Bandsaw Blade Tpi Chart

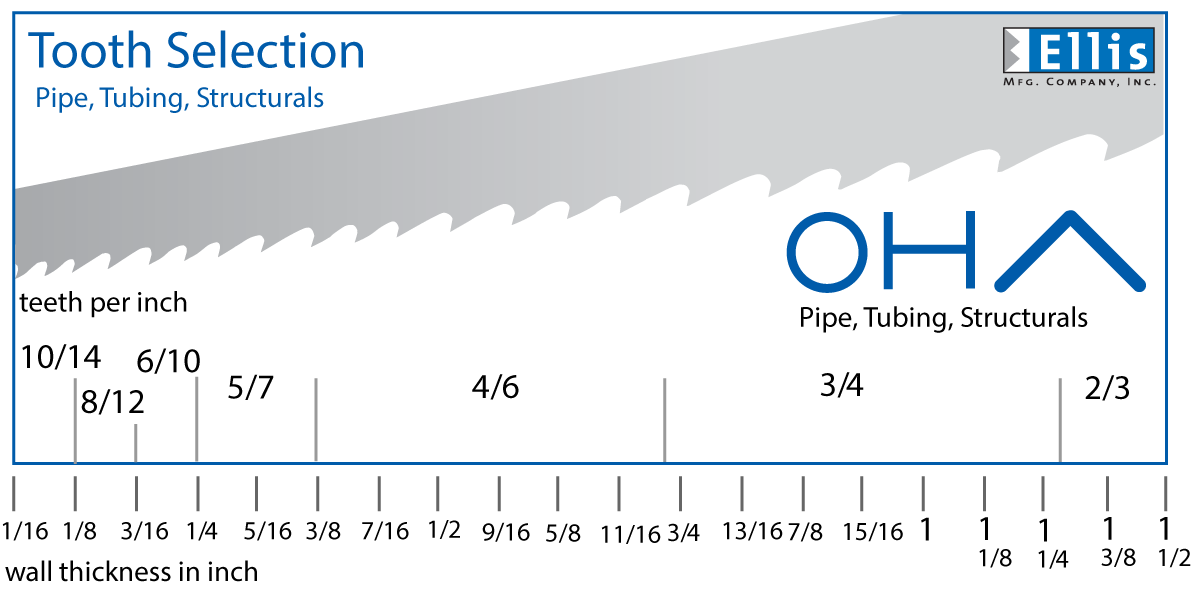

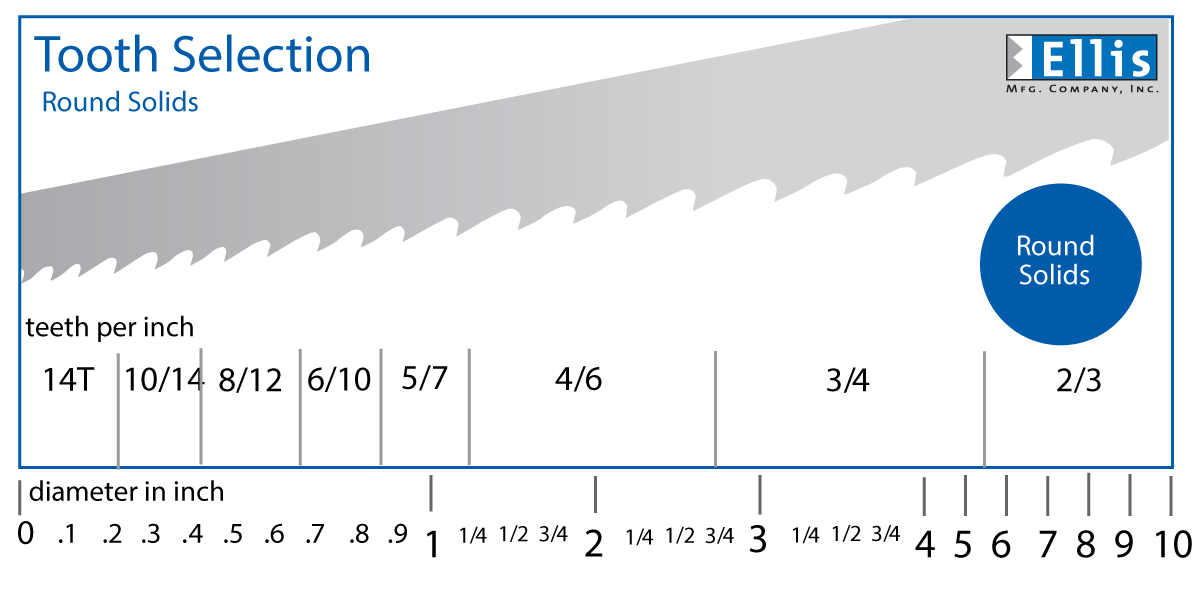

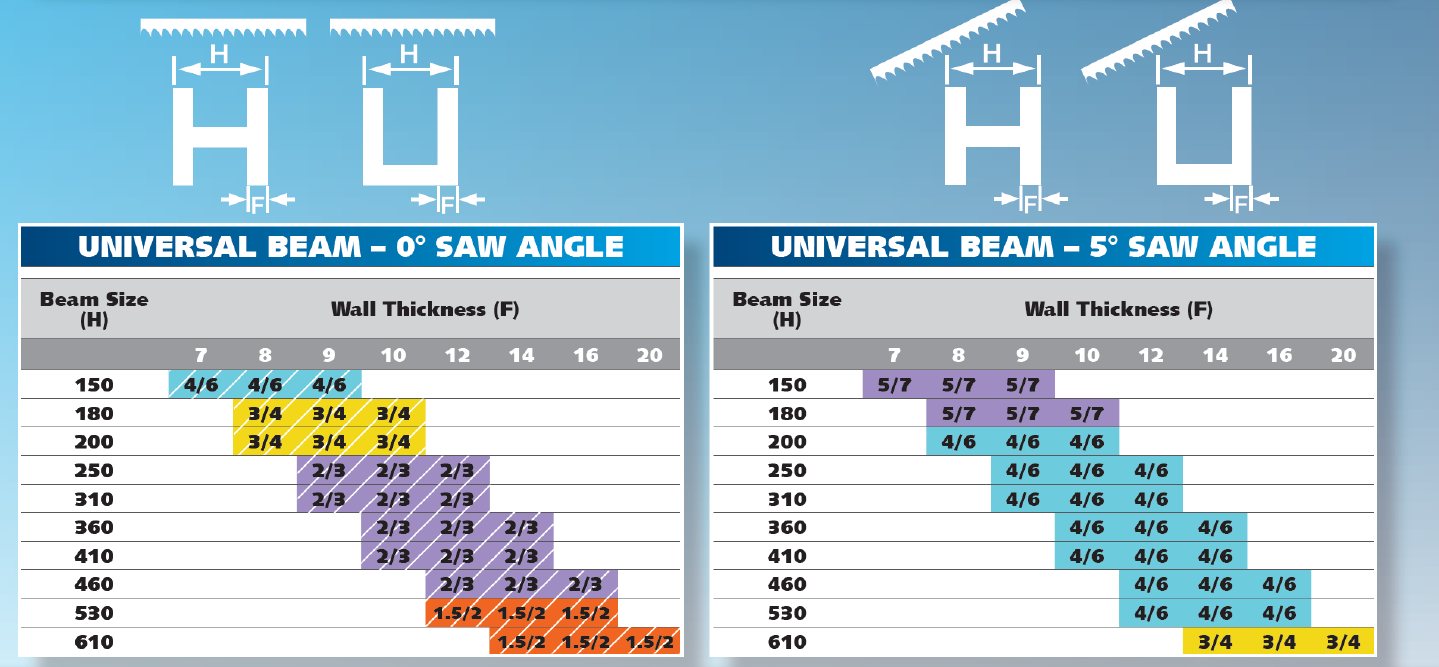

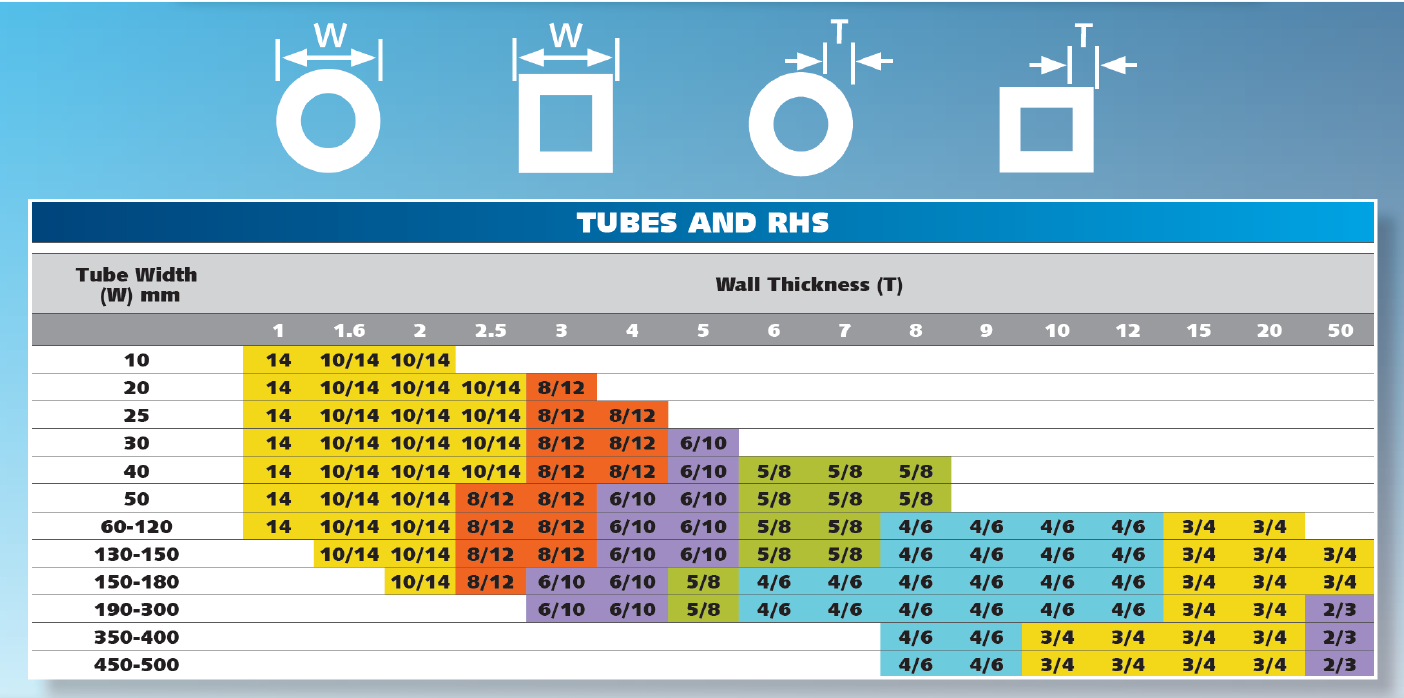

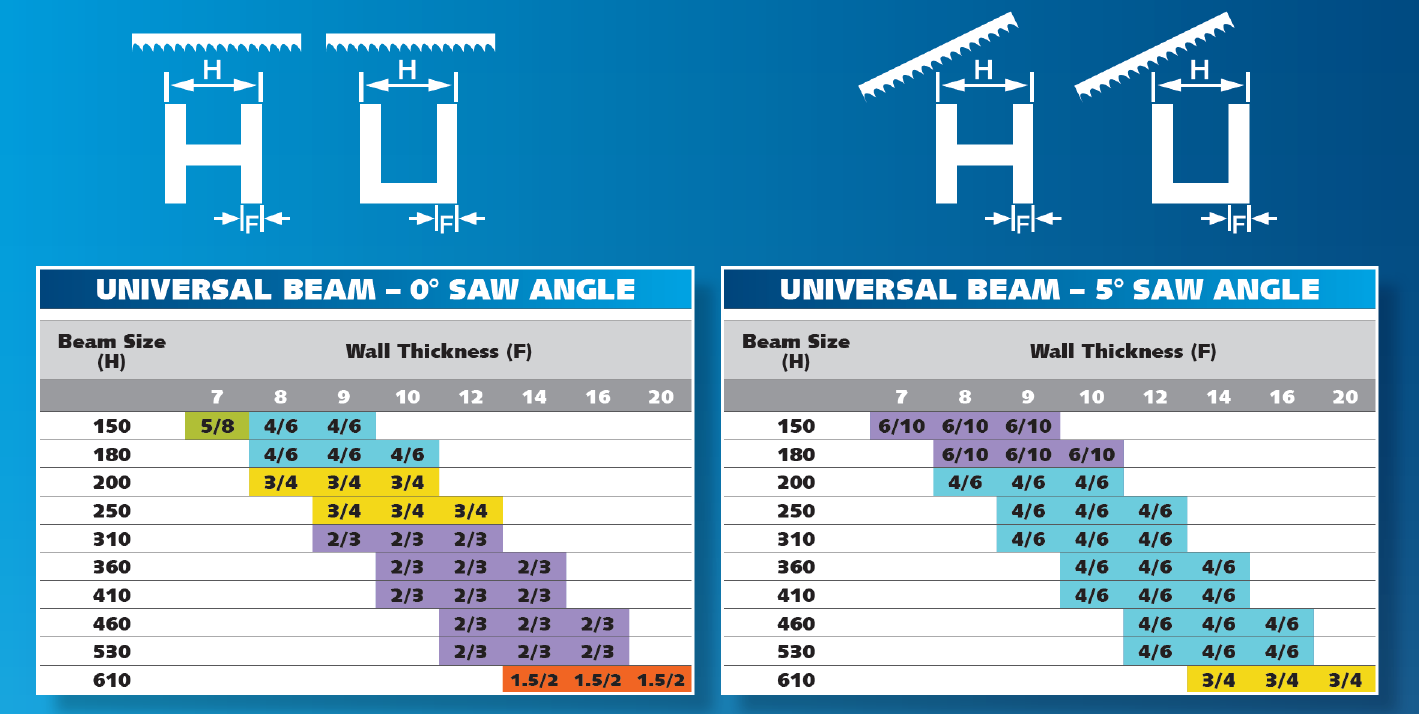

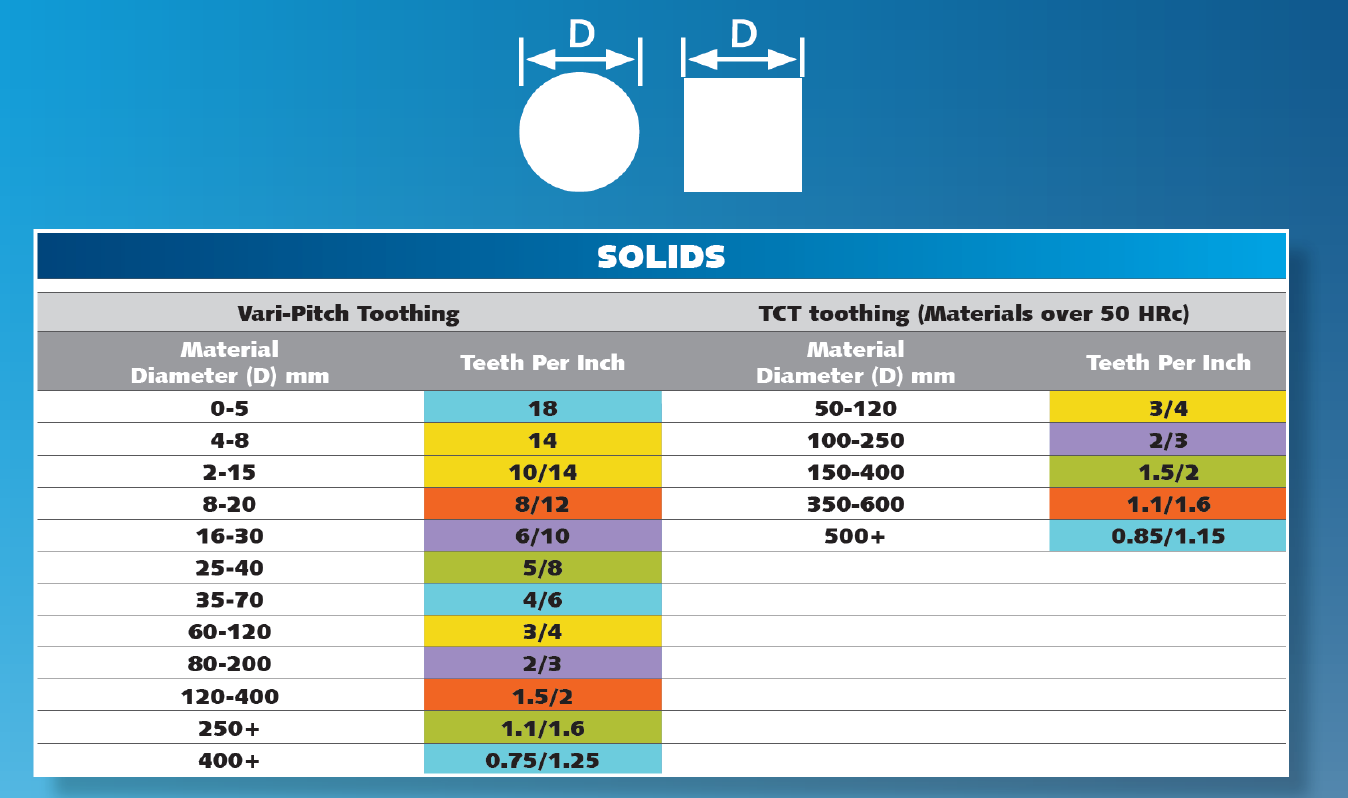

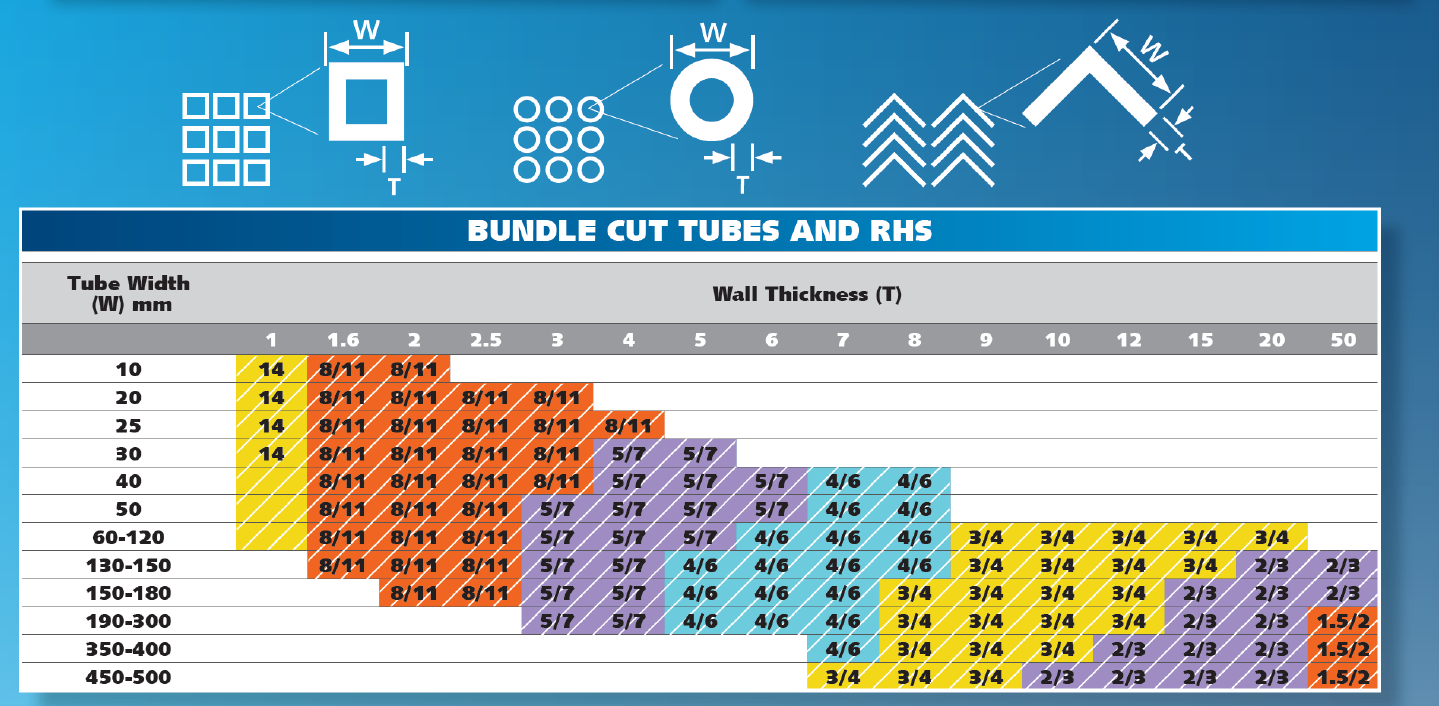

Bandsaw Blade Tpi Chart - Web tpi selection is arguably the most important decision when selecting a band saw blade. The information below will give you the best blade recommendation in most cases. Web tpi, or teeth per inch, is a crucial factor in selecting the right band saw blade for your project. Tpi refers to the number of teeth on the blade per inch (or 25.4mm depending on how you work) of its length. Industry standards are — a minimum of 3 teeth in the cut — a maximum of 24 teeth in the cut — with the optimum number of 12 teeth in the cut. Web to help choose a band saw blade, here is a chart showing the recommended number of teeth for various materials and thicknesses: How to choose the correct number of teeth per inch (tpi) installing your band saw blade 1. Web when selecting tpi remember: Delivers accurate cuts across a broad range of materials. Move up to the correct material size next to the chart. Includes 3 units ( $7.32 /unit) $ 21 97. Web about this item. Use band saw blades or jigsaw blades for small and intricate jobs, and tackle demolition projects with reciprocating saw blades. Web a finer tooth saw blade setting — 18 to 32 tpi — should be used for thinner metals and plastics under 0.25″ (or 1/4″). Maximum blade. Web a finer tooth saw blade setting — 18 to 32 tpi — should be used for thinner metals and plastics under 0.25″ (or 1/4″). The information below will give you the best blade recommendation in most cases. Web tpi, or teeth per inch, is a crucial factor in selecting the right band saw blade for your project. Web i. Maximum blade life is achieved by selecting a medium pitch blade, slow saw speed and medium rate feed. Occasionally i may cut aluminum up to 1 1/2. Web when selecting tpi remember: Web the ultimate bandsaw blade tpi guide is the perfect tool for those that are new to bandsaw blades. Master other jobsite cuts with circular saw blades. Using this chart, find the colored chart for the type of material you wish to cut. The chart below, developed by starrett®, offers guidelines for tpi selection based on material thickness. The tpi defines the pitch of the blade, which can vary from 1 to 32 tpi. Maximum blade life is achieved by selecting a medium pitch blade, slow saw. Move up to the correct material size next to the chart. Matrix ii high speed steel edge of the band saw blade is designed for heat and wear resistance. Maximum blade life is achieved by selecting a medium pitch blade, slow saw speed and medium rate feed. Select a tooth per inch (tpi) based on the charts below. It is. Follow across to the chart for the appropriate t.p.i. Find material dimensions on bottom of chart and move up for appropriate teeth per inch. (603) questions & answers (27) hover image to zoom. Move up to the correct material size next to the chart. Select a tooth per inch (tpi) based on the charts below. Includes 3 units ( $7.32 /unit) $ 21 97. The chart below, developed by starrett®, offers guidelines for tpi selection based on material thickness. Master other jobsite cuts with circular saw blades. Industry standards are — a minimum of 3 teeth in the cut — a maximum of 24 teeth in the cut — with the optimum number of 12. Follow across to the chart for the appropriate t.p.i. Most resaw blades feature a low tpi configuration. The information below will give you the best blade recommendation in most cases. Web about this item. Web how to choose the correct number of teeth per inch (tpi) the number of teeth per inch (tpi) is important in obtaining the finish desired. Tpi refers to the number of teeth on the blade per inch (or 25.4mm depending on how you work) of its length. The 14 tpi constant pitch blade that comes on the. Web about this item. Use band saw blades or jigsaw blades for small and intricate jobs, and tackle demolition projects with reciprocating saw blades. Web thicker materials require. How to choose the correct number of teeth per inch (tpi) installing your band saw blade 1. Web band saw tooth size (teeth per inch) is determined by the size and type of material to be cut and the desired finish. But how do you know which blade is the right blade? High speed steel cutting edge with 8% cobalt. Web band saw tooth size (teeth per inch) is determined by the size and type of material to be cut and the desired finish. Web get the best, most efficient performance from your band saw with the proper blade. Occasionally i may cut aluminum up to 1 1/2. Use band saw blades or jigsaw blades for small and intricate jobs, and tackle demolition projects with reciprocating saw blades. The information below will give you the best blade recommendation in most cases. How to choose the correct number of teeth per inch (tpi) installing your band saw blade 1. Web tpi selection is arguably the most important decision when selecting a band saw blade. In this guide, i will tell you everything you need to know to make informed purchases when it comes to band saw blades. Web whether you’re tackling an intricate task or a major build, we have the right blades at lowe’s for every cut. Move up to the correct material size next to the chart. Maximum blade life is achieved by selecting a medium pitch blade, slow saw speed and medium rate feed. Web when selecting tpi remember: Unplug the saw, then loosen the tension on the upper wheel.with all the blade guides backed off, slip the new blade around the wheels and then tension it. Web band saw tooth size is determined by the size and type of material to be cut and the desired finish. Select a tooth per inch (tpi) based on the charts below. Using this chart, find the colored chart for the type of material you wish to cut.

Band Saw Blade Tooth Selection Ellis Mfg, Inc.

Band Saw Blades Ellis Mfg, Inc.

The Ultimate Bandsaw Blade TPI Guide

The Ultimate Bandsaw Blade TPI Guide

The Ultimate Bandsaw Blade TPI Guide

The Ultimate Bandsaw Blade TPI Guide

Band Saw Blade Tpi Chart

TPI SELECTOR DeWalt Band Saw Blades

Wood Bandsaw Blade Tpi Chart

The Ultimate Bandsaw Blade TPI Guide

Delivers Accurate Cuts Across A Broad Range Of Materials.

Web About This Item.

Web Increased Cutting Rates Are Obtained By Using A Coarser Tooth Pitch, Higher Saw Speed And Faster Rate Of Feed.

Industry Standards Are — A Minimum Of 3 Teeth In The Cut — A Maximum Of 24 Teeth In The Cut — With The Optimum Number Of 12 Teeth In The Cut.

Related Post: