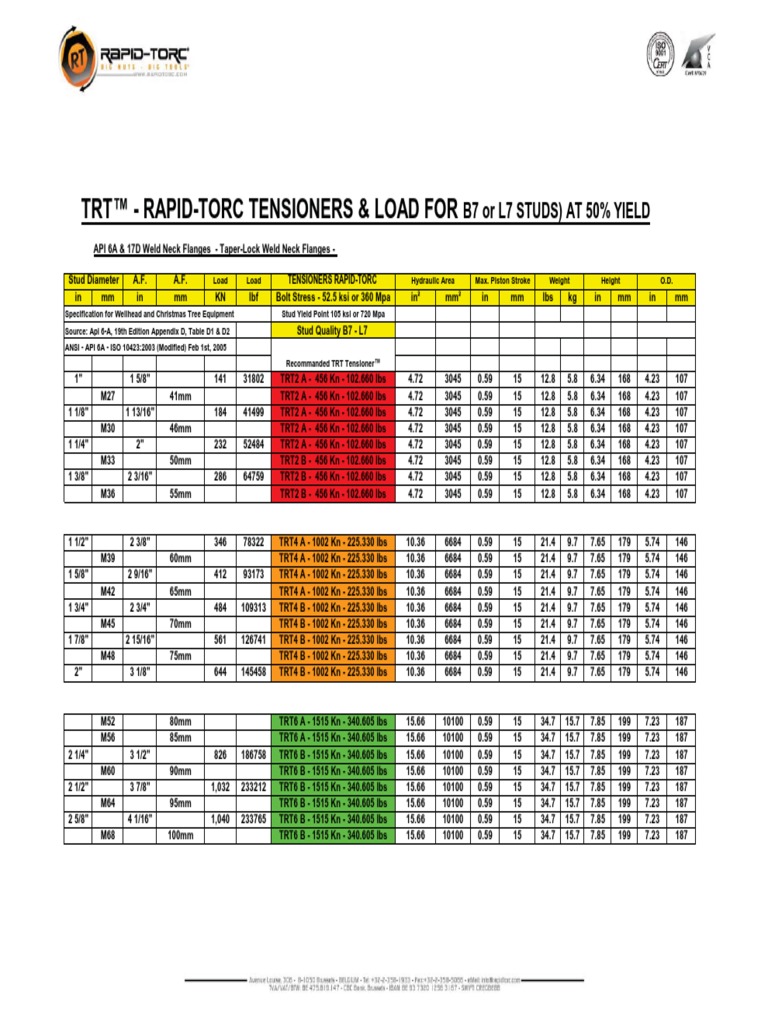

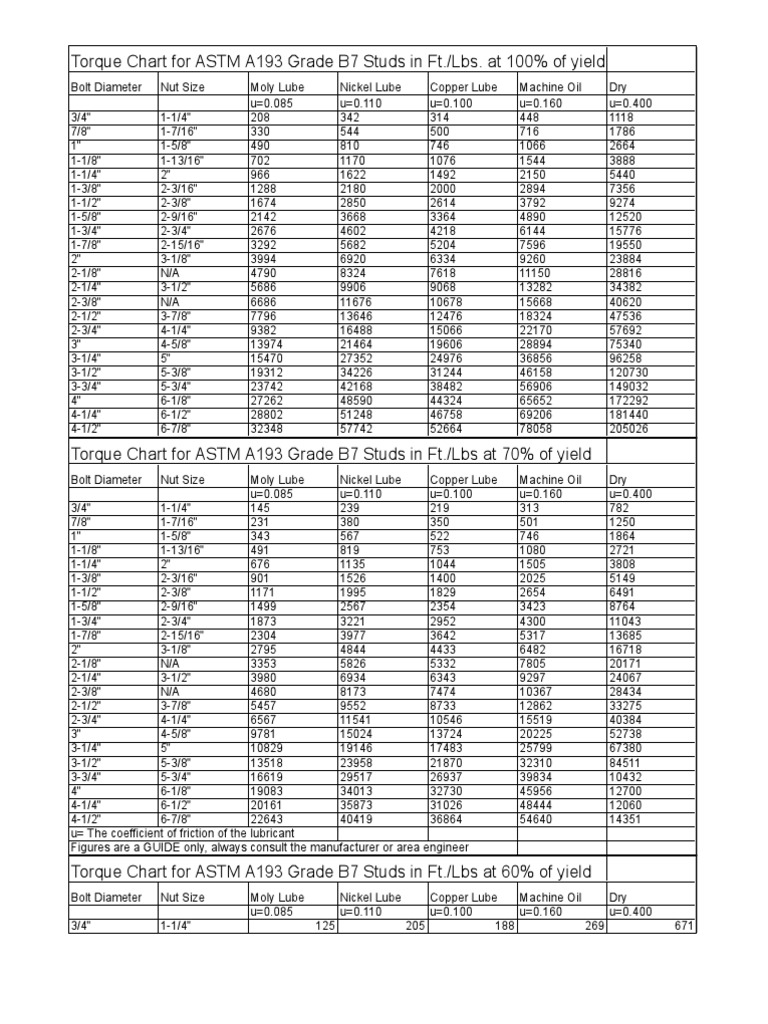

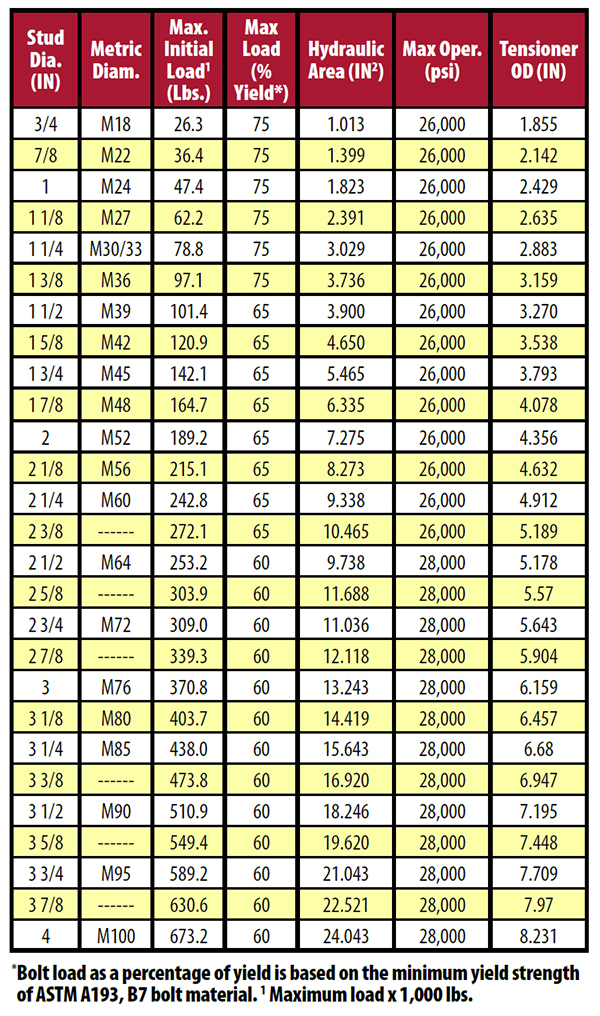

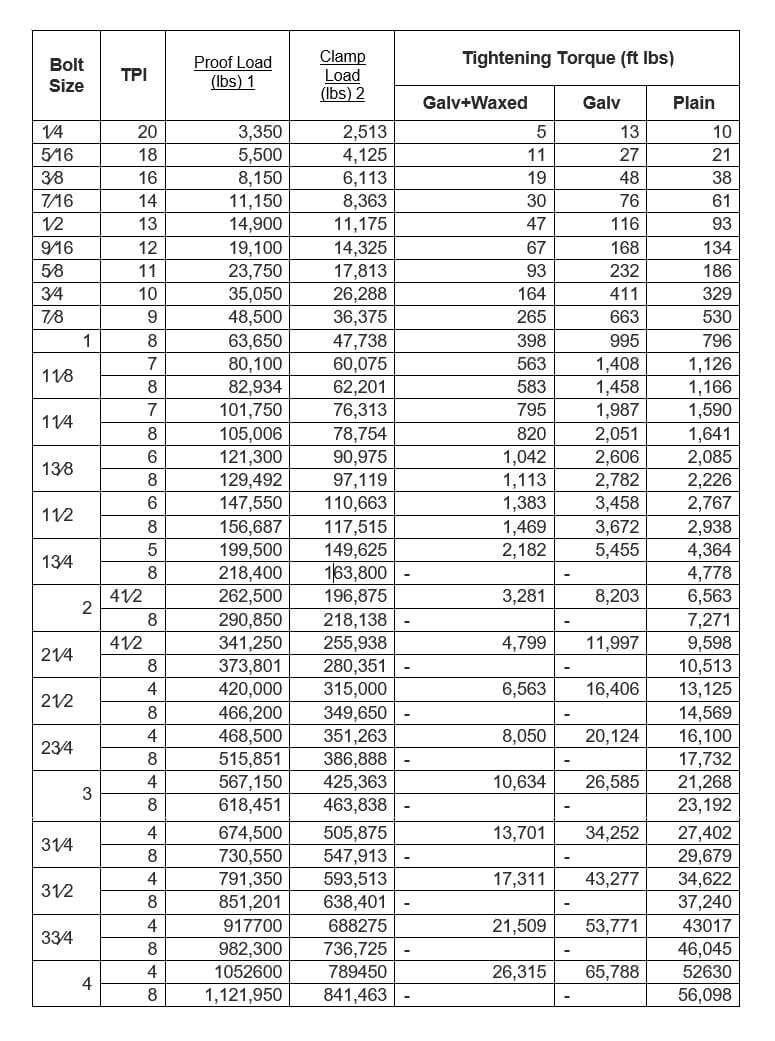

B7 Stud Torque Chart

B7 Stud Torque Chart - Tightening torque (ft lbs) galv. Web download torque value chart. These estimated torque calculations are offered as a guide for your. Web the document provides torque charts for astm a193 grade b7 studs at various percentages of yield (100%, 70%, 60%, 50%, 40%, 30%) and with different lubricants. Web recommended torque for b7 studs (astm a193) based upon 50% yield. Web required torque (ftlbs) custom (insert k) this spread sheet is to be used as a guide. Covering bolts on wellhead equipment, valves and chokes, and loose flanged connectors. Web tightening torque (ft lbs) galv + wax. Web this chart is to be used a guide only, always refer to oem specifications or local engineer call alltite, inc. Web the torque values can only be achieved if nut (or tapped hole) has a proof load greater than or equal to the bolt's minimum ultimate tensile strength. Astm a193, grade “b7” studs | lubricant: Web tightening torque (ft lbs) galv + wax. Covering bolts on wellhead equipment, valves and chokes, and loose flanged connectors. Tightening torque (ft lbs) plain. The above table is applicable only for a193 grade b7 and a193 grade b16 stud bolts. Covering bolts on wellhead equipment, valves and chokes, and loose flanged connectors. 0.14, 0.18 or 0.20 torque values calculated. Web 75% of 36,000 psi is utilized. Web tightening torque (ft lbs) galv + wax. The table is applicable for various types of gaskets and lubricants, and. Web recommended torque for b7 studs (astm a193) based upon 50% yield. Web as specified in api 6a, clamp load calculated as 50% of the yield strength for the b7 and l7 specified in astm a193/a193m and a320/a320m. Web download torque value chart. Web ength for the b7 and l7 specified in astm a. Moly paste | nut factors (k): Refer to manufactures speci cations or your companies engineering. Ses 75% of the yield strength. Web the torque values can only be achieved if nut (or tapped hole) has a proof load greater than or equal to the bolt's minimum ultimate tensile strength. Web torque chart for astm a193 grade b7 studs in ft./lbs at 40% of yield. Web clamp. These estimated torque calculations are offered as a guide for your. Coatings such as teflon or. The above table is applicable only for a193 grade b7 and a193 grade b16 stud bolts. Web 75% of 36,000 psi is utilized. It lists nominal diameter, threads per inch,. Web tightening torque (ft lbs) galv + wax. These estimated torque calculations are offered as a guide for your. Coatings such as teflon or. It lists nominal diameter, threads per inch,. Web recommended torque for b7 studs (astm a193) based upon 50% yield. Moly paste | nut factors (k): These estimated torque calculations are offered as a guide for your. Web ength for the b7 and l7 specified in astm a. Web as specified in api 6a, clamp load calculated as 50% of the yield strength for the b7 and l7 specified in astm a193/a193m and a320/a320m. Web torque chart for astm a193. It lists nominal diameter, threads per inch,. The table is applicable for various types of gaskets and lubricants, and. Coatings such as teflon or. Moly paste | nut factors (k): Tightening torque (ft lbs) galv. It lists nominal diameter, threads per inch,. Web this table is applicable for ptfe coated bolts with k=0.12. The above table is applicable only for a193 grade b7 and a193 grade b16 stud bolts. Tightening torque (ft lbs) plain. Web the torque values can only be achieved if nut (or tapped hole) has a proof load greater than or equal. 0.14, 0.18 or 0.20 torque values calculated. The above table is applicable only for a193 grade b7 and a193 grade b16 stud bolts. Web this chart is to be used a guide only, always refer to oem specifications or local engineer call alltite, inc. Tightening torque (ft lbs) galv. Web tightening torque (ft lbs) galv + wax. Tightening torque (ft lbs) galv. Web recommended torque for b7 studs (astm a193) based upon 50% yield. All results should be analyzed against actual field results to establish their validity. Refer to manufactures speci cations or your companies engineering. Web the torque values can only be achieved if nut (or tapped hole) has a proof load greater than or equal to the bolt's minimum ultimate tensile strength. 0.14, 0.18 or 0.20 torque values calculated. Ses 75% of the yield strength. Web clamp load calculated as 75% of the yield strength for the b7, b16 and l7 specified in astm a193/a193m and a320/a320m. Web 75% of 36,000 psi is utilized. Moly paste | nut factors (k): The above table is applicable only for a193 grade b7 and a193 grade b16 stud bolts. Web tightening torque (ft lbs) galv + wax. Web required torque (ftlbs) custom (insert k) this spread sheet is to be used as a guide. Web the torque values can only be achieved if nut (or tapped hole) has a proof load greater than or equal to the bolt's minimum ultimate tensile strength. Web as specified in api 6a, clamp load calculated as 50% of the yield strength for the b7 and l7 specified in astm a193/a193m and a320/a320m. These estimated torque calculations are offered as a guide for your.Torque for B7 L7 Stud Bolts Mechanical Engineering Nature

Torque Chart for ASTM A193 Grade B7 Studs Motor Oil Nut (Hardware)

B7 Studs Torque Specs basement wall studs

ASTM A193 Grade B7 Torque Chart Boltport Fasteners PDF Screw

B7 Studs Torque Specs basement wall studs

B7 Bolt Torque Chart A Visual Reference of Charts Chart Master

TorqueTension Chart for B7 Strength Of Materials Yield (Engineering)

B7 Studs Torque Specs basement wall studs

ASTM A193 Grade B7 Bolts Grade B7 Stud & Hex Bolts B7 Fasteners

B7 Studs Torque Specs basement wall studs

The Prevailing Torque Lock Nut Clamp Loads Are Listed At 75% Of The Proof Loads Specified For The Appropriate.

Web This Chart Is To Be Used A Guide Only, Always Refer To Oem Specifications Or Local Engineer Call Alltite, Inc.

Web Find Astm A193 Grade B7 Stud Bolt Torque Chart At 100% Of Yield, 70% Yield, 60% Of Yield, 50% Of Yield, 40% Of Yield And 30% Of Yield.

Web The Document Provides Torque Charts For Astm A193 Grade B7 Studs At Various Percentages Of Yield (100%, 70%, 60%, 50%, 40%, 30%) And With Different Lubricants.

Related Post: