Casting Design

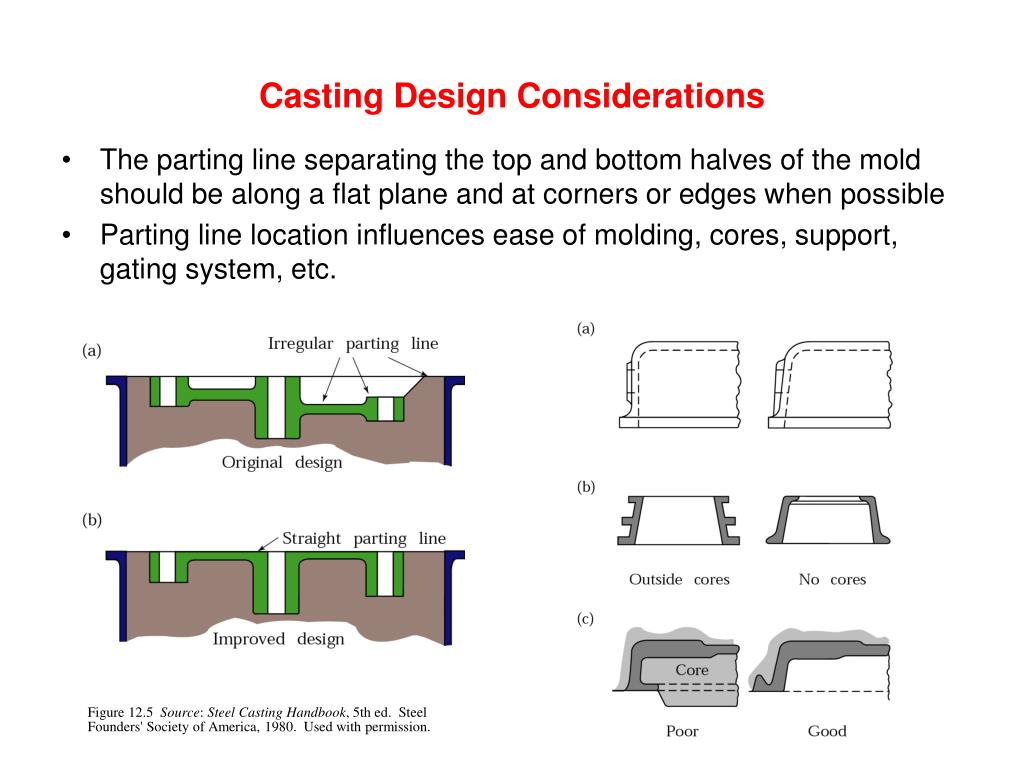

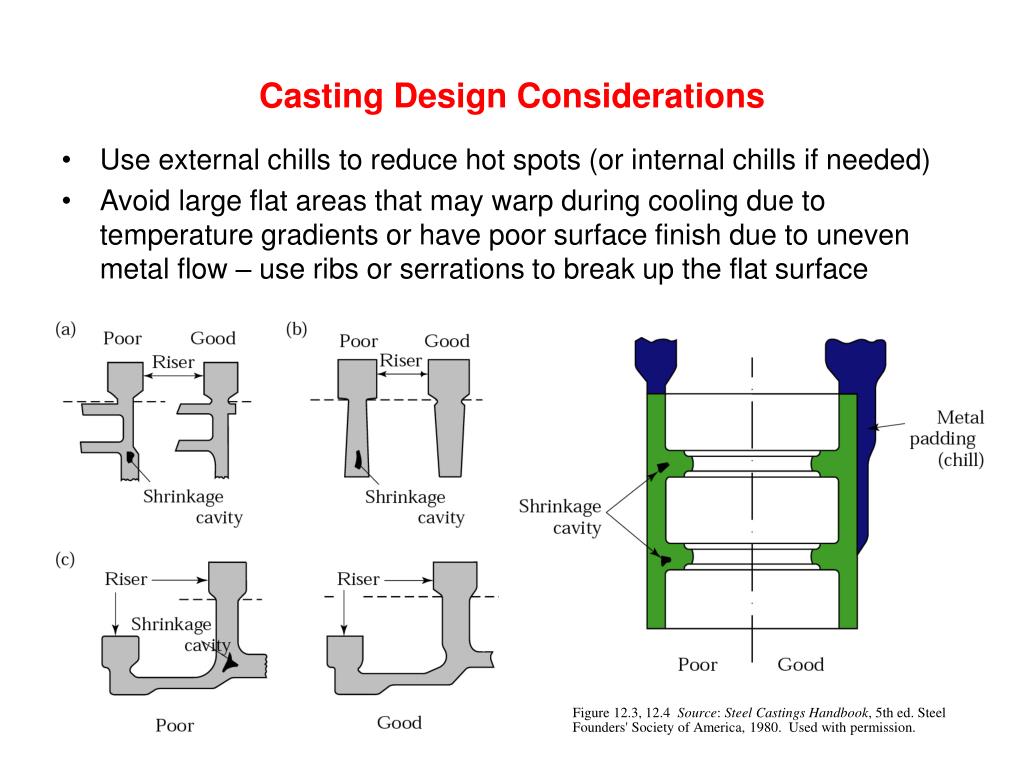

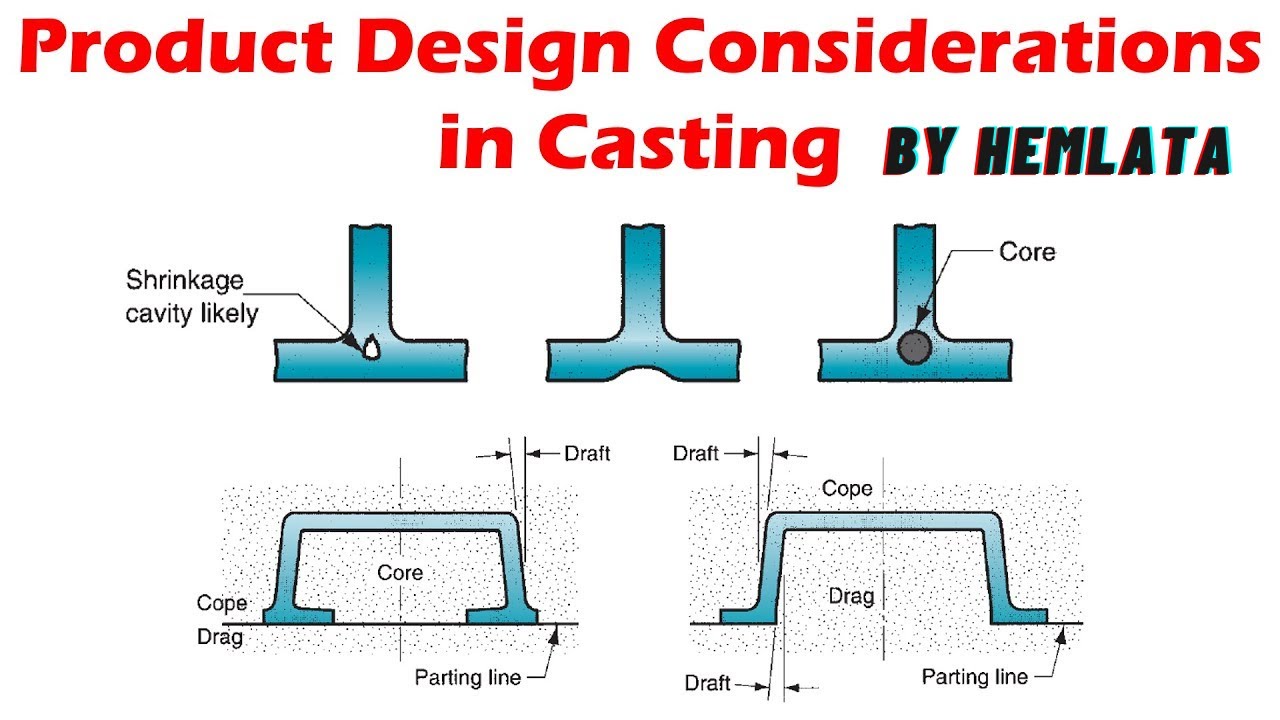

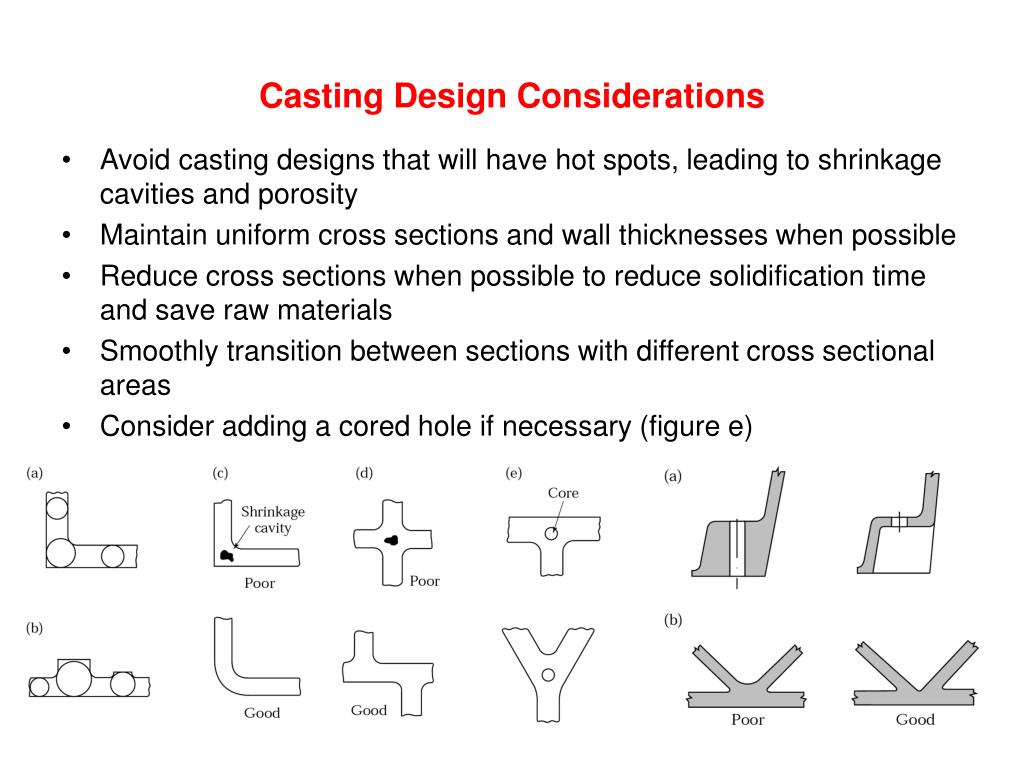

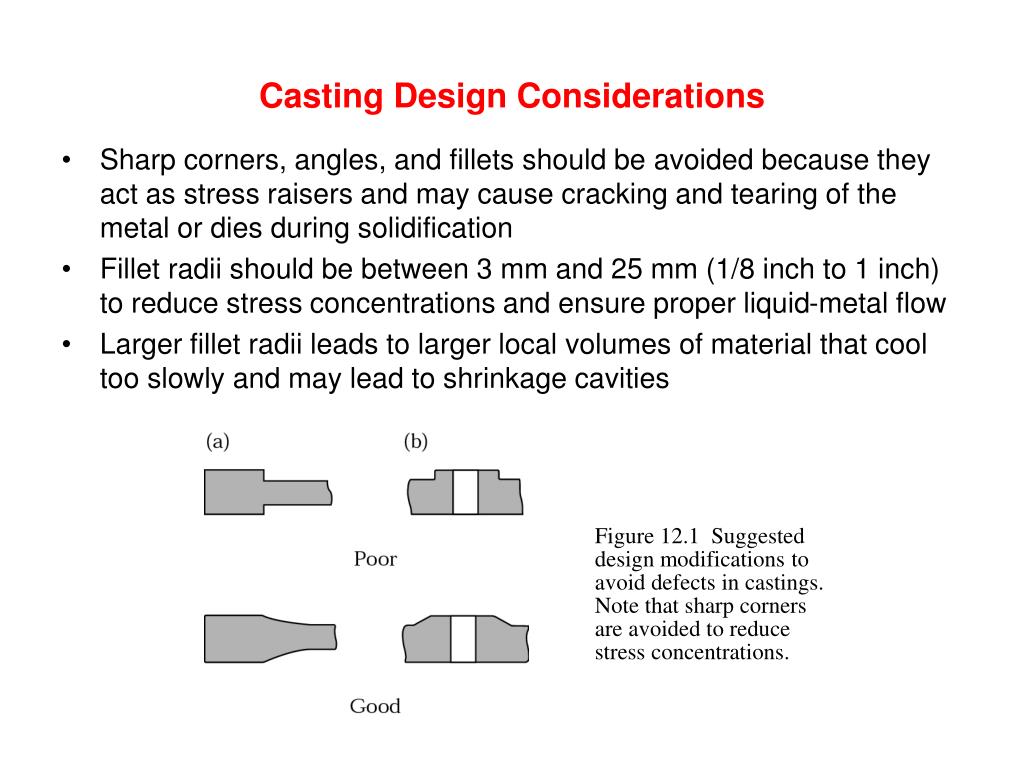

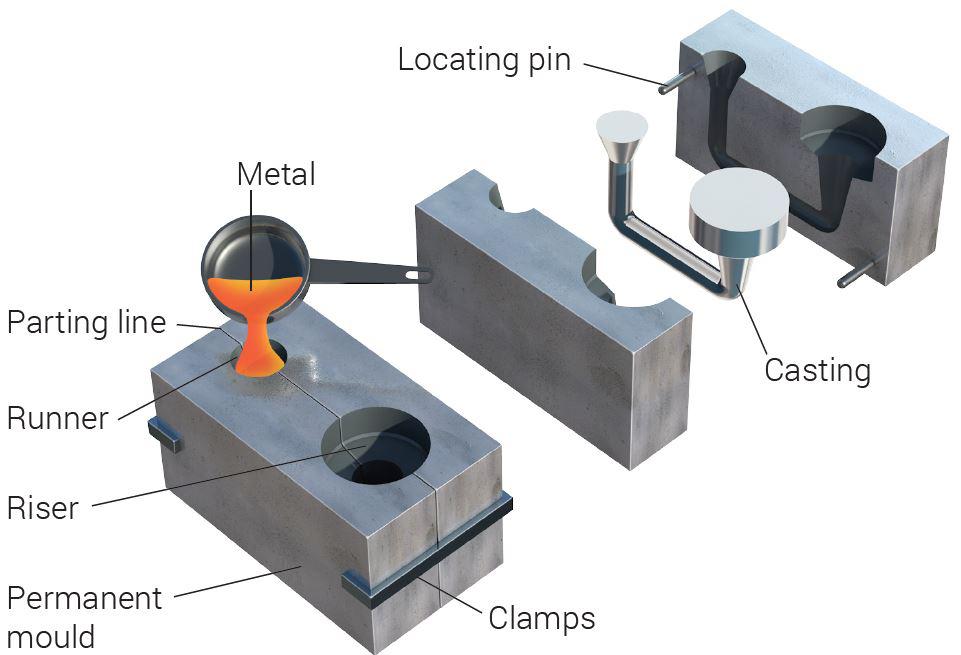

Casting Design - Web an engineer must take an approach to casting design that considers everything including structural function, molten metal flowing into a shape and solidifying, machining methods, assembly, testing, final use and abuse. Web good metal casting design means creating the simplest mold that will produce a desired shape. Participants will explore alloy selection, metalcasting process capabilities and limitations, with their effects on casting design, and the impact of secondary operations. Once the metal solidifies, the casting is removed by breaking the mold or ejecting it. Once solidified, the mold is broken or ejected to retrieve the casting. This method enables the production of intricate and complex components with specific properties. Web there are sections on foundry processes, casting design, tolerances of sand castings, quality assurance methods specific to foundries, an alloy selection guide for nonferrous sand casting alloys and a collection of metalcasting glossaries. Web metaltek focuses on three primary metal casting processes: Web casting is a manufacturing process in which molten material, like metal, is poured into a mold and allowed to harden. This process requires expert knowledge of metals and casting methods to find the best value in a quality casting. Web metaltek focuses on three primary metal casting processes: Material specification and grade (e.g. Each comes with numerous design considerations ranging from overall shape to surface finish to dimensional tolerance. Web the modern casting process is divided into two main categories: If only a pattern is provided, then the dimensions of the casting are as predicted by the pattern. Web casting is a manufacturing process in which molten material, like metal, is poured into a mold and allowed to harden. This method enables the production of intricate and complex components with specific properties. Web an engineer must take an approach to casting design that considers everything including structural function, molten metal flowing into a shape and solidifying, machining methods,. Centrifugal casting, sand casting, and investment casting. Web there are sections on foundry processes, casting design, tolerances of sand castings, quality assurance methods specific to foundries, an alloy selection guide for nonferrous sand casting alloys and a collection of metalcasting glossaries. This process requires expert knowledge of metals and casting methods to find the best value in a quality casting.. Web good metal casting design means creating the simplest mold that will produce a desired shape. Participants will explore alloy selection, metalcasting process capabilities and limitations, with their effects on casting design, and the impact of secondary operations. Web the casting design process is a manufacturing process where molten material like a liquified metal is poured into the casting mold. Web good metal casting design means creating the simplest mold that will produce a desired shape. Web casting is a manufacturing process in which molten material, like metal, is poured into a mold and allowed to harden. If only a pattern is provided, then the dimensions of the casting are as predicted by the pattern. Participants will explore alloy selection,. Web this course delves into the major factors that affect final part design. Participants will explore alloy selection, metalcasting process capabilities and limitations, with their effects on casting design, and the impact of secondary operations. Centrifugal casting, sand casting, and investment casting. Web metaltek focuses on three primary metal casting processes: It discusses the design concepts that designers and foundries. Once the metal solidifies, the casting is removed by breaking the mold or ejecting it. Material specification and grade (e.g. Web good metal casting design means creating the simplest mold that will produce a desired shape. This process requires expert knowledge of metals and casting methods to find the best value in a quality casting. Web the casting design process. Each comes with numerous design considerations ranging from overall shape to surface finish to dimensional tolerance. Web an engineer must take an approach to casting design that considers everything including structural function, molten metal flowing into a shape and solidifying, machining methods, assembly, testing, final use and abuse. Web metaltek focuses on three primary metal casting processes: Web the modern. Web this course delves into the major factors that affect final part design. Each comes with numerous design considerations ranging from overall shape to surface finish to dimensional tolerance. This process requires expert knowledge of metals and casting methods to find the best value in a quality casting. Web the modern casting process is divided into two main categories: Web. Web casting is a manufacturing process in which molten material, like metal, is poured into a mold and allowed to harden. Drawings should include dimensional tolerances, indications of surfaces to be machined, and datum points for locating. Each comes with numerous design considerations ranging from overall shape to surface finish to dimensional tolerance. Web this course delves into the major. If only a pattern is provided, then the dimensions of the casting are as predicted by the pattern. Web there are sections on foundry processes, casting design, tolerances of sand castings, quality assurance methods specific to foundries, an alloy selection guide for nonferrous sand casting alloys and a collection of metalcasting glossaries. Web an engineer must take an approach to casting design that considers everything including structural function, molten metal flowing into a shape and solidifying, machining methods, assembly, testing, final use and abuse. Web this course delves into the major factors that affect final part design. Participants will explore alloy selection, metalcasting process capabilities and limitations, with their effects on casting design, and the impact of secondary operations. Web casting is a manufacturing process in which molten material, like metal, is poured into a mold and allowed to harden. Web the casting design process is a manufacturing process where molten material like a liquified metal is poured into the casting mold of a specific shape and allowed to cool or solidify within the printed mold. Web the modern casting process is divided into two main categories: Web good metal casting design means creating the simplest mold that will produce a desired shape. Drawings should include dimensional tolerances, indications of surfaces to be machined, and datum points for locating. Each comes with numerous design considerations ranging from overall shape to surface finish to dimensional tolerance. This method enables the production of intricate and complex components with specific properties. Centrifugal casting, sand casting, and investment casting. It discusses the design concepts that designers and foundries can use to obtain maximum performance from cast parts. Material specification and grade (e.g.

PPT Metal Casting Processes PowerPoint Presentation, free download

PPT Metal Casting Processes PowerPoint Presentation, free download

Patterns Clinch River Casting Iron Casting Foundry TN

CASTING DESIGN DESIGN GUIDELINES FOR CASTING PRODUCT DESIGN

A Beginner's Guide to Casting Design PumpWorks Castings

PPT Metal Casting Processes PowerPoint Presentation, free download

PPT Metal Casting Processes PowerPoint Presentation, free download

5 Different Methods Used in Casting

Metal Casting Process Metal casting, Metal casting process, Metal

Casting Design

Once Solidified, The Mold Is Broken Or Ejected To Retrieve The Casting.

This Process Requires Expert Knowledge Of Metals And Casting Methods To Find The Best Value In A Quality Casting.

Web Metaltek Focuses On Three Primary Metal Casting Processes:

Once The Metal Solidifies, The Casting Is Removed By Breaking The Mold Or Ejecting It.

Related Post: