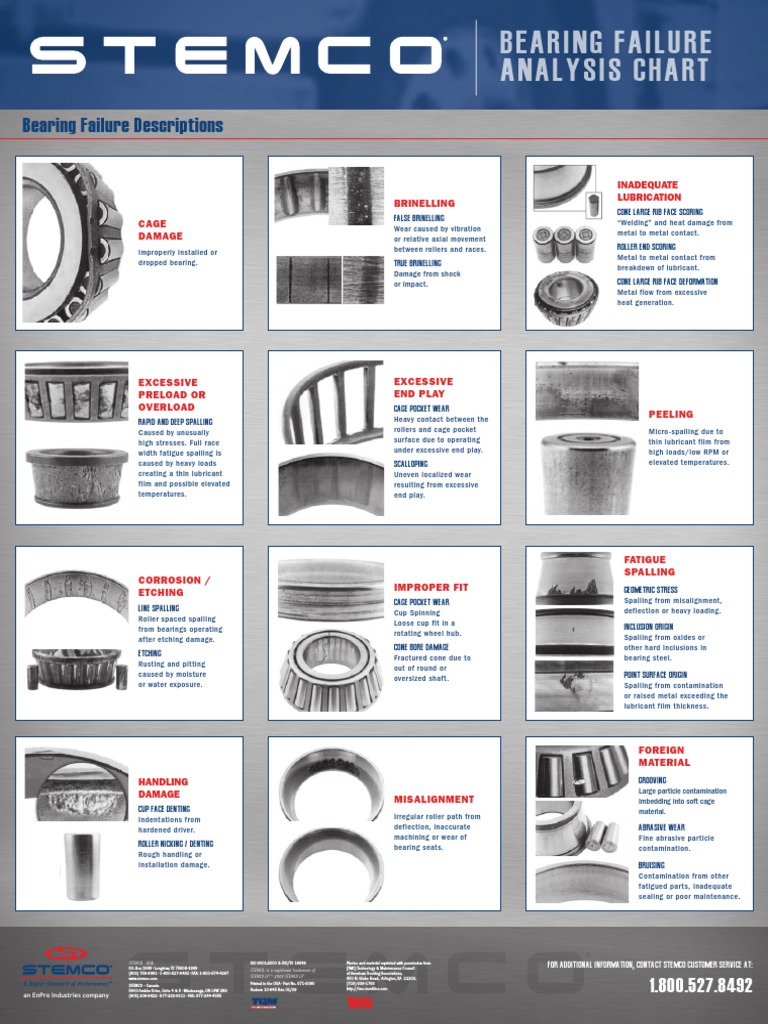

Bearing Failure Chart

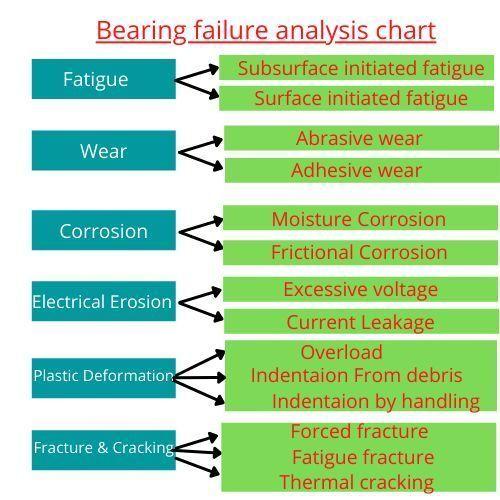

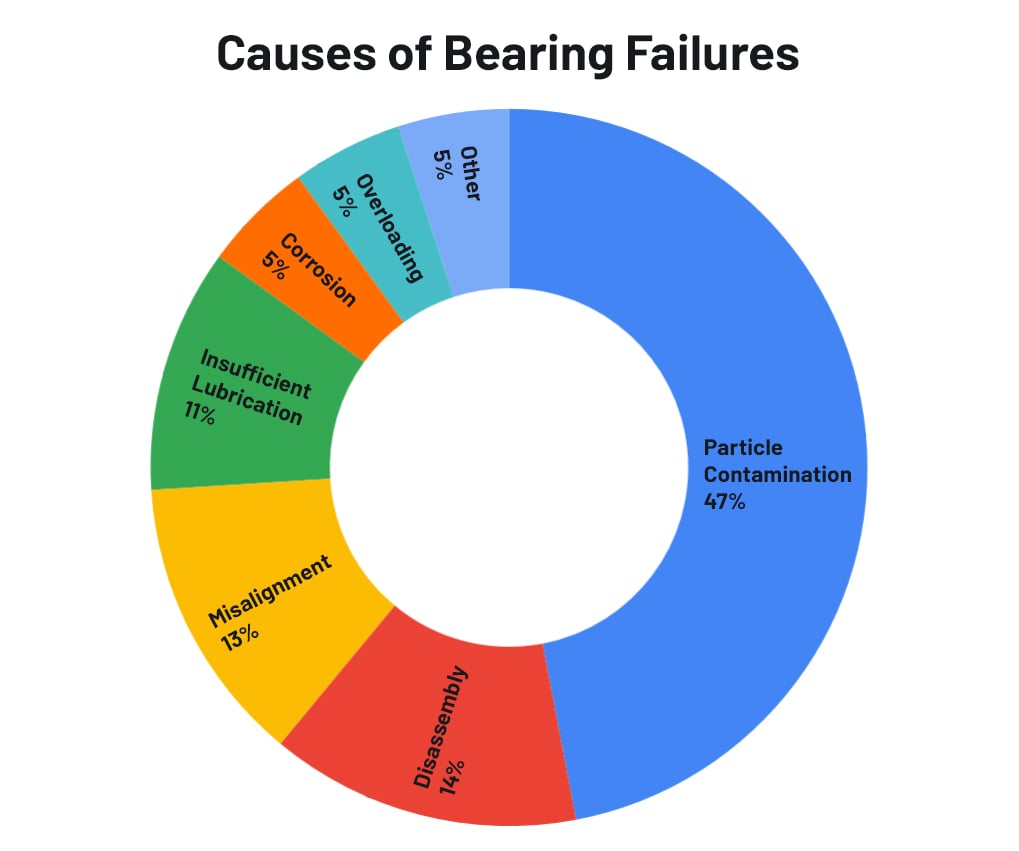

Bearing Failure Chart - Typical causes include improper tool selection (hardened drivers) and poor handling practices which can lead to point surface origin (pso) spalls. Inaccurate wear of housing or shafts. Most of the other bearing components can be repaired or replaced. With broad and deep expertise in material science and tribology, we’ve developed this guide to help you identify and analyze bearing damage, including possible causes and preventative courses of action. 1.1 determination of operating data. 1.6 assessment of the complete. Even when bearings are being used under ideal conditions, failures of bearings are caused by deterioration of the material due to rolling fatigue. Web damage happens when there isn’t a sufficient amount of bearing lubricant to separate the rolling and sliding contact surfaces during service. Web august 10, 2022 15 minutes. 1.5 dismounting the damaged bearing. Web a basic understanding of bearing failures and failure analy sis. Focuses the investigation on the rings. Use of worn or improperly dressed grinding wheel when resizing the crankshaft. Specific remedies for each situation are also suggested. Some of the most common ones include: Web damage happens when there isn’t a sufficient amount of bearing lubricant to separate the rolling and sliding contact surfaces during service. Web eight major causes of premature engine bearing failure, along with percentage figures which indicate how often each has been found to be the prime contributor to a bearing’s premature failure. Flaws, in most cases, are readily apparent.. Most of the other bearing components can be repaired or replaced. Improperly installed or dropped bearing. This practice can prevent complete system breakdowns and inform the design of new bearing products. The iso 15243, which was last updated in 2017, sets out six main categories or modes into which bearing failures can be grouped; Web each characteristic is described in. Being able to identify failure modes and causes of rolling bearing damage is the first step towards avoiding repeat failures and improving machinery reliability. Saul later fell into offering pagan sacrifices and failure to uphold god’s commands, leading god to turn his favor away from saul’s line and toward saul’s captain,. Web eight major causes of premature engine bearing failure,. Improperly installed or dropped bearing. Learn how to spot the clues to eliminate the problem from the source and maximize your bearing life. Web august 10, 2022 15 minutes. Web determine the causes of the failure comparing the failure patterns with available standard photos from iso 15243 and/or bearing manufacturers. 1.5 dismounting the damaged bearing. Caused by unusually high stresses. Web determine the causes of the failure comparing the failure patterns with available standard photos from iso 15243 and/or bearing manufacturers. Determine the necessary corrective actions required in order to avoid the recurrence of the same failure. Web one way to minimize bearing damage is to be sure of the right bearing for your application. Web bearing damage analysis reference guide. Ecclesiastes, and the song bearing his name, as well as 2 (and possibly more) of the psalms. Web according to schaeffler, 85% of bearing failures are preventable. Web each characteristic is described in detail and is shown in diagram form, accompanied by a color photograph. 1.4 assessment of bearing in mounted condition. Improper fit in housings or shafts. Web determine the causes of the failure comparing the failure patterns with available standard photos from iso 15243 and/or bearing manufacturers. 1.6 assessment of the complete. Caused by unusually high stresses. Caused by unusually high stresses. Web according to schaeffler, 85% of bearing failures are preventable. Most of the other bearing components can be repaired or replaced. Improperly installed or dropped bearing. Learn how to spot the clues to eliminate the problem from the source and maximize your bearing life. Use of worn or improperly dressed grinding wheel when resizing the crankshaft. Web damage happens when there isn’t a sufficient amount of bearing lubricant to separate the rolling and sliding contact surfaces during service. Web according to schaeffler, 85% of bearing failures are preventable. 1.3 inspection of the bearing environment. Protect and keep the failed bearing for future use as comparison. This practice can prevent complete system breakdowns and inform the design. Journals may result as tapered, hourglass shape or barrel shape. Caused by unusually high stresses. With the knowledge presented in this publication, it is possible to assess simple failure situations and start the right analysis. Being able to identify failure modes and causes of rolling bearing damage is the first step towards avoiding repeat failures and improving machinery reliability. Full race width fatigue spalling is caused by heavy loads creating a thin lubricant film and possible elevated temperatures. Each concern stems from a small group of interrelated and preventable causes. Web a basic understanding of bearing failures and failure analy sis. Improperly installed or dropped bearing. Saul later fell into offering pagan sacrifices and failure to uphold god’s commands, leading god to turn his favor away from saul’s line and toward saul’s captain,. Even when bearings are being used under ideal conditions, failures of bearings are caused by deterioration of the material due to rolling fatigue. Flaws, in most cases, are readily apparent. It will help to determine if the bearing can be a candidate for remanufacturing. 1.1 determination of operating data. Web august 10, 2022 15 minutes. Specific remedies for each situation are also suggested. Web determine the causes of the failure comparing the failure patterns with available standard photos from iso 15243 and/or bearing manufacturers.

Bearing Damage Reference Wall Chart RMS Ltd

Bearing failure analysis chart CNC Prog

Bearing Damage Reference Wall Chart RMS Ltd

Bearing Failure Analysys Chart Building Engineering Mechanical

Engine Bearing Failure Chart

Bearing Failure Poster English King Bearings Engine Bearing

Koyo bearingfailurechartposter

Bearing Damage Reference Wall Chart RMS Ltd

Bearing Failure Analysis

What Causes Bearing Failures and Preventative Measures You Need to Know

Rolling Bearings Are At The Heart Of Most Machines And Vehicles.

Focuses The Investigation On The Rings.

Learn How To Spot The Clues To Eliminate The Problem From The Source And Maximize Your Bearing Life.

This Practice Can Prevent Complete System Breakdowns And Inform The Design Of New Bearing Products.

Related Post: