Aluminum Tig Welding Settings Chart

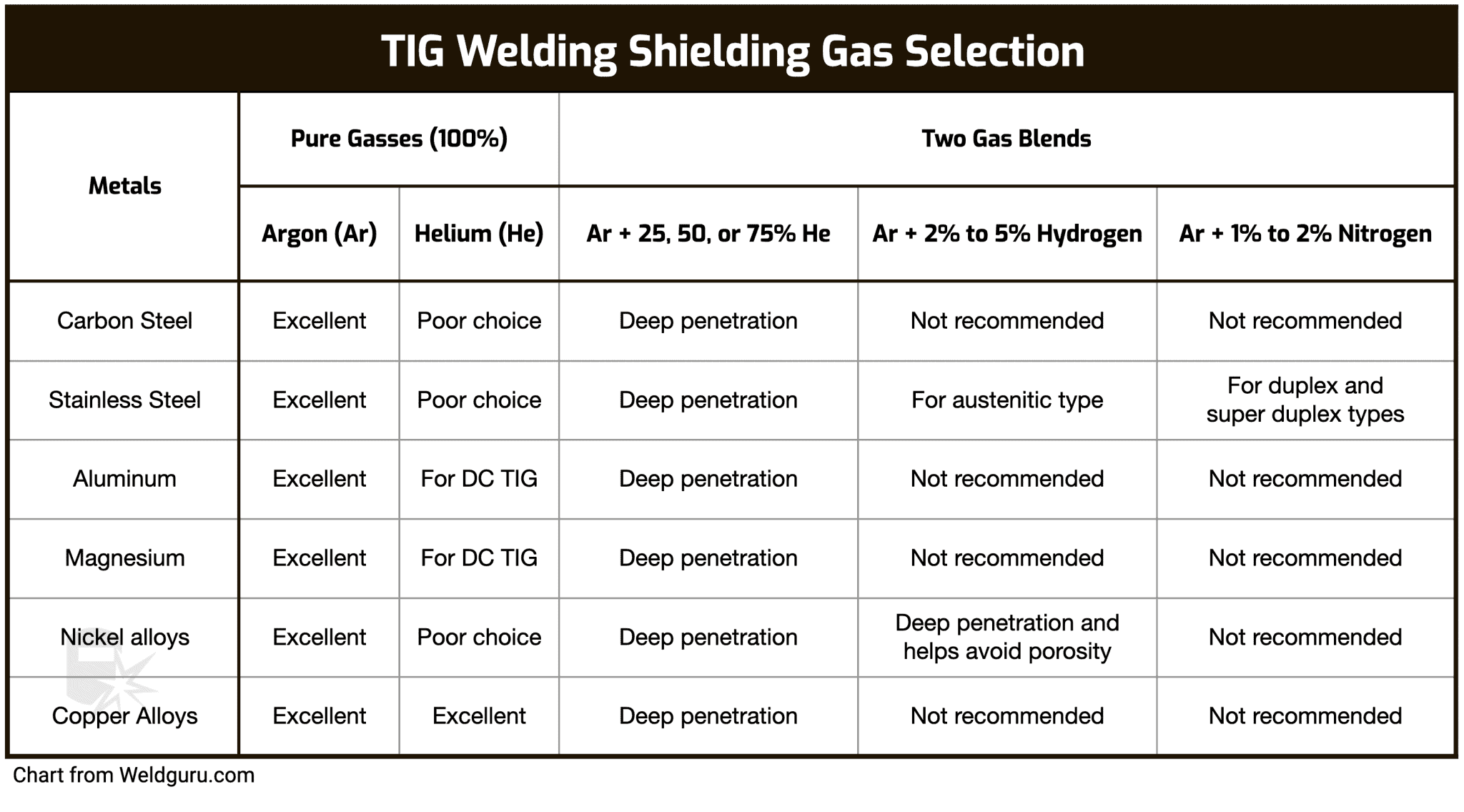

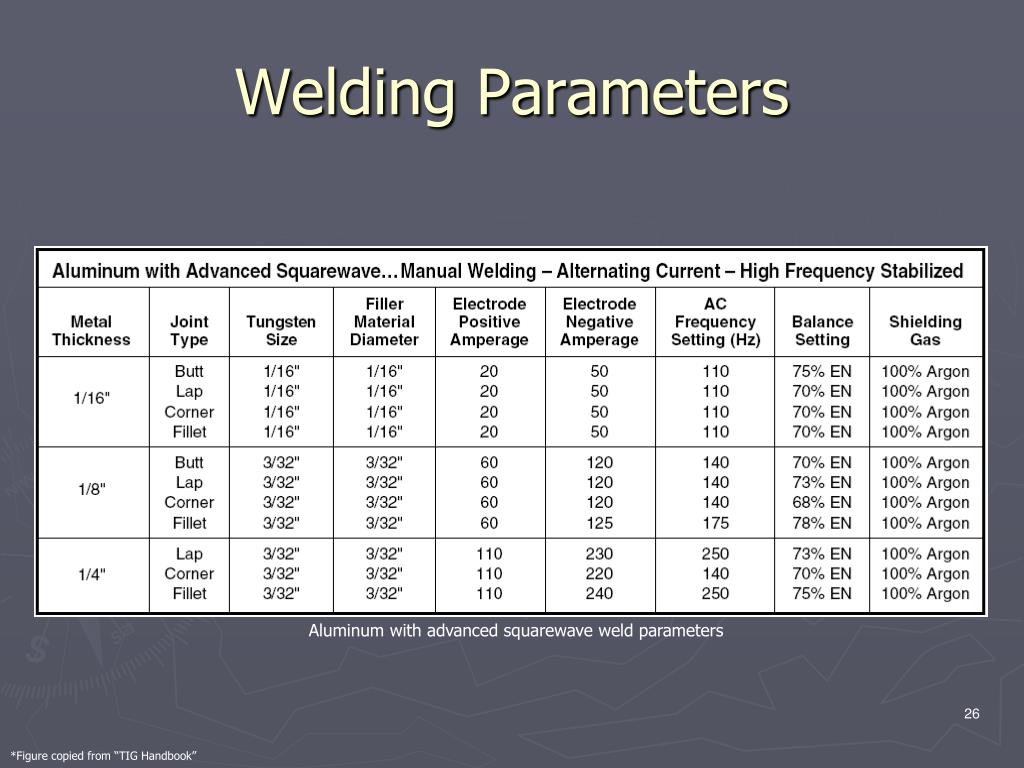

Aluminum Tig Welding Settings Chart - Web a tig welding chart visually represents the welding parameters needed to achieve a specific weld. Whether you're new to tig welding or want to hone your skills, you're in the right place. Web aluminum melts at about 1,200 degrees fahrenheit, and aluminum oxide melts at nearly 4,000 degrees. The gas flow rate is crucial to ensure the joint's durability, integrity, and quality. Set up the welder for dc welding with reversed polarity. Web one of the best choices for welding aluminum is a tig welder that runs on ac power, and you will get many of the most excellent prices. How to tig weld aluminum? For example, if you are using a number 5 cup, you want your argon flow around 12.5 cfh. Use a foot pedal or hand control for amperage. Web an aluminum tig welding settings chart provides essential parameters like amperage and gas flow. This approximation can be changed based on personal preference and the area in. Web what settings do i use to tig weld aluminum? Web an aluminum tig welding settings chart provides essential parameters like amperage and gas flow. Use ac (alternating current) when welding aluminum and magnesium. You should always use a wire brush to. Tap the bottom row buttons; You’ll do most tig welding of aluminum with ac at high frequency. Web aluminum melts at about 1,200 degrees fahrenheit, and aluminum oxide melts at nearly 4,000 degrees. Web for the best appearance, highest quality and leak free welds on aluminum, ac tig welding is the process of choice. Gas flow rates for tig welding. Follow our four steps below to practice and advance your tig welding skills with aluminum. It caters to different material types and thicknesses for effective welding. Turn on the machine and the rear panel; The primary gas used is argon and in some applications on thick aluminum when additional penetration. Web use the right materials. Web one of the best choices for welding aluminum is a tig welder that runs on ac power, and you will get many of the most excellent prices. Web with a little practice — and some basic best practices to help beginning welders — you can produce the results you want. For example, if you are using a number 5. Practice before starting the weld. The gas flow rate is crucial to ensure the joint's durability, integrity, and quality. The primary gas used is argon and in some applications on thick aluminum when additional penetration. Turn on the machine and the rear panel; Web for the best appearance, highest quality and leak free welds on aluminum, ac tig welding is. Web with a little practice — and some basic best practices to help beginning welders — you can produce the results you want. The aluminum settings require you to use pure tungsten or thoriated tungsten with a green, red and yellow band. In everything i've researched, you're supposed to weld aluminum hot and fast compared to mild steel, i'm also. Web see the chart below for recommended flow rates. Web aluminum settings for tig welding. Gas flow rates for tig welding. Web one of the best choices for welding aluminum is a tig welder that runs on ac power, and you will get many of the most excellent prices. Tap the bottom row buttons; Use a foot pedal or hand control for amperage. Turn on the machine and the rear panel; You’ll do most tig welding of aluminum with ac at high frequency. For example, if you are using a number 5 cup, you want your argon flow around 12.5 cfh. Filler metal can be either wire or rod and should be compatible with. Tig welding, or tungsten inert gas welding, demands precision and control over various settings for optimal results. How to tig weld aluminum? Tig setting, are these charts right?? Filler metal must be dry, free of. There is a wide range of settings you can use for welding aluminum. Gas flow rates for tig welding. Get the aluminum as clean as possible. It outlines the optimal settings based on material thickness and joint type. Web settings for tig welding aluminum. An led green light will ensure you have the chosen option; Tap the bottom row buttons; Get the aluminum as clean as possible. Web settings for tig welding aluminum. Web what settings do i use to tig weld aluminum? Web aluminum settings for tig welding. Set up the welder for dc welding with reversed polarity. Web aluminum melts at about 1,200 degrees fahrenheit, and aluminum oxide melts at nearly 4,000 degrees. Gather the right electrode, rods, and shielding gas. Before getting started, there are a few important settings you need to understand and adjust, including the current, gas flow rate and amperage. Web a tig welding settings chart provides essential parameters like amperage, voltage, and gas flow. Web a good rule of thumb is to set your cfh to 2.5x your cup size. Web for the best appearance, highest quality and leak free welds on aluminum, ac tig welding is the process of choice. Follow our four steps below to practice and advance your tig welding skills with aluminum. Web with a little practice — and some basic best practices to help beginning welders — you can produce the results you want. You’ll do most tig welding of aluminum with ac at high frequency. Gas flow rates for tig welding.

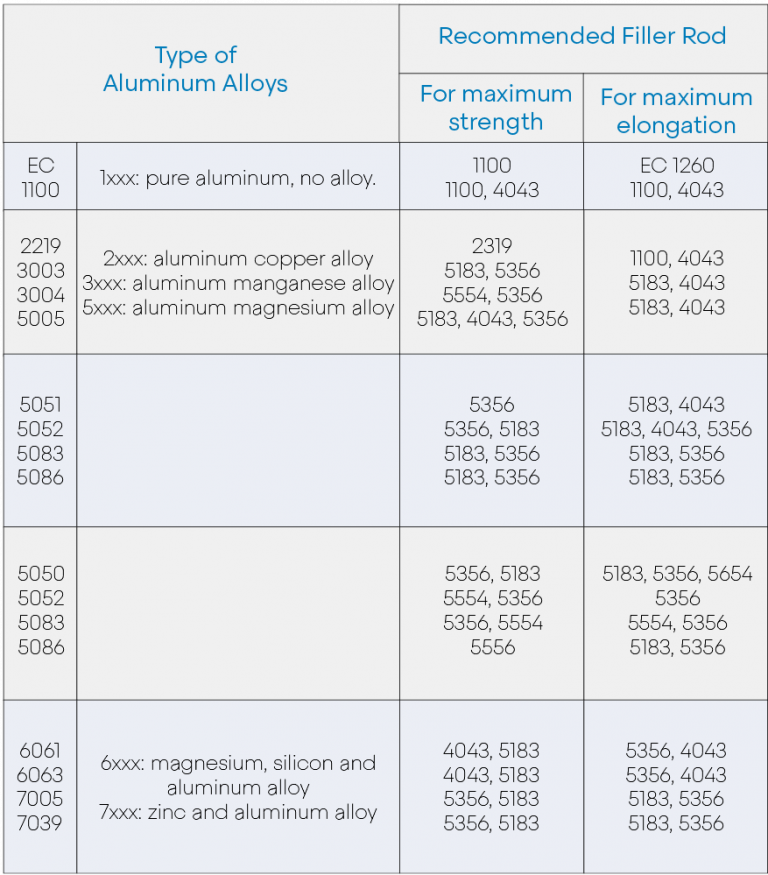

Tig Welding Filler Rod Selection Chart

Aluminum Tig Rod Chart

Tig Welding Charts For Aluminum

Tig Welder Settings Chart

Tig Welding Settings Chart

Aluminum Tig Welding Settings Chart

Aluminum Tig Welding Settings Chart Optimal Precision

Aluminum Tig Welding Settings Chart

Tig Welding Charts For Aluminum

Tig Welding Settings Chart

Web An Aluminum Tig Welding Settings Chart Provides Essential Parameters Like Amperage And Gas Flow.

Use Ac (Alternating Current) When Welding Aluminum And Magnesium.

Here You Can Find Articles, Videos, Webinars And All Things Tig.

Select A Topic Below To Get Started.

Related Post: