Brinell Hardness Chart

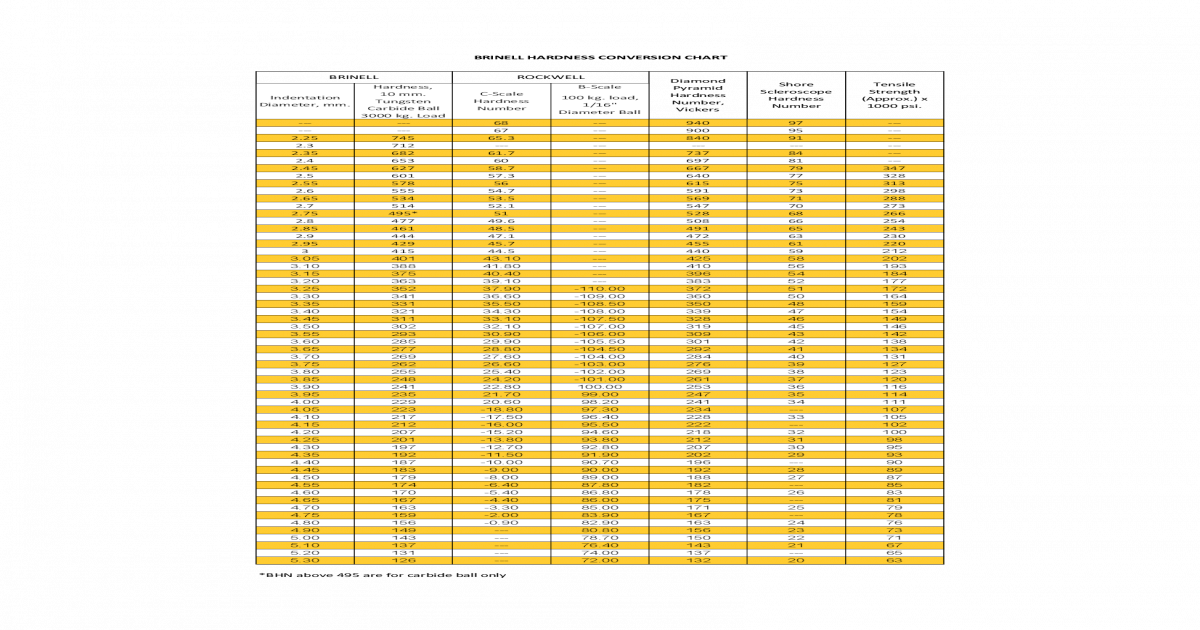

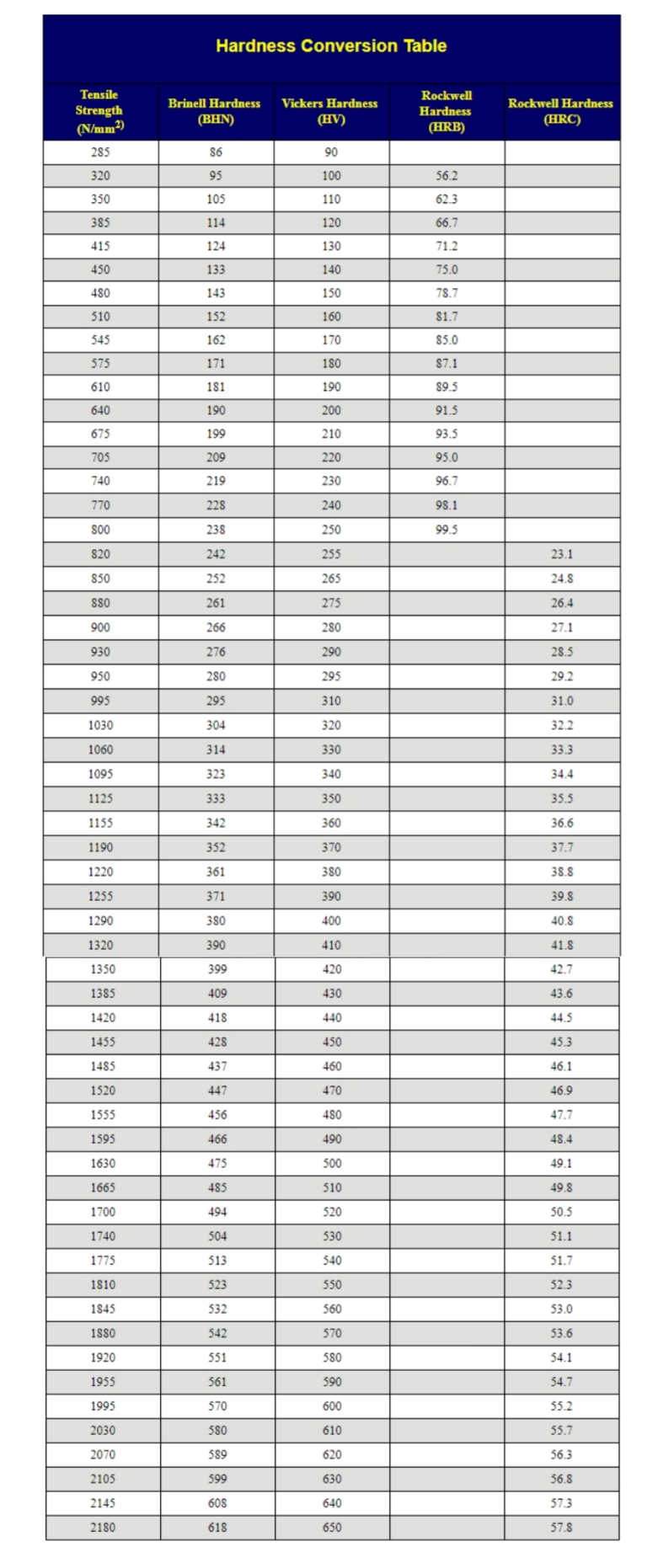

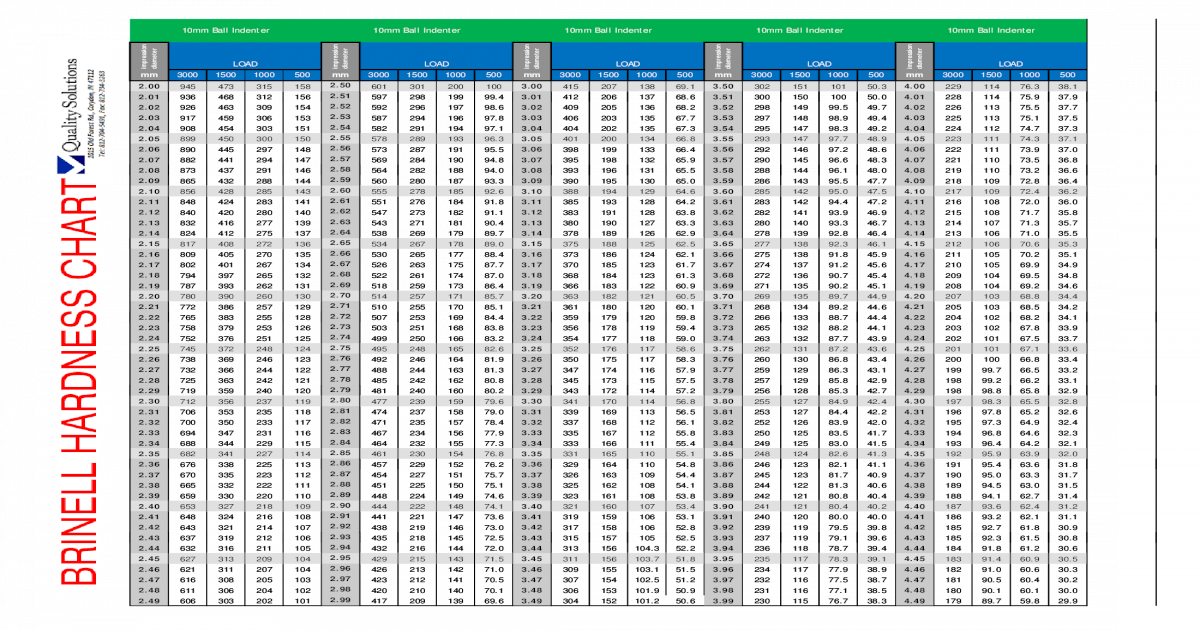

Brinell Hardness Chart - Web the brinell hardness test method is the most commonly used hardness measurement technique in the industry. In the brinell hardness testing, the hardness of a metal is determined by measuring the permanent indentation size produced by an indenter. A hardness test for larger samples. It is one of several definitions of hardness in materials science. These conversion charts are provided for guidance only as each scales uses different methods of measuring hardness. As the brinell hardness test (hbw) indentation leaves a relatively large impression, the brinell hardness test is better suited to larger samples with a coarse or inhomogeneous grain structure, such as castings and forgings. The right hand column show an approximate equivalent tensile strength. Web the brinell hardness test is commonly used to determine the hardness of materials like metals and alloys. Web this table shows approximate hardness of steel using brinell, rockwell b and c and vickers scales. Web a well structured brinell hardness number reveals the test conditions, and looks like this, 75 hb 10/500/30 which means that a brinell hardness of 75 was obtained using a 10mm diameter hardened steel with a 500 kilogram load applied for a period of 30 seconds. Web the brinell hardness test is commonly used to determine the hardness of materials like metals and alloys. In the brinell hardness testing, the hardness of a metal is determined by measuring the permanent indentation size produced by an indenter. Web brinell hardness test (bhn) the brinell hardness test consists of indenting the test material with a 10mm diameter hardened. Web a well structured brinell hardness number reveals the test conditions, and looks like this, 75 hb 10/500/30 which means that a brinell hardness of 75 was obtained using a 10mm diameter hardened steel with a 500 kilogram load applied for a period of 30 seconds. Web the brinell hardness test is commonly used to determine the hardness of materials. These conversion charts are provided for guidance only as each scales uses different methods of measuring hardness. Web a well structured brinell hardness number reveals the test conditions, and looks like this, 75 hb 10/500/30 which means that a brinell hardness of 75 was obtained using a 10mm diameter hardened steel with a 500 kilogram load applied for a period. It is one of several definitions of hardness in materials science. These conversion charts are provided for guidance only as each scales uses different methods of measuring hardness. Hbw stands for hardness brinell wolfram carbide. Web the brinell hardness test is commonly used to determine the hardness of materials like metals and alloys. Web the brinell hardness test method is. A hardness test for larger samples. Web this table shows approximate hardness of steel using brinell, rockwell b and c and vickers scales. These conversion charts are provided for guidance only as each scales uses different methods of measuring hardness. The test is achieved by applying a known load to the surface of the tested material through a hardened steel. A hardness test for larger samples. Web this table shows approximate hardness of steel using brinell, rockwell b and c and vickers scales. In the brinell hardness testing, the hardness of a metal is determined by measuring the permanent indentation size produced by an indenter. It is one of several definitions of hardness in materials science. The test is achieved. A hardness test for larger samples. Web the brinell hardness test is commonly used to determine the hardness of materials like metals and alloys. The test is achieved by applying a known load to the surface of the tested material through a hardened steel ball of known diameter. Web this table shows approximate hardness of steel using brinell, rockwell b. As the brinell hardness test (hbw) indentation leaves a relatively large impression, the brinell hardness test is better suited to larger samples with a coarse or inhomogeneous grain structure, such as castings and forgings. The test is achieved by applying a known load to the surface of the tested material through a hardened steel ball of known diameter. A hardness. In the brinell hardness testing, the hardness of a metal is determined by measuring the permanent indentation size produced by an indenter. Hbw stands for hardness brinell wolfram carbide. Web a well structured brinell hardness number reveals the test conditions, and looks like this, 75 hb 10/500/30 which means that a brinell hardness of 75 was obtained using a 10mm. Web brinell hardness test (bhn) the brinell hardness test consists of indenting the test material with a 10mm diameter hardened steel or tungsten ball subjected to a load of 3000 kg. A hardness test for larger samples. Web the brinell hardness test is commonly used to determine the hardness of materials like metals and alloys. It is one of several. Web this table shows approximate hardness of steel using brinell, rockwell b and c and vickers scales. The right hand column show an approximate equivalent tensile strength. For softer materials, there are alternate scales using a 1500 kg or 500 kg load to avoid excessive indentation. Web the brinell hardness test method is the most commonly used hardness measurement technique in the industry. These conversion charts are provided for guidance only as each scales uses different methods of measuring hardness. As the brinell hardness test (hbw) indentation leaves a relatively large impression, the brinell hardness test is better suited to larger samples with a coarse or inhomogeneous grain structure, such as castings and forgings. In the brinell hardness testing, the hardness of a metal is determined by measuring the permanent indentation size produced by an indenter. Hbw stands for hardness brinell wolfram carbide. Web brinell hardness test (bhn) the brinell hardness test consists of indenting the test material with a 10mm diameter hardened steel or tungsten ball subjected to a load of 3000 kg. A hardness test for larger samples. It is one of several definitions of hardness in materials science.

Brinell hardness at high temperature of OLT 35K steel, after tempering

King Brinell Chart

Brinell Hardness Conversion Chart

(PDF) Brinell Hardness Conversion Chart PDFSLIDE.US

Brinell Hardness Chart Printable

Printable Brinell Hardness Chart Firearms Ammunition

Brinell hardness measurement along the simulated sample Download

brinell hardness chart printable pdfqs brinell hardness chart.pdf Â

Brinell Scale HBW 10/3000 Chart PDF Chemical Product Engineering

Brinell Hardness Conversion Chart

Web A Well Structured Brinell Hardness Number Reveals The Test Conditions, And Looks Like This, 75 Hb 10/500/30 Which Means That A Brinell Hardness Of 75 Was Obtained Using A 10Mm Diameter Hardened Steel With A 500 Kilogram Load Applied For A Period Of 30 Seconds.

Web The Brinell Hardness Test Is Commonly Used To Determine The Hardness Of Materials Like Metals And Alloys.

The Test Is Achieved By Applying A Known Load To The Surface Of The Tested Material Through A Hardened Steel Ball Of Known Diameter.

Related Post: