C Charts

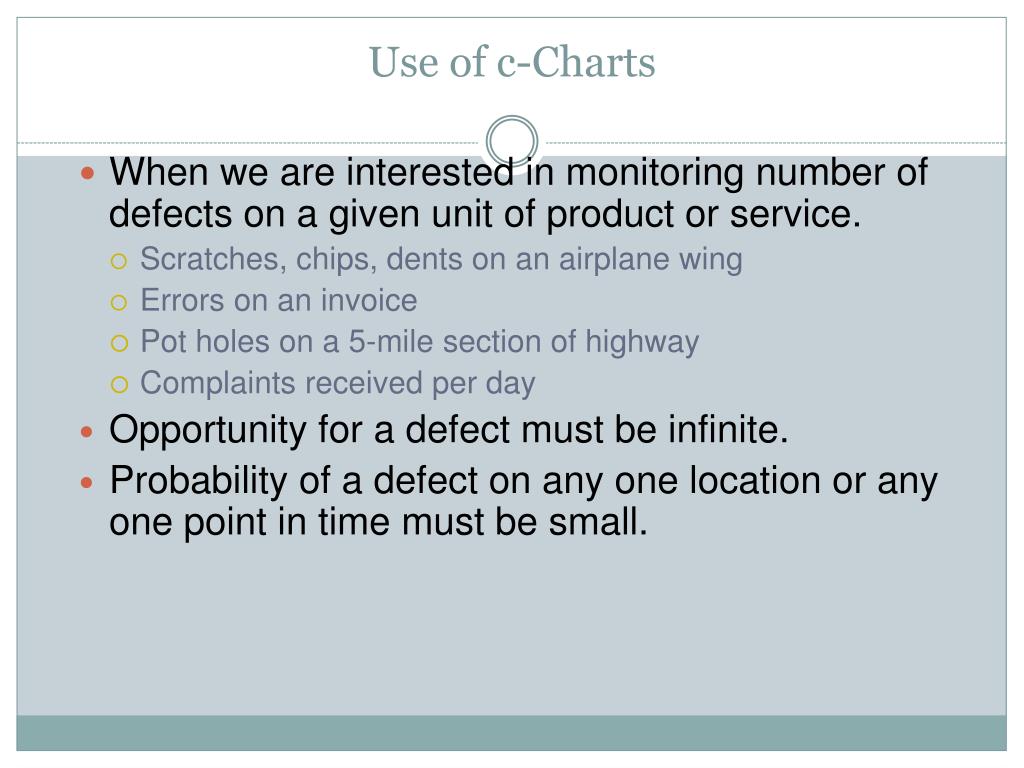

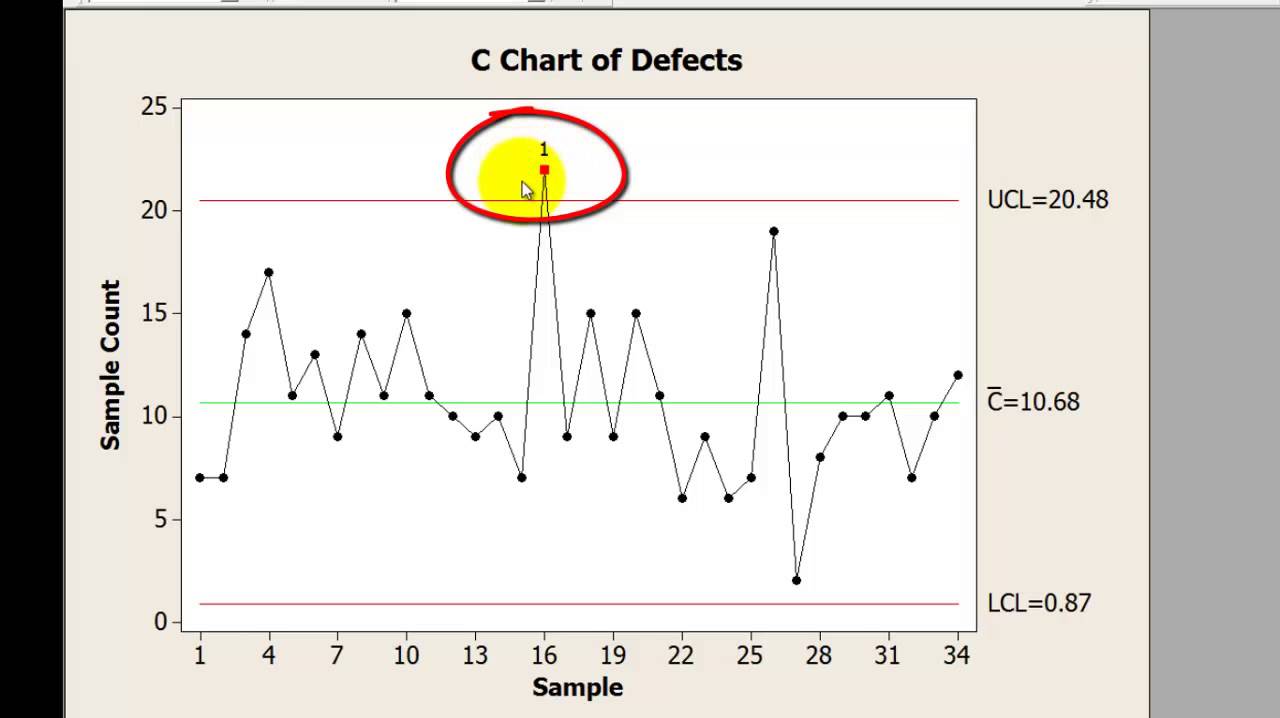

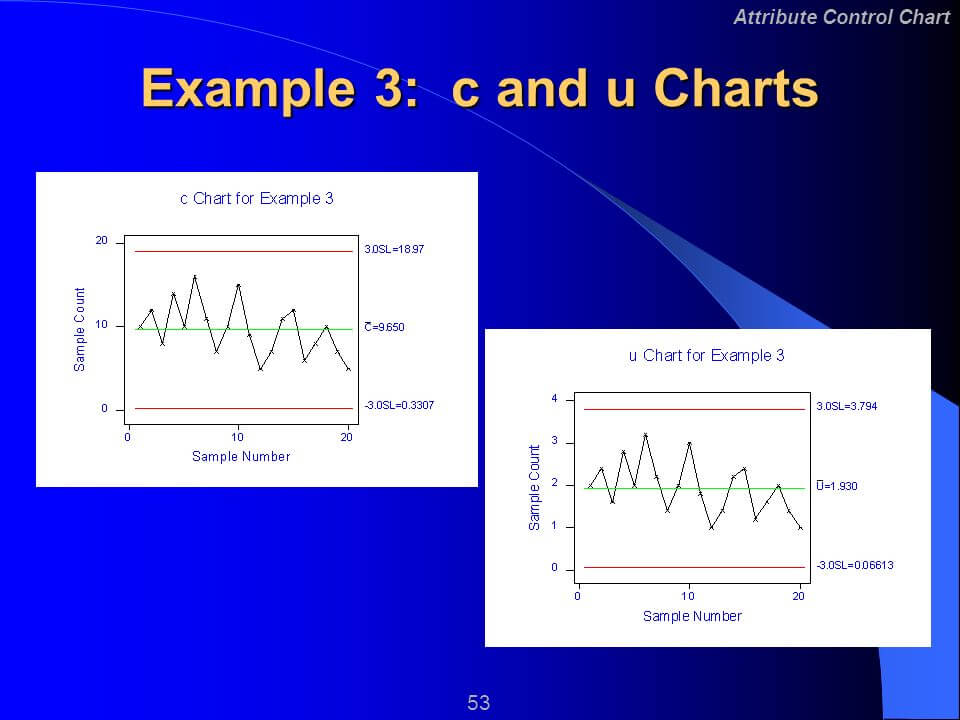

C Charts - Web what is a c chart? Web the c chart is used when the data can only be whole numbers, as in counting, it is known as attribute, or discrete data. Use this control chart to monitor process stability over time so that you can identify and correct instabilities in. 1 on the billboard 200, unseating taylor swift’s “the tortured poets department” after 12 weeks. There are no real surprises listed, here. C chart is also known as the control chart for defects (counting of the number of defects). Key output includes the c chart and the test results. Web the descriptions below provide an overview of the different types of control charts to help practitioners identify the best chart for any monitoring situation, followed by a description of the method for using control charts for analysis. Eminem’s latest album, “the death of slim shady (coup de grâce),” has debuted at no. Web quality control charts represent a great tool for engineers to monitor if a process is under statistical control. 4 on the oricon weekly singles ranking and no. Download free qi macros trial. There are no real surprises listed, here. 8 on the japan hot 100). The center line is the average number of nonconformities. Web data mining and analysis. Where m is the number of groups included in the analysis. In its first week, “the tortured poets department” hit 891.34 million album streams stateside, according to. If you are not sure which tests apply in your specific situation, use tests 1 and 2 when you first establish the control limits based on your data.. Eminem’s latest album, “the death of slim shady (coup de grâce),” has debuted at no. Web data mining and analysis. They are used to determine the variation in the number of defects in a constant subgroup size. Injuries per month or falls per month). Nba.com staff group a group b group c usa 🇺🇸 secure the first spot in group. In its first week, “the tortured poets department” hit 891.34 million album streams stateside, according to. Web a c chart is a type of control chart that shows how many defects or nonconformities are in samples of constant size, taken from a process (misra, 2008). Use this control chart to monitor process stability over time so that you can identify. Use the center line to observe how the. It is generally used to monitor the number of defects in constant size units. Subgroup size usually refers to the area being examined. On the tests tab, select 1 point > k standard deviations from center line (test 1) and k points in a row on same side of center line (test. The center line on a c chart represents the average number of defects per subgroup. Web find out the standings, upcoming game schedule and results from previous games throughout the olympic tournament. Download free qi macros trial. The count of occurrences of a criteria of interest in a sample of items. There is a difference between a defect and defective,. Web just days after its release, “supernatural” soared into the top 10 of the japanese singles charts (hitting no. It is also occasionally used to monitor the total number of events occurring in a given unit of time. On the tests tab, select 1 point > k standard deviations from center line (test 1) and k points in a row. Web here's a look at the depth chart that the texans shared on their official twitter account. Every item in the sample is evaluated for only the number of defects, flaws, or occurrences, etc. This “unit” is commonly referred to as an inspection unit and may be “per day” or “per square foot” of some other predetermined sensible rate. Web. Web just days after its release, “supernatural” soared into the top 10 of the japanese singles charts (hitting no. Control charts are a simple yet powerful tool that helps us understand if a process is “stable or in control.” control charts are used in the control phase of the dmaic (define, measure, analyze, improve, and control) process. Subgroup size usually. Web the c chart is used when the data can only be whole numbers, as in counting, it is known as attribute, or discrete data. In its first week, “the tortured poets department” hit 891.34 million album streams stateside, according to. Download free qi macros trial. Click ok in each dialog box. Paul dejong has walked over. Web a c chart is a data analysis technique for determining if a measurement process has gone out of statistical control. Web find out the standings, upcoming game schedule and results from previous games throughout the olympic tournament. Web use c chart to monitor the number of defects where each item can have multiple defects. Subgroup size usually refers to the area being examined. Web the descriptions below provide an overview of the different types of control charts to help practitioners identify the best chart for any monitoring situation, followed by a description of the method for using control charts for analysis. On the tests tab, select 1 point > k standard deviations from center line (test 1) and k points in a row on same side of center line (test 2). First, indicate the number of samples: The c chart is used with a constant sample size where you are counting the number of defects in the sample. Web in an unusual twist, dejong made a short walk to the royals' dugout amidst the ongoing series, ready to don his new team's colors and contribute to their infield depth. Use this control chart to monitor process stability over time so that you can identify and correct instabilities in. Use the center line to observe how the. Injuries per month or falls per month). Web what are control charts? Web instructions for entering measurements: They are used to determine the variation in the number of defects in a constant subgroup size. To ensure that your results are valid, consider the following guidelines when you collect data, perform the analysis, and interpret your results.

PPT Statistical Process Control PowerPoint Presentation, free

PPT Chapter 6 Control Charts for Attributes PowerPoint Presentation

PPT Control Chart Selection PowerPoint Presentation, free download

Video on C Chart procedure explained by Advance Innovation Group YouTube

CChart Calculations Download Table

C How to use Chart and Graph in Visual C YouTube

c Charts Part 1 Control Charts for Discrete Data Coursera

C Chart Calculations C Chart Formula Quality America

Control Chart 101 Definition, Purpose and How to EdrawMax Online

C CHART C bar control chart in statistical process control (SPC

It Is Also Occasionally Used To Monitor The Total Number Of Events Occurring In A Given Unit Of Time.

Every Item In The Sample Is Evaluated For Only The Number Of Defects, Flaws, Or Occurrences, Etc.

C Chart Is Also Known As The Control Chart For Defects (Counting Of The Number Of Defects).

Web A C Chart Is A Type Of Control Chart That Shows How Many Defects Or Nonconformities Are In Samples Of Constant Size, Taken From A Process (Misra, 2008).

Related Post: