Asphalt Rolling Patterns

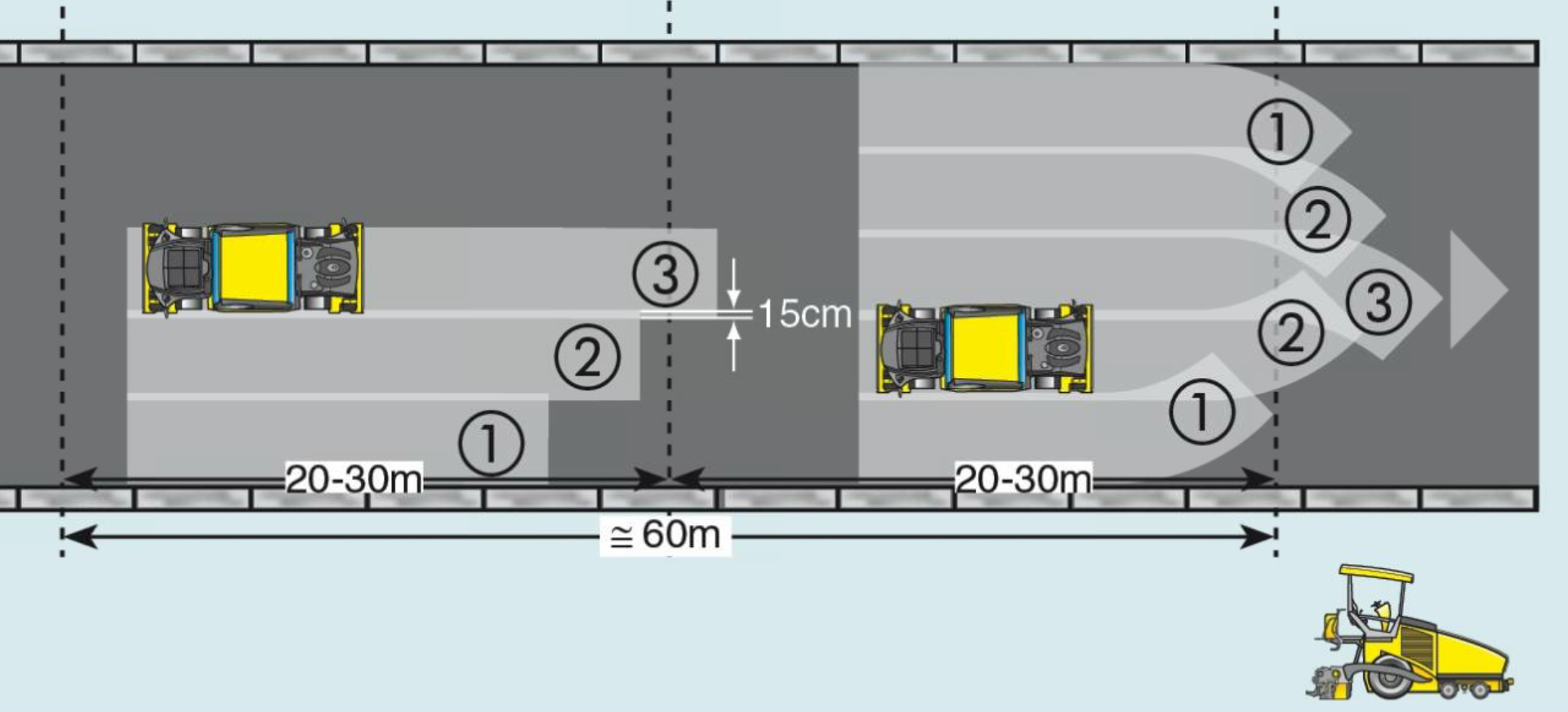

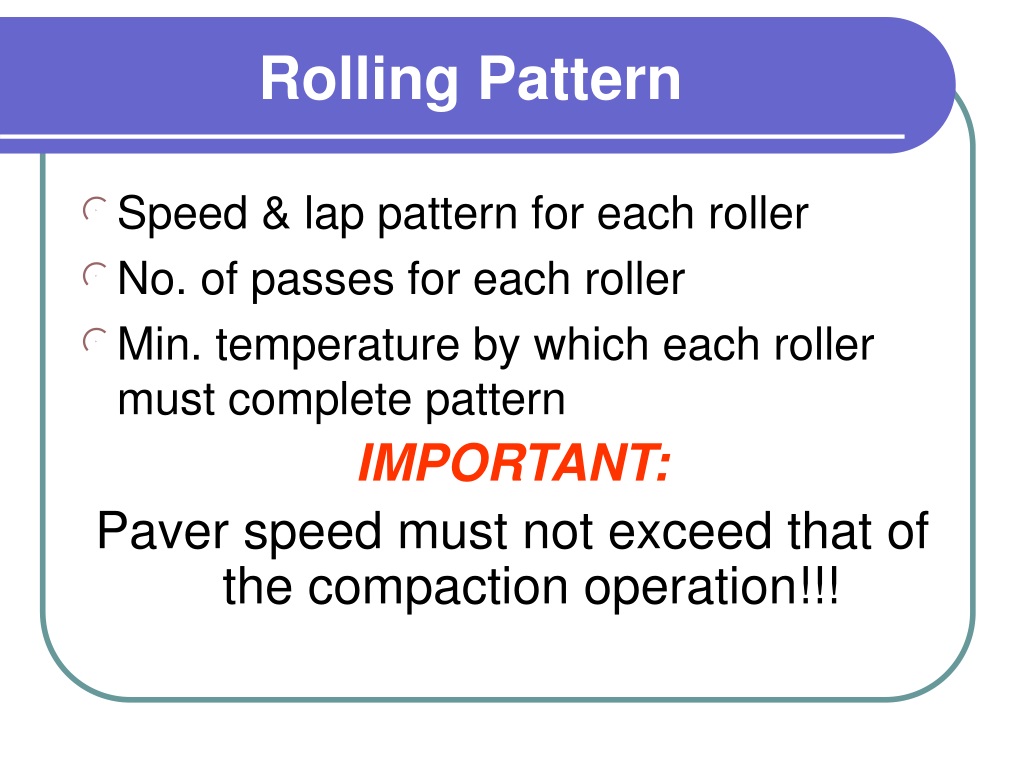

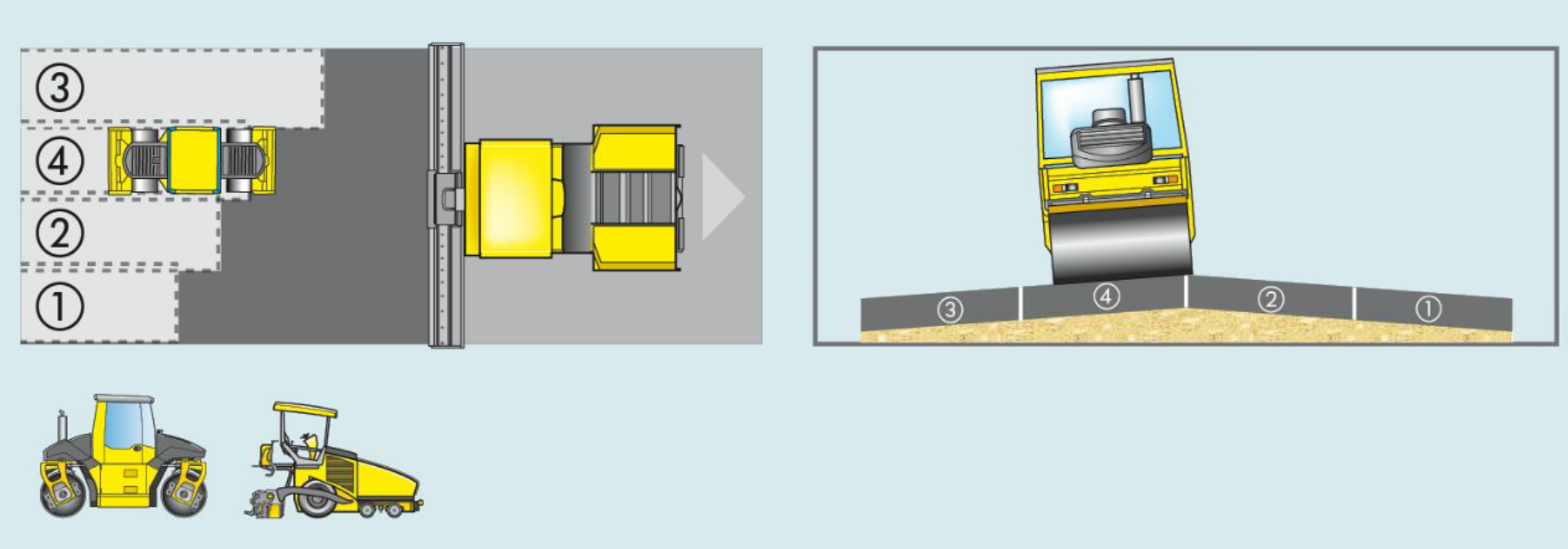

Asphalt Rolling Patterns - Web proper rolling ensures asphalt overlay smoothness. Web the rolling pattern used directly affects compaction. Complete breakdown rolling before the mix cools below a temperature consistent with achieving target density. For those mixes that exhibit tenderness, this permits density to be reached before the mix. Web how to use a rolling train. First, you have the breakdown roller, which develops the majority of the density in an asphalt layer. Web let’s dive into some basic rolling patterns and a few mix designs that influence change in those patterns. As the paving crew starts their day, our roadway specialist art works with the roller operators. Web it contains explanations to the different rolling patterns and a number of basic rules and notes for successful compaction of rolled asphalt. To avoid overlay bumps, use the right roller and avoid over compaction. Web the four primary elements of plant output, transportation, laydown, and compaction are carefully balanced to achieve best results. Web how to use a rolling train. Web proper rolling ensures asphalt overlay smoothness. As the paving crew starts their day, our roadway specialist art works with the roller operators. Web from proper paver setup to achieving optimum mat temperature and. For most mixes, it permits the highest production to be achieved. Develop your best rolling pattern part 1. Web let’s dive into some basic rolling patterns and a few mix designs that influence change in those patterns. Web how to use a rolling train. Web the four primary elements of plant output, transportation, laydown, and compaction are carefully balanced to. Certificate of insurancewarranty/guaranteeoperating since 1986maintenance plan This technique accomplishes two objectives. When any one of these items. Web the rolling pattern used directly affects compaction. To avoid overlay bumps, use the right roller and avoid over compaction. Web the rolling train is the most common compaction approach, but echelon rolling may be the best option to compact while the asphalt is at higher temperatures. For most mixes, it permits the highest production to be achieved. “compaction is the single most important factor that affects pavement performance in terms of durability, fatigue life, resistance to deformation,. For those. Web the rolling train is the most common compaction approach, but echelon rolling may be the best option to compact while the asphalt is at higher temperatures. For most mixes, it permits the highest production to be achieved. To avoid overlay bumps, use the right roller and avoid over compaction. Develop your best rolling pattern part 1. Seal coating ·. Web from proper paver setup to achieving optimum mat temperature and conducting the rolling pattern at just the right time — each step in the process will. Certificate of insurancewarranty/guaranteeoperating since 1986maintenance plan Web proper rolling ensures asphalt overlay smoothness. Web the rolling pattern used directly affects compaction. Complete breakdown rolling before the mix cools below a temperature consistent with. Web the rolling pattern used directly affects compaction. Web from proper paver setup to achieving optimum mat temperature and conducting the rolling pattern at just the right time — each step in the process will. Web it contains explanations to the different rolling patterns and a number of basic rules and notes for successful compaction of rolled asphalt. Web the. Web from proper paver setup to achieving optimum mat temperature and conducting the rolling pattern at just the right time — each step in the process will. Web let’s dive into some basic rolling patterns and a few mix designs that influence change in those patterns. This technique accomplishes two objectives. Web the rolling train is the most common compaction. Effective rolling pattern with the correct roller the rolling pattern you use directly affects the results of your compacting job. Web it contains explanations to the different rolling patterns and a number of basic rules and notes for successful compaction of rolled asphalt. Web the rolling train is the most common compaction approach, but echelon rolling may be the best. Web the four primary elements of plant output, transportation, laydown, and compaction are carefully balanced to achieve best results. The train usually starts with a. Free estimateslicensed & insuredprice matching available10% off for veterans This technique accomplishes two objectives. First, you have the breakdown roller, which develops the majority of the density in an asphalt layer. Web the four primary elements of plant output, transportation, laydown, and compaction are carefully balanced to achieve best results. As the paving crew starts their day, our roadway specialist art works with the roller operators. Complete breakdown rolling before the mix cools below a temperature consistent with achieving target density. “compaction is the single most important factor that affects pavement performance in terms of durability, fatigue life, resistance to deformation,. Web let’s dive into some basic rolling patterns and a few mix designs that influence change in those patterns. Web an efficient rolling pattern that covers as much of the paved area in as short amount of time as possible is generally the best approach to achieving density. Develop your best rolling pattern part 1. For most mixes, it permits the highest production to be achieved. Web a rolling train consists of a series of rollers that follow each other in a specific sequence to achieve the desired compaction. For those mixes that exhibit tenderness, this permits density to be reached before the mix. Web the rolling train is the most common compaction approach, but echelon rolling may be the best option to compact while the asphalt is at higher temperatures. Free estimateslicensed & insuredprice matching available10% off for veterans Web how to use a rolling train. First, you have the breakdown roller, which develops the majority of the density in an asphalt layer. Web proper rolling ensures asphalt overlay smoothness. When any one of these items.

How to Use Asphalt Compaction Rolling Patterns for Target Asphalt

Rolling Asphalt Patterns Pattern.rjuuc.edu.np

How to Use Asphalt Compaction Rolling Patterns for Target Asphalt

AsphaltPro Magazine AsphaltPro Magazine How to Roll for Bonus, Part

PPT BEST PRACTICES for ASPHALT PAVING FIELD OPERATIONS PowerPoint

PPT Hot Mix Asphalt Production and Placement PowerPoint Presentation

AsphaltPro Magazine AsphaltPro Magazine How to Roll for Bonus, Part

Asphalt QMS Manual All Items

How to Use Asphalt Compaction Rolling Patterns for Target Asphalt

TXAPA Best Practices for Compaction and Rolling Patterns YouTube

Seal Coating · Resurfacing · Patching · Maintenance · New Construction

Web It Contains Explanations To The Different Rolling Patterns And A Number Of Basic Rules And Notes For Successful Compaction Of Rolled Asphalt.

Web The Rolling Pattern Used Directly Affects Compaction.

Certificate Of Insurancewarranty/Guaranteeoperating Since 1986Maintenance Plan

Related Post: