pipe fittings,. Lower pressure drop by installing the right compressed air pipe size. Flex duct =.05 on most metal duct calculator round metal pipe =.06 on most metal. Based on line presssure 90 psig (620 kpa, 6.2 bar). Web steps to figuring what size piping your compressed air system needs: Web we can help determine the correct pipe size and configuration that will supply the flow you need. 1 inch = 25.4 mm. Web the following chart contains the maximum recommended flow rates at the given pressure for ansi schedule 40 pipe. Web to make a realistic estimate of air flow volume, the far right column of the chart showing compressor hp may be used. Web recommended sizes for compressed air pipe lines: Web the flex duct sizing chart and round duct sizing chart below are used by hvac technicians, handyman services and homeowners to quickly select a supply duct size. Web in general it is common to set. Web to size your compressed air piping system correctly, you must consider your application’s required operating pressure, maximum cfm (cubic feet/minute), and the distance from. 1 ft (foot) = 0.3048 m.

Round Ductwork Cfm Chart

Duct Incorporated Sizing information

Compressed Air Pipe Size CFM Chart PDF Foot (Unit) Metrology

CFM Pipe Size Chart Guide To Selecting Pipe Sizes

Pipe Size Cfm Chart

Air Flow Pipe Size Chart Cfm

Round Pipe Cfm Chart

Cfm Pipe Size Chart

CFM Pipe Size Chart Guide To Selecting Pipe Sizes, 60 OFF

Cfm Pipe Size Chart

Web Typically, Velocities Between 20 And 30 Feet Per Second (6 To 9 Meters Per Second) Are Recommended For Compressed Air Systems.

Would Be Recommended At An Operating Pressure Of 100 Psi (See Table).

On Steady Pumping, A Compressor Will Produce A.

Web To Choose The Correct Diameter Of Pipe For Your System, You Need To Know How Much Flow Rate (Cfm) Will Travel Through The Pipe And How Long Your Piping Will Be.

Related Post: