Aluminum Mig Welding Settings Chart

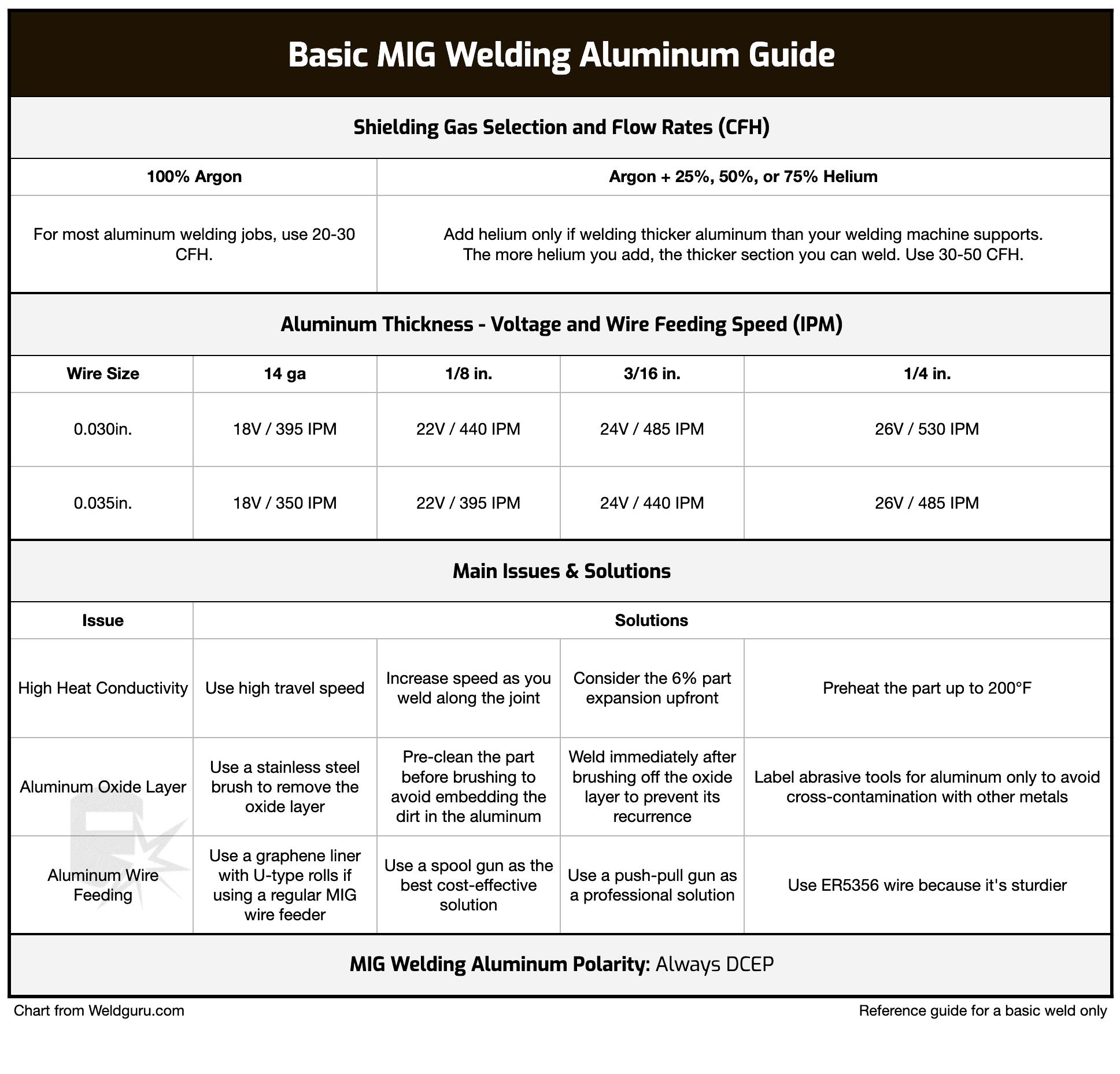

Aluminum Mig Welding Settings Chart - Web here are charts showing the wire speed and voltage speed settings required for mig aluminum welding. As part of the process, you will learn how to select the correct filler metal for the specific type of aluminum that. Web how to set up a mig welder for aluminum welding with the right equipment, electrode choices, the right shielding gas and proper welder voltage setting. Web here are charts showing the wire speed and voltage speed settings required for mig aluminum welding. The best filler materials for mig welding aluminum include brass shim stock,. Aluminum requires a higher heat input due to its high thermal conductivity. Aluminum oxide removal needs to be done before you start working and degreasing. Qualified welding procedures utilizing tested practices should be developed for actual. Web the chart below provides approximate welding parameters as a starting point only. Web our 15 tips and tricks for mig welding aluminum 1. Web mig (metal inert gas) welding, also known as gas metal arc welding (gmaw), is a welding process that uses a continuous wire electrode and a shielding gas. The best filler materials for mig welding aluminum include brass shim stock,. As part of the process, you will learn how to select the correct filler metal for the specific type of. But before using these values, we suggest that you have a. Qualified welding procedures utilizing tested practices should be developed for actual. Web our 15 tips and tricks for mig welding aluminum 1. Web how to set up a mig welder for aluminum welding with the right equipment, electrode choices, the right shielding gas and proper welder voltage setting. These. Web the chart below provides approximate welding parameters as a starting point only. Aluminum oxide removal needs to be done before you start working and degreasing. The best filler materials for mig welding aluminum include brass shim stock,. Web what settings are best for mig welding aluminum? These instructions apply to most makes and models of. Qualified welding procedures utilizing tested practices should be developed for actual. Aluminum oxide removal needs to be done before you start working and degreasing. Web mig welding is also called as gas metal arc welding (gmaw) is a type of welding that is done using a continuously fed mig wire electrode and a shielding gas that melts and. But before. Web how to set up a mig welder for aluminum welding with the right equipment, electrode choices, the right shielding gas and proper welder voltage setting. Web our 15 tips and tricks for mig welding aluminum 1. Web what settings are best for mig welding aluminum? These instructions apply to most makes and models of. But before using these values,. Aluminum requires a higher heat input due to its high thermal conductivity. I say do it with a hand wire brush or a cup wire brush. The best filler materials for mig welding aluminum include brass shim stock,. Order the millermatic mig calculator for good starting. These instructions apply to most makes and models of. These instructions apply to most makes and models of. Web here are charts showing the wire speed and voltage speed settings required for mig aluminum welding. Web how to set up a mig welder for aluminum welding with the right equipment, electrode choices, the right shielding gas and proper welder voltage setting. But before using these values, we suggest that. Web our 15 tips and tricks for mig welding aluminum 1. Web here are charts showing the wire speed and voltage speed settings required for mig aluminum welding. These instructions apply to most makes and models of. But before using these values, we suggest that you have a decent. Aluminum requires a higher heat input due to its high thermal. Web removing the oxide. Aluminum oxide removal needs to be done before you start working and degreasing. Aluminum requires a higher heat input due to its high thermal conductivity. Qualified welding procedures utilizing tested practices should be developed for actual. But before using these values, we suggest that you have a. But before using these values, we suggest that you have a. As part of the process, you will learn how to select the correct filler metal for the specific type of aluminum that. These instructions apply to most makes and models of. Web how to set up a mig welder for aluminum welding with the right equipment, electrode choices, the. Qualified welding procedures utilizing tested practices should be developed for actual. I say do it with a hand wire brush or a cup wire brush. Web what settings are best for mig welding aluminum? Web check the inside cover of your millermatic® welder for optimal starting setting or to fine tune for your application. Order the millermatic mig calculator for good starting. The best filler materials for mig welding aluminum include brass shim stock,. Web here are charts showing the wire speed and voltage speed settings required for mig aluminum welding. Web mig (metal inert gas) welding, also known as gas metal arc welding (gmaw), is a welding process that uses a continuous wire electrode and a shielding gas. Web here are charts showing the wire speed and voltage speed settings required for mig aluminum welding. Web our 15 tips and tricks for mig welding aluminum 1. But before using these values, we suggest that you have a decent. As part of the process, you will learn how to select the correct filler metal for the specific type of aluminum that. Aluminum requires a higher heat input due to its high thermal conductivity. Aluminum oxide removal needs to be done before you start working and degreasing. Web the chart below provides approximate welding parameters as a starting point only. What’s the right technique for mig welding aluminum?

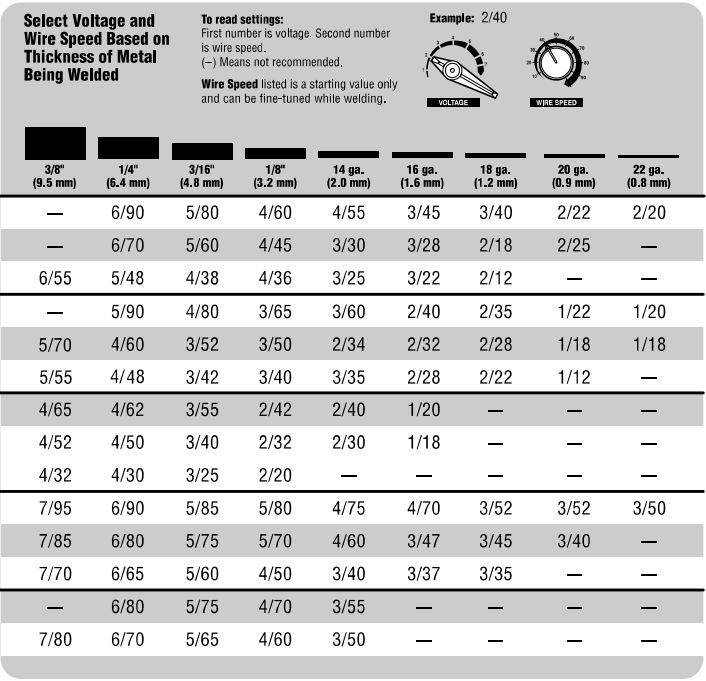

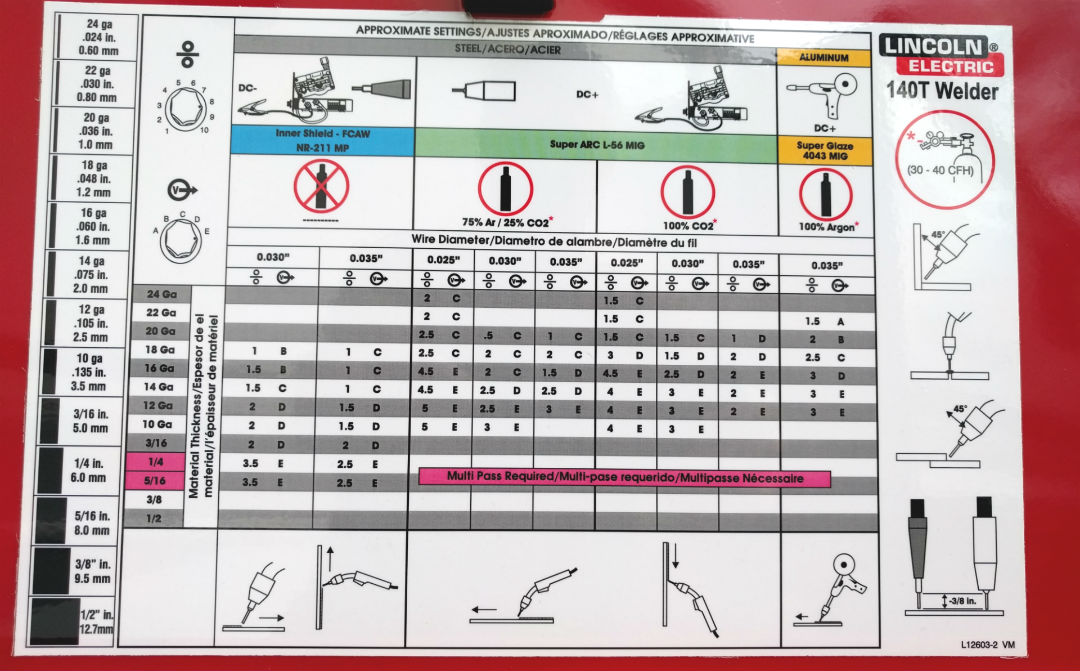

Mig Welding Setting Chart

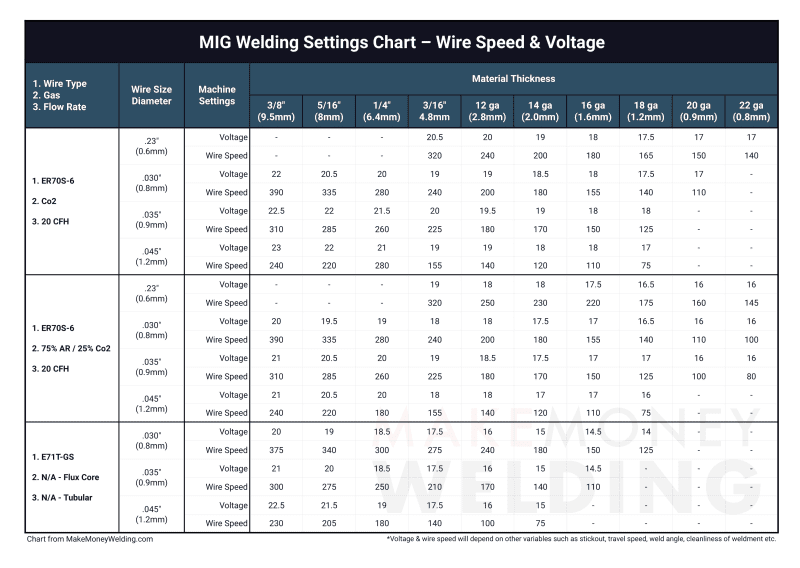

Important MIG Welder Settings You Need to Know (with Chart)

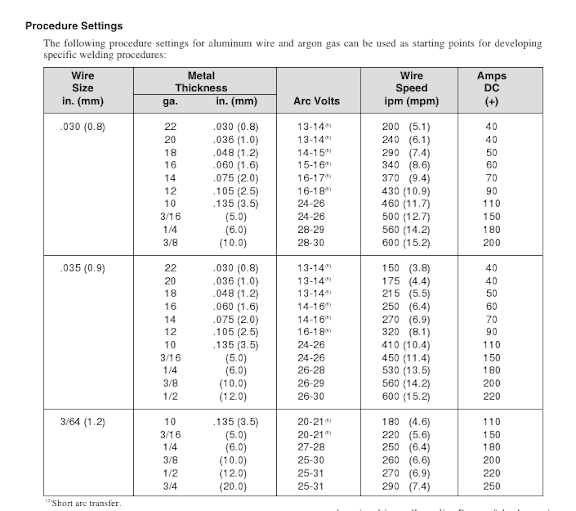

Aluminum Mig Welding Amperage Chart

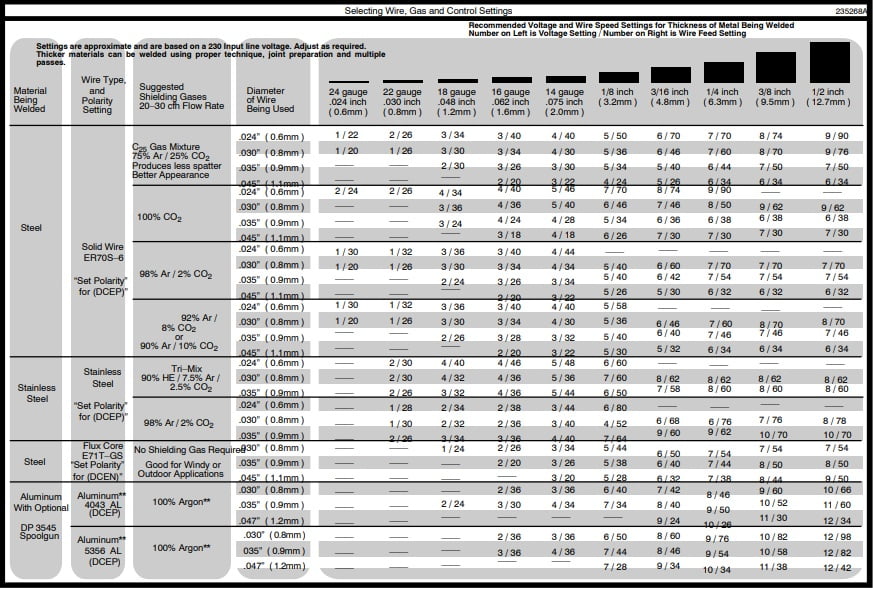

How To MIG Weld Aluminum Beginners Guide (with Chart)

Mig Welding Settings Chart

Aluminum Mig Welding Amperage Chart

aluminum mig welding settings chart

aluminum mig welding settings chart

Mig Welding Chart Settings And Guides

How To MIG Weld Aluminum Beginners Guide (with Chart)

Web Mig Welding Is Also Called As Gas Metal Arc Welding (Gmaw) Is A Type Of Welding That Is Done Using A Continuously Fed Mig Wire Electrode And A Shielding Gas That Melts And.

Web How To Set Up A Mig Welder For Aluminum Welding With The Right Equipment, Electrode Choices, The Right Shielding Gas And Proper Welder Voltage Setting.

These Instructions Apply To Most Makes And Models Of.

But Before Using These Values, We Suggest That You Have A.

Related Post: