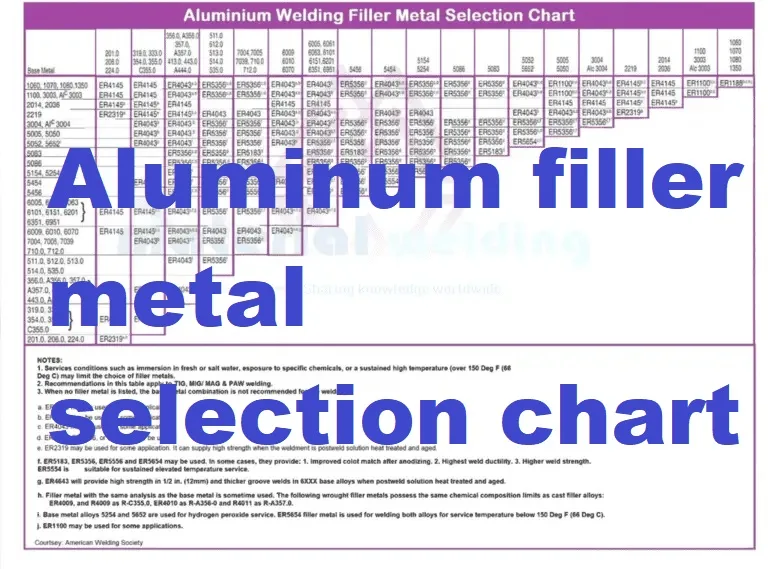

Aluminum Filler Rod Chart

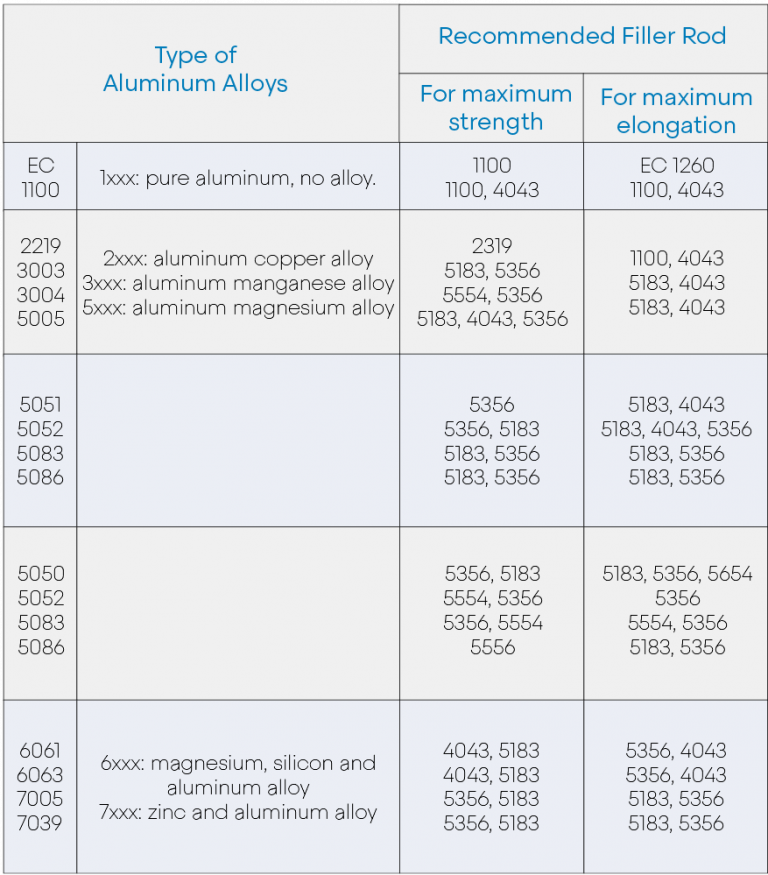

Aluminum Filler Rod Chart - Web filler metal for general purpose welding 20tg 2240 er4145 er4145 er4145 efm 1450 357.1, er4043' er5'j56c' er4c143v er404ai„, 512.0 5141 er5356'.a eh 4043 ef5'j560 7121 eirs356i ers356' er5556' er4043 er40,t3e er4043t er4043' er4043 45 er5355 er535s' er535ð' er5353' er5356' ea535ð' eh5356' er535ð' er5356'. 4047 can be used in lieu of 4043. Web and impact loading are factors directly associated with a weldment. This chart is a tool that is designed to help you select the most. Filler metal selection for aluminum welding. Read and understand this information. Application, and the desired weld metal properties. Web in this article, we will introduce an aluminum filler metal selection chart that simplifies the process of selecting the right filler metal for welding aluminum, helping you achieve a strong and reliable weld. (2) an “a” rating for alloy 5083 to 5083 and 5083 to 5456. Web know the basic filler metal characteristics and selection criteria for aluminum to get the best welding performance. Web always refer to an aluminum filler metal selection chart to choose a filler metal that is best suited for a particular application. Filler metal selection for aluminum welding. It is therefore essential to have the answers to some basic questions prior to the selection of the most appropriate filler metal. The characteristics include weldability, strength, ductility, corrosion resistance, thermal. Web this article provides a comprehensive matrix for selecting an aluminum filler alloy for the gas tungsten arc and gas metal arc welding processes, based on the various requirements or service conditions. Appropriate filler metal, taking into consideration base metal, the. Web filler metal for general purpose welding 20tg 2240 er4145 er4145 er4145 efm 1450 357.1, er4043' er5'j56c' er4c143v er404ai„,. A table lists the nominal strengths of aluminum filler metals. Web and impact loading are factors directly associated with a weldment. Web it’s worth the effort since getting the variables right, including the filler rod, allows you to create strong, beautiful tig welds on a consistent basis. No rating for alloy 5456 to 5456. This chart is a tool that. Read and understand this information. Appropriate filler metal, taking into consideration base metal, the. Web it’s worth the effort since getting the variables right, including the filler rod, allows you to create strong, beautiful tig welds on a consistent basis. 4047 can be used in lieu of 4043. Web welding filler metal databook. The alloys are rated from a to d for characteristics like corrosion resistance, machinability and more. Web filler metal for general purpose welding 20tg 2240 er4145 er4145 er4145 efm 1450 357.1, er4043' er5'j56c' er4c143v er404ai„, 512.0 5141 er5356'.a eh 4043 ef5'j560 7121 eirs356i ers356' er5556' er4043 er40,t3e er4043t er4043' er4043 45 er5355 er535s' er535ð' er5353' er5356' ea535ð' eh5356' er535ð' er5356'.. Learn how to select the right tig welding filler rod size and composition with helpful guidelines and charts. Warning protect yourself and others. Brazing and soldering alloys and fluxes may produce fumes and gases hazardous to your health.• before use, read. However, aluminum is a tricky metal, so make sure you know what alloy you are welding and what the. Application, and the desired weld metal properties. Web filler metal charts www.harrisproductsgroup.com * the higher the ˜uidity rating, the faster the alloy ˜ows within the melting range. Web this article provides a comprehensive matrix for selecting an aluminum filler alloy for the gas tungsten arc and gas metal arc welding processes, based on the various requirements or service conditions. Web. Web if the chart shows that you can use either 4043 or 5356 then there are a few more things we need to consider: Brazing and soldering alloys and fluxes may produce fumes and gases hazardous to your health.• before use, read. Web filler metal charts www.harrisproductsgroup.com * the higher the ˜uidity rating, the faster the alloy ˜ows within the. This chart is a tool that is designed to help you select the most. Web selecting the correct filler alloy for aluminum is based on the operating conditions of the finished welded component. Brazing and soldering alloys and fluxes may produce fumes and gases hazardous to your health.• before use, read. Application, and the desired weld metal properties. Over 30. Web this article provides a comprehensive matrix for selecting an aluminum filler alloy for the gas tungsten arc and gas metal arc welding processes, based on the various requirements or service conditions. Web if the chart shows that you can use either 4043 or 5356 then there are a few more things we need to consider: It is therefore essential. Web know the basic filler metal characteristics and selection criteria for aluminum to get the best welding performance. Over 30 different aluminum alloys are listed in the table. Warning protect yourself and others. Web filler metal for general purpose welding 20tg 2240 er4145 er4145 er4145 efm 1450 357.1, er4043' er5'j56c' er4c143v er404ai„, 512.0 5141 er5356'.a eh 4043 ef5'j560 7121 eirs356i ers356' er5556' er4043 er40,t3e er4043t er4043' er4043 45 er5355 er535s' er535ð' er5353' er5356' ea535ð' eh5356' er535ð' er5356'. Application, and the desired weld metal properties. This chart is a tool that is designed to help you select the most. No rating for alloy 5456 to 5456. Practicing welding this material — especially for welding operators new to the material — is also a good idea. A table lists the nominal strengths of aluminum filler metals. Application, and the desired weld metal properties. At temperature above 150f this alloy is. Web selecting the correct filler alloy for aluminum is based on the operating conditions of the finished welded component. Brazing and soldering alloys and fluxes may produce fumes and gases hazardous to your health.• before use, read. Web it’s worth the effort since getting the variables right, including the filler rod, allows you to create strong, beautiful tig welds on a consistent basis. Appropriate filler metal, taking into consideration base metal, the. Read and understand this information.

Aluminum filler metal selection charts

Aluminum Filler Rod Selection Chart

Tig Welding Filler Rod Selection Chart Reviews Of Chart

Tig Aluminum Filler Rod Chart

Aluminum Filler Metal Selection Chart

Tig Weld Aluminum Filler Rod

Tig Aluminum Filler Rod Chart

Aluminum Filler Rod Selection Chart

Aluminum Filler Alloy Selection Chart PDF Welding Construction

Tig Welding Filler Rod Selection Chart

Web In This Article, We Will Introduce An Aluminum Filler Metal Selection Chart That Simplifies The Process Of Selecting The Right Filler Metal For Welding Aluminum, Helping You Achieve A Strong And Reliable Weld.

Filler Metal Selection For Aluminum Welding.

Web Always Refer To An Aluminum Filler Metal Selection Chart To Choose A Filler Metal That Is Best Suited For A Particular Application.

The Alloys Are Rated From A To D For Characteristics Like Corrosion Resistance, Machinability And More.

Related Post: